Patents

Literature

69 results about "Galaxolide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

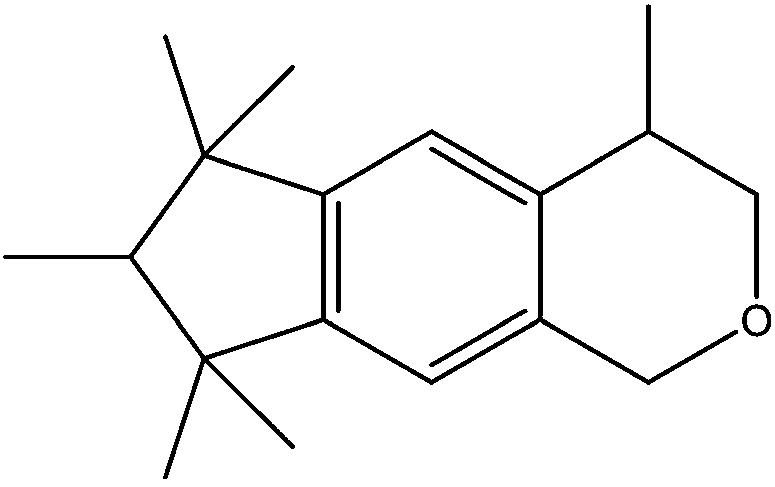

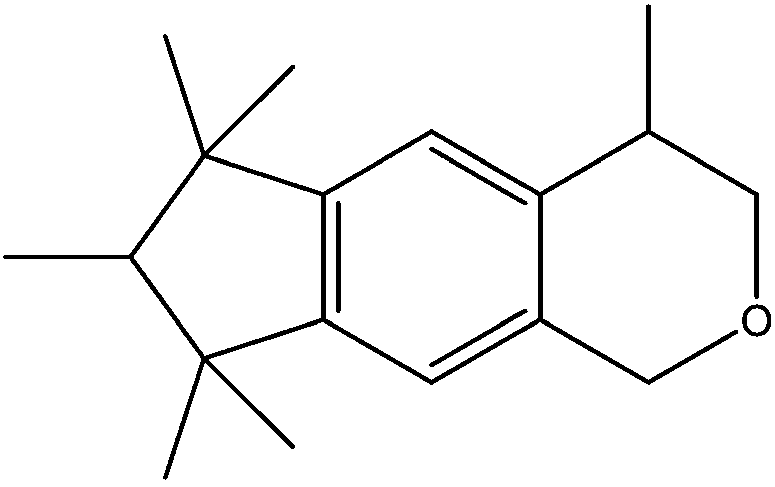

Galaxolide (trade name; also known as Abbalide, Pearlide, Astrolide, Musk 50, Polarlide; chemical name 1,3,4,6,7,8-hexahydro-4,6,6,7,8,8,-hexamethyl-cyclopenta[g]benzopyran or HHCB) is a synthetic musk with a clean sweet musky floral woody odor used in fragrances. It is one of the musk components that perfume and cologne manufacturers use to add a musk odor to their products. Galaxolide was first synthesized in 1965, and used in the late 1960s in some fabric softeners and detergents. High concentrations were also incorporated in fine fragrances.

Compound fruit fragrance and flower fragrance essence for daily chemicals and preparation method thereof

InactiveCN105316109AImprove stabilityMeet the needs of material and cultural lifeEssential-oils/perfumesBenzoic acidDamascone

Owner:广东铭康香精香料有限公司

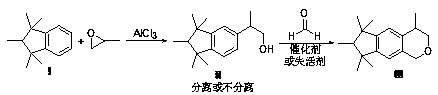

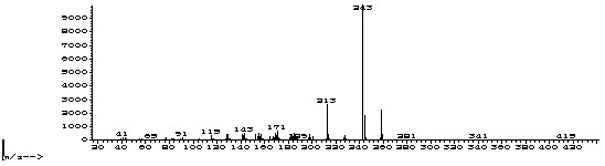

Synthetic process of galaxolide

The invention relates to a synthetic process of galaxolide. When an intermediate 1,1,2,3,3-pentamethylindane is prepared, macroporous strong-acidic styrenes cation exchanging resin prepared by the process is selected as a catalyst to react under a condition of no solvent, so that the pollution of waste gas, waste solids and waste water can be reduced, the solid catalysis is easy to separate, the industrialized production is facilitated, and the yield reaches up to 70 percent or more.

Owner:杭州更蓝生物科技有限公司

Galaxolide green synthesis technology

InactiveCN108586420AEasy to separateReduce "three wastes" pollutionOrganic chemistryChemical recyclingGalaxolideStrong acids

The invention relates to a galaxolide green synthesis technology. During preparation of an intermediate pentamethyl indane, the prepared sulfonic acid-type strong-acid cation exchange resin is selected as a catalyst for a reaction under solvent-free condition, three wastes pollution is reduced, solid catalysis is easy for separation, the technology is in favor of industrial production, and the yield can achieve as high as more than 70%.

Owner:杭州更蓝生物科技有限公司

Lemon essence for water-based ink and preparation method of lemon essence

The invention relates to lemon essence for water-based ink. The lemon essence is prepared from, by weight, 1%-30% of lemon essence, 5%-55% of compound modification oligosaccharide and deionized water. The lemon essence is composed of lemon oil, litsea cubeba oil, citral diethyl acetal, myrac aldehyde, bergamot aldehyde, lemonile, decanal, caprylic aldehyde, dodecanenitrile, citonellye nitrile, ethyl methylphenylglycidate, linalyl acetate, linalool, lilial, benzyl acetate, cyclamen aldehyde, terpilenol, terpinyl acetate, anisic aldehyde, verdyl acetate, geraniol, geranyl acetate, citronellol, citronellyl acetate, isocyclocitral, styralyl acetate, isoeugenol, ionone, heliotropin, iso-longitolanone, HHCB and ethyl alcohol. The invention further provides a preparation method of the lemon essence for the water-based ink. According to the lemon essence for the water-based ink and the preparation method of the lemon essence, the compound modification oligosaccharide is used as a wall material, the lemon essence is wrapped so that lemon nanocapsule slow-release essence can be formed, and therefore fragrance depositing and water solubility of the essence are improved.

Owner:SHANGHAI INST OF TECH

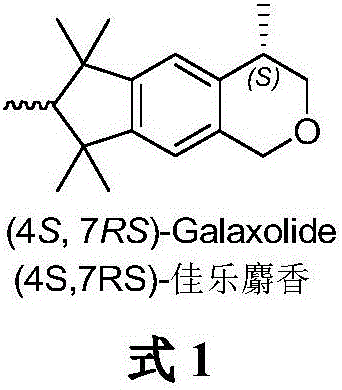

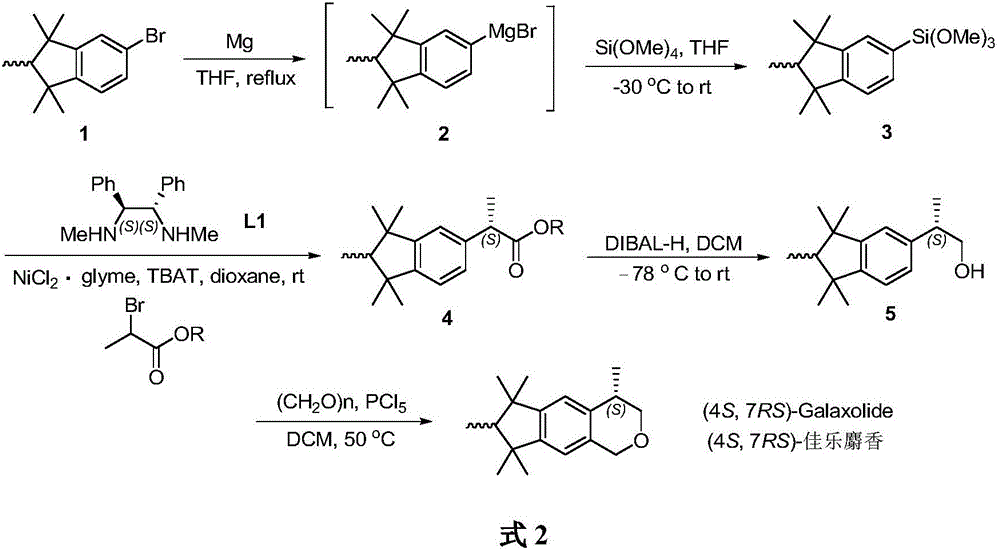

(4S, 7RS)-galaxolide synthesis method

The invention belongs to the technical field of chemical synthesis of essences and flavors and particularly relates to a (4S, 7RS)-galaxolide synthesis method. The method includes: subjecting bromo-pentamethyl indane and metallic magnesium to reaction to generate a Grignard reagent, and then subjecting to reaction with tetramethoxyl silane to obtain pentamethyl indane silane; subjecting the pentamethyl indane silane to asymmetric Hiyama cross coupling reaction with racemic 2-bromopropionate under catalysis of (1S, 2S)-N,N-dimethyl-1,2-diphenyl diaminoethane and nickel chloride to synthesize (S)-hexamethyl indane acid ester; reducing the (S)-hexamethyl indane acid ester by diisobutyl aluminum hydride (DIBAL-H) to obtain (S)-hexamethyl indanol, and finally subjecting to reaction with paraformaldehyde to obtain (4S, 7RS)-galaxolide. The (4S, 7RS)-galaxolide synthesis method is simple in synthetic route and mild in reaction condition, the overall yield reaches 40%, and product optical purity is 91%.

