Patents

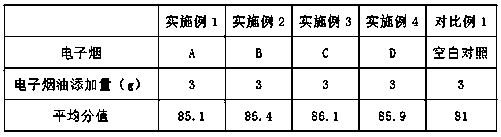

Literature

55 results about "Methyl phenylacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl phenylacetate is an organic compound that is the methyl ester of phenylacetic acid, with the structural formula C₆H₅CH₂COOCH₃. It is a colorless liquid that is only slightly soluble in water, but soluble in most organic solvents.

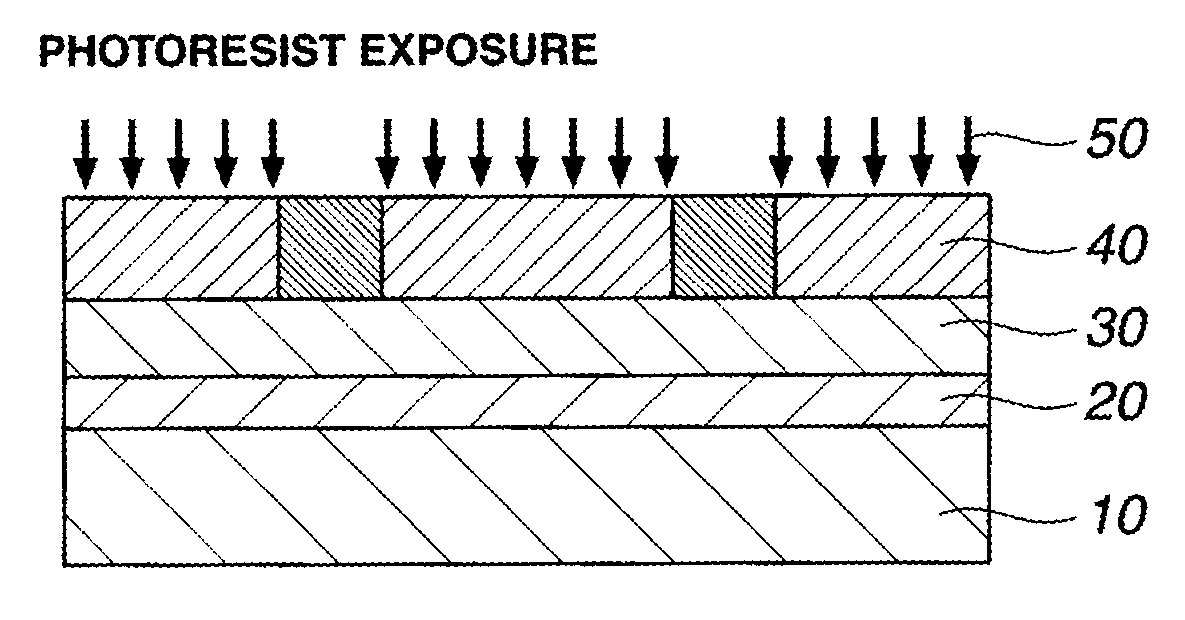

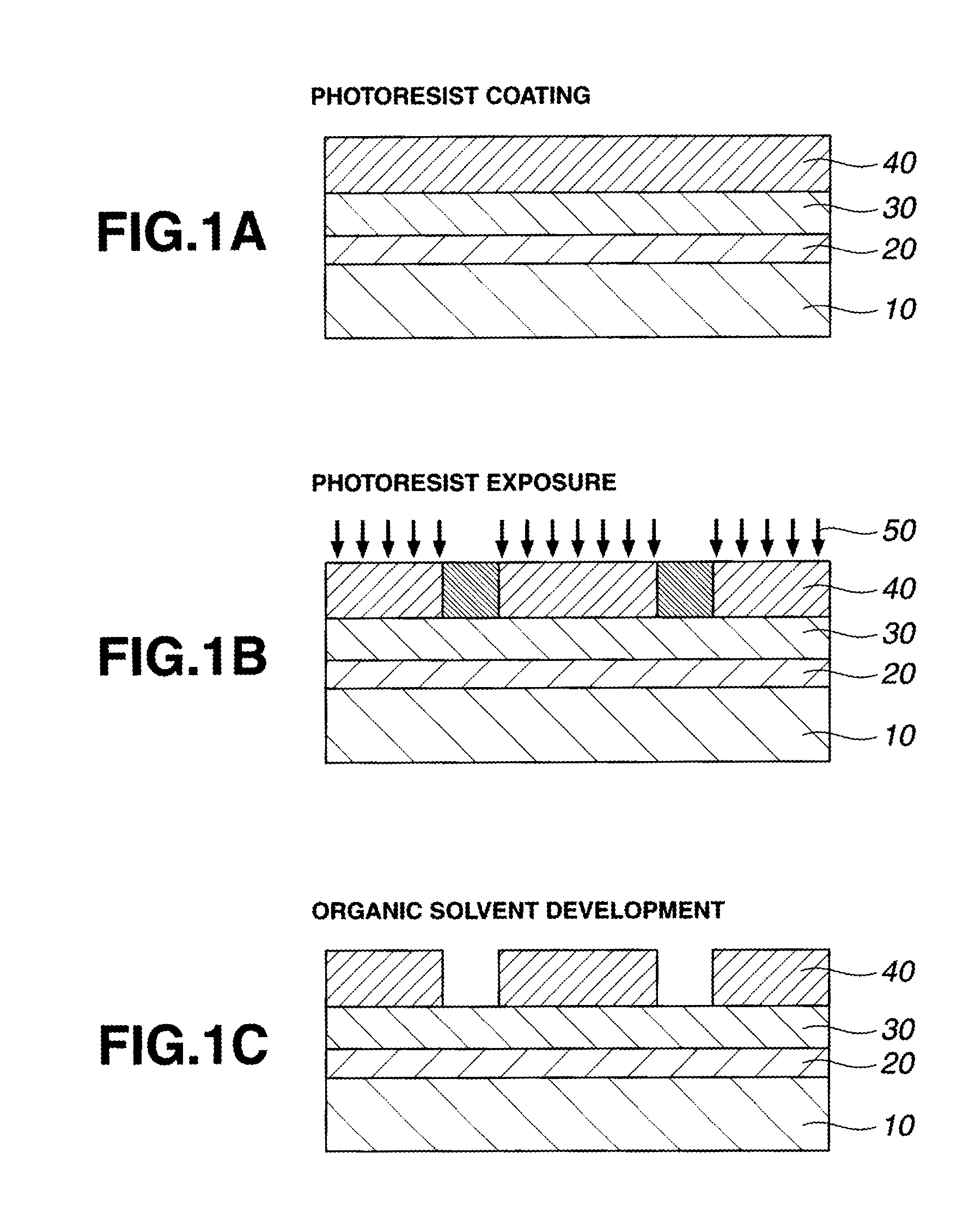

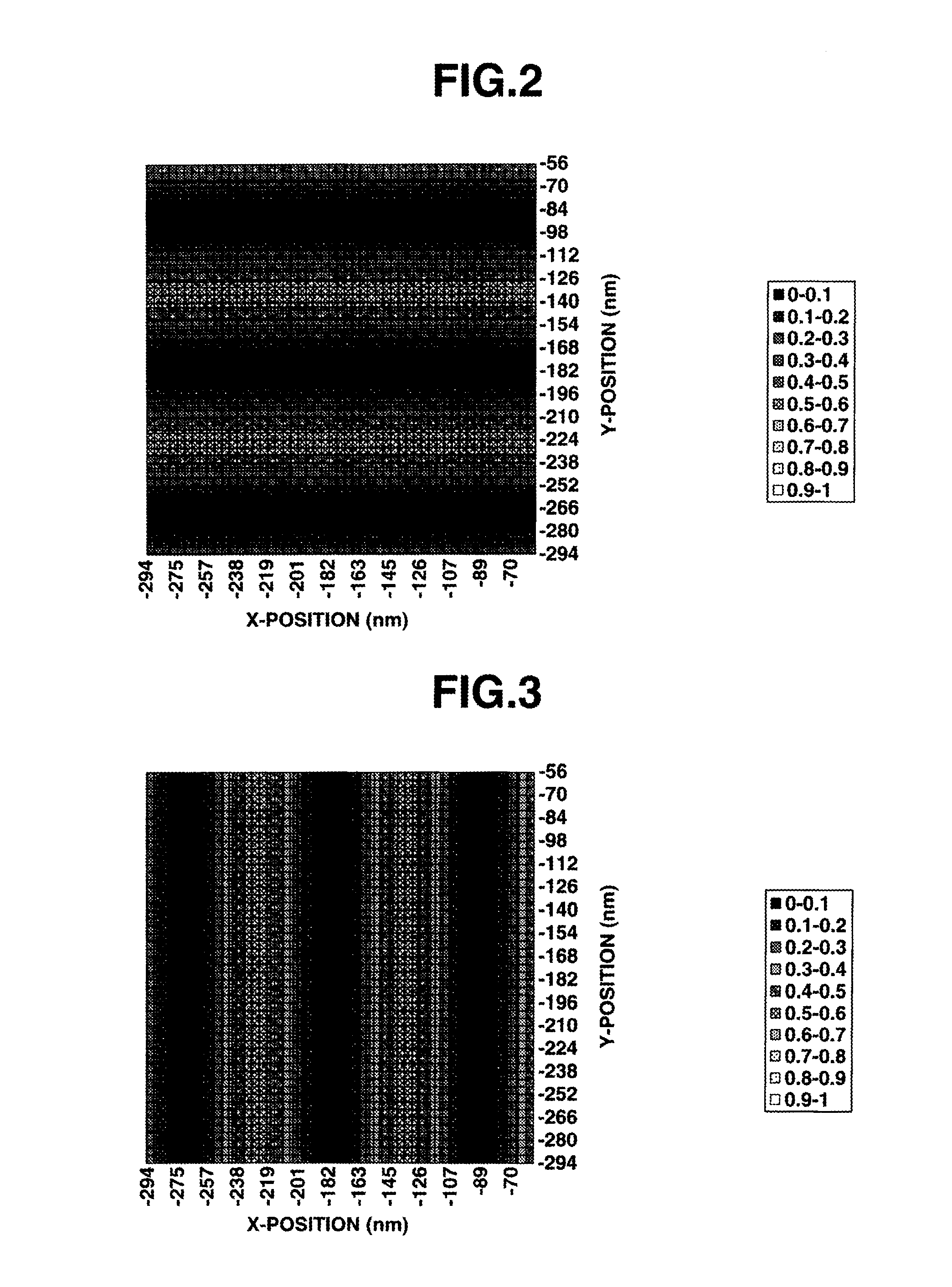

Patterning process

ActiveUS20120009529A1High dissolution contrastIncrease contrastPhotomechanical exposure apparatusMicrolithography exposure apparatusResistMeth-

A pattern is formed by applying a resist composition comprising a (meth)acrylate copolymer comprising both recurring units having an acid labile group-substituted carboxyl group and recurring units having a lactone ring, an acid generator, and an organic solvent onto a substrate, prebaking the composition to form a resist film, exposing the resist film to high-energy radiation, baking, and developing the exposed film with a developer. The developer comprises at least 40 wt % of an organic solvent selected from methyl benzoate, ethyl benzoate, phenyl acetate, benzyl acetate, methyl phenylacetate, benzyl formate, phenylethyl formate, methyl 3-phenylpropionate, benzyl propionate, ethyl phenylacetate, and 2-phenylethyl acetate.

Owner:SHIN ETSU CHEM IND CO LTD

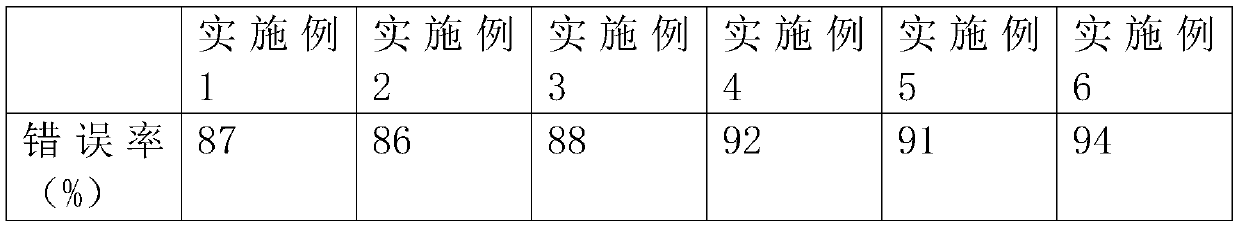

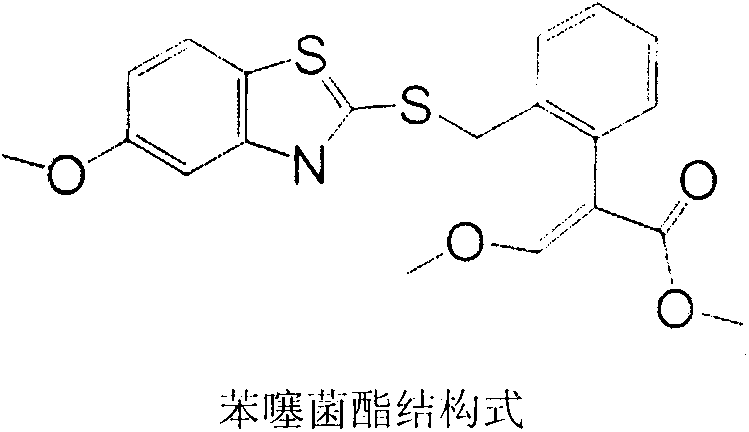

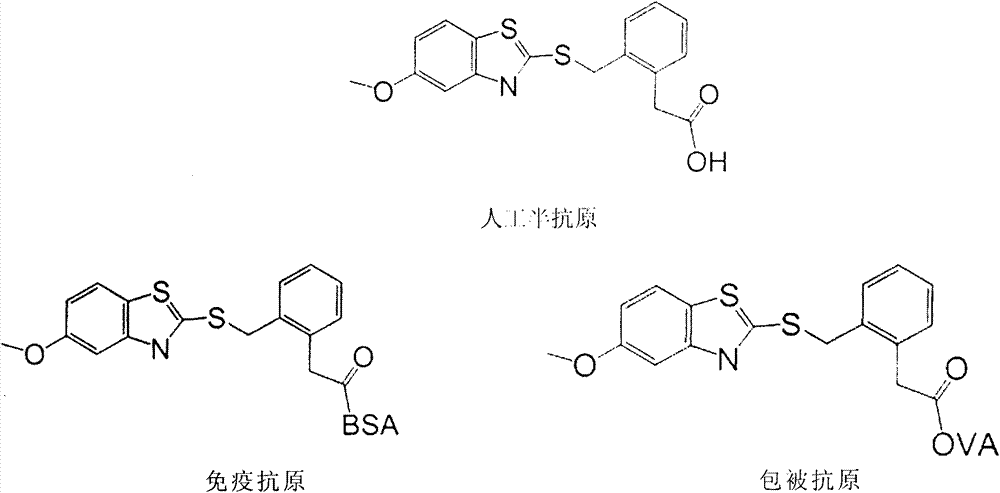

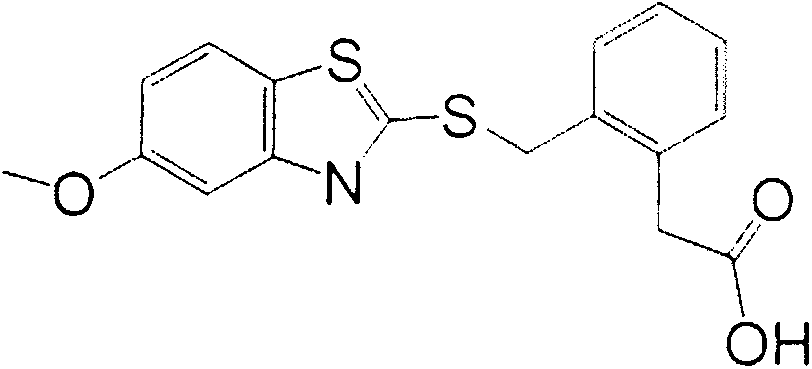

Preparation method of benzothiostrobin hapten, artificial antigen and specific antibody and application thereof

