Brewing technology of pineapple fruit wine

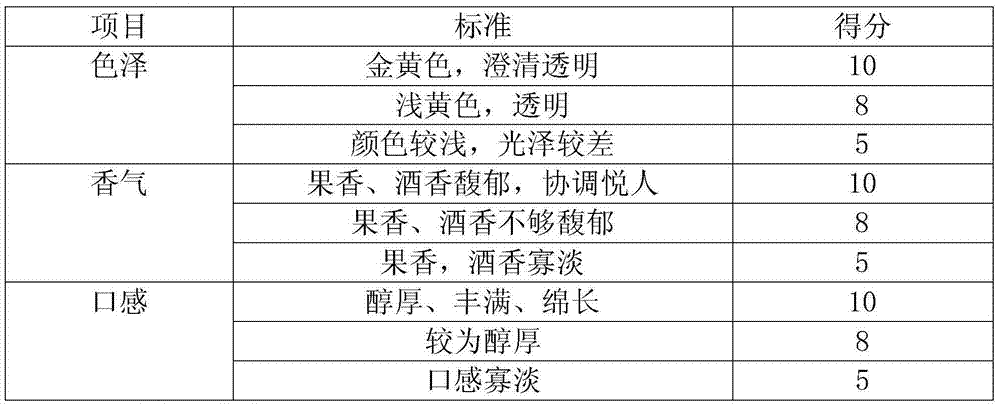

A pineapple and fruit wine technology, applied in the field of pineapple fruit wine brewing technology, can solve the problems affecting the quality of the finished product, the loss of aroma components, etc., and achieve the effect of golden, transparent, glossy, mellow and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Cut a hole from the top of the pineapple, take out the pulp, and microwave-dry the intact peel to a moisture content of 6% for later use;

[0017] 2) Cut the pulp into pieces, beat it into pineapple pulp, add amylase to the pineapple pulp at a ratio of 100U / L for liquefaction, the temperature is 50°C, and the liquefaction time is 40min; then add glucoamylase at a ratio of 200U / L for saccharification , the saccharification temperature is 45°C, and the saccharification time is 2h;

[0018] 3) Use the intact peel as a container, pour the saccharified pineapple pulp into it, adjust the sugar content of the pineapple pulp to 22°Brix, inoculate yeast, carry out main fermentation at 20°C for 7 days, and then cool down to 15°C for post-fermentation for 15 days ;

[0019] 4) The fermented liquid is taken out from the peel, filtered and clarified to obtain pineapple wine.

Embodiment 2

[0025] 1) Cut a hole from the top of the pineapple, take out the pulp, and microwave-dry the intact peel to a moisture content of 8% for later use;

[0026] 2) Cut the pulp into pieces, beat it into pineapple pulp, add amylase to the pineapple pulp at a ratio of 1000U / L for liquefaction, the temperature is 60°C, and the liquefaction time is 60min; then add glucoamylase at a ratio of 1000U / L for saccharification , the saccharification temperature is 60°C, and the saccharification time is 3h;

[0027] 3) Use the intact peel as a container, pour the saccharified pineapple slurry into it, adjust the sugar content of the pineapple slurry to 26°Brix, inoculate yeast, carry out main fermentation at 30°C for 9 days, and then cool down to 20°C for post-fermentation for 30 days ;

[0028] 4) The fermented liquid is taken out from the peel, filtered and clarified to obtain pineapple wine.

Embodiment 3

[0030] 1) Cut a hole from the top of the pineapple, take out the pulp, and dry the intact peel at a vacuum of 0Pa and a temperature of -30°C until the moisture content is 6% for later use;

[0031] 2) Cut the pulp into pieces, beat it into pineapple pulp, add amylase to the pineapple pulp at a ratio of 100U / L for liquefaction, the temperature is 50°C, and the liquefaction time is 40min; then add glucoamylase at a ratio of 200U / L for saccharification , the saccharification temperature is 45°C, and the saccharification time is 2h;

[0032] 3) Use the intact peel as a container, pour the saccharified pineapple pulp into it, adjust the sugar content of the pineapple pulp to 22°Brix, inoculate yeast, carry out main fermentation at 20°C for 7 days, and then cool down to 15°C for post-fermentation for 15 days ;

[0033] 4) The fermented liquid is taken out from the peel, filtered and clarified to obtain pineapple wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com