Preparation method of dark tea and dark tea brick

A technology for dark tea and tea bricks, which is applied in the field of dark tea preparation, can solve the problems that tender-leaf tea leaves are easily damaged by high temperature, tea bricks are susceptible to moisture and oxidation, and the yield of tender-leaf tea leaves is low. Rich, green and astringent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

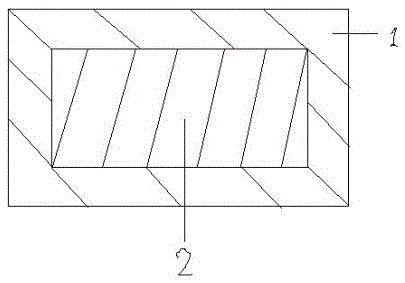

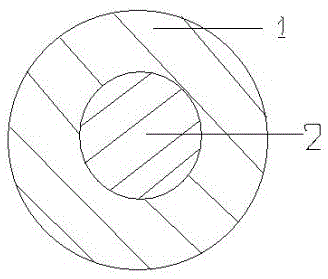

Image

Examples

Embodiment 1

[0032] Raw materials: 100kg of fresh tea leaves

[0033] 1. Preparation of raw materials: pick tea leaves, including large leaf tea and young leaf tea, clean them, and put them in a centralized place for later use;

[0034] 2. Finishing: Use a drum-type greening machine to finish greening, heat it with firewood, wait until the tea leaves are soft, the color turns dark green, the surface is dull, the grass gas is eliminated, the aroma overflows, the thick stems are not easy to break, and they are uniform, that is greening Moderate;

[0035] 3. Kneading: Knead while it is hot, use a tea kneading machine, and load about 20kg each time. In order to make the leaves evenly turn and knead fully, the kneading machine rotates at 30r / min. It is suitable for thick and old leaves to be wrinkled and folded;

[0036] 4. Heap fermentation: choose a clean indoor floor, avoid light and wind, the indoor temperature is 25°C, and the humidity is 70%. Immediately pile up the rolled tea leaves t...

Embodiment 2

[0042] Raw materials: 100kg of fresh tea leaves

[0043] 1. Preparation of raw materials: pick tea leaves, including large leaf tea and young leaf tea, clean them, and put them in a centralized place for later use;

[0044] 2. Finishing: Use a drum-type greening machine to finish greening, heat it with firewood, wait until the tea leaves are soft, the color turns dark green, the surface is dull, the grass gas is eliminated, the aroma overflows, the thick stems are not easy to break, and they are uniform, that is greening Moderate;

[0045]3. Kneading: Knead while it is still hot, and use a tea kneading machine to knead it. Each time is about 22kg. In order to make the leaves turn evenly and knead fully, the rotation speed of the kneading machine is 40r / min. It is suitable for thick and old leaves to be wrinkled and folded;

[0046] 4. Stacking fermentation: choose a clean indoor floor, avoid light and wind, indoor temperature is 25 ℃, humidity is 75%. Immediately pile up th...

Embodiment 3

[0052] Raw material: 100kg of fresh tea leaves

[0053] 1. Preparation of raw materials: Pick tea leaves, including large-leaf tea leaves and tender-leaf tea leaves, clean them, and place them in a centralized place for later use;

[0054] 2. Fixing: Use a drum-type fixing machine to fix the greens and heat them with firewood. When the tea leaves are soft, the color becomes dark green, the surface is dull, the grass gas is eliminated, the aroma overflows, and the thick stems are not easily broken, and the tea leaves are uniform. Moderate;

[0055] 3. Kneading: Knead while it is still hot, and use a tea kneading machine to knead it. Each time is about 25kg. In order to make the leaves turn evenly and knead fully, the rotation speed of the kneading machine is 50r / min. It is suitable for thick and old leaves to be wrinkled and folded;

[0056] 4. Stacked fermentation: choose a clean indoor floor, avoid light and wind, indoor temperature is 25 ℃, humidity is 80%. Immediately pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com