Galaxolide green synthesis technology

A green synthesis technology of Jiale musk, applied in chemical recycling, organic chemistry, etc., can solve the problems of high cost, difficult waste liquid treatment, high toxicity of chlorobenzene, etc., to increase production rate, improve equipment corrosion and harm to staff Physical damage, reduce the effect of "three wastes" pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

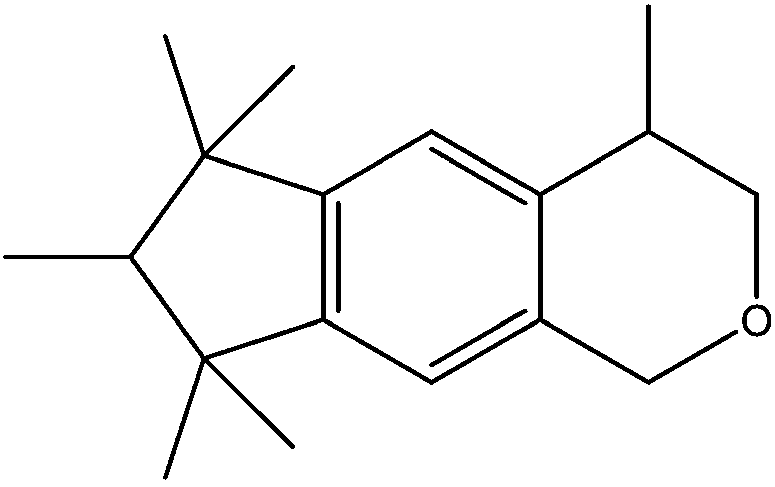

Image

Examples

Embodiment 1

[0029] Sulfonic acid type strongly acidic cation exchange resin, its preparation method comprises the following steps,

[0030] (1) Put 0.25g of gelatin into a four-necked flask equipped with 60.0g of deionized water, stir and heat up to 45°C, add 0.025g of hydroxymethylcellulose after the gelatin is dissolved, and use 5% NaOH aqueous solution and 5% boric acid Aqueous solution The pH of the aqueous phase was adjusted to 10 to obtain a hydrosol solution. 0.5 g of dibenzoyl peroxide was added to 18 g of glycidyl methacrylate and 8.7 g of divinylbenzene mixture, and added to the above-mentioned hydrosol solution for suspension polymerization to obtain 53 g of bead-shaped cross-linked copolymer skeletons.

[0031] (2) 10 g of the bead-shaped cross-linked copolymer skeleton obtained in step (1) is added to 50 mL of 15% sodium sulfamate aqueous solution and 30 g of N, N-dimethylmethylene formamide at a pH of 8 The sulfonic acid type strongly acidic cation exchange resin is obtaine...

Embodiment 2

[0033] Sulfonic acid type strongly acidic cation exchange resin, its preparation method comprises the following steps,

[0034] (1) Put 0.35g of gelatin into a four-necked flask equipped with 60.0g of deionized water, stir and heat up to 45°C, add 0.025g of hydroxymethylcellulose after the gelatin is dissolved, and use 5% NaOH aqueous solution and 5% boric acid Aqueous solution The pH of the aqueous phase was adjusted to 11 to obtain a hydrosol solution. 0.8 g of dibenzoyl peroxide was added to 20.0 g of glycidyl methacrylate and 12 g of divinylbenzene mixture, and added to the above-mentioned hydrosol solution for suspension polymerization to obtain 25 g of bead-shaped cross-linked copolymer skeletons.

[0035] (2) 15 g of the bead-shaped cross-linked copolymer skeleton obtained in step (1) is added to 60 mL of 17% sodium sulfamate aqueous solution and 42 g of N,N-dimethylmethylene formamide at a pH of 8 The sulfonic acid type strongly acidic cation exchange resin is obtaine...

Embodiment 3

[0037] (1) Synthesis of pentamethylindane

[0038]Add tert-amyl alcohol 88g and 5.6g of sulfonic acid type strongly acidic cation exchange resin prepared in Example 1 into the reactor, then add α-methylstyrene 100g dropwise to the reactor while stirring; control the stirring speed and the dropping speed , reacted at 40°C for 10 hours. The reacted material was left to stand, layered, filtered to separate the sulfonic acid type strongly acidic cation exchange resin catalyst for reuse, and the organic phase was rectified to separate the unreacted raw material to obtain 123.2 g of indane, with a yield of 72.8%;

[0039] (2) Synthesis of hexamethylindanol

[0040] Add 18.8g of pentamethylindane and 100mL of dichloromethane into the reactor, and add anhydrous 1.3g of ZnCl at a temperature of -15°C 2 , and turn on the stirrer, after stirring for a period of time, slowly add 29g of propylene oxide in 30mL of dichloromethane solution, continue to react for 10 hours, add to the ice-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com