The invention relates to a preparation method of a benzothiostrobin antigen and antibody and an application thereof, belonging to the technical field of immunochemical analysis. The chemical name of benzothiostrobin is 2-[[(5-methoxy-2-benzothiazole)-thiomethyl]-alpha-(E)-methoxymethylene]methyl phenylacetate. Under an alkaline condition, carboxylic ester in the benzothiostrobin structure is hydrolyzed to synthesize an artificial hapten of which the chemical name is 2-[[(5-methoxy-2-benzothiazole)-thiomethyl]-alpha-(E)-methoxymethylene]phenylacetic acid; the artificial hapten is coupled with bovine serum albumin and ovalbumin respectively to prepared an artificial antigen. The BALB / c female mouse is immunized by the artificial antigen to obtain a specific monoclonal antibody of benzothiostrobin. The antibody does not experience a cross reaction with other compounds. An enzyme linked immunosorbent assay method established by use of the antibody can be applied to quick, sensitive, convenient and cheap detection of benzothiostrobin residues in environment and agricultural products.

Owner:NANJING AGRICULTURAL UNIVERSITY

Preparation method of ipratropium bromide

The invention discloses a preparation method of ipratropium bromide. The method comprises the following steps that as a starting material, methyl phenylacetate (III) undergoes the substitution reaction to produce alpha-formyl methyl phenylacetate (IV); tropic alcohol reacts with bromomethane to produce a compound (II); the compound (II) reacts with a compound (IV) to produce a compound (V); the compound (V) undergoes a reductive reaction to produce ipratropium bromide anhydrous substance, and then ipratropium bromide (VII) is produced through refining preparation. The method has the advantages of simple operation, high safety, a low cost and suitability for industrial production.

Owner:HANGZHOU BIO SINCERITY PHARMA TECH CO LTD

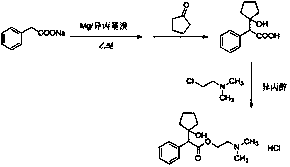

Alpha hydroxy - alpha phenyl phenylacetic acid 8 - aza dicyclo [3. 2. 1] - 3 heptyl ester, midbody compound, and preparation method

InactiveCN101003535AMild reaction conditionsShort reaction timeOrganic chemistryHydrobromidePhenylacetic acid

This invention discloses a method for preparing a key intermediate of trospium chloride, alpha-hydroxy-alpha-phenylphenylacetic acid 8-azabicyclo[3.2.1]-3-heptyl ester, and the intermediates during the preparation process, alpha-hydroxy-alpha-phenyl phenylacetic acid 8-aralkyl oxyl formyl-8-azabicyclo[3.2.1]-3-heptyl ester, and hydrobromide of alpha-Br-phenylphenylacetic acid 8-azabicyclo[3.2.1]-3-heptyl ester. The method comprises: interesterifying between tropinol and alpha-hydroxy-alpha-phenyl phenylacetic acid methyl ester, demethylating and hydrolyzing twice. The method has such advantages as mild reaction conditions, easy operation, short reaction period, little pollution, and stable product quality.

Owner:LUJIAN MEDICINS TECH SHANGHAI

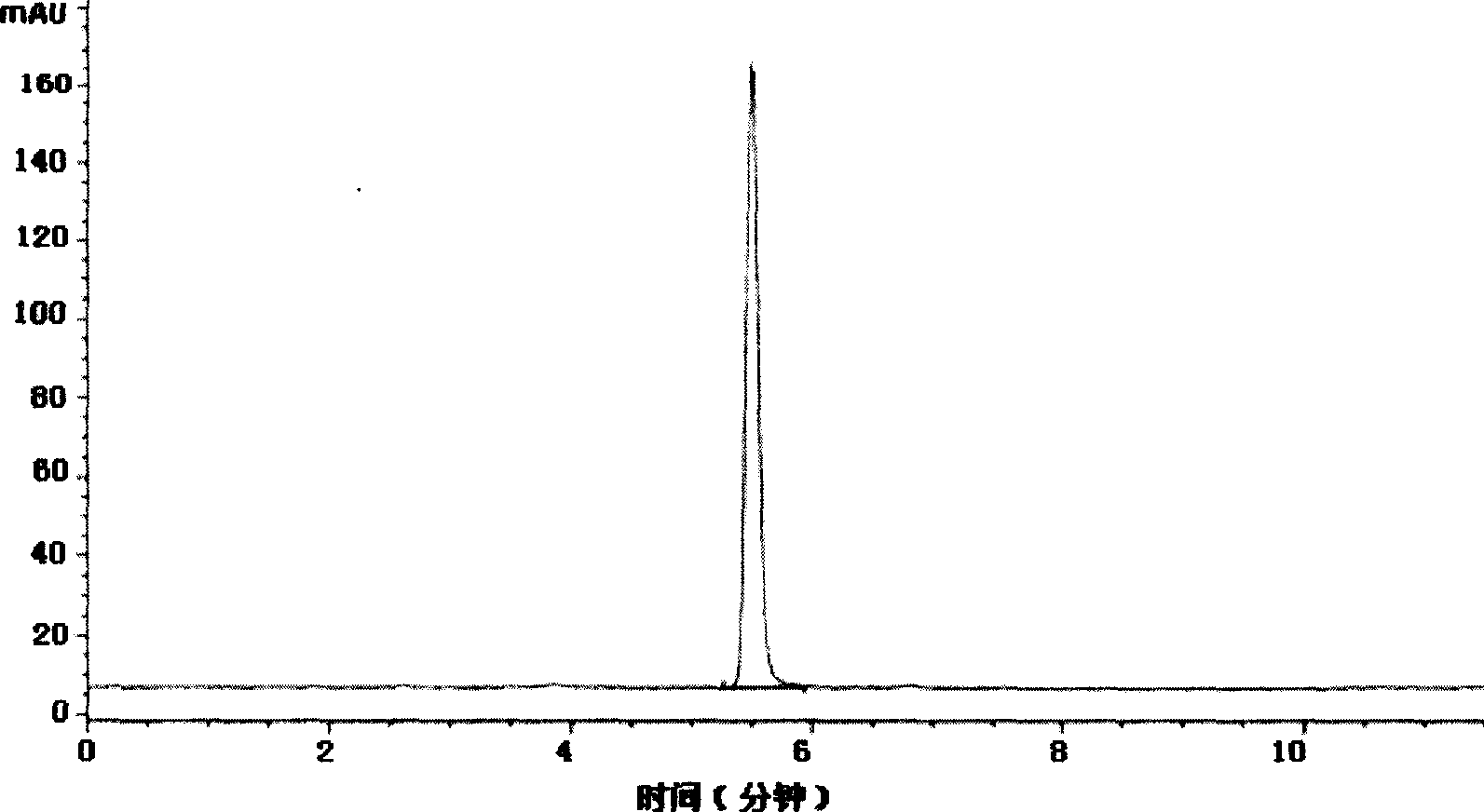

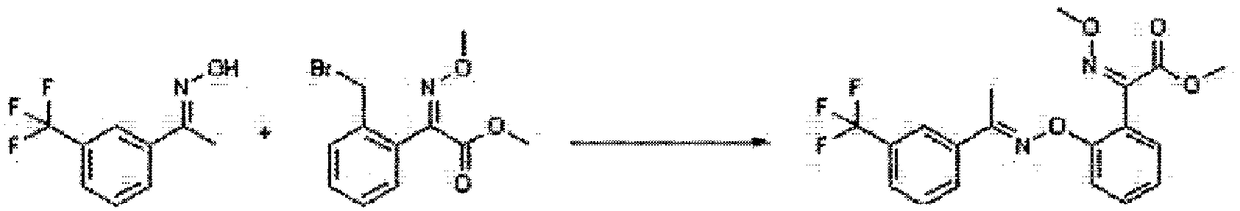

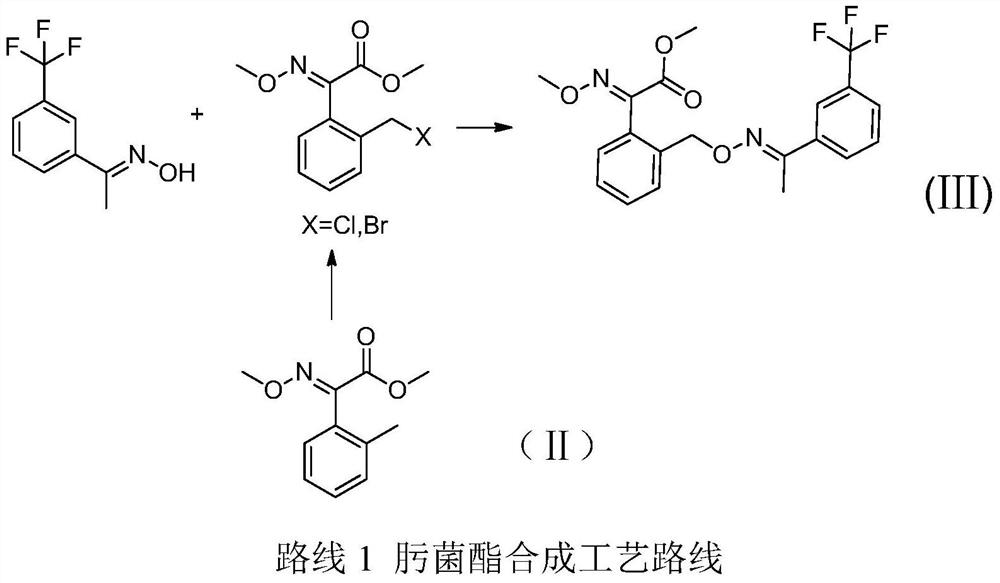

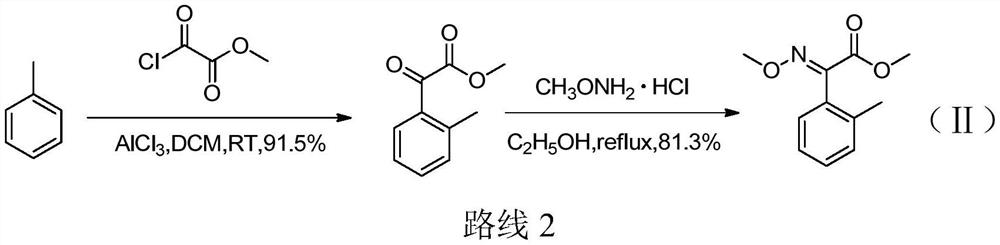

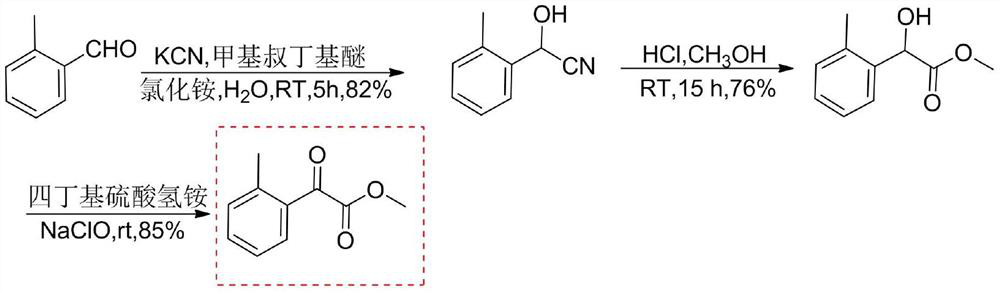

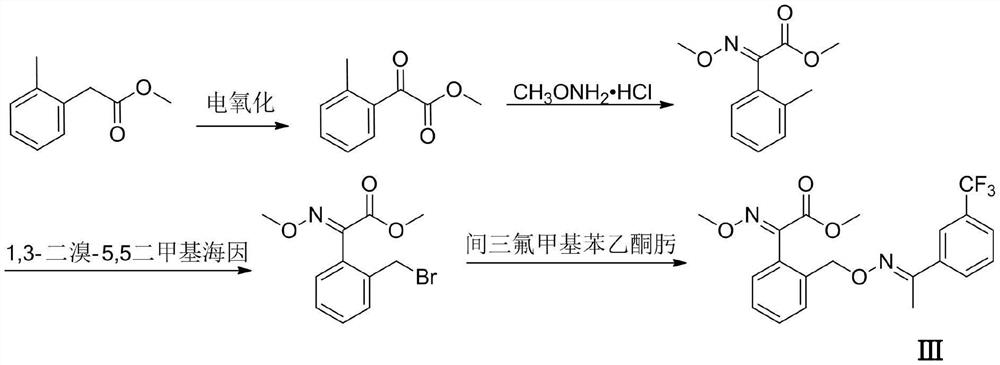

Trifloxystrobin synthesizing method

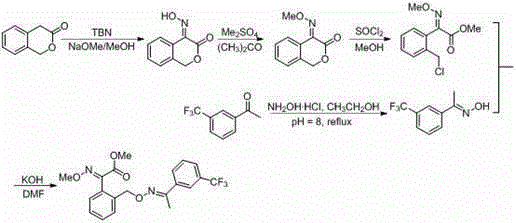

The invention discloses a trifloxystrobin synthesizing method, and relates to the preparation of trifloxystrobin in organic chemicals. The trifloxystrobin synthesizing method comprises the following steps of using hydroxy methyl phenylacetic acid lactone as raw material to react with TBN (tributyrin), absolute methanol and sodium methoxide to obtain (E)-3-keto-4-(isonitroso)isochroman; using the (E)-3-keto-4-(isonitroso)isochroman to react with acetone and potassium carbonate, and dropwise adding the acetone solution of dimethyl sulfate after a large amount of bright yellow solids occurs, so as to obtain (E)-3-keto-4-(methoxyimino)isochroman; dissolving the obtained (E)-3-ketone-4-(methoxyimino)isochroman by methanol, and dropwise adding thionyl chloride under the low-temperature condition to prepare (E)-2-chlororated methyl-alpha-methoxyimino methyl phenylacetate; after the catalysis of 3-(trifluoromethyl)acetophenone and hydroxylamine hydrochloride, using absolute ethyl alcohol and as solvent to obtain light earthy yellow solid (E)-3-(trifluoromethyl)acetophenone oxime; enabling the (E)-2-bromomethyl-alpha-methoxyimino methyl phenylacetate and the (E)- 3-(trifluoromethyl)acetophenone oxime to react in a DMF (dimethyl formamide) solution of the potassium hydroxide, so as to obtain the white solid of trifloxystrobin.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