Owner:北京安胜瑞力科技有限公司

Lily essence for daily chemicals and preparation method thereof

ActiveCN104946391AIncrease momentumStrong floral fragranceEssential-oils/perfumesBiotechnologyPropanoic acid

The invention provides a lily essence for daily chemicals and a preparation method thereof. The lily essence is prepared from the following raw materials: cis-6-nonenol; kalong; ethyl vanillin; florhydral; cyanine; allyl cyclohexyloxyacetate; prenylacetate; pino acetaldehyde%; melonal%; allyl heptylate; styralyl acetate; matricaria ester; fructone; cis-3-hexenyl acetate; ligustral; geranyl acetate; geranyl acetate; Delta-Damascone; hexyl acetate; cis-3-Hexenyl salicylate; sandalore; ethyl-2-methylbutyrate; vanillyl alcohol; phenoxyethyl isobutyrate; allyl cyclohexanepropionate; methyl decenol; phenethyl alcohol; cyclamen aldehyde; verdyl acetate; isomethyl ionone; lemon oil; benzyldimethylcarbinyl butyrate; 2-tert-butylcyclohexanol acetate; iso E super; galaxolide stock solution; peach aldehyde; hexyl salicylate; Lily aldehyde; linalool; methyl dihydrojasmonate; and dipropylene glycol. The lily essence has fresh and penetrating top note, strong natural sense, full body note, good floral sense, and lasting basic note.

Owner:广东铭康香精香料有限公司

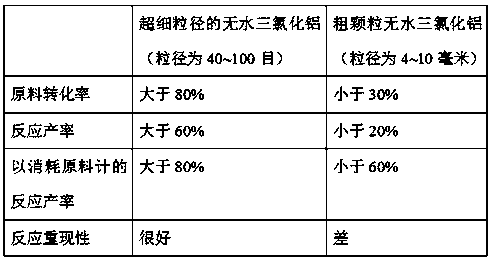

Method for preparing galaxolide under catalysis of superfine aluminum trichloride

The invention relates to a method for preparing galaxolide under catalysis of superfine aluminum trichloride. The method is characterized by comprising the following steps: 1, adding pentamethyl indanand anhydrous aluminum trichloride with particle size of 5 meshes or blow to a solvent, and cooling the solution to subzero 30-subzero 20 DEG C, wherein the mass ratio of the pentamethyl indan to anhydrous aluminum trichloride is (1.5-2):1; 2, dropwise adding propylene oxide to dissolve in the solution in the solvent during stirring, and conducting a reaction at subzero 30-subzero 5 DEG C for 1-2h to produce hexamethyl indanol, wherein the mass ratio of the propylene oxide to pentamethyl indan is (0.3-0.5):1; 3, continuously adding a deactivating agent and formaldehyde or formaldehyde equivalents, heating the mixture to 5-65 DEG C to react for 0.5-4 h to produce galaxolide, wherein the molar ratio of the deactivating agent, the formaldehyde or formaldehyde equivalents to the pentamethylindan is (1-2):1 and (0.5-1):1; and 4, performing purification. The method has the advantages as follows: aluminum trichloride powder with superfine particle size is used, the raw material conversionrate and product yield are significantly increased, the reaction time is shortened, the reaction has good reproducibility, energy is saved, production efficiency is improved, and the production cost is reduced.

