Green tea essence and preparation method thereof

A technology for green tea essence and green tea extract, applied in the field of essence, can solve the problems of unrealistic aroma, difficult for consumers, unnatural, etc., and achieve the effects of good unnatural feeling, improved aroma quality, and natural aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

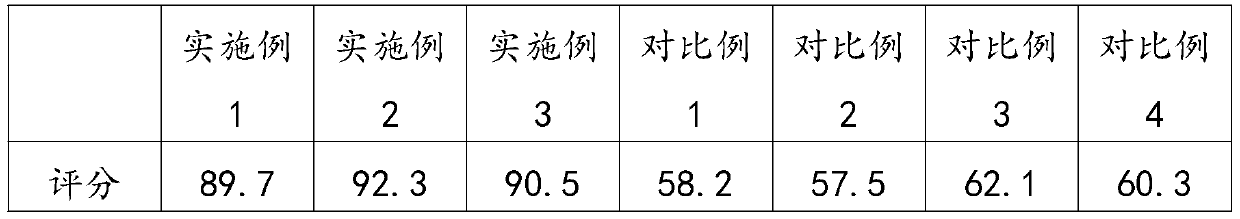

Examples

Embodiment 1

[0024] A kind of green tea essence, its raw material is made up of following components by weight percentage:

[0025] Ambroxan 0.10%, Menthol 1.30%, Jiale Musk 2.25%, Phenethyl Phenylacetate 0.50%, Methylhexyl cinnamaldehyde 6.60%, Geraniol 1.60%, Citronellol 0.20%, Phenylethanol 6.40% , Linalool 5.40%, leaf alcohol 0.10%, terpineol 0.60%, methyl dihydrojasmonate 14.40%, privetaldehyde 0.15%, ethyl ionone 0.60%, gamma undecolactone 0.20 %, green tea extract 1.00%, linalool oxide 0.10%, bergamot oil 1.60%, brazilian orange oil 0.30%, brazilian orange oil terpene 7.60%, dipropylene glycol 49.00%.

[0026] Wherein, the specific preparation method of green tea extract is:

[0027] (1) Pour air with a temperature of 65° C., a relative humidity of 30%, and a flow rate of 1.2 m / s into the fresh green tea leaves for 65 minutes;

[0028] (2) the green tea leaves treated in step (1) are first dried at 75°C for 5min, then dried at 65°C for 15min, and finally dried at 50°C for 45min to...

Embodiment 2

[0036] A kind of green tea essence, its raw material is made up of following components by weight percentage:

[0037] Ambroxan 0.20%, Menthol 2.00%, Musk Musk 2.50%, Phenethyl Phenylacetate 0.50%, Methylhexyl cinnamaldehyde 8.00%, Geraniol 1.60%, Citronellol 0.40%, Phenylethanol 6.40% , linalool 5.40%, leaf alcohol 0.10%, terpineol 0.60%, methyl dihydrojasmonate 14.80%, privetaldehyde 0.25%, ethyl ionone 1.00%, gamma undecolactone 0.30 %, green tea extract 1.00%, linalool oxide 0.10%, bergamot oil 1.60%, brazilian orange oil 0.50%, brazilian orange oil terpene 8.00%, dipropylene glycol 44.75%.

[0038] Wherein, the specific preparation method of green tea extract is:

[0039] (1) Air with a temperature of 68° C., a relative humidity of 32%, and a flow rate of 1.4 m / s was introduced into the fresh green tea leaves, and treated for 55 minutes;

[0040](2) the green tea leaves treated in step (1) are first dried at 77°C for 4min, then dried at 68°C for 12min, and finally dried...

Embodiment 3

[0048] A kind of green tea essence, its raw material is made up of following components by weight percentage:

[0049] Ambroxan 0.30%, Menthol 2.50%, Musk Musk 2.75%, Phenethyl Phenylacetate 0.60%, Methylhexyl cinnamaldehyde 8.80%, Geraniol 1.80%, Citronellol 0.60%, Phenylethanol 6.80% , Linalool 5.60%, leaf alcohol 0.20%, terpineol 0.80%, methyl dihydrojasmonate 15.60%, privetaldehyde 0.35%, ethyl ionone 1.20%, gamma undecolactone 0.40 %, green tea extract 1.50%, linalool oxide 0.20%, bergamot oil 2.20%, brazilian orange oil 0.60%, brazilian orange oil terpene 8.20%, dipropylene glycol 39.00%.

[0050] Wherein, the specific preparation method of green tea extract is:

[0051] (1) Pour air with a temperature of 70° C., a relative humidity of 35%, and a flow rate of 1.6 m / s into the fresh green tea leaves for 45 minutes;

[0052] (2) drying the green tea leaves treated in step (1) at 80°C for 3min first, then drying at 70°C for 10min, and finally drying at 55°C for 35min to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com