Thickening agent, thickening agent composition and preparation method of thickening agent

A tackifier and mixture technology, applied in the directions of polymer adhesive additives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of low universality and increase the cost of encapsulant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of above-mentioned tackifier comprises the steps:

[0044] Provide organohydrogensiloxane oligomers, olefins containing epoxy groups, allyl esters, catalysts, first solvents and second solvents;

[0045] mixing an organohydrogensiloxane oligomer with a first solvent to obtain a first mixture;

[0046] Mixing the epoxy group-containing olefin, allyl ester, catalyst and second solvent to obtain a second mixture;

[0047] The first mixture and the second mixture are mixed and reacted at 40°C-100°C for 2h-5h to obtain a colorless transparent or colorless translucent tackifier; the reaction temperature is preferably 50°C-90°C. In order to control the reaction rate, the mixing method of the first mixture and the second mixture is preferably dropwise mixing.

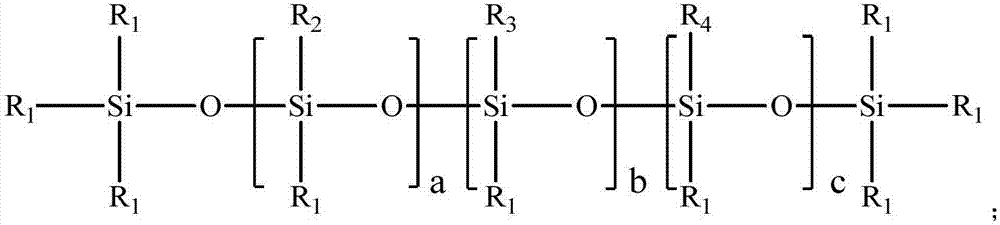

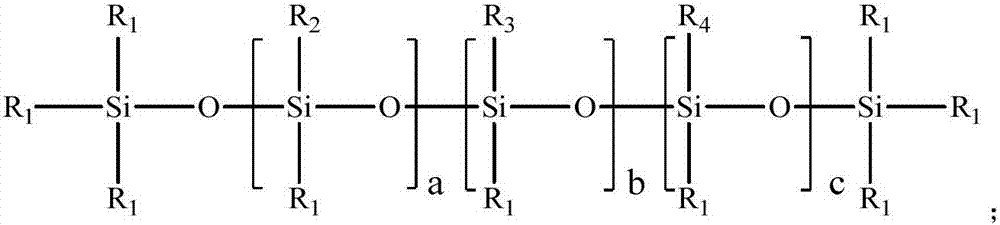

[0048] The above-mentioned tackifiers are, for example, the following structures:

[0049]

[0050]

[0051] The above a, b, c are all greater than or equal to 1, and 10≤a+b+c≤60.

[0052...

Embodiment 1

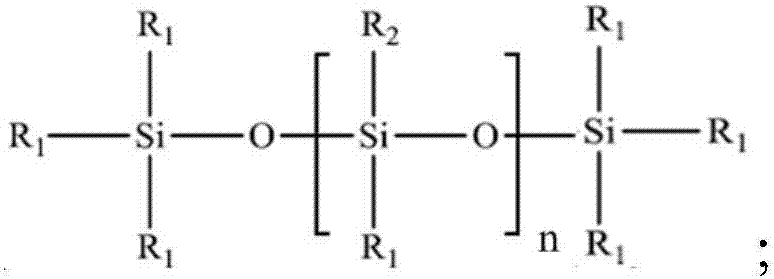

[0064] The present embodiment provides a kind of tackifier, structural formula is as follows:

[0065]

[0066] The preparation method of the above-mentioned thickening agent is: in the 500mL four-necked flask that reflux condenser, thermometer, dropping funnel and mechanical stirrer are housed, toluene 94.18g and organohydrogensiloxane oligomer (117.72g, 0.06 mol), heated to 80°C, added dropwise allyl glycidyl ether (61.56g, 0.54mol), allyl propionate (41.04g, 0.36mol), Karstedt catalyst (0.88g, concentration 0.25%) within 30min After the dropwise addition of the mixture with toluene (82.08g), it was reacted at 80°C for 3 hours at a constant temperature to obtain a reaction product. The reaction product was stirred and cooled to room temperature, added activated carbon (61.6g) baked at 150°C for 3h, stirred for 3h, and filtered; then the resulting material was desolventized at 120°C and a vacuum of 40mmHg to obtain 161.94g of Color transparent tackifier. The structure of...

Embodiment 2

[0069] The present embodiment provides a kind of tackifier, structural formula is as follows:

[0070]

[0071] The preparation method of above-mentioned viscosifier is: in the 1L four-necked flask that reflux condenser, thermometer, dropping funnel and mechanical stirrer are housed, toluene (244.2g) and organohydrogensiloxane oligomer (244.2g , 0.1mol), heated to 75°C, added dropwise glycidyl acrylate (64g, 0.5mol), allyl butyrate (64g, 0.5mol), Karstedt catalyst (0.6g, concentration 0.5%) and toluene in 40min (128g) of the mixture, after the dropwise addition was completed, it was reacted at a constant temperature at 75° C. for 4 hours to obtain a reaction product. The reaction product was stirred and cooled to room temperature, and activated carbon (48g) baked at 140°C for 3h was added, stirred for 6h, and filtered; then the resulting material was desolventized at 140°C and a vacuum of 30mmHg to obtain 279.9g of colorless Transparent tackifier. The structure of organoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com