Owner:ANHUI JINGHE IND

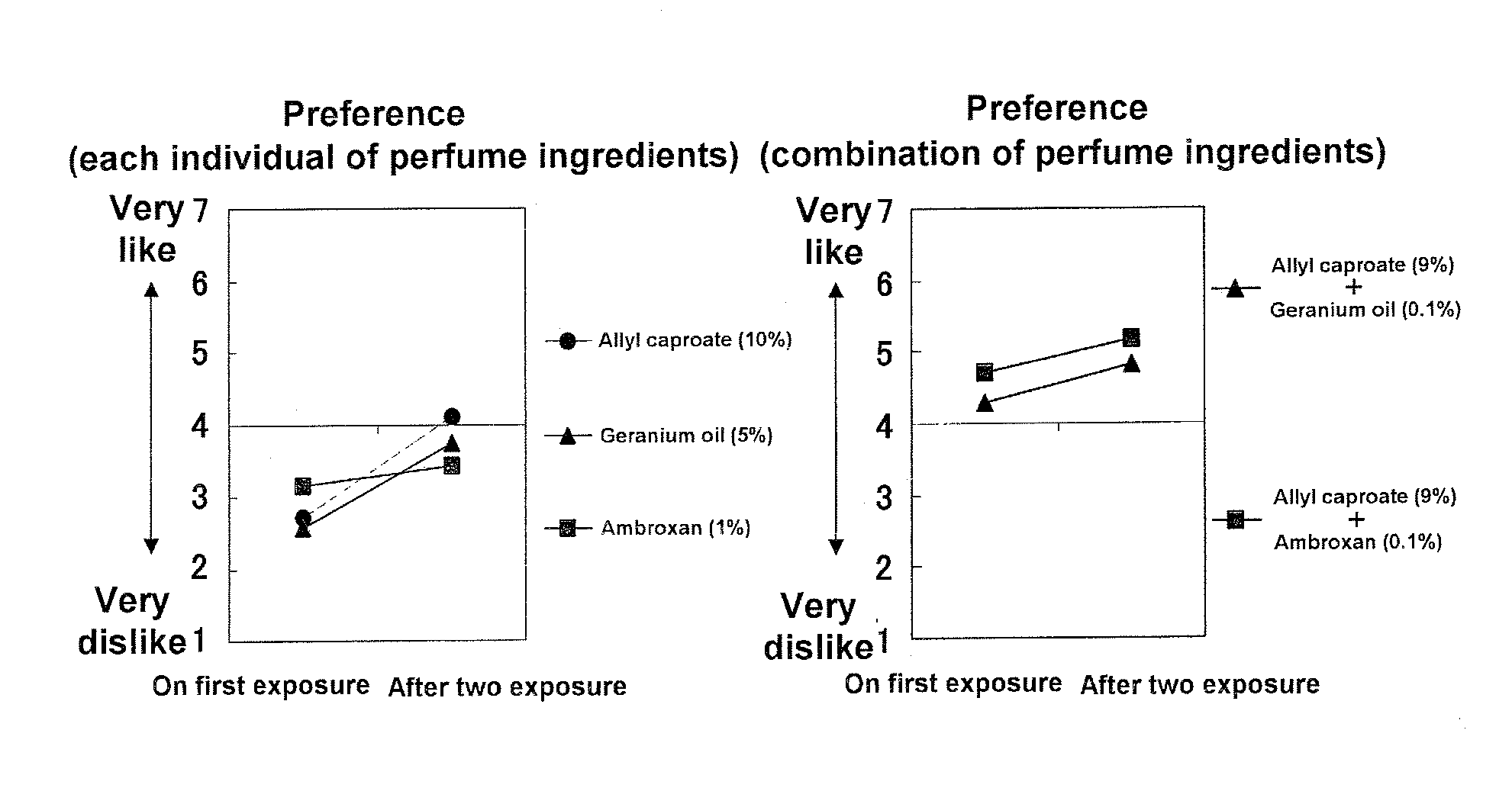

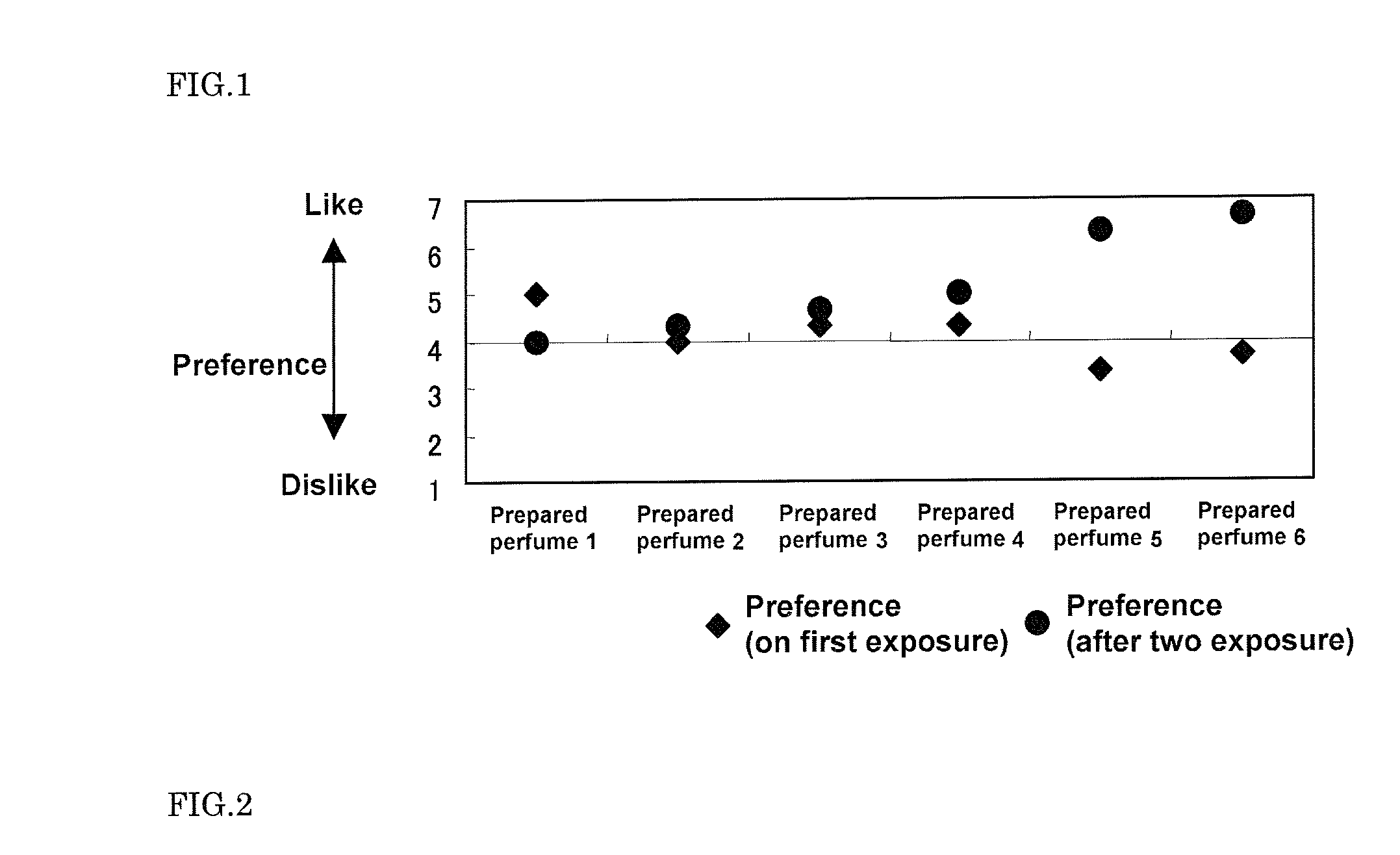

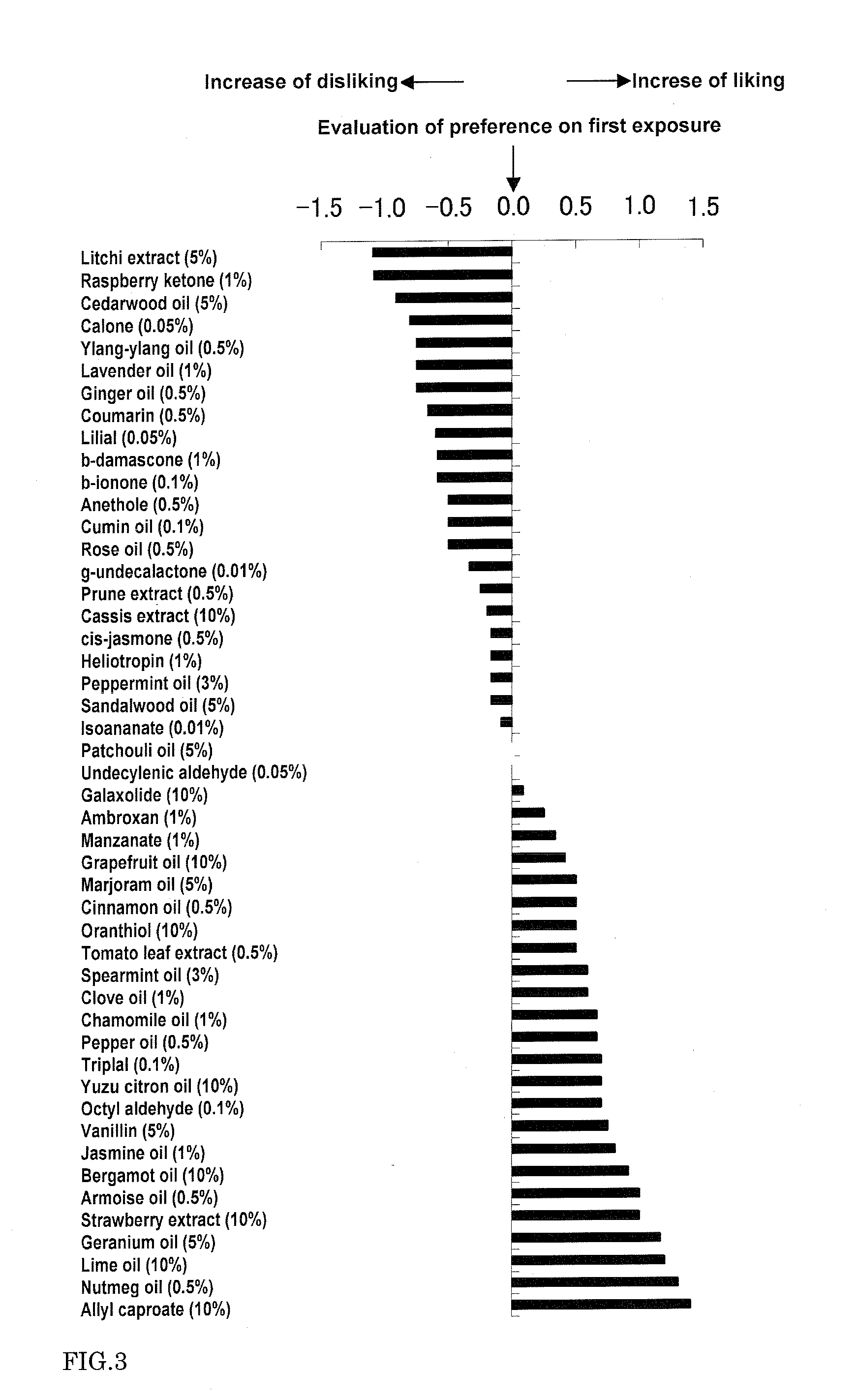

Method For Selecting Perfume Ingredient, Method For Formulating Fragrance, And Preference-Enhancing Agent

ActiveUS20100168253A1Improve preferenceIncrease impressionBiocideCosmetic preparationsManzanateGrapefruit oil

The present invention provides a method for selecting a perfume ingredient that can enhance a preference therefor by continuous use from among arbitrary perfume ingredients; a perfume composition and a preference-enhancing agent that can give a high preference therefor and enhance the preference by continuous use; and a hair cleanser that can offer excellent use texture and improve the use texture by continuous use.A method for selecting a perfume ingredient comprising; conducting the following evaluation (A) and / or (B) on arbitrary perfume ingredients and making a selection with the evaluation result as an indicator:(A) an evaluation of an impression of the “density” of a fragrance on first exposure and an evaluation of an impression of the “density” of the fragrance after two or more exposures; and(B) an evaluation of an impression of the “cheerfulness” of a fragrance on first exposure and an evaluation of an impression of the “cheerfulness” of the fragrance after two or more exposures. A perfume composition comprising a perfume ingredient selected by the method for selecting a perfume ingredient.A hair cleanser comprising (i) an amphoteric surfactant, (ii) a cationic polymer, (iii) an N-acyl-N-methyltaurine-based anionic surfactant, and (iv) one or more selected from the group consisting of galaxolide, ambroxan, manzanate, grapefruit oil, marjoram oil, cinnamon oil, aurantiol, tomato leaf extract, spearmint oil, clove oil, chamomile oil, pepper oil, Triplal, Yuzu citron (Citrus junos) oil, octylaldehyde, vanillin, jasmine oil, bergamot oil, armoise oil, strawberry extract, geranium oil, lime oil, nutmeg oil, and allyl caproate.