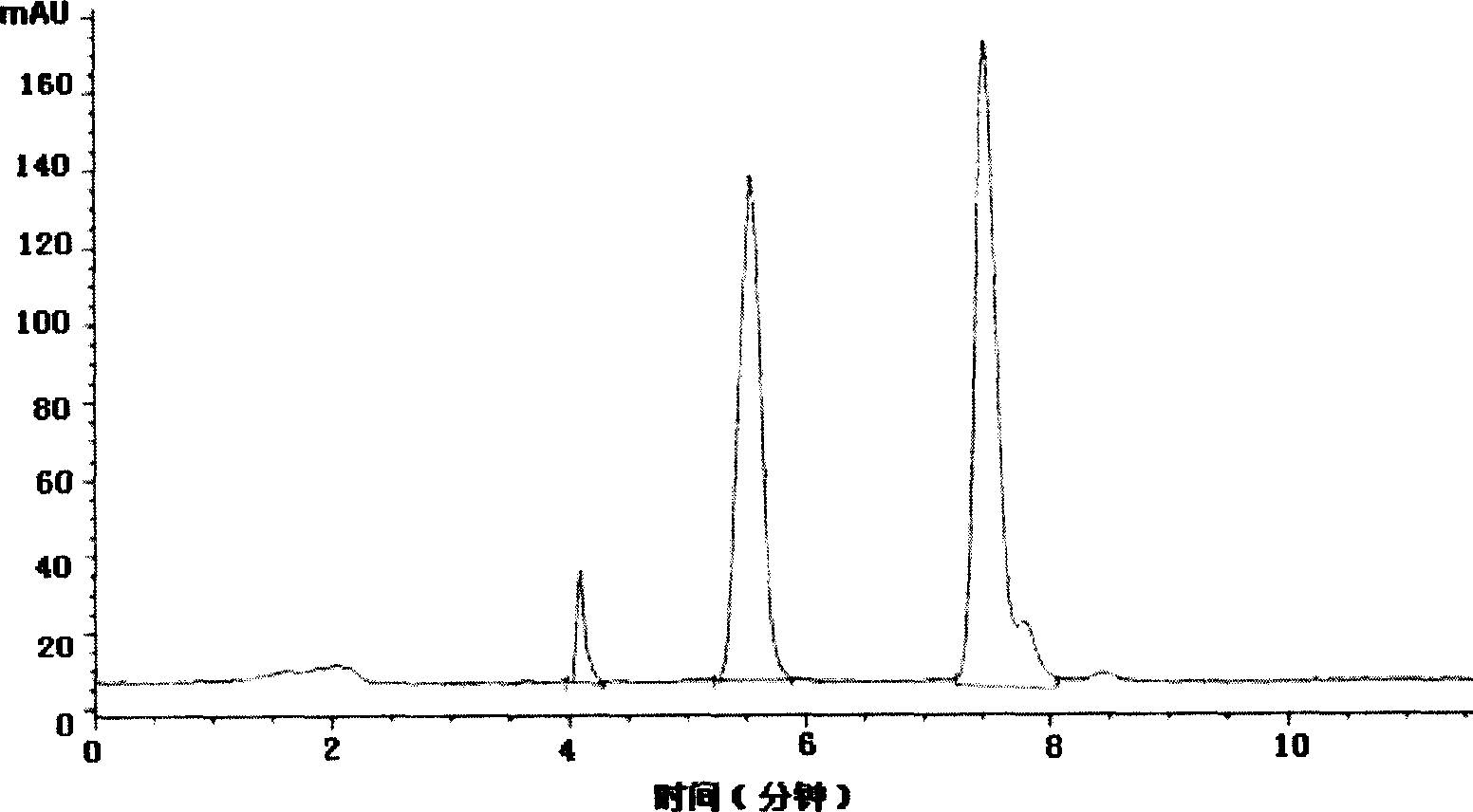

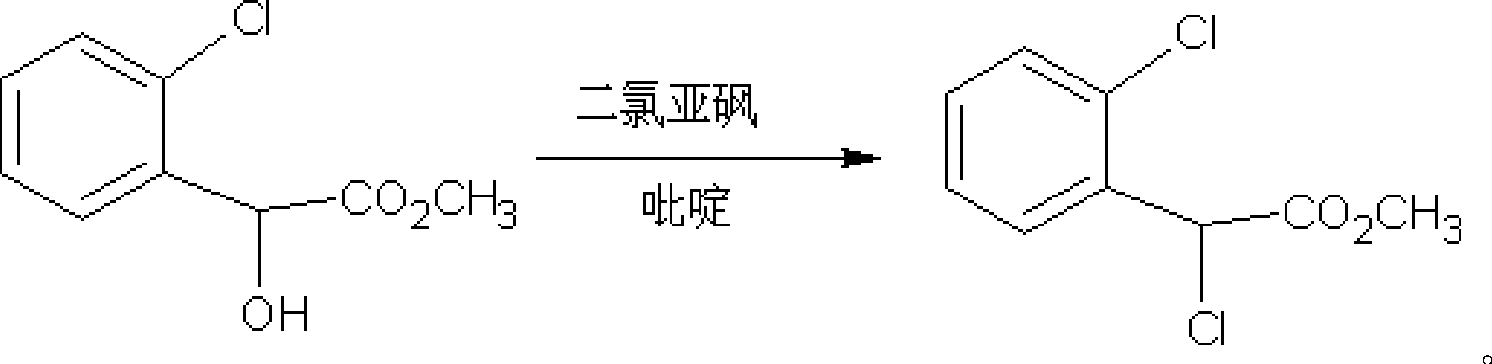

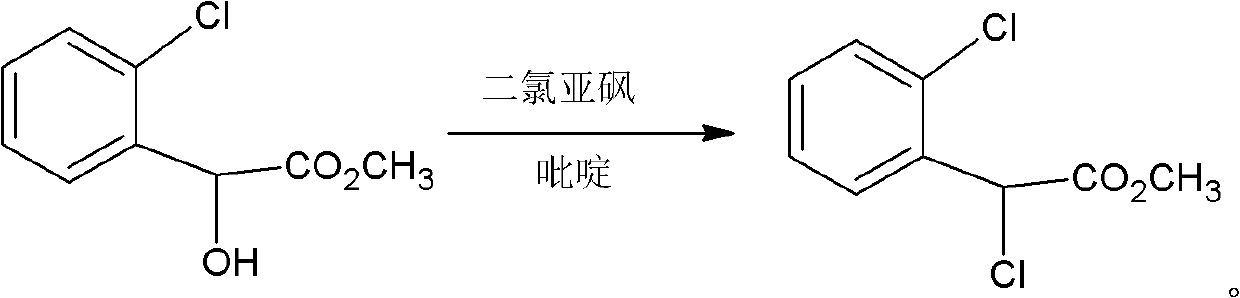

Method for synthesizing alpha-chlorine (2-chlorine) methyl phenyl acetate

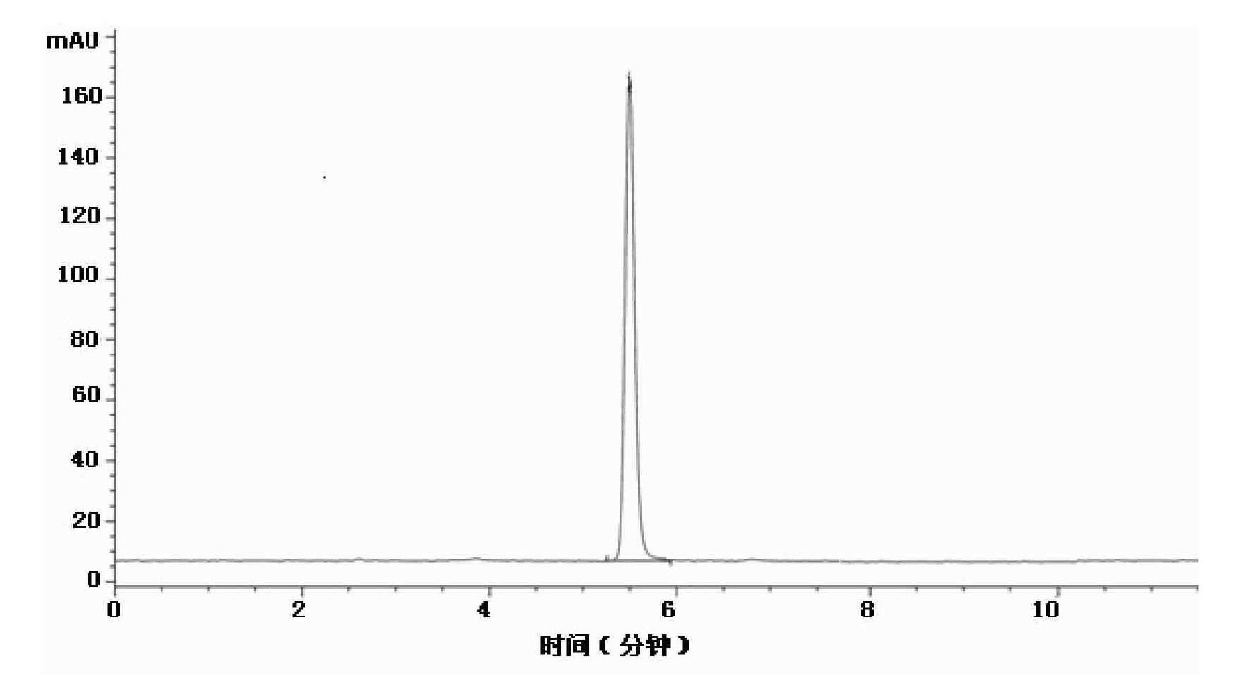

ActiveCN101434540AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationChemical synthesisMethyl o-chloromandelate

The invention relates to a synthetic method of Alpha-chloro-(2-chloro) methyl phenyl acetate, pertaining to the field of chemical synthesis. The technical problem to be solved by the invention is that a high-purity synthetic method of the Alpha-chloro-(2-chloro) methyl phenyl acetate with high purity is provided. The technical proposal comprises the steps as follows: pyridine is tanken as a solvent, and O-chloro mandelic acid methyl ester reacts with thionyl chloride under the condition of 25 DEG C to 80 DEG C for 0.5h to 5h, and then filtered. Filtrate is extracted by water for impurity removal, and anhydrous sodium sulfate is added for removing water. Filtering is carried out for removing solid sodium sulfate and the filtrate is depressurized for distilling off the solvent to obtain the Alpha-chloro-(2-chloro) methyl phenyl acetate. The reaction formula is shown as the formula in upper right side.

Owner:重庆莱美隆宇药业有限公司

Honey essence for daily chemicals

ActiveCN110106024AIncrease aroma intensityPure aromaEssential-oils/perfumesAgainst vector-borne diseasesEthyl phenylacetatePhenethyl acetate

The invention relates to the field of essences, and provides a honey essence for daily chemicals in order to solve the problem that the difference between the aroma of existing honey essence and nature aroma is great. The honey essence for the daily chemicals is prepared from, by mass, 0.1-1 part of phenethyl acetate, 0.1-1 part of isoamyl acetate, 0.01-0.15 part of geranyl acetate, 0.1-1 part ofethyl acetate, 0.1-1 part of ethyl pelargonate, 1-15 parts of phenylethyl isobutyrate, 0.1-1.5 parts of isoamyl isovalerate, 0.5-3 parts of ethyl lactate, 0.1-1 part of ethyl phenylacetate, 0.5-1.5 parts of butyl phenylacetate, 0.1-1 part of methyl phenylacetate, 1-10 parts of phenylethyl phenylacetate, 5-20 parts of phenethyl alcohol, 0.1-1 part of citronellol, 0.01-0.2 part of geraniol, 0.5-3 parts of artificial cognac oil, 1-10 parts of methyl cedryl ether, 0.5-3 parts of ethyl maltol, 0.1-1 part of damascenone, 0.1-1.5 parts of delta damascone, 0.1-1.5 parts of 4-hydroxy-2,5-dimethyl-3(2H)-furanone and 50-70 parts of dipropylene glycol. By controlling the usage ratio of all the components, the aroma intensity of the honey essence for the daily chemicals is easily improved, and the aroma given off by the honey essence for the daily chemicals is closer to the natural aroma.

