A low-odor high-resilience sponge for passenger car seats and preparation method thereof

A high-resilience, low-odor technology, applied in the sponge field, can solve the problems that the odor content and resilience performance cannot meet the environmental performance and mechanical properties of car seat sponges, the foaming volume is large, and the health is damaged. Suitable for large-scale industrial production, stable reaction rate and high foaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

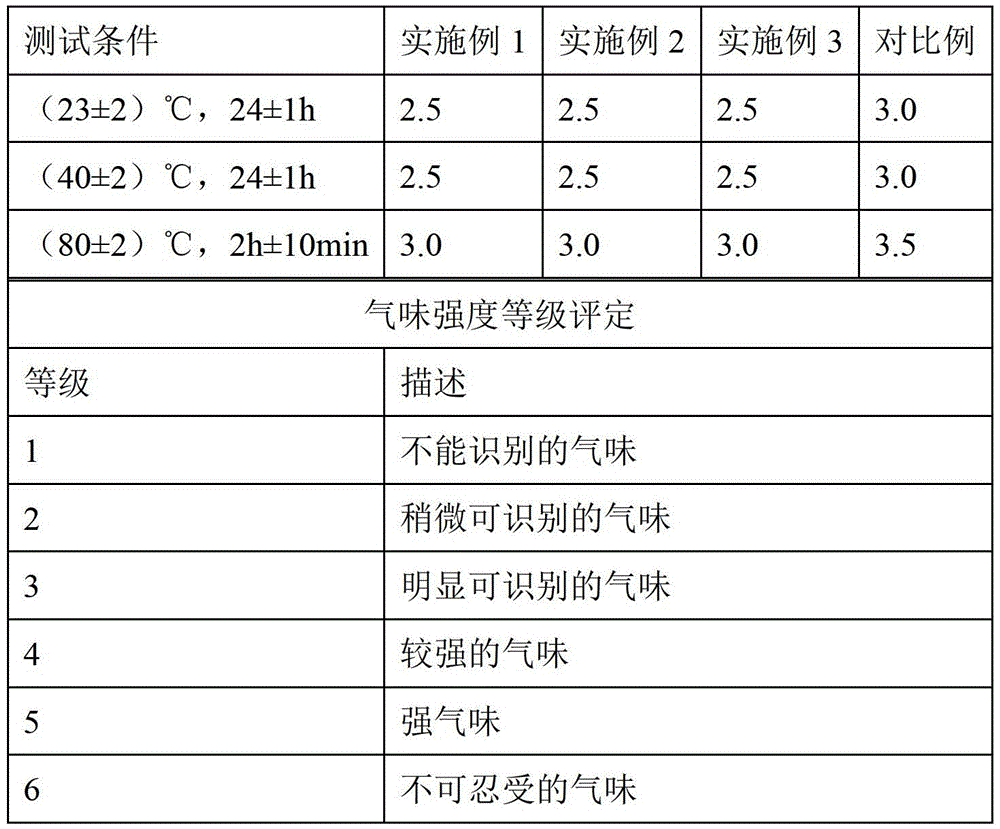

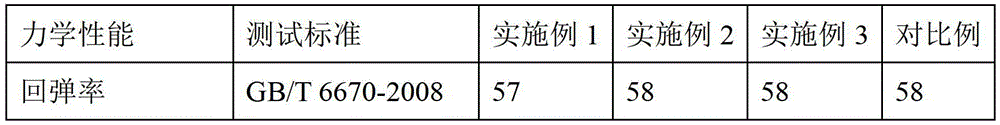

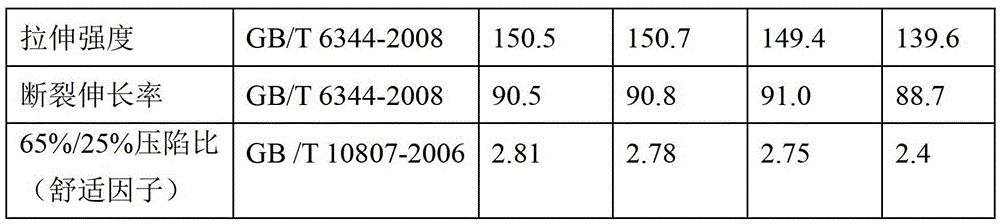

Examples

Embodiment 1

[0024] The low-odor and high-resilience passenger car seat sponge of this embodiment is made of a combination material and a black material in a mass ratio of 100:60, wherein the combination material is composed of the following components by weight: polyether multi-component 50 parts of alcohol, 35 parts of grafted polyether, 0.3 part of amine catalyst, 0.35 part of early gel catalyst, 0.7 part of late gel catalyst, 3 parts of water, 1 part of diethanolamine, 0.5 part of silicone oil.

[0025] The black material is modified diphenylmethane diisocyanate. The modified diphenylmethane diisocyanate is prepared by the following method: the content of 4,4'-diphenylmethane diisocyanate is 40%, and the balance is 2,4'-diphenylmethane diisocyanate and The diphenylmethane diisocyanate of 2,2'-diphenylmethane diisocyanate is mixed and reacted with the first polyether with 90% ethylene oxide content and the second polyether with 25% ethylene oxide content to obtain A modified intermediate ...

Embodiment 2

[0032] The low-odor and high-resilience passenger car seat sponge of this embodiment is made of a combination material and a black material in a mass ratio of 100:55, wherein the combination material is composed of the following parts by weight: polyether multi-component 65 parts of alcohol, 20 parts of grafted polyether, 0.2 parts of amine catalyst, 0.5 parts of early gel catalyst, 0.6 parts of late gel catalyst, 4 parts of water, 1 part of triethanolamine, 0.7 parts of silicone oil.

[0033] The black material is modified diphenylmethane diisocyanate. The modified diphenylmethane diisocyanate is prepared by the following method: the content of 4,4'-diphenylmethane diisocyanate is 60%, and the balance is 2,4'-diphenylmethane diisocyanate and The diphenylmethane diisocyanate of 2,2'-diphenylmethane diisocyanate is mixed and reacted with the first polyether with 70% ethylene oxide content and the second polyether with 25% ethylene oxide content to obtain A modified intermediate w...

Embodiment 3

[0040] The low-odor and high-resilient passenger car seat sponge of this embodiment is made of a combination material and a black material in a mass ratio of 100:58, wherein the combination material is composed of the following components by weight: 80 parts of alcohol, 50 parts of grafted polyether, 0.25 parts of amine catalyst, 0.2 parts of early gel catalyst, 0.5 parts of late gel catalyst, 3.5 parts of water, 0.5 parts of diethanolamine, 0.5 parts of triethanolamine, and 0.6 parts of silicone oil.

[0041] The black material is modified diphenylmethane diisocyanate. The modified diphenylmethane diisocyanate is prepared by the following method: the content of 4,4'-diphenylmethane diisocyanate is 80%, and the balance is 2,4'-diphenylmethane diisocyanate and The diphenylmethane diisocyanate of 2,2'-diphenylmethane diisocyanate is mixed and reacted with the first polyether with 50% ethylene oxide content and the second polyether with 25% ethylene oxide content to obtain A modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com