Owner:SHISEIDO CO LTD

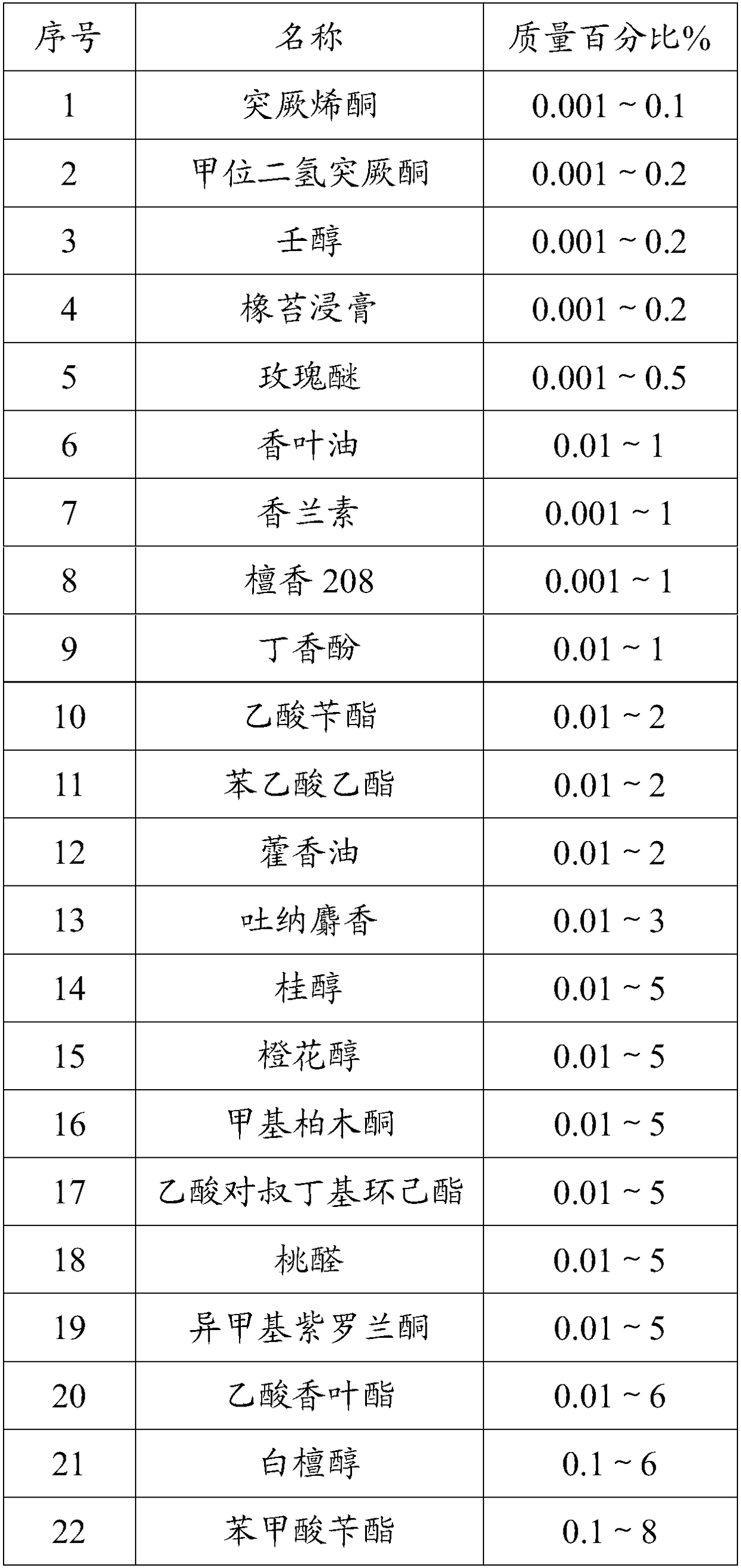

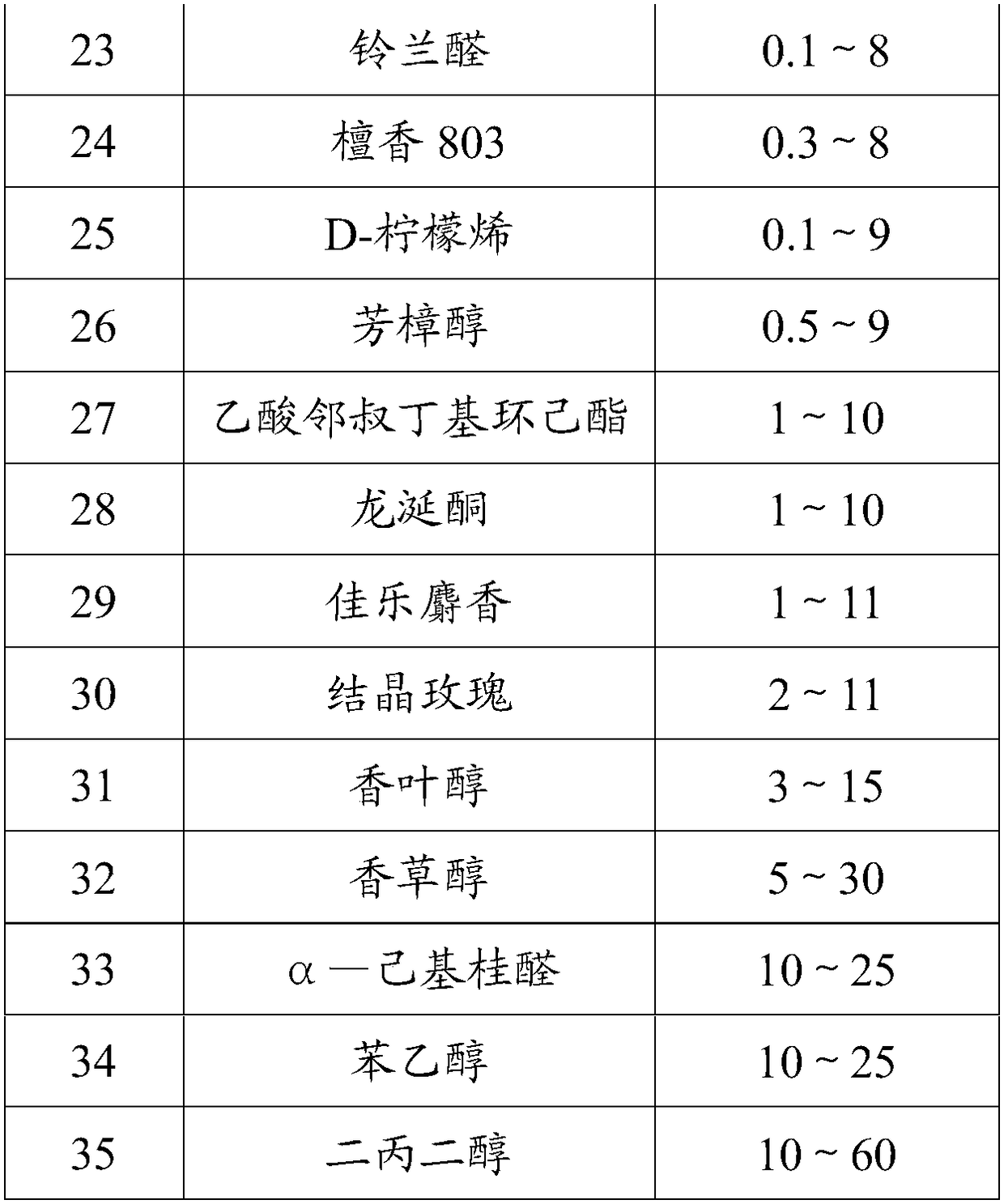

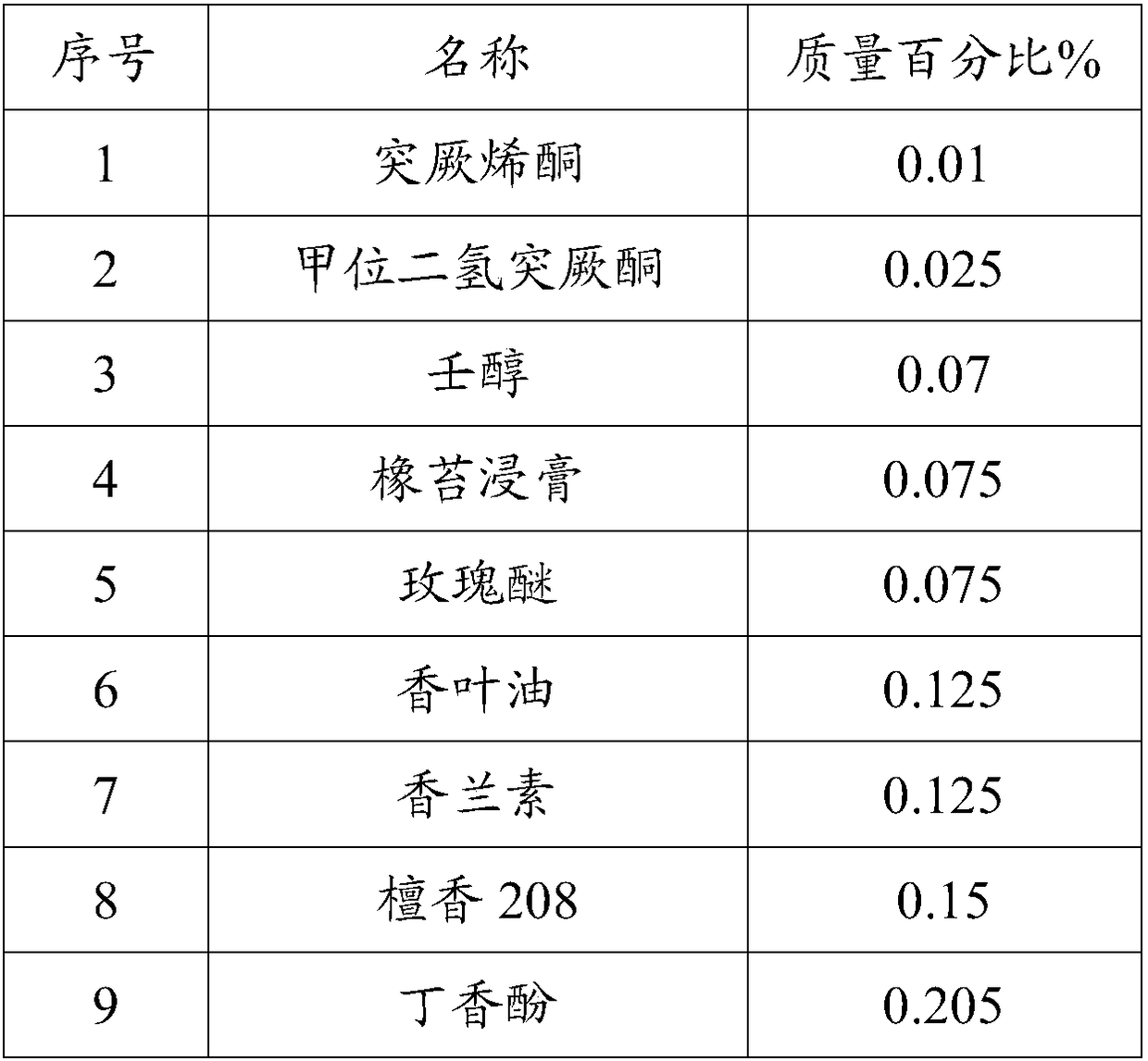

High-temperature resistance rose perfume and preparation method thereof

InactiveCN108219944AHigh degree of simulationImprove high temperature resistanceEssential-oils/perfumesEthyl phenylacetateGalaxolide

The invention discloses high-temperature resistance rose perfume and a preparation method thereof. The high-temperature resistance rose perfume is prepared from the following components according to apreset ratio: damascenone, damascone alpha, rose oxide, nonanol, geranium oil, vanillin, eugenol, sandal 208, benzyl acetate, ethyl phenylacetate, rosone, cinnamic alcohol, nerol, methyl cedryl ketone, 4-tert-butyl cyclohexyl acetate, geranyl acetate, benzyl benzoate, sandal 803, o-tert-butyl cyclohexyl acetate, geraniol, vanillin alcohol, phenylethyl alcohol, dipropylene glycol, an oak moss extractum, herba pogostemonis oil, tonalid, peach aldehyde, iso-mythyl ionone, bangalol radjanol, lilial, D-limonene, linalool, ambrotone, galaxolide and alpha-hexyl cinnamal. The rose perfume provided bythe invention is high in simulation degree and high temperature resistance ability.