Owner:广州宝士迪香精香料有限公司

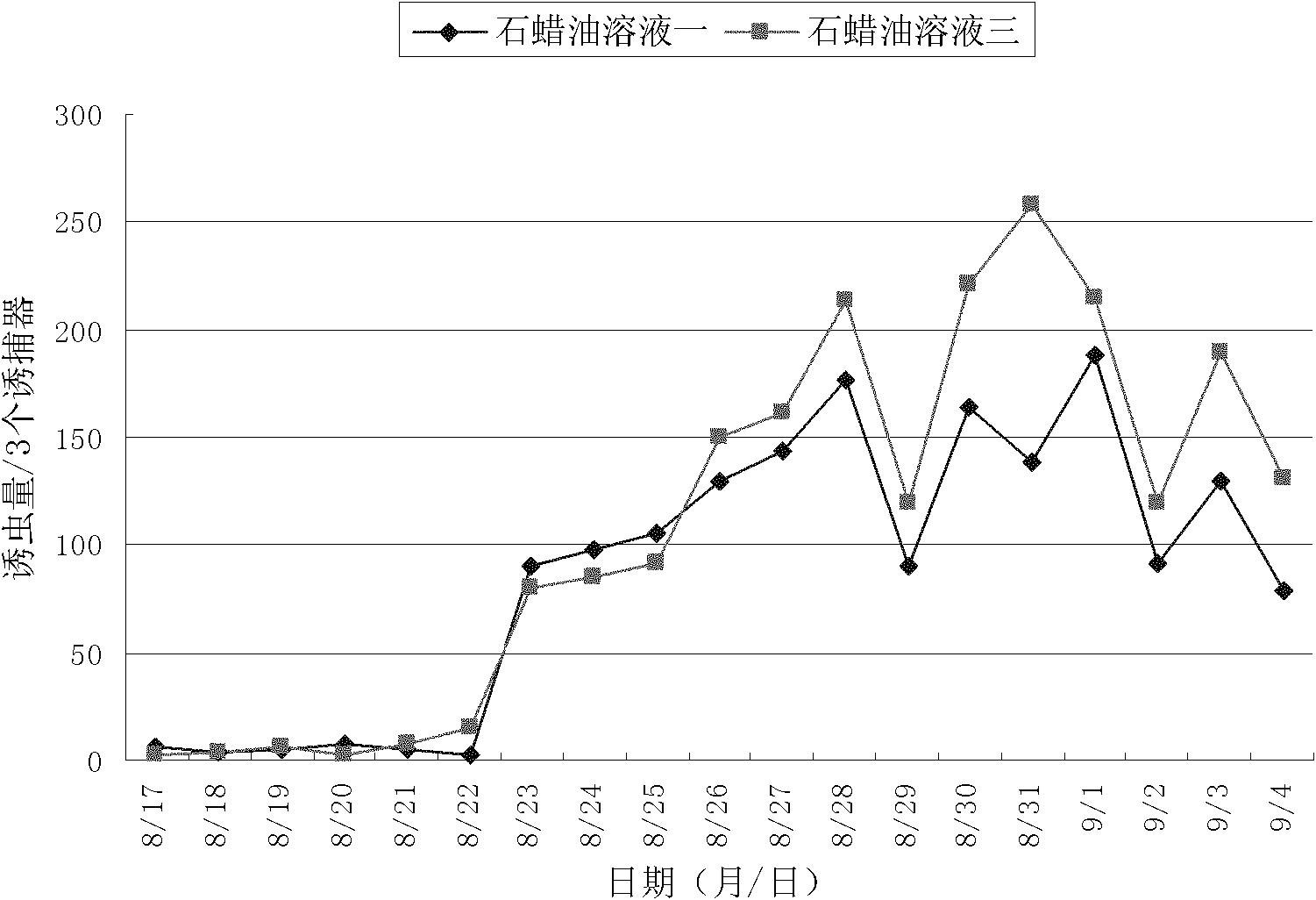

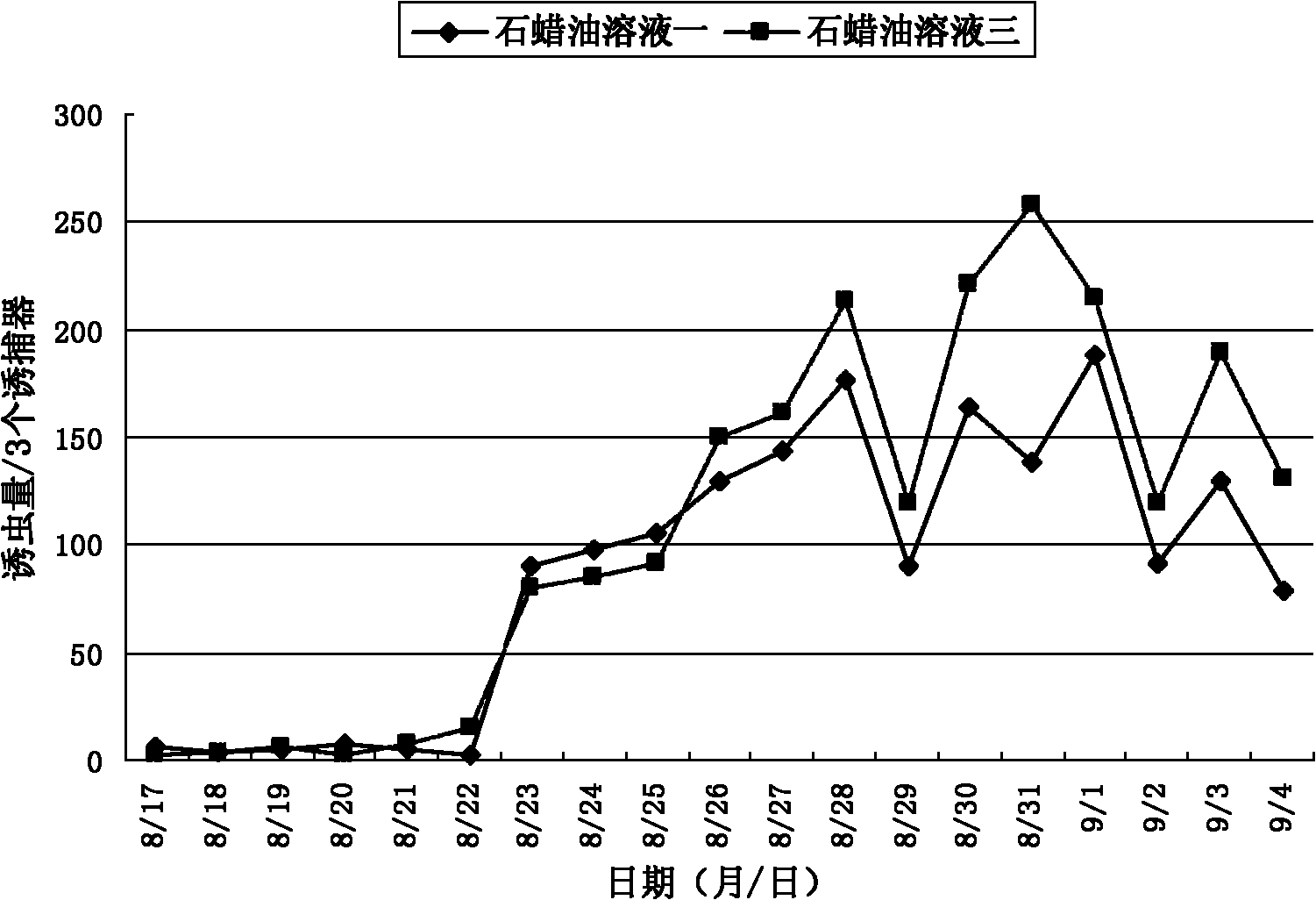

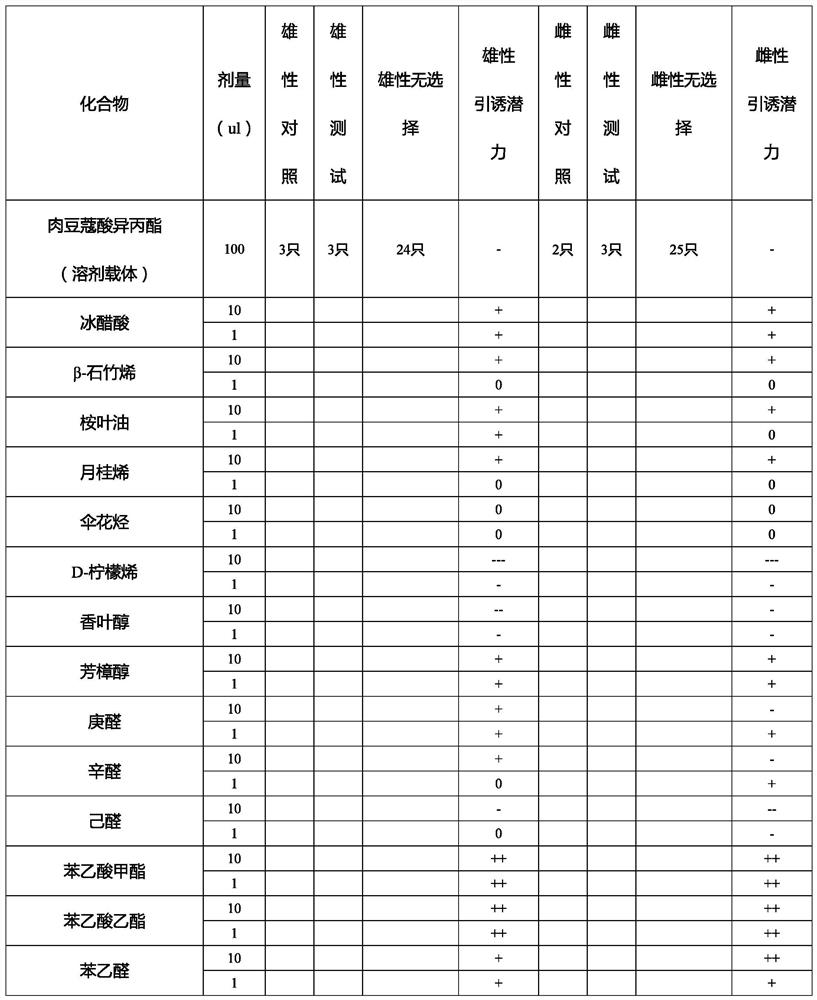

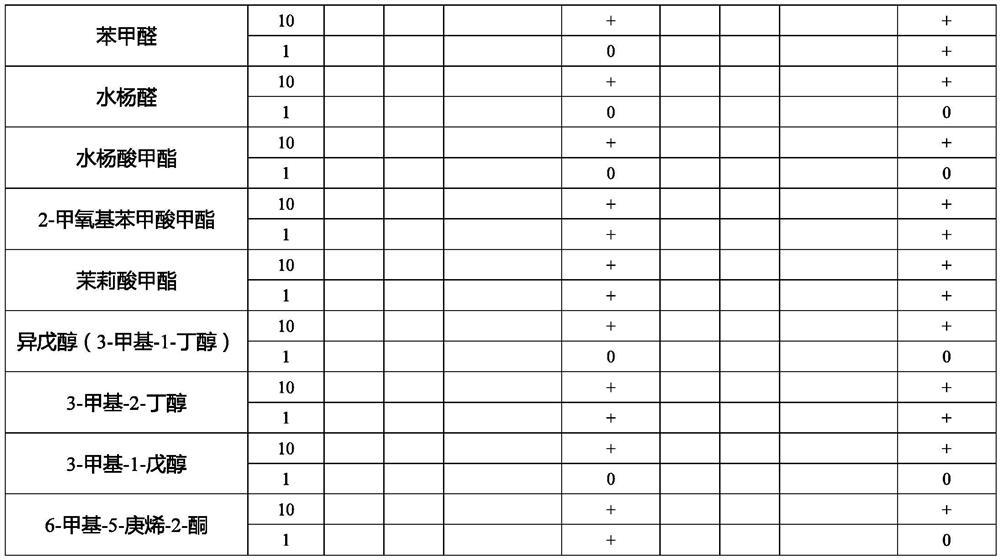

Bisexual adult attractant for colorado potato beetles

InactiveCN102084860ALower resistanceImprove biological activityBiocidePest attractantsCaryophylleneChemical control

The invention discloses a bisexual adult attractant for colorado potato beetles, which comprises the following components by weight percent: 70-80% of component I and 20-30% of 2-phenylethanol, wherein the component I is methyl phenylacetate or beta-caryophyllene. The invention simultaneously discloses another bisexual adult attractant for the colorado potato beetles, which comprises the following components by weight percent: 4-7% of methyl phenylacetate, 90-95% of beta-caryophyllene and 1-3% of 2-phenylethanol. By applying the attractant, occurrence dynamics of the colorado potato beetles in a field can be monitored, chemical control can be guided, and the colorado potato beetles can be simultaneously directly controlled through the mass trapping method.

Owner:ZHEJIANG FORESTRY UNIVERSITY +1

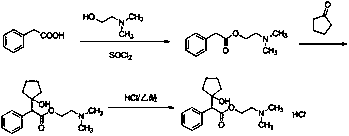

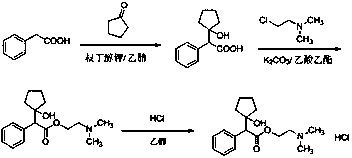

Preparation method of cyclopentolate hydrochloride intermediate

InactiveCN110483274ALow priceSufficient supplyPreparation from carboxylic acid saltsOrganic compound preparationGrignard reagentPhenylacetic acid

The invention belongs to the technical field of pharmaceutical chemicals, and relates to a preparation method of a cyclopentolate hydrochloride intermediate. Methyl phenylacetate is used as a raw material, the price is low, the methyl phenylacetate is commercially produced, the goods source is sufficient, and the quality is stable. The commercially available Grignard reagent is adopted, so that the risk that flammable and explosive reagents are used and are not controlled when the Grignard reagent is self-made is avoided. Commercially available Grignard reagents have been industrially produced and are convenient and easy to obtain. And the intermediate is purified by adopting a crystallization solvent, so that the purity of the intermediate is ensured, the preparation yield of the cyclopentolate hydrochloride is increased, and subsequent crystallization and impurity removal processes are reduced. And the production risk and the labor protection requirement of workers are reduced, environmental protection is facilitated, and the economic benefit is improved. The yield of phenylacetic acid can reach 95% or above, the purity of phenylacetic acid can reach 99.9% or above, the production requirements of the cyclopentolate hydrochloride intermediate are completely met, and the yield and purity of the product 2-(1-hydroxycyclopentyl)-phenylacetic acid are much higher than those of 2-(1-hydroxycyclopentyl)-phenylacetic acid produced by a common method.

