Detection method for simultaneously determining plurality of flavor substances in cigarette cut tobaccos

A technology of aroma substances and detection methods, which is applied in the field of tobacco detection, can solve problems such as the lack of detection methods for important aroma substances in shredded cigarette tobacco, the quantification of important aroma substances in difficult shredded tobacco, and the lack of quantitative research on the uniformity of flavoring, etc., to achieve a simple detection and analysis method Convenience, improvement of cigarette product quality, and simple pre-treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

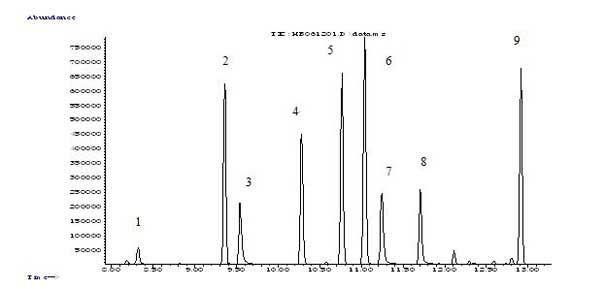

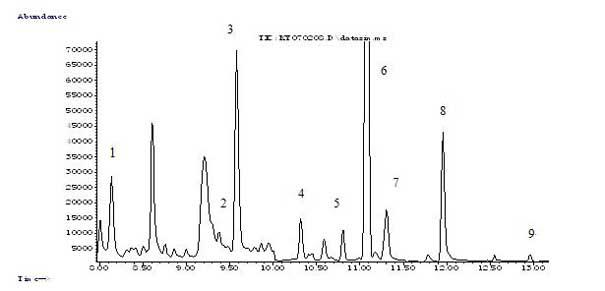

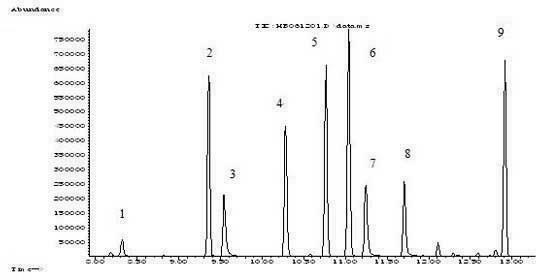

Image

Examples

Embodiment 1

[0021] A detection method for simultaneously determining several aroma substances in shredded cigarette tobacco, said several aroma substances refer to furanone, isopentyl isovalerate, maltol, nicotinone, menthol, ethyl maltol, 5-hydroxy Methylfurfural, Anethole. The method of the present invention uses solvent vibration extraction and gas chromatography-mass spectrometry to simultaneously measure the contents of several aroma substances in shredded cigarette tobacco, comprising the following steps:

[0022] Prepare test samples: samples are taken from flavored shredded tobacco or unflavored shredded tobacco or tobacco essence in the cigarette shredding process.

[0023] When preparing to test samples, continuously sample each batch of shredded tobacco 30 times, each sampling interval is 1min, each time sampling is 100g, one batch of samples is taken every day, and a total of 5 batches are taken in 5 days, and mixed as test samples .

[0024] ② Prepare standard solutions o...

Embodiment 2

[0029] For the simultaneous determination of furanone, isopentyl isovalerate, maltol, nicotine, menthol, ethyl maltol, 5-hydroxymethylfurfural and anethole in cut tobacco It uses solvent vibration extraction and gas chromatography-mass spectrometry to determine several important aroma substances in cigarette shred samples or flavors used in samples.

[0030] The method of the invention first screens the pretreatment experimental conditions, and optimizes the experimental parameters. Specifically include the following steps:

[0031] ①Preparation of samples for testing: samples can be taken from any of flavored shredded tobacco, unflavored shredded tobacco, and tobacco essence in the cigarette making thread process. In this embodiment, flavored cut tobacco is selected. The sampling position of the flavored shredded tobacco sample can be collected at a fixed position after the exit of the flavoring drum on the silk making line. After the operation is stable in each batch, cont...

Embodiment 3

[0050] Prepare chromatographically pure solvents: dichloromethane, absolute ethanol, methyl tert-butyl ether, n-hexane, standard products: furanone (CAS: 3658-77-3), isoamyl isovalerate (CAS: 659-70 -1), maltol (CAS: 118-71-8), nicotine (CAS: 4883-60-7), menthol (CAS: 89-78-1), ethyl maltol (CAS: 4940-11 -8), 5-Hydroxymethylfurfural (CAS: 67-47-0), anethole (CAS: 104-46-1), naphthalene (CAS: 91-20-3), the purity is not less than 99%. There is no shredded tobacco added to a certain brand of cigarettes.

[0051] Prepare equipment and instruments: electronic balance, ultrasonic cleaning machine, oscillator, rotary evaporator, 7890-5975C gas chromatography mass spectrometry instrument, capillary column (elastic capillary column HP-5MS column, the specification is 30m×0.25mmi.d×0.25 μm i.d.). These equipment instruments all can adopt prior art equipment instrument.

[0052] Preparation of working standard solution: mix furanone, isopentyl isovalerate, maltol, nicotine ketone, me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com