Owner:鼎和(东莞)生物科技有限公司

Osmanthus flower essence for water-based ink and preparing method of osmanthus flower essence

InactiveCN105087162ASystem stabilityLong lasting fragranceInksEssential-oils/perfumesBiotechnologyBenzoic acid

The invention relates to osmanthus flower essence for water-based ink. The osmanthus flower essence for the water-based ink consists of the following ingredients in percentage by weight: 1 to 30 percent of osmanthus flower essence, 5 to 55 percent of composite modified oligosaccharide and deionized water, wherein the osmanthus flower essence consists of beta-ionone, dihydro-beta-ionone, linalool, alpha-jasminolene, alpha-amyl cinnamic aldehyde, isoamyl salicylate, benzyl salicylate, benzyl benzoate, galaxolide, citronellol, geraniol, cinnamyl alcohol, cognac oil, tetradecyl aldehyde, para-mentha-8-thiolone with the mass percent concentration being 1 percent, terpilenol, methyl anthranilate, osmanthus flower extracts and ethyl alcohol. The invention also provides a preparing method of the osmanthus flower essence for the water-based ink. The composite modified oligosaccharide is used as a wall material; the osmanthus flower essence is coated to form nanocapsule slow-release essence, so that the fragrance retention and the water solubility of the essence are improved; the preparing method is applicable to the perfuming of the water-based ink. The osmanthus flower essence for the water-based ink has the advantages that the fragrance is exquisite; the natural feeling is high; the fragrance retention is durable.

Owner:SHANGHAI INST OF TECH

Green apple essence used for water-based ink and preparation method of green apple essence

InactiveCN105132169ANo stratificationSystem stabilityEssential-oils/perfumesPropanoic acidGalaxolide

The invention provides green apple essence used for water-based ink. The green apple essence is prepared from, by weight, 1-30% of green apple flavor, 5-55% of composite modified oligosaccharide and deionized water. The green apple flavor is prepared from ligustral, leaf alcohol, cis-3-hexenyl acetate, cis-3-hexenyl isovalerate, trans-2-hexenal, trans-2-hexenyl acetate, styralyl propionate, linalool, linalyl acetate, fructone, peach aldehyde, isoamyl isovalerate, isoamyl acetate, allyl caproate, sweet orange oil, acetic acid, acetic acid, geranyl acetate, damascene, benzyl acetate, lilial, cedryl acetate, acetoxy-2-tert-butylcyclohexane, ethyl acetoacetate, tonkalide, galaxolide and ethyl alcohol. Composite modified oligosaccharide serves as a wall material for wrapping green apple essence, green apple nanometer capsule slow-release essence is formed, and therefore the fragrance holding property and the water solubility of the essence are improved, and the green apple essence is suitable for perfuming of water-base ink.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Flavoring rose essence for daily chemicals

PendingCN110229717AIncrease aroma intensityOutstanding aromaEssential-oils/perfumesGalaxolideDipropylene glycol

Directed at the problem that the fragrance of blended flavoring rose essence is greatly different from the fragrance of natural roses, the invention provides a flavoring rose essence for daily chemicals, belonging to the field of essence. The flavoring rose essence comprises the following components by mass: 45 to 55 parts of phenylethyl alcohol, 5 to 15 parts of citronellol, 1 to 10 parts of nerol, 1 to 10 parts of geraniol, 1 to 10 parts of rhodinol, 1 to 10 parts of ambrotone, 5 to 15 parts of galaxolide, 0.1 to 1 part of delta damascene, 0.01 to 0.1 part of rose oxide, 0.5 to 1.5 parts ofrose geranium oil, 0.1 to 1 part of damascenone and 10 to 20 parts of dipropylene glycol. By controlling the proportion of each component during preparation of the flavoring rose essence for daily chemicals, the aroma intensity of the flavoring rose essence for daily chemicals can be increased, the aroma given off by the flavoring rose essence for daily chemicals is closer to the natural aroma ofroses and is purer and richer, and thus, desired aroma can be generated by adding only a small amount of the flavoring rose essence into daily chemicals.

Owner:广州宝士迪香精香料有限公司

Perfume essence added with evertal

The invention discloses a perfume essence added with evertal. The perfume essence mainly comprises the following components in mass percent: 10% of leaf alcohol, 1.2% of D-limonene, 0.2% of liffarome iff, 4.2% of import linalool, 0.1% of evertal, 1% of ethyl maltol, 5% of linalyl acetate, 5% of methyl violet, 2% of cashmeran, 5% of helional, 6% of methyl cedryl ether, 15% of methyl dihydrojasmonate, 8% of methyl cedryl ketone, 15% of galaxolide, 2% of exaltolide, 23.6% of dipropylene glycol and the like. The essence has the characteristics of pervaporation, agreeability and lasting aroma because of the raw material combination.

Owner:TIANJIN DOUBLE HORSE FLAVOR & FRAGRANCE NEW TECH

Perfume essence with karanal added

The invention discloses a perfume essence with karanal added. The invention is composed of the following ingredients according to the mass percent: 10% Galaxolide, 5% palchouli oil, 5% dihydromyrcenol, 10% imported linalool, 8% phenylethyl alcohol, 6% citronellol, 5% 2-ethyl-4-(2,2,3-trimethyl-3-cyclopenten-1-yl)-2-Buten-1-ol, 3% rosalin, 20% ambrotone, 1% geraniol, 0.08% 4-Methyl-3-decen-5-ol, 5% ethyl linalool, 6% florol, 0.2% cetalox, 0.03% rose oxide, 14.19% dipropylene glycol and 1.5% karanal. The invention is a classic middle east fragrance type, which is a middle east fragrance perfectly melted with damascus roses full of middle east mystery colors and matched with the light delicate powder.

Owner:TIANJIN DOUBLE HORSE FLAVOR & FRAGRANCE NEW TECH

Cat-driving essence as well as preparation method and application thereof

ActiveCN103911214AEffective in repelling catsEssential-oils/perfumesAnimal repellantsLemon oilYlang-Ylang oil

The invention discloses cat-driving essence as well as a preparation method and an application thereof. The cat-driving essence is obtained by adding a certain amount of bergamot oil, lemon oil, citral, linalyl acetate, sweet orange oil, terpilenol, terpinyl acetate, methyl ortho-aminobenzoate, decanal, geranyl acetate, lemonile, geranium oil, menthol, benzyl acetate, benzyl alcohol, linalool, dihydro jasmine with mass fraction of 10%, hydroxycitronellal, benzpyrole with mass fraction of 10%, dihydromyrcenol, methyl ionone, lyral, oil of daidai leaf, ylang ylang oil, gamma-delta-lacton, leaf alcohol, benzyl benzoate, benzyl propionate, methyl dihydrojasmonate, p-cresyl acetate, jasmonyl, phenylacetic acid, eugenol, myracaldehyde, absolute of jasmine, geraniol, cis-3-hexenyl benzoate, galaxolide with mass fraction of 50% and propylene glycol into a container in sequence, shaking uniformly, standing and ageing for two weeks. The cat-driving essence is remarkable in cat-driving effect.

Owner:福建中益制药有限公司

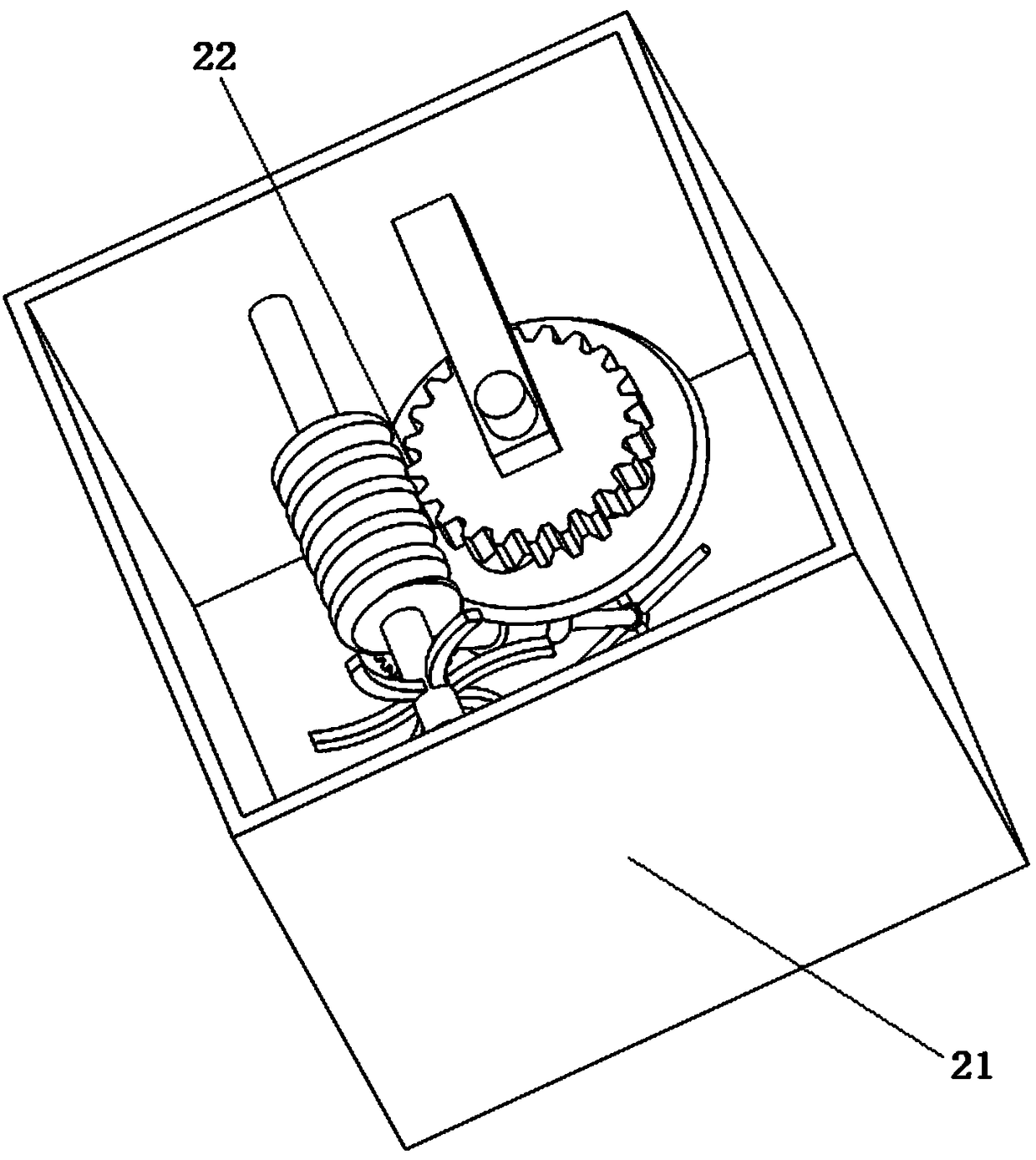

Vehicle-mounted perfume and vehicle-mounted perfume box

ActiveCN108126228ARefreshingHas a calming effectAir-treating devicesDeodrantsEthylene diamineCITRATE ESTER