Owner:SHANDONG SHEN LIAN BIOLOGY TECH CO LTD

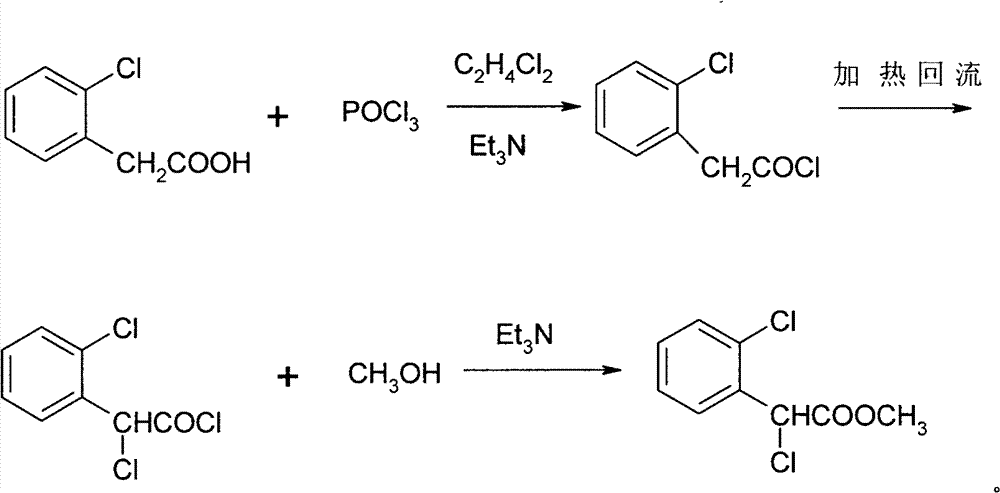

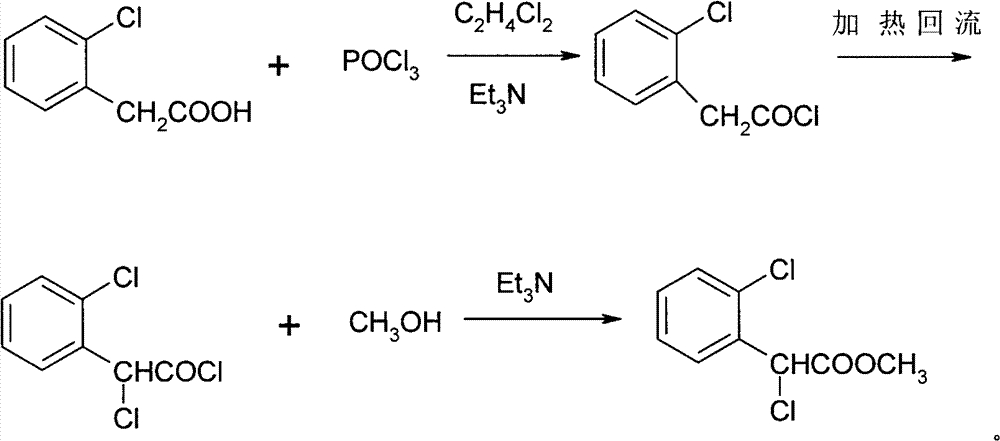

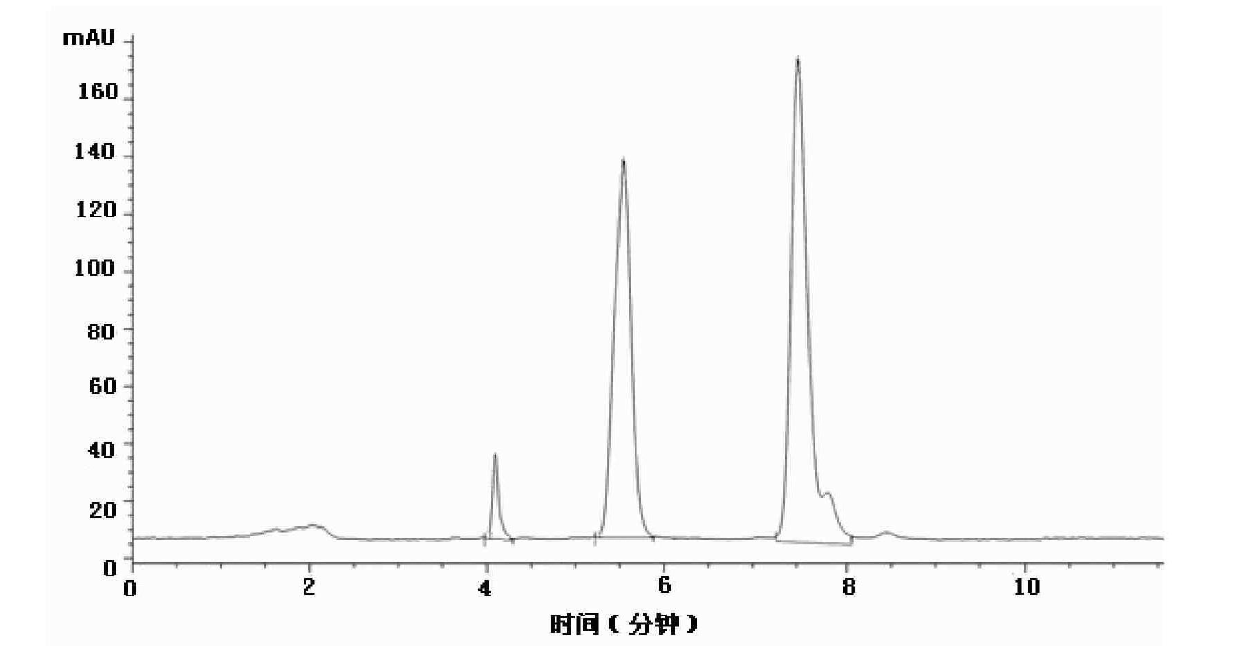

Production method of alpha-chlorine (2-chlorine) methyl phenylacetate

InactiveCN103360254AReduce manufacturing costImprove protectionPreparation from carboxylic acid halidesPhenylacetic acidEthane Dichloride

The invention discloses a production method of an alpha-chlorine (2-chlorine) methyl phenylacetate and aims to provide a method which is low-price and available in starting raw materials, high in purity and stable in quality of product, easy and feasible in process, environment-friendly, low in production cost and easy in industrial production. The method comprises the following steps of: using a continuous method, taking chlorophenylacetic acid as a raw material, carrying out acylation reaction for the chlorophenylacetic acid and phosphorus oxychloride at a temperature of 5-10 DEG C for 2-2.5 hours, and subsequently, carrying out chlorination reaction at a temperature of 80-85 DEG C for 4-5 hours, then carrying out esterification reaction with methyl alcohol at a temperature of 35-40 DEG C for 2-2.5 hours, washing a reaction solution by using pure water to remove impurity, drying and filtering a dichloroethane layer, and subsequently, decompressing and concentrating to remove solvents and acquire the alpha-chlorine (2-chlorine) methyl phenylacetate. According to the method, the low-price and available chlorophenylacetic acid is taken as the raw material in the method, so that the production cost is significantly reduced; the phosphorus oxychloride is taken as an acylating agent and a chlorinating agent, so that the purity of the product is improved and the product is environment-friendly. By applying the continuous method, the method is simple and feasible in the technological process, easy to control in the reaction processes and suitable for industrial production.

Owner:TIANJIN HENGTIANLI CHEM

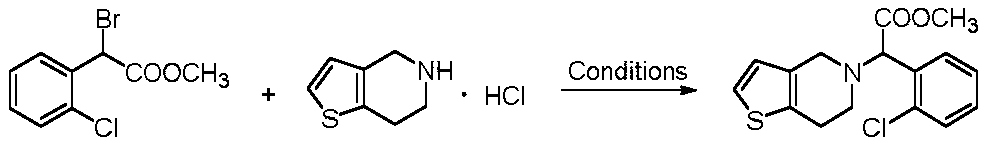

Method for preparing clopidogrel intermediate alpha-bromo (2-chloro) methyl phenylacetate by recycling aqueous solution method

PendingCN111499511AReduce inputImprove bromine atom utilizationOrganic compound preparationCarboxylic acid esters preparationChlorobenzenePhenylacetic acid

The invention provides a method for preparing clopidogrel intermediate alpha-bromo (2-chloro) methyl phenylacetate by recycling an aqueous solution method. According to the method, o-chlorophenylacetic acid is adopted as a main raw material, an organic solvent and water in an appropriate proportion are optimized to serve as a bromination mixed solvent, a two-phase reaction mode is adopted in the reaction process, a bromine-containing wastewater solution can be reused without complex treatment, a target product is prepared through bromination and esterification reactions, and the yield reaches78% or above; the method provided by the invention is based on a technical scheme of recycling an aqueous solution containing a bromination reagent. In the process production process, the input amountof a new bromination reagent is reduced to a great extent, the bromine atom utilization rate of the bromination reagent is increased, the problems of wastewater treatment and discharge are reduced, the pressure of environmental pollution is reduced, meanwhile, the reaction conditions are relatively mild, treatment is simple, and industrial production is facilitated.

Owner:ZHEJIANG LIAOYUAN PHARM CO LTD

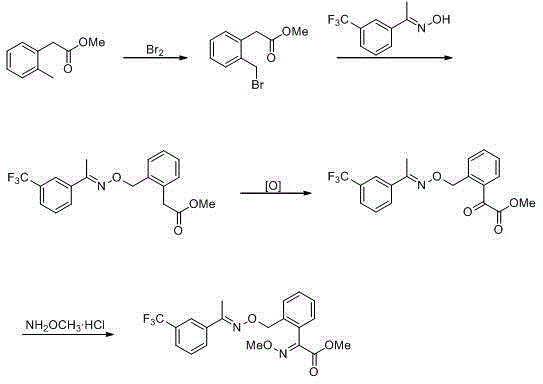

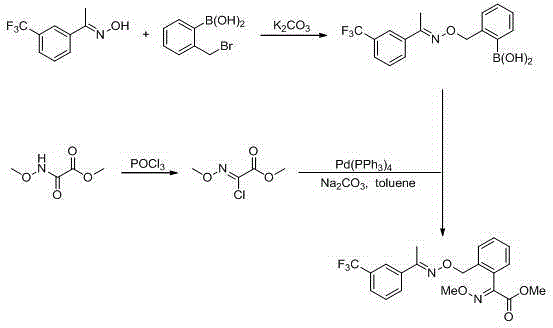

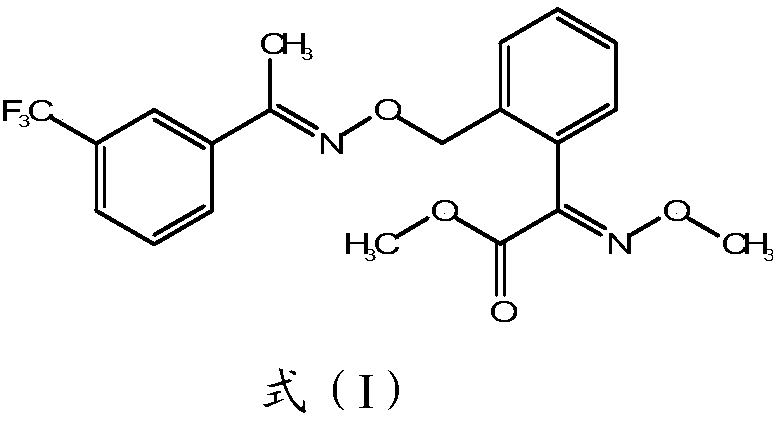

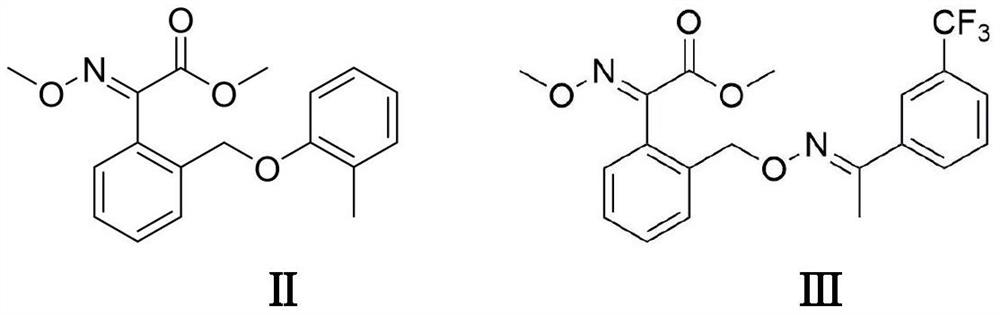

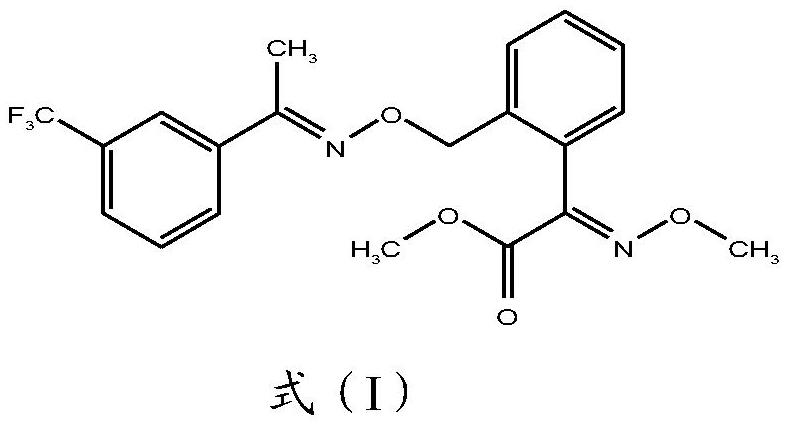

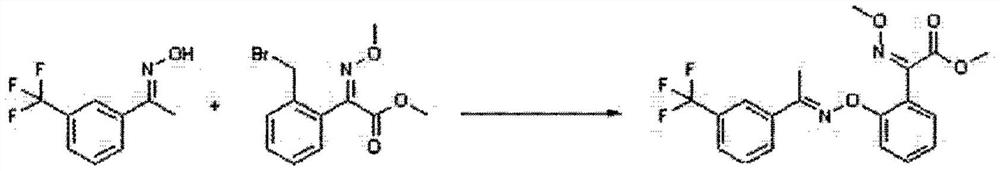

A novel process for the preparation of trifloxystrobin

ActiveCN108368033AEasy to getEasy disposalOrganic compound preparationCarboxylic acid esters preparationFree formStereochemistry

The present invention relates to a novel process for preparation of methyl (Alpha E)-(Alpha - (methoxyimino)-2-[[[(E)-[1-[3- (trifluoromethyl) phenyl] ethylidene] amino] oxy] methyl] benzeneaceate (Trifloxystrobin) compound of formula (I) in free form or in agro chemically acceptable salt form useful as a pest control agent.The present invention also relates to a novel process for preparation of methyl (2E)-[2-(bromomethyl) phenyl] (methoxyimino) ethanoate of formula (X) intermediate of Trifloxystrobin.

Owner:GSP CROP SCI PVT

Application of amino acid sequence in identifying odor compounds

InactiveCN109957002AIncreased sensitivitySimple processCell receptors/surface-antigens/surface-determinantsMaterial analysis by electric/magnetic meansMethyl phenylacetateOctanol

The invention relates to an application of an amino acid sequence in identifying odor compounds. Specifically, the invention relates to the application of the amino acid sequence shown in SEQ ID No.2in identifying the odor compounds. The odor compounds are at least one of trans-2-hexenol, cinnamaldehyde, methyl phenylacetate, 4-ethylacetophenone, trans-3-hexenol and n-octanol.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Passion fruit essence

InactiveCN107474954AFull of fragranceRich fragranceEssential-oils/perfumesPhenethyl acetateEthyl butyrate

Passion fruit essence is disclosed. The essence includes, by mass, 10-12 parts of methyl anthranilate, 20-22 parts of hexadecanal, 5-6 parts of ethyl butyrate, 3-5 parts of amyl butyrate, 3-5 parts of amyl valerate, 2-3 parts of allyl heptanoate, 2-3 parts of ethyl heptanoate, 18-20 parts of myristyl aldehyde, 5-6 parts of sweet orange oil, 3-4 parts of phenethyl acetate, 3-4 parts of ethyl maltol, 4-5 parts of vanillin, 2-3 parts of amyl acetate, and 13-15 parts of methyl phenylacetate. The essence has fresh and pleasant passion fruit fragrance, full fragrance, a strong natural sense, long duration time and obvious characteristic fragrance, can be widely applied in daily chemical products, and can meet ever-growing material and cultural needs of the people.

