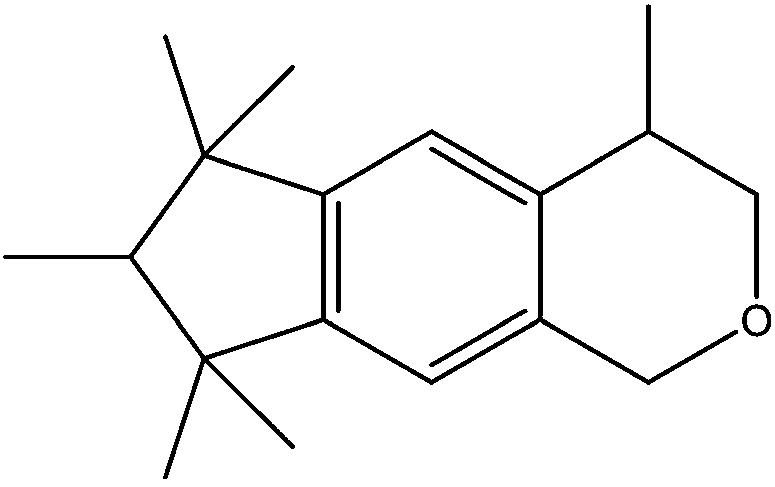

Synthetic process of galaxolide

A technology of Jiale musk and synthesis process, applied in the direction of organic chemistry, can solve the problems of difficult waste liquid treatment, high cost, high toxicity of chlorobenzene, etc., and achieve the effects of reducing the pollution of "three wastes", increasing production rate, and improving equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the macroporous strong acid styrene cation exchange resin includes the following steps:

[0029] 1) Prepare solution A with 300 mL of 0.5% polyvinyl alcohol and 400 mL of ammonium sulfate solvent with a mass concentration of 4%;

[0030] 2) Take 10g of chloropropylene oxide, 20g of polyethylene polyamine and 200mL of toluene to prepare solution B;

[0031] 3) Resin preparation: increase the temperature of solution A to 30°C, add solution B while stirring, stir well and increase the temperature to 90°C, polymerize for 3 hours, then soak the obtained resin in ether for 5-6 hours, and then clean water Carry out multiple cleanings and vacuum drying, the drying temperature is 60~80℃, and the vacuum degree is 100Pa.

Embodiment 2

[0033] The preparation method of the macroporous strong acid styrene cation exchange resin includes the following steps:

[0034] 1) Prepare solution A with 0.8% polyvinyl alcohol and 4.5% ammonium sulfate solvent;

[0035] 2) Take 5 g of chloropropylene oxide, 20 g of polyvinyl polyamine and 30 mL of xylene to prepare solution B;

[0036] 3) Resin preparation: The solution A was heated to 40°C, and solution B was added while stirring. After thorough stirring, the temperature was raised to 100°C, and the polymerization reaction was carried out for 4 hours. Then the obtained resin was soaked in ether for 5 hours, and then cleaned with water. The second cleaning, vacuum drying, the drying temperature is 80 ℃, the vacuum degree is 100 Pa.

Embodiment 3

[0038] (1) Synthesis of pentamethylindan

[0039] Add 88 g of tert-amyl alcohol and 8.8 g of the macroporous strongly acidic styrene cation exchange resin prepared in Example 1 into the reactor, and then add 100 g of α-methyl styrene to the reactor while stirring; control the stirring speed and Dropping rate, react at 40°C for 10 hours. The reacted materials are left to stand, layered, filtered to separate the macroporous strong acid styrene cation exchange resin catalyst, which can be reused, and the organic phase is rectified to separate the unreacted raw materials to obtain 121.8 g of indane, with a yield of 72%;

[0040] (2) Synthesis of hexamethylindanol

[0041] Add 18.8g of pentamethylindane and 100mL of dichloromethane into the reactor, and add anhydrous 1.3g of AlCl at a temperature of -15°C 3 , And turn on the stirrer, slowly add 29 g of propylene oxide in 30 mL of dichloromethane solution after stirring for a period of time, continue the reaction for 10 hours, add to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com