The invention discloses a vehicle-mounted perfume. The vehicle-mounted perfume is prepared from the following raw materials in parts by weight: 70-80 parts of ethanol, 15-20 parts of basil, 15-20 parts of shaddock peel, 15-20 parts of mixed petals, 10-15 parts of folium eucalypti, 3-6 parts of galaxolide, 1-3 parts of citrate, 1-2 parts of isopropyl myristate, 1-2 parts of ethyl maltol, 0.5-1 parts of dipotassium glycyrrhizinate and 0.1-0.5 part of sodium ethylene diamine tetracetate. The invention further provides a vehicle-mounted perfume box. The perfume box is of a cube and comprises a perfume box cover body and a perfume box body, wherein the perfume box cover body and the perfume box body are clamped and fixed; the perfume box body comprises a box body and a volatilization mechanismmounted in the box body; and the volatilization mechanism comprises a stirring device and a fan device. The vehicle-mounted perfume has the efficacies of refreshing and mind, promoting mentality, adjusting nerves and easing mental anxiety; and meanwhile, the volatilization speed of the perfume can be adjusted according to different selective requirements and environment temperatures, so that the vehicle-mounted perfume is convenient and safe to use.

Owner:嘉兴沃瑞科技有限公司

Fragrant composition and application of same

InactiveCN106221911ALong lasting fragranceWide applicabilityEssential-oils/perfumesDetergent perfumesGalaxolideAmbroxide

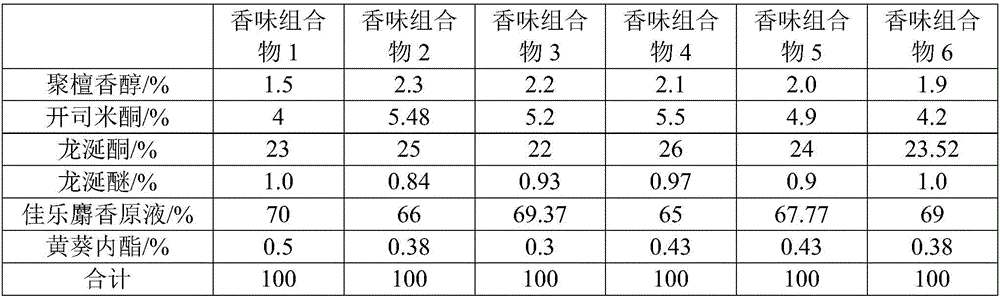

The invention discloses a fragrant composition and an application of the same. The fragrant composition includes, by weight, 1.5-2.3% of poly-santalol, 4-5.5% of cashmeran, 22-26% of ambrotone, 0.8-1.0% of ambroxide, 65-70% of galaxolide stock liquid, and 0.3-0.5% of ambrettolide. The fragrant composition, when being added to essences in different fragrance types, enables fragrance to be durable and achieves excellent fragrance remaining effect. The fragrant composition can be used in daily-use essences in different types.

Owner:广州爱普香精香料有限公司

Strawberry essence and preparation method therefor

InactiveCN105368577ALong lasting fragranceRealistic aromaEssential-oils/perfumesFragariaOrganic solvent

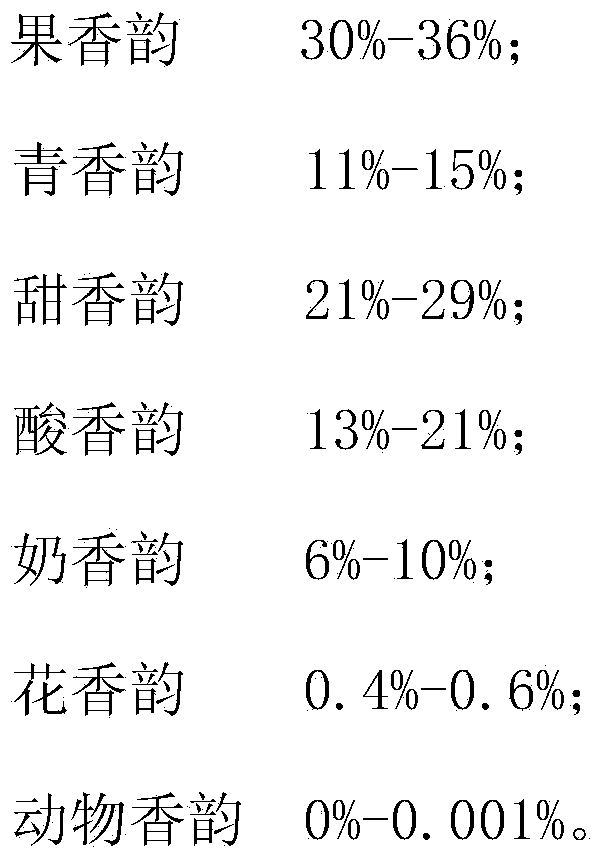

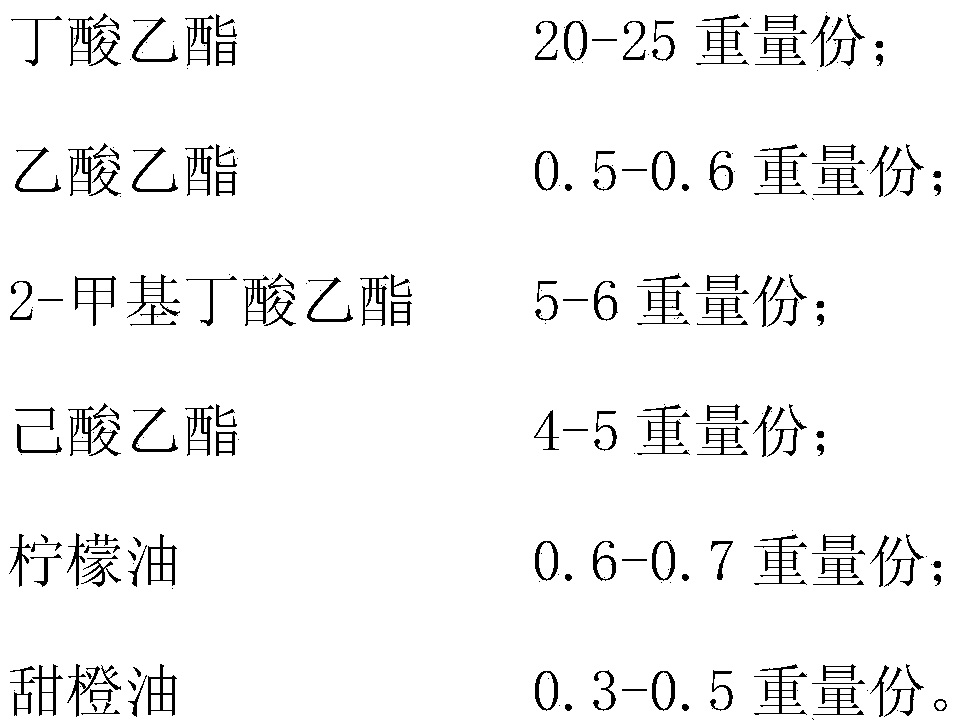

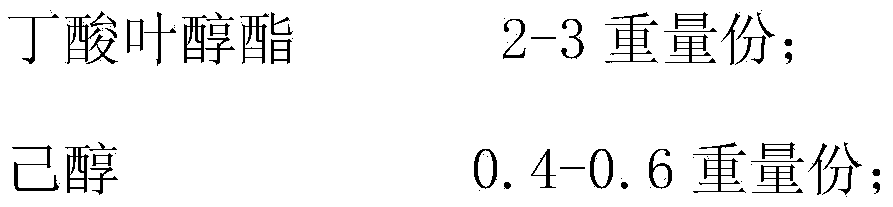

The present invention provides strawberry essence which comprises a scent raw material and an organic solvent with a mass ratio of (4-8):95. According to fragrance classification, calculated by percentage by mass, the scent raw material comprises: 30%-36% of fruit fragrance; 11%-15% of grass fragrance; 21%-29% of sweet fragrance; 13%-21% of acid fragrance; 6%-10% of milk fragrance; 0.4%-0.6% of flower fragrance; and 0%-0.001% of animal fragrance. The invention further provides a preparation method for the strawberry essence. The method comprises: prolonging lasting time of the essence through raw materials such as methyl cinnamate, lauric acid, myristic acid, methyl dihydrojasmonate, galaxolide; and simulatively preparing strawberry essence with a vivid scent and a good scent lasting effect from fruit fragrance, grass fragrance, sweet fragrance, acid fragrance, flower fragrance and animal fragrance by combining scent branching of strawberries. The strawberry essence and the preparation method therefor can be used for flavoring of life supplies such as daily chemical supplies.

