Method for preparing clopidogrel intermediate alpha-bromo (2-chloro) methyl phenylacetate by recycling aqueous solution method

A technology of methyl phenylacetate and clopidogrel, which is applied in the field of organic synthesis technology and drug synthesis technology, can solve the problems of low yield and environmental protection, and achieve simple treatment, reduce the pressure of environmental pollution, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

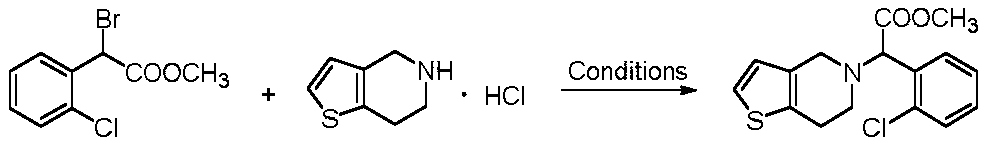

Image

Examples

Embodiment 1

[0022] Add 100g (0.58mol) of 2-chlorophenylacetic acid, 119.4g (1.16mol) of sodium bromide, 116g of 50% sulfuric acid solution, 300mL of dichloromethane, and 300mL of water into a 1.0L three-necked reaction flask, and stir at room temperature. Control the internal temperature at 10-15°C, slowly add 394g of 30% hydrogen peroxide dropwise, and the dropping temperature does not exceed 20°C. After the dropwise addition, the temperature was raised to 30° C., and the reaction was continued for 36 hours. After the reaction was completed, the liquids were separated, and the aqueous layer was used for the next reaction. The organic layer was washed with saturated aqueous sodium thiosulfate solution and dried over anhydrous sodium sulfate. Dichloromethane was distilled off under reduced pressure at 35°C to obtain 117.2 g of light yellow crystalline solid with a yield of 81%. Add the solid to 80 mL of methanol solution containing concentrated sulfuric acid (containing 0.046 mol of sulfu...

Embodiment 2

[0023] Embodiment 2 (application scheme):

[0024] 100g (0.58mol) of 2-chlorophenylacetic acid, 71g (0.69mol) of sodium bromide, 116g of 50% sulfuric acid solution, 300mL of dichloromethane, and 300mL of mechanically applied aqueous solution (the content of bromide ion is about 0.18g / mL) were added to In a 1.0L three-necked reaction flask, stir at room temperature. Control the internal temperature at 10-15°C, slowly add 394g of 30% hydrogen peroxide dropwise, and the dropping temperature does not exceed 20°C. After the dropwise addition, the temperature was raised to 30° C., and the reaction was continued for 36 hours. After the reaction was completed, the liquids were separated, and the aqueous layer was used for the next reaction. The organic layer was washed with saturated aqueous sodium thiosulfate solution and dried over anhydrous sodium sulfate. Dichloromethane was distilled off under reduced pressure at 35°C to obtain 120.1 g of light yellow crystalline solid with a y...

Embodiment 3

[0025] Embodiment 3 (application scheme):

[0026] 100g (0.58mol) of 2-chlorophenylacetic acid, 71g (0.69mol) of sodium bromide, 116g of 50% sulfuric acid solution, 300mL of dichloromethane, and 300mL of mechanically applied aqueous solution (the content of bromide ion is 0.20g / mL) were added to 1.0 L three-necked reaction flask, stirring at room temperature. Control the internal temperature at 10-15°C, slowly add 394g of 30% hydrogen peroxide dropwise, and the dropping temperature does not exceed 20°C. After the dropwise addition, the temperature was raised to 30° C., and the reaction was continued for 36 hours. After the reaction was completed, the liquids were separated, and the aqueous layer was used for the next reaction. The organic layer was washed with saturated aqueous sodium thiosulfate solution and dried over anhydrous sodium sulfate. Dichloromethane was distilled off under reduced pressure at 35°C to obtain 115.7 g of light yellow crystalline solid with a yield o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com