Owner:安徽香杰香精科技有限公司

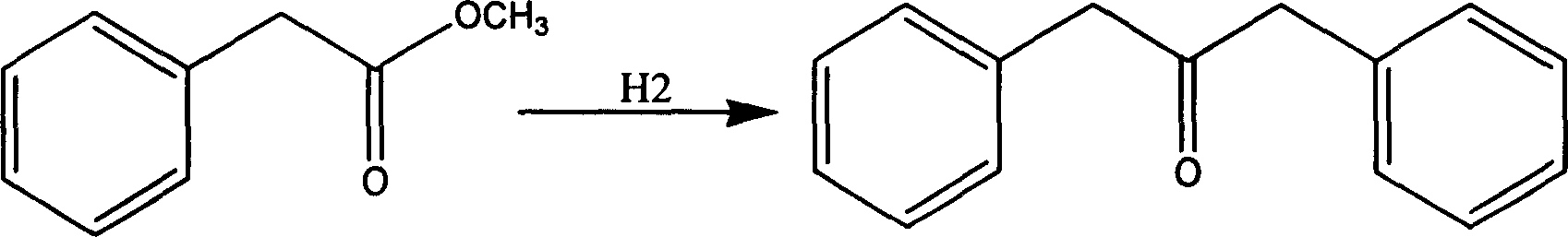

Catalytic synthesis of 1,3-diphenyl acetone

InactiveCN1680246AImprove conversion rateHigh selectivityPreparation by hydrogenolysisHydrogenGas phase

A catalytic synthesis of 1,3-diphenyl acetone by methyl phenylacetate gas-phase hydrogenation is carried out by taking composite manganese-aluminum as catalyst, loading manganese oxide on gamma -Al2O3, directly catalyzing methyl phenylacetate by catalyst, synthesizing 1,3-diphenyl acetone, or modifying one or several elements of Zr, Zn or Cr. The reacting temperature is 300-500deg.C, the mol ratio of hydrogen ester is 10-100, LHSV=1.0-8.0hr-1. The single-pass percent conversion of methyl phenylacetate reaches to 98.4%, and the selectivity of 1,3-diphenyl acetone reaches to 66.7%.

Owner:FUDAN UNIV

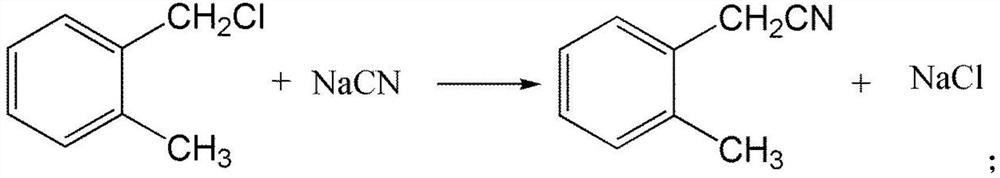

Synthesis method of methyl phenylacetate

PendingCN113912489AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationPhenylacetic acidCombinatorial chemistry

The invention belongs to the field of chemistry, and particularly relates to a synthetic method of methyl phenylacetate. According to the method, benzyl chloride and the like are used as raw materials, methyl phenylacetate is prepared through substitution reaction and addition reaction, and the synthetic product is high in yield and good in purity.

Owner:宁夏常晟药业有限公司

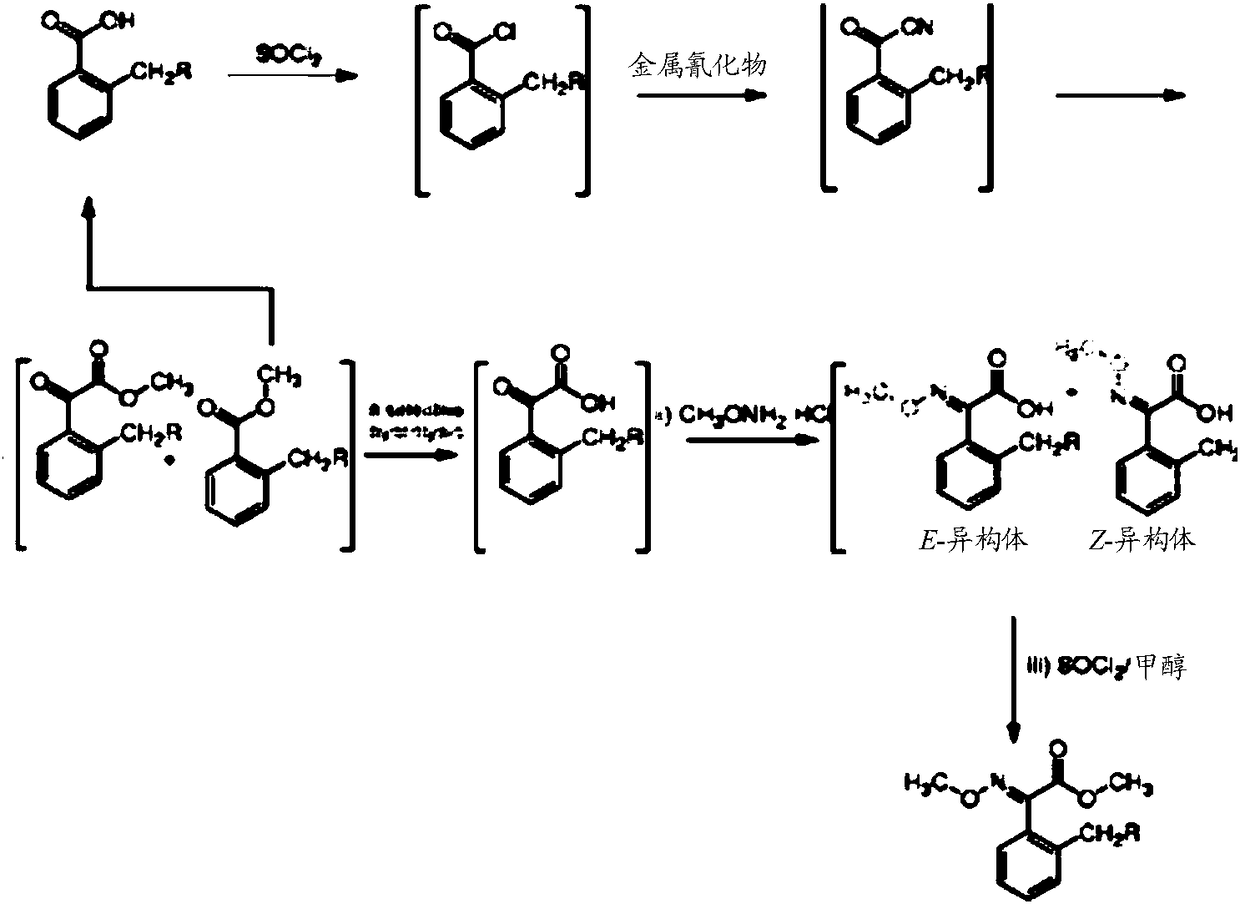

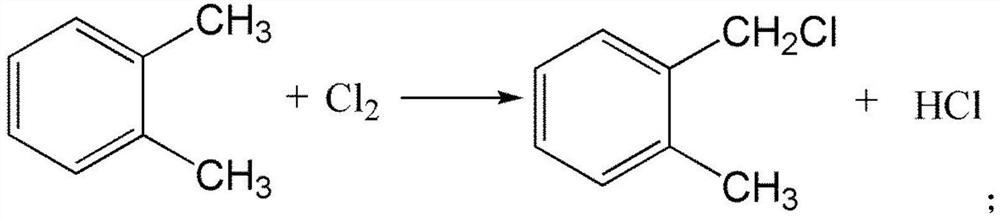

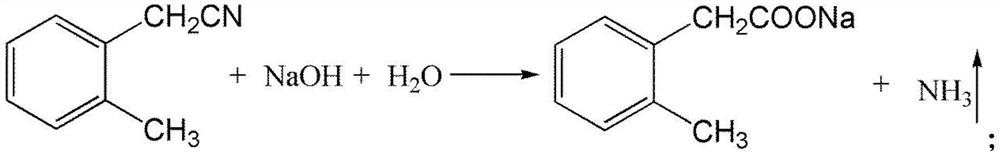

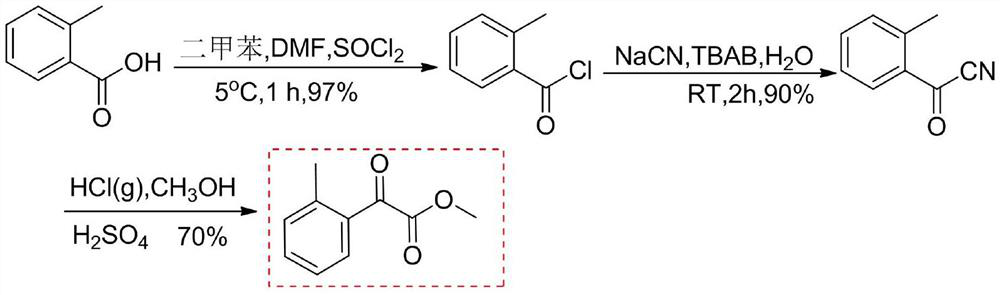

Synthesis method of 3-isochromanone

PendingCN112125876AEmission reductionMeet the use requirementsOrganic chemistrySodium acetatePhenylacetic acid

The invention belongs to the technical field of synthesis of organic intermediates, and particularly relates to a synthesis method of 3-isochromanone, which comprises the following steps of: (1) synthesizing o-methyl benzyl chloride by using o-xylene as a raw material; (2) synthesizing o-methyl benzyl cyanide by taking o-methyl benzyl chloride as a raw material; (3) synthesizing sodium o-methyl phenylacetate by taking o-methyl benzyl cyanide as a raw material; (4) synthesizing o-methyl phenylacetic acid by taking sodium o-methyl phenylacetate as a raw material; (5) synthesizing 2-chloromethylphenylacetic acid by taking o-methyl phenylacetic acid as a raw material; and (6) synthesizing 3-isochromanone by taking 2-chloromethyl phenylacetic acid as a raw material. The synthesis method of 3-isochromanone has the advantages of simple reaction process, easily available raw materials, mild reaction conditions, high product yield, low production cost, high yield, high product purity, good quality, low production waste discharge amount and the like, the product purity is greater than or equal to 99.5%, the production yield is greater than or equal to 92%, and the product meets the use requirements of foreign high-end users.

Owner:NINGXIA SIKEDA BIOTECH CO LTD

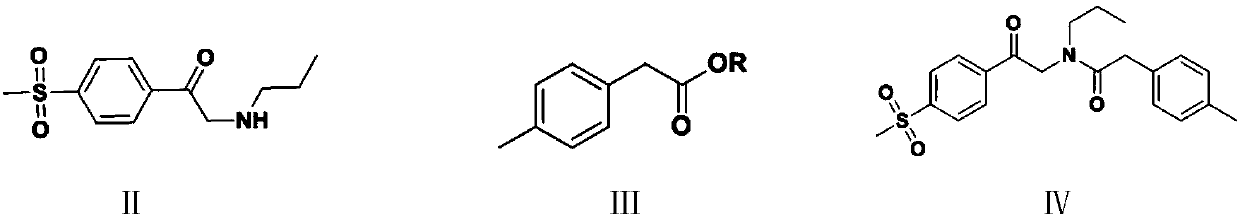

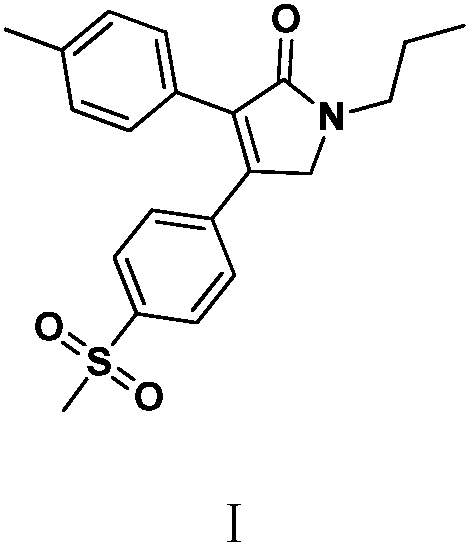

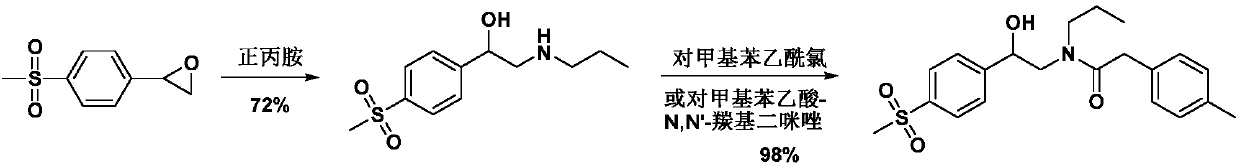

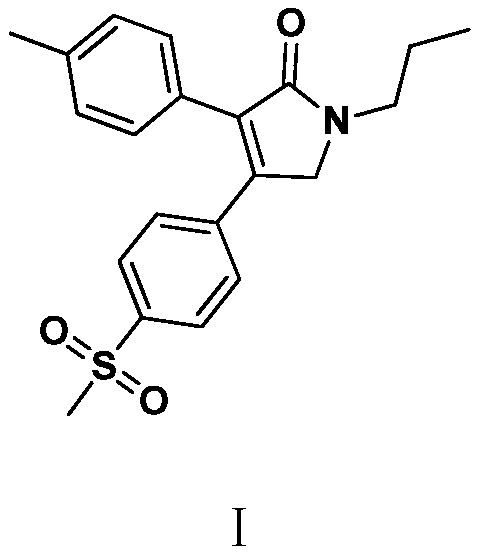

Preparation method of imrecoxib

The invention provides a preparation method of imrecoxib. The preparation method of the imrecoxib comprises the steps that alpha-n-propylamino-4-methyl sulfonate acetophenone (II) and 4-methyl phenylacetate (III) are used as main raw materials, amidation is carried out to obtain N-n-propyl-N-P-methanesulfonyl benzoyl methyl-4-methyl-phenylacetamide (IV), and then the imrecoxib (I) is obtained through an intramolecular cyclization reaction under the action of alkali and ester. The preparation method of the imrecoxib is short in synthetic route and simple and convenient in operation, is easy topurify, has low requirements on equipment, is easy to realize, has less waste water generation quantity, is environmentally friendly, and is suitable for large-scale industrial production; and meanwhile, the reaction selectivity is good, by-products are less, and the product yield and purity are high.