Owner:SHANGHAI INST OF TECH

Green tea essence and preparation method thereof

PendingCN110724599AImprove aroma qualityStable chemical propertiesEssential-oils/perfumesBiotechnologyPhenethyl acetate

The invention discloses green tea essence and a preparation method thereof, wherein the raw materials comprise: ambroxide, menthol, galaxolide, phenylethyl phenylacetate, alpha-hexylcinnamaldehyde, geraniol, citronellol, phenylethyl alcohol, linalool, leaf alcohol, terpineol-alpha, methyl dihydrojasmonate, ligustral, beta-ionone, gamma-unsecalactone, a green tea extract, linalool oxide, bergamot oil, Brazilian sweet orange oil, Brazilian sweet orange terpene and dipropylene glycol. According to the invention, the green tea essence can well keep the refreshing and tender fragrance of natural green tea, is natural, vivid and pure in fragrance, and is accepted by consumers.

Owner:宁波芬畅凝科香精香料有限公司

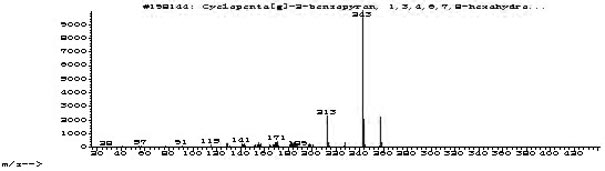

Method for determining galaxolide in trace amount in water sample

The invention relates to a method for determining galaxolide in trace amount in water sample by means of the co-utilization of solid phase microextraction (SPME) and GC-MS, belonging to the field of environmental monitoring. The method comprises two steps, namely drawing of a standard curve and determination of samples. The determination of samples is characterized in that water samples are subjected to the filtration of filter membrane (0.45mum), a fixed amount of samples are then put in an extraction flask and subjected to immersed extraction for 40 minutes at 35 DEG C, followed by the analysis of GC-MS intermediately, and finally, the amount is determined by external standard method according to peak appearance area. The method has excellent linearity in the range from 200 to 1500ng / L and 7.9% of RSD according to parallel determination of standard solution. The method also has the advantage of being convenient, fast, accurate and the like, and is particularly suitable for the determination of galaxolide in municipal sewage.

Owner:SHANGHAI INST OF TECH

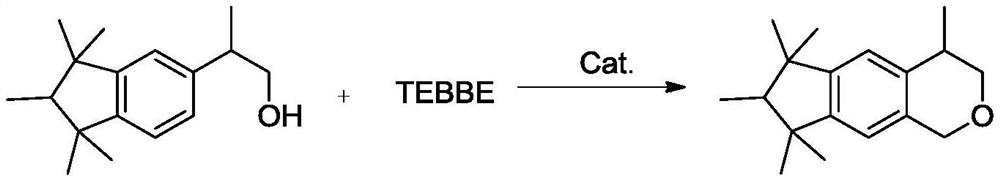

Preparation method of galaxolide

ActiveCN112321557AAvoid security issuesAvoid corrosionOrganic chemistryEssential-oils/perfumesPtru catalystGalaxolide

The invention discloses a preparation method of galaxolide, which comprises the following steps: carrying out methylene etherification reaction on hexamethyl indanol and a TEBBE reagent (CAS: 67719-69-1) under the action of a supported Pd catalyst, carrying out condensation cyclization to generate galaxolide, and carrying out continuous rectification to separate the product. The supported Pd catalyst is represented as Pd-X / Y, X is selected from triphenylphosphine, tributylphosphine, tricyclohexylphosphine, bis(diphenylphosphine) methane, 1, 2-bis(diphenylphosphine) ethane and 4, 5-bis(diphenylphosphin)-9,9-dimethyl xanthene, and Y is selected from carbon nanotubes, ordered mesoporous carbon, neutral alumina, silica, a molecular sieve and kaolin. The process provided by the invention avoidsthe problems of complex process, serious equipment corrosion, low safety, environmental friendliness and the like in the prior art, and the raw material conversion rate and the product selectivity can reach 93% or above.

Owner:WANHUA CHEM GRP CO LTD

Perfume preparation and preparation method thereof

InactiveCN103784385ASuppress alcohol tasteImprove sweet and clear (green) fragranceCosmetic preparationsToilet preparationsGalaxolideAlcohol

The invention provides a perfume preparation and a preparation method thereof. The perfume preparation is prepared from the following components in mass percentage: alcohol prepared by fermenting with corns as main raw materials and deodorizing 65-85%, deionized water 3-12%, essence 3-25%, muscone 0.1-2%, benzyl benzoate 0.1-2%, musk 105 0.1-3%, benzyl salicylate 0.1-3%, galaxolide 0.1-3%, benzoin paste 0.1-1%, and isopropyl myristate 0.1-0.3%. The perfume preparation and the preparation method thereof suppress alcohol odor of perfume, improve faint scent and tranquil and enjoyable grade of perfume, greatly improve fragrance retaining effect of perfume, and increase quality and grade of perfume.

Owner:陈孟桃

Laundry detergent essence added with levocitronellyl nitrile

InactiveCN106190565ASteady patternAroma RhymeEssential-oils/perfumesDetergent perfumesGalaxolidePhenethyl alcohol

The invention discloses laundry detergent essence added with levocitronellyl nitrile. The laundry detergent essence is composed of, by mass, 0.1% of deca-aldehyde, 0.15% of methyl nonyl acetaldehyde, 0.05% of allyl hexylate, 0.5% of allyl phenoxyacetate, 1% of amyl cinnamaldehyde, 0.5% of mugwort oil, 1.5% of benzyl acetate, 8% of benzyl salicylate, 4% of citronellol, 4% of galaxolide, 2% of geraniol, 0.5% of geranyl acetate, 11.2% of methyl dihydrojamonate, 8% of alpha-hexyl cinnamaldehyde, 1.5% of isoborneol acetate, 2.5% of lilial, 8% of linalool, 8% of linalyl acetate, 1% of methyl ionone, 7% of sweet orange oil, 3% of phenethyl alcohol, 1% of levo-cymbopogon and 23.75% of dipropylene glycol. The laundry detergent essence is stable in structure, compound in aroma, capable of releasing aroma layer by layer, novel in aroma and lasting in aroma.

Owner:TIANJIN DOUBLE HORSE FLAVOR & FRAGRANCE NEW TECH

Treatment method of recycled pentamethyl indane

ActiveCN111925272AImprove conversion rateIncrease productivityHydrocarbonsChemical modification purification/separationAlkaline waterGalaxolide

The invention relates to a treatment method for recovering pentamethyl indane in galaxolide production. The treatment method comprises the following steps: adding a certain amount of ferrous sulfate into a recovered pentamethyl indane solution, and slowly and dropwise adding a certain amount of concentrated sulfuric acid to provide an acidic environment; after the concentrated sulfuric acid is dropwise added, controlling a certain temperature, dropwise adding hydrogen peroxide and carrying out Fenton oxidation reaction; after dropwise adding is completed, carrying out heating to a certain temperature to continue the reaction, and after the reaction is completed, conducting standing for layering and separating out lower-layer acid water; adding excessive alkaline water into an upper-layer pentamethyl indane phase for neutralization; and after neutralization is completed, separating out lower-layer alkaline water to obtain treated pentamethyl indane. According to the method, the conversion rate of pentamethyl indane is increased, production cost is reduced, production efficiency is greatly improved, the reaction efficiency and the material utilization rate of the whole production process are optimized, and the economic benefits of enterprises are increased.

Owner:安徽金轩科技有限公司

Musk essence for water-based inks and preparation method thereof

InactiveCN105038987AImprove fragranceGood water solubilityInksEssential-oils/perfumesGalaxolideSalicylic acid

The invention provides a musk essence for water-based inks, which is composed of the following components in percentage by weight: 1-30% of musk essence, 5-55% of composite modified oligosaccharide and the balance of deionized water. The musk essence is composed of cyclopentadecanolide, musk 105, Jiale musk, Tokyo musk, Kuizi musk, musk T, ambergris ether, labdanum concrete, musk seed oil, benzyl salicylate, sandalwood 803, sandalwood 208, vetiver oil, patchouli oil, iraldeine, storax paste, 10 wt% indole, geranium oil, coumarin and ethanol. The invention also provides a preparation method of the musk essence for water-based inks. The composite modified oligosaccharide is used as a wall material to be coated on the musk essence so as to form the musk nanocapsule slow-release essence, thereby enhancing the fragrance persistence and water solubility of the essence; and thus, the musk essence is suitable for perfuming the water-based ink. The musk essence for water-based inks has the advantages of delicate and realistic fragrance and high fragrance persistence.

Owner:SHANGHAI INST OF TECH

Aromatic paster

PendingCN108261339AEasy to pressPaste effect is goodCosmetic preparationsToilet preparationsEpoxySandalwood oil

The invention provides an aromatic paster and relates to the field of articles for daily life. The aromatic paster comprises a paster body consisting of an adhesive layer, an absorbent layer, a printed layer and a waterproof layer made of a waterproof material. The absorbent layer and the adhesive layer are respectively arranged at two sides of the waterproof layer; the printed layer is arranged on the absorbent layer and printed with patterns; the absorbent layer absorbs an essence which comprises, by mass, 20-30% of methyl dihydrojasmonate, 10-20% of ambrotone, 5-15% of lilial, 5-15% of linalool, 5-10% of phenethyl alcohol, 1-10% of lemon oil, 1-5% of bergamot oil, 5-20% of galaxolide, 0.1-1% of absolute oil of jasmine, 0.1-1% of absolute oil of rose, 0.1-1% of sandalwood oil and 5-15% of epoxy resin. The adhesive layer is of a laminating layer made of an adhesive material; the outer surfaces of the adhesive layer and the absorbent layer are both of rugged structures; the adhesive layer, the waterproof layer, the absorbent layer and the printed layer are bonded integrally. The aromatic paster is convenient to carry and use and good in adhesion and has long fragrance holding time.

