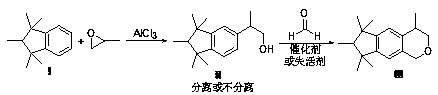

Method for preparing galaxolide under catalysis of superfine aluminum trichloride

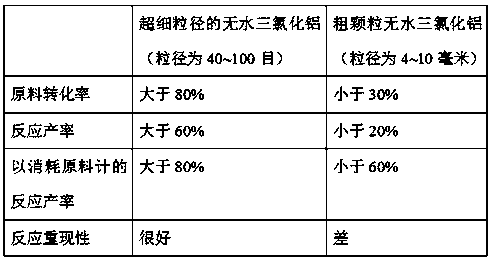

A technology of fine aluminum trichloride and Jiale musk, applied in the direction of organic chemistry, can solve the problems of poor reproducibility, low reaction conversion rate and yield, long reaction time, etc., achieve good reproducibility and improve production efficiency , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) In a 1000 ml three-neck round bottom flask, add 147 grams of pentamethylindane (80% purity), 142 grams of chlorobenzene and 88 grams of anhydrous aluminum trichloride powder with a particle size of 60 mesh, stir and cool to -20 degrees Celsius;

[0024] (2) Add dropwise a mixed solution of 50 grams of propylene oxide and 100 grams of chlorobenzene to the solution in step (1), and the dropwise addition is completed in about 2 to 3 hours, and continue to react at -20 degrees Celsius for 2 hours, and then slowly add 15 grams of water was added dropwise in about 0.5 hours, then the cold bath was removed, 44 grams of dimethoxymethane was added dropwise, the addition was completed in about 0.5 hours, and the reaction was continued for 2 hours at 25 degrees Celsius;

[0025] (3) Slowly add 375 grams of water dropwise to the reaction solution in step (2), and add it in about 0.5 hours. After the addition, stir for 1 hour, let it stand for 0.5 hours, separate the organic lay...

Embodiment 2

[0028] Contrast experiment, other conditions and operation are identical with embodiment 1, only difference is, use the granular anhydrous aluminum trichloride powder of 4~10 millimeters of particle diameters to replace 60 mesh anhydrous aluminum trichloride powders, reaction The conversion rate is 21% in terms of pentamethylindan, and the reaction yield is 12% (based on the consumption of pentamethylindan, the reaction yield is 57%).

Embodiment 3

[0030] (1) In a 1000 ml three-neck round bottom flask, add 149 grams of pentamethylindane (81% purity), 145 grams of chlorobenzene and 89 grams of anhydrous aluminum trichloride powder with a particle size of 100 mesh, stir and cool to -25 degrees Celsius;

[0031] (2) Add dropwise a mixed solution of 51 grams of propylene oxide and 100 grams of chlorobenzene to the solution in step (1), and the dropwise addition is completed in about 2 to 3 hours, and continue to react at -25 degrees Celsius for 2 hours, and then slowly add 30 grams of methanol was added dropwise in about 0.5 hours, then the cold bath was removed, 20 grams of paraformaldehyde was added dropwise, the addition was completed in about 0.5 hours, and the reaction was continued for 2 hours at 25 degrees Celsius;

[0032] (3) Slowly add 380 grams of water dropwise to the reaction solution in step (2), and add it in about 0.5 hours. After the addition, stir for 1 hour, let it stand for 0.5 hours, separate the organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com