Owner:XINFA PHARMA

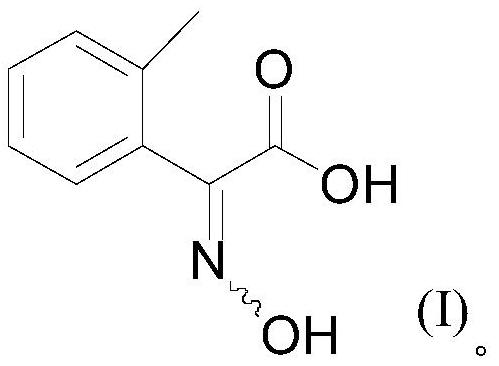

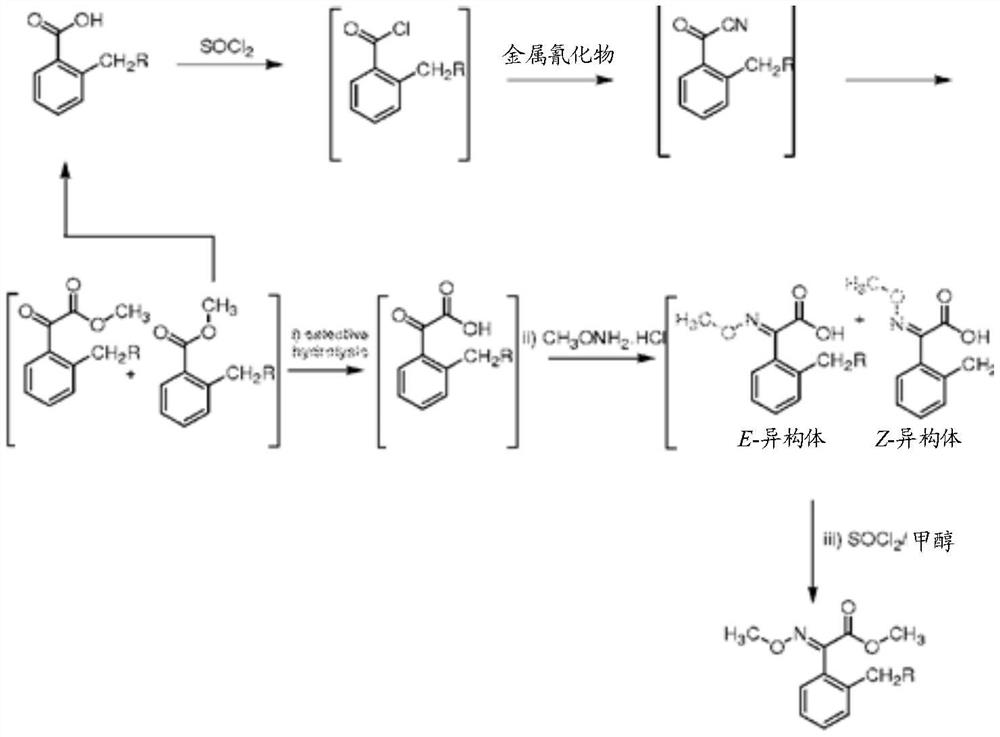

Preparation method of (E)-2-methyl-alpha-methoxyimino methyl phenylacetate and intermediate thereof

The invention provides a preparation method of (E)-2-methyl-alpha-methoxyimino methyl phenylacetate and an intermediate thereof, and the intermediate 2-methyl-alpha-hydroxyimino phenylacetic acid is prepared by taking 2-methyl-alpha-hydroxyimino phenylacetonitrile as a raw material, carrying out hydrolysis reaction in the presence of an alkaline substance, and then acidifying to obtain the 2-methyl-alpha-hydroxyimino phenylacetic acid. According to the method, 2-methyl-alpha-hydroxyimino phenylacetic acid is taken as the raw material and reacts with a methylation reagent in the presence of an alkaline substance, and (E)-2-methyl-alpha-methoxyimino methyl phenylacetate is obtained. According to the method, 2-methyl-alpha-hydroxyimino phenylacetonitrile is used as the raw material, 2-methyl-alpha-hydroxyimino phenylacetic acid is generated through hydrolysis, the operation is simple, the cost is low, the reaction condition is mild, and the yield is high. In the preparation process of (E)-2-methyl-alpha-methoxyimino methyl phenylacetate, methylation of hydroxyl and esterification of carboxyl are completed by adopting a one-pot method, so that the operation is simplified, the reaction yield is high, and the cost is low.

Owner:JIANGXI TIANYU CHEM CO LTD

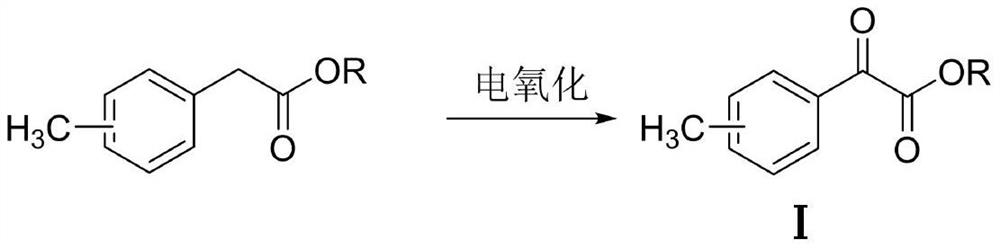

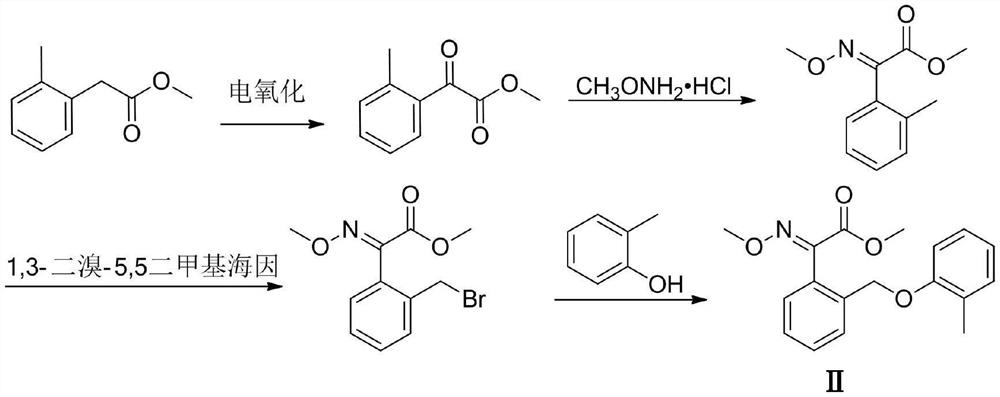

Electrooxidative Preparation Method of Kresstrobin and Trifloxystrobin Intermediates

ActiveCN113308705BLow selectivityHigh purityElectrolysis componentsElectrolytic organic productionElectrolytic agentOrganosolv

Owner:湖北中迅长青科技有限公司

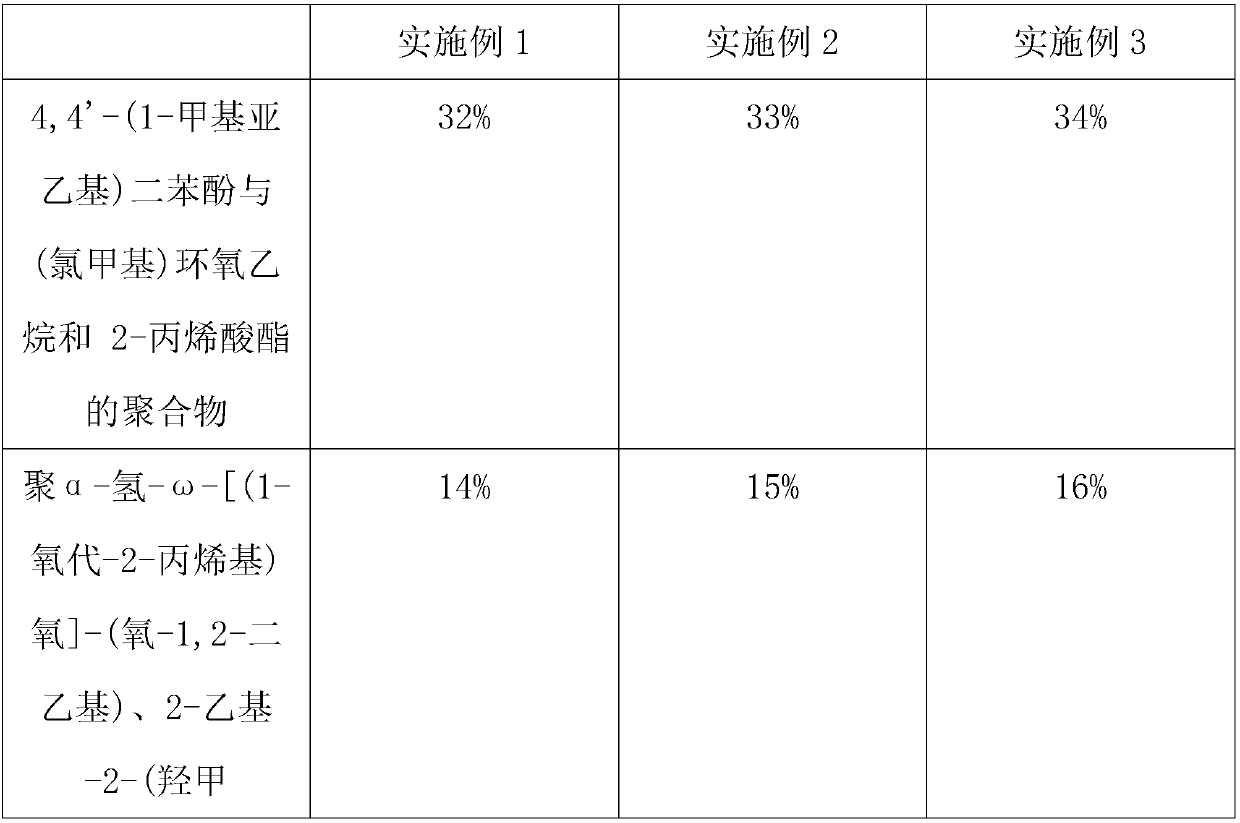

UV putty with high light guide performance for plate processing and preparation method of UV putty

InactiveCN111378311AGood chemical resistanceImprove water resistanceFilling pastesTripropylene glycolPolymer science

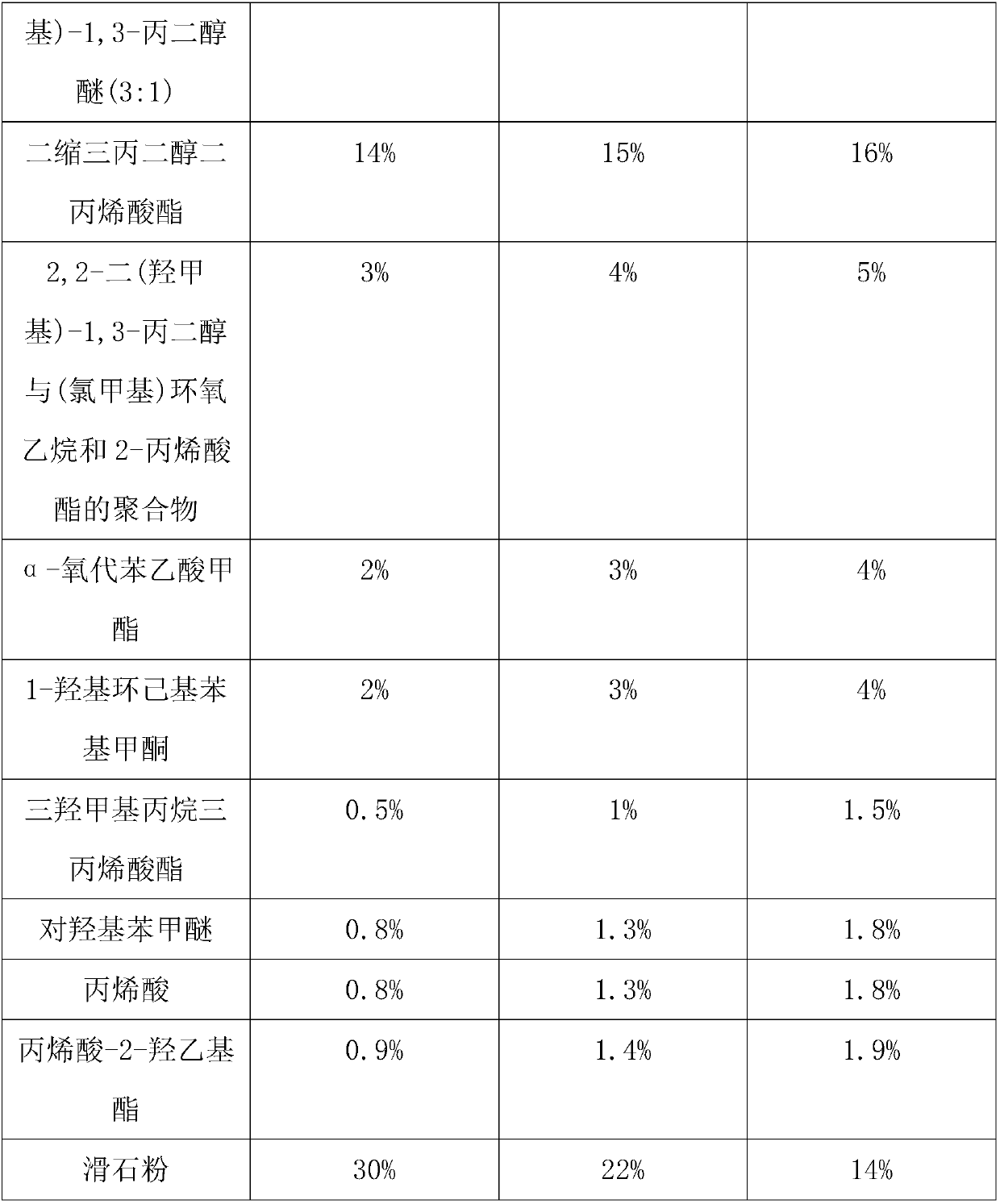

The invention discloses UV putty with high light guide performance for plate processing. The UV putty with high light guide performance for plate processing includes following components by mass: 32-34% of a polymer of 4,4'-(1-methylethylidene)diphenol and (chloromethyl)ethylene oxide and 2-acrylate, 14-16% of poly[alpha]-hydro-omega-[(1-oxo-2-propylene)oxy]-(oxy-1,2-diethyl) and 2-ethyl-2-hydroxymethyl-1,3-propylene glycol ether (3:1), 14-16% of tripropylene glycol diacrylate, 2-4% of alpha-methyl phenoxyacetate, 2-4% of 1-hydroxycyclohexyl phenyl ketone, 0.5-1.5% of trimethylolpropane triacrylate, 0.8-1.8% of p-hydroxyanisole, 0.8-1.8% of acrylic acid, 0.9-1.9% of acrylic acid-2-hydroxyethyl ester and 14-30% of talcum powder. According to the preparation method of the high-light-guiding-performance UV putty for plate processing, the resistance of the putty layer can be improved, the quality of a final paint product is higher, the curing speed can be high, the requirement for the speed of 25 m / min of a production line can be met, and the productivity is improved.

Owner:泰州市龙洋木业有限公司

Method for synthesizing alpha-chlorine (2-chlorine) methyl phenyl acetate

ActiveCN101434540BHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationChemical synthesisMethyl o-chloromandelate

Owner:重庆莱美隆宇药业有限公司

A kind of preparation method of Erecoxib

ActiveCN110386891BEase of industrial productionReduce productionOrganic chemistryPhenacylPropylamine

The invention provides a preparation method of imrecoxib. The preparation method of the imrecoxib comprises the steps that alpha-n-propylamino-4-methyl sulfonate acetophenone (II) and 4-methyl phenylacetate (III) are used as main raw materials, amidation is carried out to obtain N-n-propyl-N-P-methanesulfonyl benzoyl methyl-4-methyl-phenylacetamide (IV), and then the imrecoxib (I) is obtained through an intramolecular cyclization reaction under the action of alkali and ester. The preparation method of the imrecoxib is short in synthetic route and simple and convenient in operation, is easy topurify, has low requirements on equipment, is easy to realize, has less waste water generation quantity, is environmentally friendly, and is suitable for large-scale industrial production; and meanwhile, the reaction selectivity is good, by-products are less, and the product yield and purity are high.

