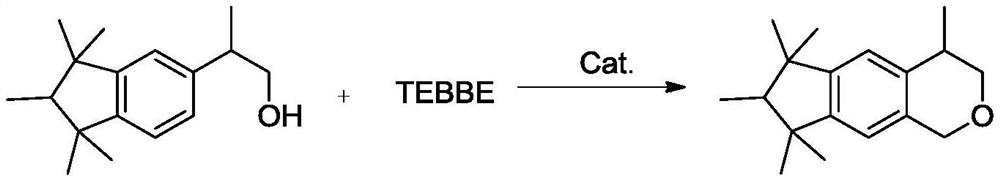

Preparation method of galaxolide

A technology of Jiale musk and catalyst, which is applied in the directions of essential oil/fragrance, fat production, organic chemistry, etc., can solve the problems of complex and cumbersome process, cumbersome process, serious equipment corrosion, etc., achieve simple process route, and promote condensation and cyclization reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 89.7g of palladium acetate and 113.4g of tricyclohexylphosphine in 500g of distilled water, raise the temperature to 60°C and stir for 3 hours. After the end, add 127.5g of 4A molecular sieves under stirring to obtain slurry A;

[0039] Using 20wt% sodium bicarbonate solution as alkaline precipitating agent B, respectively heating slurry A and alkaline precipitating agent B to 30°C, and slowly adding alkaline precipitating agent B to slurry A until the pH of the system is 9, Control the reaction temperature of the precipitation process to 30°C; then age at 80°C for 2 hours to obtain the slurry;

[0040] The slurry was filtered, washed with deionized water to obtain a filter cake, and the filter cake was dried at 100°C for 7 hours, then calcined at 300°C for 12 hours, crushed and pressed into tablets to obtain Catalyst 1. After ICP analysis, it is determined that in Catalyst 1, by mass (if there is no special mark, the crystal water of the above-mentioned metal salt ...

Embodiment 2

[0042] Mix 84.0g of palladium chloride and 148.2g of 1,2-bisdiphenylphosphineethane in 500g of distilled water, raise the temperature to 50°C and stir for 6h, after the end, add 97.8g of neutral alumina under stirring and mix to obtain slurry A;

[0043] Use 20wt% ammonium carbonate solution as alkaline precipitant B, heat slurry A and alkaline precipitant B to 40°C respectively, and slowly add alkaline precipitant B to slurry A until the pH of the system is 8.0, Control the reaction temperature of the precipitation process to 40°C; then age at 90°C for 1.5h to obtain the slurry;

[0044] The slurry was filtered and washed with deionized water to obtain a filter cake, and the filter cake was dried at 110°C for 9 hours, then calcined at 450°C for 7 hours, crushed and pressed into tablets to obtain Catalyst 2. After ICP analysis, it was determined that in catalyst 2, the percentages of the following components in the total mass of catalyst 2 were: 17% of Pd, 50% of 1,2-bisdiphe...

Embodiment 3

[0046] Mix 431.3g of tetrakistriphenylphosphine palladium and 83.4g of tributylphosphine in 1000g of distilled water, raise the temperature to 70°C and stir for 4 hours. After the end, add 75.5g of silicon dioxide and mix under stirring to obtain slurry A;

[0047] Use 15wt% ammonia solution as alkaline precipitant B, heat slurry A and alkaline precipitant B to 40°C respectively, and slowly add alkaline precipitant B to slurry A until the pH of the system is 10.0, and control The reaction temperature of the precipitation process is 40°C; then the slurry is obtained after aging at 70°C for 3 hours;

[0048] The slurry was filtered and washed with deionized water to obtain a filter cake. The filter cake was dried at 90° C. for 10 h, then calcined at 400° C. for 10 h, crushed and pressed into tablets to obtain Catalyst 3 . After ICP analysis, it was determined that in the catalyst 3, the percentages of the following components in the total mass of the catalyst 3 by mass were: 20% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com