Immersion type frosting-powder glass processing machine

A processing machine and frosting powder technology, which is applied in the field of immersion frosting powder glass processing machines, can solve the problems of reducing light transmission, influence of soaking liquid concentration, concentration change, etc., and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

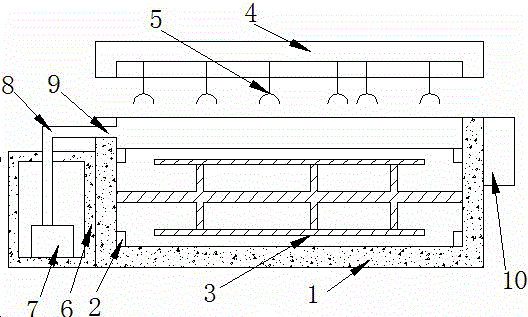

[0013] Such as figure 1 The immersion type frosted powder glass processing machine shown includes immersion tank 1, inductor 2, agitator 3, top plate 4, claw 5, material pool 6, feed pump 7, feed pipe 8, feed mouth 9 and processor 10; the agitator 3 is installed in the soaking tank 1; the sensor 2 is installed at the corner of the soaking tank 1; the top plate 4 is installed at the top of the soaking tank 1; the hook 5 is installed in On the top plate 4; the material pool 6 is installed on the left side of the soaking pool 1; the feed pump 7 is installed in the material pool 6; the feed pipe 8 is installed on the feed pump 7; the feed pipe 9 connected to the feed port 8; the processor 10 is installed on the right side of the immersion tank 1; the processor 10 is connected to the sensor 2, the feed pump 7 and the agitator 3.

[0014] Wherein, the claw 5 is a retractable claw; the sensor 2 is a density sensor.

[0015] The immersion-type frosted powder glass processing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com