Owner:XINFA PHARMA

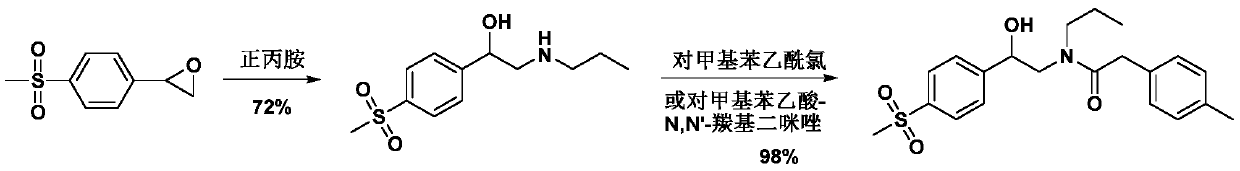

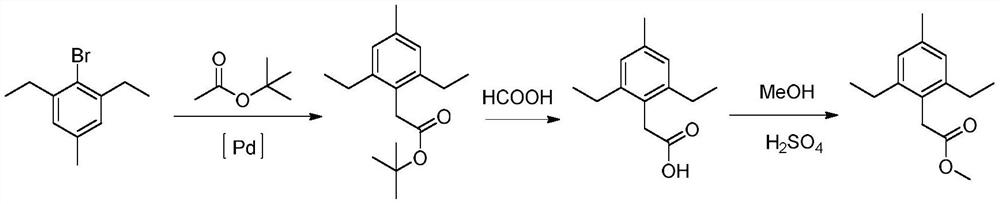

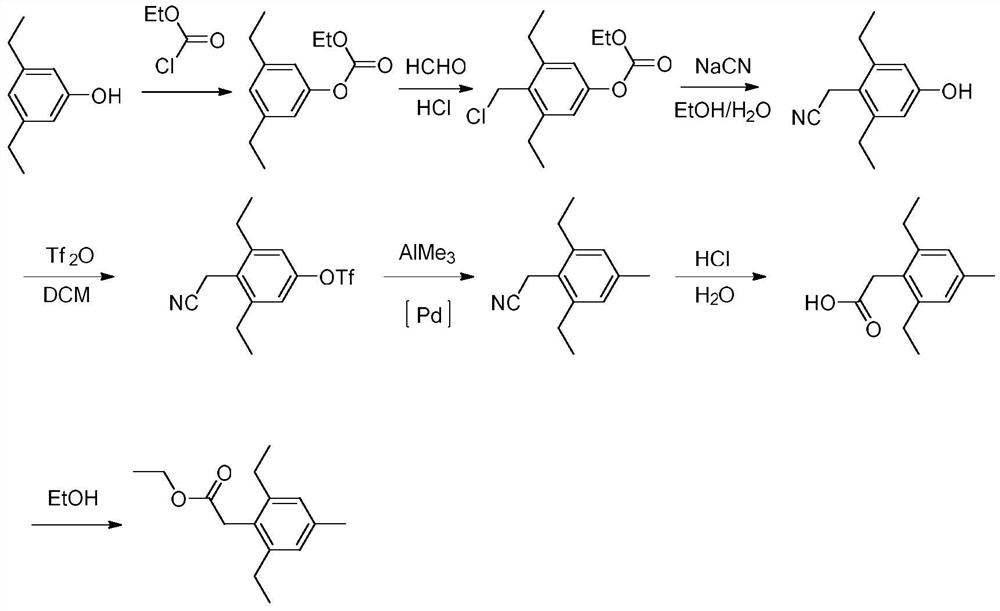

Method for synthesizing 2,6-diethyl-4-methylphenylacetate

PendingCN113121341AReduce usageThe preparation method has few stepsOrganic compound preparationCarboxylic acid esters preparationPtru catalystOrganic synthesis

The invention relates to the technical field of organic synthesis, in particular to a method for synthesizing 2,6-diethyl-4-methylphenylacetate by taking 2,6-diethyl-4-methylbromobenzene as a raw material, which comprises the following steps: firstly reacting 2,6-diethyl-4-methylbromobenzene with n-butyllithium and then conducting reacting with borane trimethyl ester to generate 2,6-diethyl-4-methylphenylboronic acid; and reacting the 2,6-diethyl-4-methylphenylboronic acid with glycine alkyl ester hydrochloride to generate the 2,6-diethyl-4-methylphenylacetate. The preparation method of the 2,6-diethyl-4-methyl phenylacetate provided by the invention has the advantages that the steps are fewer, the use of an expensive noble metal catalyst and a highly toxic cyaniding reagent is avoided, the cost is reduced, the process is simplified, the yield is higher, the defects in the prior art are overcome, and the preparation method is suitable for large-scale industrial production.

Owner:JIANGSU FLAG CHEM IND

Electrooxidation preparation method of kresoxim-methyl and trifloxystrobin intermediates

ActiveCN113308705AControl conversion rateLow selectivityElectrolysis componentsElectrolytic organic productionElectrolytic agentEthyl group

The invention relates to an electrooxidation preparation method of methyl acetophenone acid ester as shown in a formula I. The preparation reaction is as follows: methyl is selected from 2-methyl, 3-methyl or 4-methyl; and R is selected from methyl and ethyl. The electrooxidation preparation method comprises the following steps: in a non-diaphragm electrolytic cell, installing an anode working electrode and a cathode, and taking methyl phenylacetate, a phthalimide derivative, an organic solvent, alkali and electrolyte as electrolyte; and at a certain temperature, carrying out constant-current electrolysis for a certain period of time, and carrying out an electrooxidation reaction to obtain the methyl phenyl ethyl ketone acid ester (I). The electro-oxidation preparation method of the 2-methyl acetophenone acid methyl ester can be used for preparing kresoxim-methyl and trifloxystrobin.

Owner:湖北中迅长青科技有限公司

A kind of method for preparing trifloxystrobin

ActiveCN108368033BEasy to getEasy disposalOrganic compound preparationCarboxylic acid esters preparationPhenylacetic acidPhenyl group

The present invention relates to a kind of formula (I) compound (αE)-(α-(methoxyimino)-2[[[(E) ‑[1‑(3‑(trifluoromethyl) phenyl] ethylene] amino] oxy] methyl] a new method of methyl phenylacetate (trifloxystrobin). The present invention also relates to a method for preparing trifloxystrobin Novel process for methyl (2E)-[2-(bromomethyl)phenyl](methoxyimino)acetate of ester intermediate formula (X).

Owner:GSP CROP SCI PVT

Honey and grapefruit composite fragrance type electronic cigarette oil and preparation method thereof

PendingCN110655986AImprove qualityFragrantTobacco preparationEssential-oils/perfumesBiotechnologyEthyl phenylacetate

The invention relates to the technical field of tobacco flavors and spices, and in particular, relates to honey and grapefruit composite fragrance type electronic cigarette oil and a preparation method thereof. The electronic cigarette oil comprises, in pats by mass, 0.5 to 3 parts of phenylethyl phenylacetate, 0.1 to 0.5 part of phenylacetic acid, 0.2 to 1.0 part of p-cresyl acetate, 0.5 to 3 parts of methyl phenylacetate, 0.1 to 0.5 part of menthyl acetate, 1.5 to 5.0 parts of isobutyl phenylacetate, 0.2 to 0.8 part of ethyl phenylacetate, 0.5 to 3.5 parts of damascenone, 0.2 to 0.8 part ofnatural citral, 0.5 to 3 parts of beewax absolute oil, 0.3 to 1 part of phenylamyl acetate, 0.2 to 1.0 part of vanillin, 10 to 20 parts of benzyl alcohol, 1 to 5 parts of ethyl cinnamate, 0.5 to 3 parts of isophorone oxide, 2 to 8 parts of nootkatone, 0.2 to 1.0 part of Buchu oil, 0.2 to 0.8 part of bitter apricot seed oil, 1.5 to 5.5 parts of ethyl maltol and 750 to 850 parts of propylene glycol.The electronic cigarette oil which has honey grapefruit fragrance, harmonious and natural fragrance, soft and fine smoke and comfortable taste is obtained through matching of multiple components, andthe preparation method is simple, low in cost and capable of being used for large-scale industrial production.

Owner:WUHAN HUANGHELOU FLAVOR & SPICES

Food attractant for potato tuber moth and its application

Owner:NANJING SINO GREEN BIOTECH +1

Formed adhesive used for polypropylene fiber filter tips of cigarette and its preparation method

ActiveCN102453461BReduce and reduce miscellaneous gasNot corrosiveNon-macromolecular adhesive additivesTobacco smoke filtersPolymer sciencePhenylacetic acid

The invention relates to a formed adhesive used for polypropylene fiber filter tips of cigarette, which is prepared by the following steps: dissolving granular or crystalloid menthol, dihydroactinidiolide and citric acid in ethanol, then adding solution-type gamma-hexalactone, beta-phenylethyl alcohol, water white honey, methyl phenylacetate, menthol lactate and sweet orange oil, fully stirring and dissolving, and adding to polypropylene fiber glue. The adhesive used for formed polypropylene fiber filter tips is capable of generating different tastes, effectively neutralizing the complex harmful object generated during the tobacco shred combustion, overcoming the defects of single type of polypropylene fiber filter tip in the prior art, and solving the disadvantage of difficultly direct application of tobacco shred by the above substrate.

Owner:JIANGSU DAYA CIGARETTE FILTER MATERIAL CO LTD

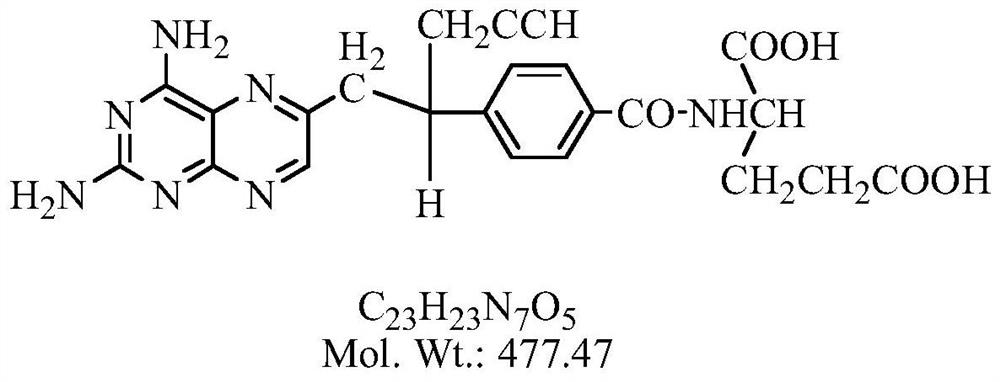

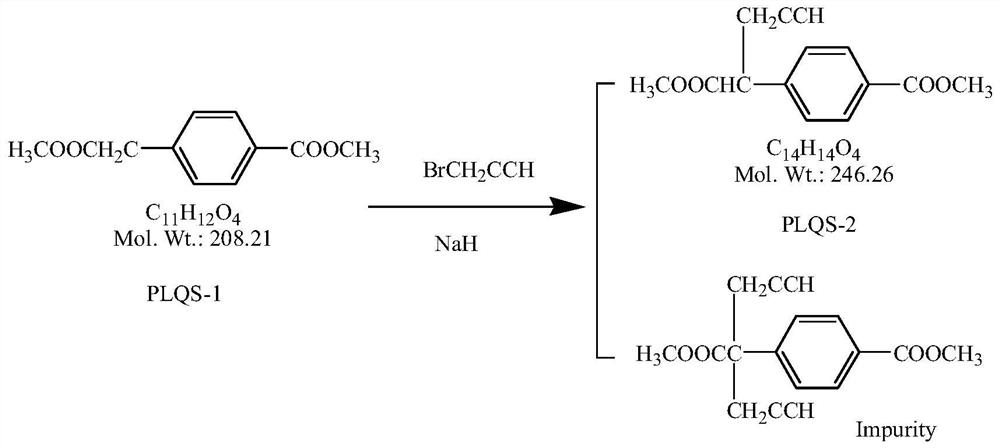

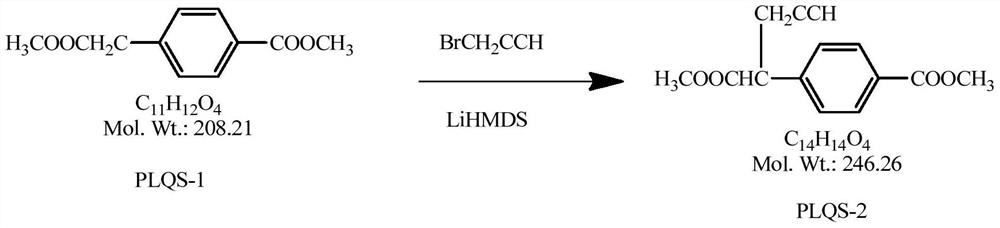

A kind of preparation method of pralatrexate intermediate

ActiveCN107488112BHigh selectivityHigh purityOrganic compound preparationCarboxylic acid esters preparationPhenylacetic acidPralatrexate

The invention belongs to the technical field of medicine, and in particular relates to a preparation method of a pralatrexate intermediate. The invention provides a method for preparing an intermediate α-propargyl-(4-methyl formate)-methyl phenylacetate with simpler operation and lower impurity content, especially the proportion of bispropargyl impurities generated in the product Obviously reduce, the yield of the target product α-propargyl-(4-methyl formate)-methyl phenylacetate of generation obviously increases, and the purity of product improves greatly, can be applied to large-scale production of pralatrexate bulk drug and The preparation of its intermediates.

Owner:SHANDONG NEWTIME PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Alpha hydroxy - alpha phenyl phenylacetic acid 8 - aza dicyclo [3. 2. 1] - 3 heptyl ester, midbody compound, and preparation method Alpha hydroxy - alpha phenyl phenylacetic acid 8 - aza dicyclo [3. 2. 1] - 3 heptyl ester, midbody compound, and preparation method](https://images-eureka.patsnap.com/patent_img/5ddbc91b-8d1a-4e13-a789-a6f48513468d/A20061002336500031.PNG)

![Alpha hydroxy - alpha phenyl phenylacetic acid 8 - aza dicyclo [3. 2. 1] - 3 heptyl ester, midbody compound, and preparation method Alpha hydroxy - alpha phenyl phenylacetic acid 8 - aza dicyclo [3. 2. 1] - 3 heptyl ester, midbody compound, and preparation method](https://images-eureka.patsnap.com/patent_img/5ddbc91b-8d1a-4e13-a789-a6f48513468d/A20061002336500041.PNG)