Owner:SHANGHAI HAOTIE SANITARY ARTICLE

Essence capable of dispelling cats and dogs

The invention discloses essence capable of dispelling cats and dogs. The essence comprises components in percentage by mass as follows: 2%-2.3% of natural lavender oil, 4.4%-4.7% of natural eucalyptus oil, 5%-5.3% of methyl dihydrojasmonate, 7%-7.3% of linalyl acetate, 1.8%-2.1% of terpinyl acetate, 0.7%-1% of citral, 7%-7.3% of ambrotone, 0.7%-1% of terpilenol, 7%-7.3% of galaxolide (50% dipropylene glycol), 15%-15.3% of linalool, 0.6%-0.9% of synthetic sandalwood 208, 2.7%-3% of synthetic sandalwood 803, 2%-2.3% of borneol, 35%-35.3% of synthetic camphor, 3.1%-3.4% of sweet orange terpene, 1%-1.3% of beta-caryophyllene and the balance of dipropylene glycol. The essence is herbal lavender odor type essence, the cats and the dogs can feel unhappy after smelling the essence and then get away, and the essence retains the odor lastingly and is fresh, pleasant, safe and harmless.

Owner:TIANJIN DOUBLE HORSE FLAVOR & FRAGRANCE NEW TECH

Rose-musk essence

The invention discloses a rose-musk essence, which is characterized in that: the rose-musk essence comprises the following compositions in percentage by weight: 7.5 to 8 percent of musk xylene, 5.5 to 6.0 percent of eugenol, 12 to 14 percent of galaxolide musk, 8.0 to 8.5 percent of geraniol, 5.0 to 5.5 percent of tonalid, 4.0 to 5.0 percent of citronellol, 2.8 to 3.2 percent of methyl cedryl ketone, 6.5 to 7.0 percent of 3,3-dimethylcyclohexyl methyl ketone, 9.0 to 11.0 percent of lilial, 5.0 to 5.4 percent of phenethyl alcohol, 2.8 to 3.0 percent of geranylacetone, 0.8 to 1.0 percent of capryl alcohol, 3.8 to 4.4 percent of coumarin, 20.0 to 24.0 percent of iso-longitolanone and 16.0 to 18.0 percent of heliotropin. The rose-musk essence is suitable for fragrant products such as white cream, lotion, fragrant molasses and the like, does not have the defect of color change, and has the advantages of pure and rich fragrance, strong persistance, low consumption and the like.

Owner:张彬

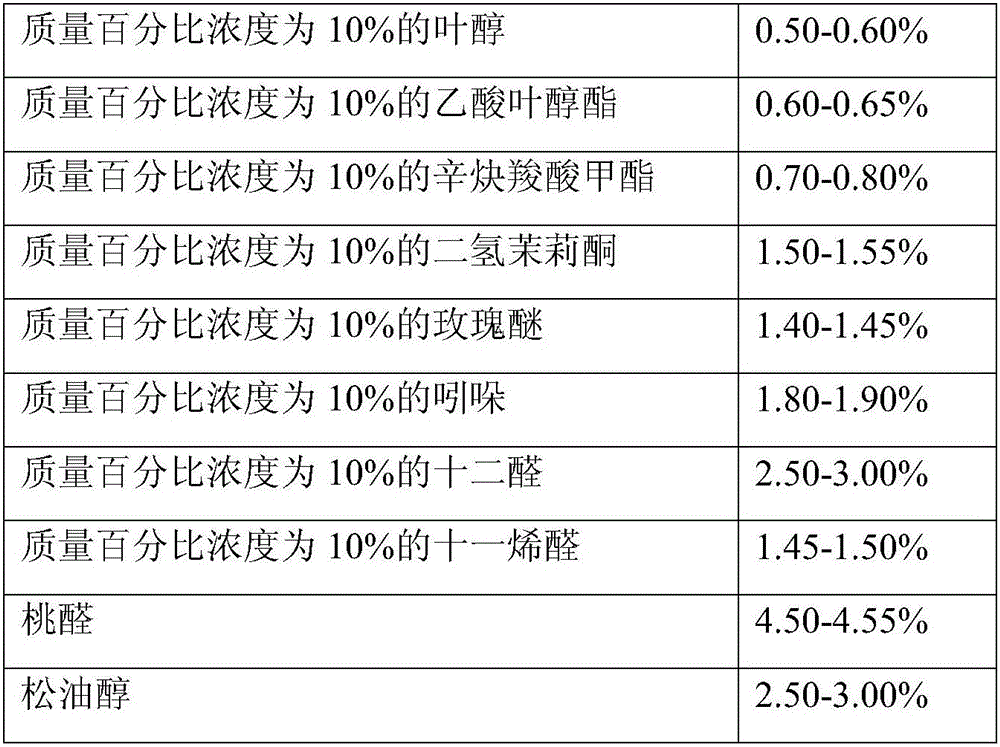

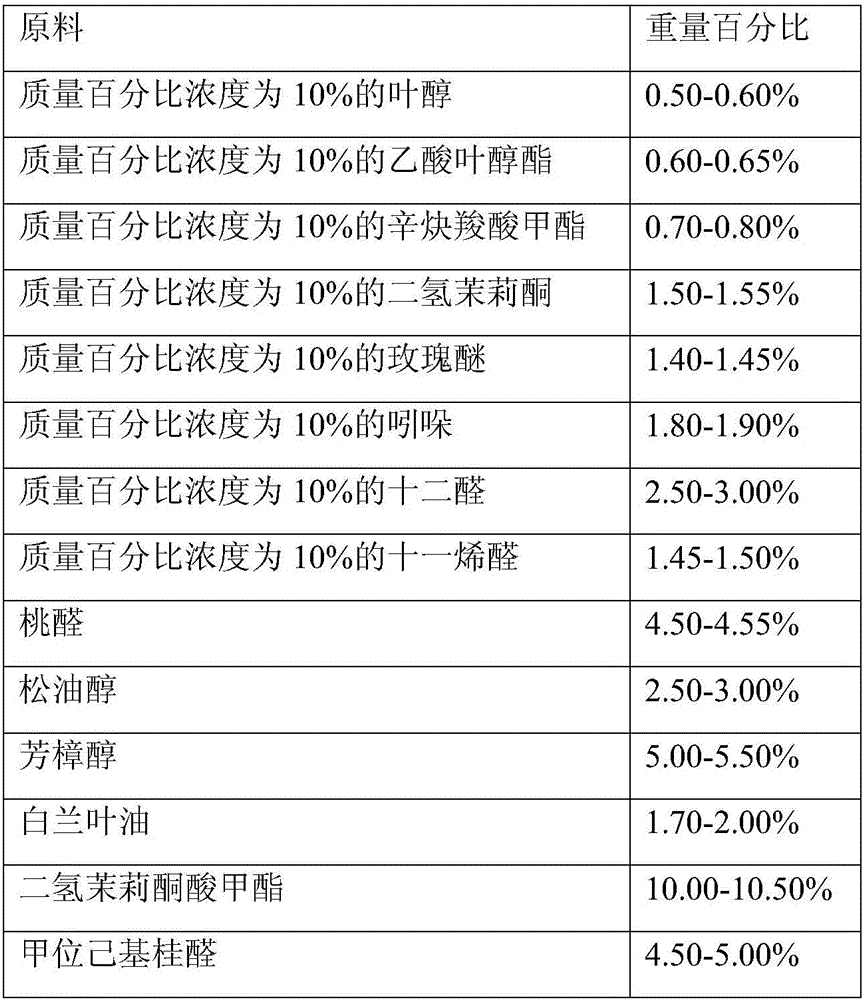

Cape jasmine flower essence and preparation method thereof

InactiveCN106281689ASweet and strong aromaLong lasting fragranceEssential-oils/perfumesPhenethyl acetateMichelia

The invention provides cape jasmine flower essence. The cape jasmine flower essence is prepared from 10% leaf alcohol, 10% cis-3-hexenyl acetate, 10% methyl 2-nonynoate, 10% dihydrojasmone, 10% rose oxide, 10% indole, 10% dodecyl aldehyde, 10% undecenal, undecan-4-olide, terpineol, linalool, michelia alba leaf oil, methyl dihydrojasmonate, alpha-hexylcinnamaldehyde, benzyl acetate, ionone, methylionone, phenethyl ethanol, phenylacetaldehyde, phenylethyl acetate, styralyl acetate, 1-phenylethyl propionate, tetrahydrogeraniol, rhodinol, dihydromyrcenol, lily aldehyde, benzyl propionate, isoeugenol, eugenol, lyral, galaxolide, ylang-ylang oil, patchouli oil and propylene glycol. The cape jasmine flower essence has sweet and rich fragrance of cape jasmine flowers and coordinated and long-lasting fragrance.

Owner:SHANGHAI INST OF TECH

Preparation method of leonurus essence

InactiveCN101618000AThe aroma is stable and long-lastingSimple aromaCosmetic preparationsToilet preparationsGalaxolideAdditive ingredient

A preparation method of leonurus essence adopts the following ingredients: 13000g of leonurus extract, 5000g of lilial, 3000g of Michelia alba leaf oil, 5000g of leonurus oil, 3000g of bergamot oil, 3000g of jasmine oil, 5000g of rose oil, 2000g of fructone, 2000g of liquorice esters, 2000g of nutgrass esters, 2000g of galaxolide, 8033000g of sandalwood, 3000g of myrac aldehyde, 1000g of hexenyl acetate and 5000g of iris esters. The preparation method comprises the following steps: accurately weighing the above ingredients according to the proportion in the formula, combining the weighed ingredients, placing the ingredients into a softening body stirrer to be stirred until all the solid is fully dissolved, carrying out stirring for another 30min, taking out the ingredients to be placed into a solid box for standing and aging and filtering the ingredients five days later to obtain the leonurus essence.

Owner:张衍华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com