A kind of graphene catalyst supported by metal particles and preparation method thereof

A technology of metal particles and graphene, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst protection, amino compound preparation, etc., can solve the problems of selectivity decline, long reaction time, catalyst consumption, etc., and achieve reduction Occurrence of by-products, reduction of the occurrence rate, and effects of stabilizing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

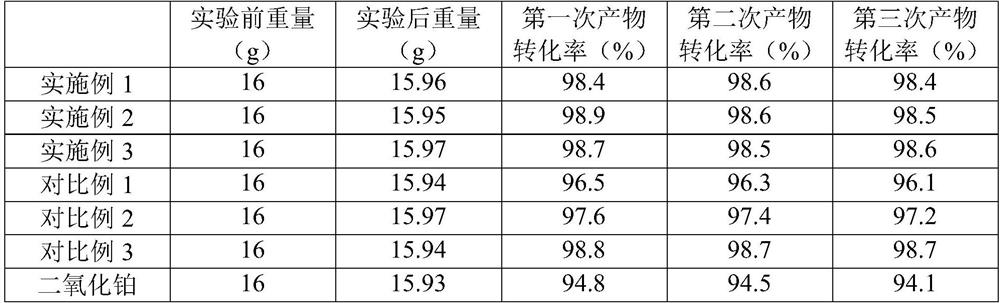

Examples

Embodiment 1

[0029] A graphene catalyst supported by metal particles, each component raw material of the graphene catalyst is as follows, in parts by weight, including 15 parts of platinum dioxide, 20 parts of graphene, 15 parts of diphenylamine, 10 parts of bromobenzene, carbon Nanotube 20 parts.

[0030] A kind of preparation method of the graphene catalyst supported by metal particles, the steps are as follows,

[0031] (1) Carry out pretreatment to platinum dioxide, put platinum dioxide under argon and oxygen atmosphere, carry out calcination at 700 ℃, heat up, carry out calcination under argon atmosphere, seal after calcination;

[0032] (2) Put the carbon nanotubes into water, perform ultrasonic vibration, and add the treated platinum dioxide under stirring at 500 r / min, and perform hydrothermal treatment after stirring evenly, at a temperature of 200° C., to obtain product A;

[0033] (3) Dissolve diphenylamine in water, add bromobenzene, add copper powder, heat to 200°C, filter th...

Embodiment 2

[0038] A graphene catalyst supported by metal particles, the raw materials of each component of the graphene catalyst are as follows, in parts by weight, including 18 parts of platinum dioxide, 23 parts of graphene, 18 parts of diphenylamine, 13 parts of bromobenzene, carbon Nanotube 23 parts.

[0039] A kind of preparation method of the graphene catalyst supported by metal particles, the steps are as follows,

[0040] (1) Carry out pretreatment to platinum dioxide, put platinum dioxide under argon and oxygen atmosphere, carry out calcination at 750 ℃, heat up, carry out calcination under argon atmosphere, seal after calcination;

[0041] (2) put the carbon nanotubes into water, perform ultrasonic vibration, add the treated platinum dioxide under stirring at 550r / min, perform hydrothermal treatment after stirring evenly, and obtain the product A at a temperature of 230°C;

[0042] (3) Dissolve diphenylamine in water, add bromobenzene, add copper powder, heat to 230°C, filter ...

Embodiment 3

[0047] A graphene catalyst supported by metal particles, the raw materials of each component of the graphene catalyst are as follows, in parts by weight, including 20 parts of platinum dioxide, 25 parts of graphene, 20 parts of diphenylamine, 15 parts of bromobenzene, carbon Nanotube 25 parts.

[0048] A kind of preparation method of the graphene catalyst supported by metal particles, the steps are as follows,

[0049] (1) Carry out pretreatment to platinum dioxide, put platinum dioxide in argon and oxygen atmosphere, carry out calcination at 800 ℃, heat up, carry out calcination under argon atmosphere, seal after calcination;

[0050] (2) put the carbon nanotubes into water, carry out ultrasonic vibration, under 600r / min stirring, add the pretreated platinum dioxide, after stirring evenly, carry out hydrothermal treatment, the temperature is 250 ℃, and obtain the product A;

[0051] (3) Dissolve diphenylamine in water, add bromobenzene, add copper powder, heat to 250°C, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com