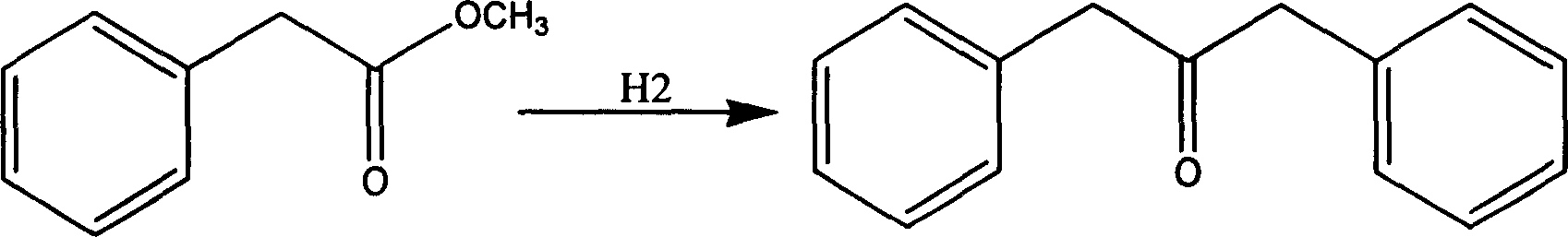

Catalytic synthesis of 1,3-diphenyl acetone

A technology of diphenylacetone and synthesis method, applied in 1, can solve problems such as non-continuous process, serious pollution, expensive and difficult to obtain raw materials, etc., and achieve the effect of high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] 1. 600 mg of manganese-aluminum catalysts prepared by the attached precipitation method are packed into a stainless steel reactor with a diameter of 8 mm. The content of manganese oxide particles in the catalyst is 10%, and the content of gamma-alumina is 90%. Catalyst is prepared as follows:

[0020] (1) Manganese oxide is supported on γ-alumina by the attachment precipitation method. Mix 4.000 grams of γ-alumina with 2.601 grams of 50% manganese nitrate aqueous solution, add ammonia water dropwise under full stirring until the precipitation is complete, continue to stir for half an hour and then let it stand for 5-20 hours. After the suspension is filtered by suction, the solid particles are used up. Ionized water washing;

[0021] (2) Add an appropriate amount of oxides to add components to the surface of the manganese-aluminum catalyst by impregnation;

[0022] (3) Dry the above solid at 80-150°C, bake it in the air atmosphere at 400-700°C for 2-5 hours, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com