Patents

Literature

40results about How to "Promote positive response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

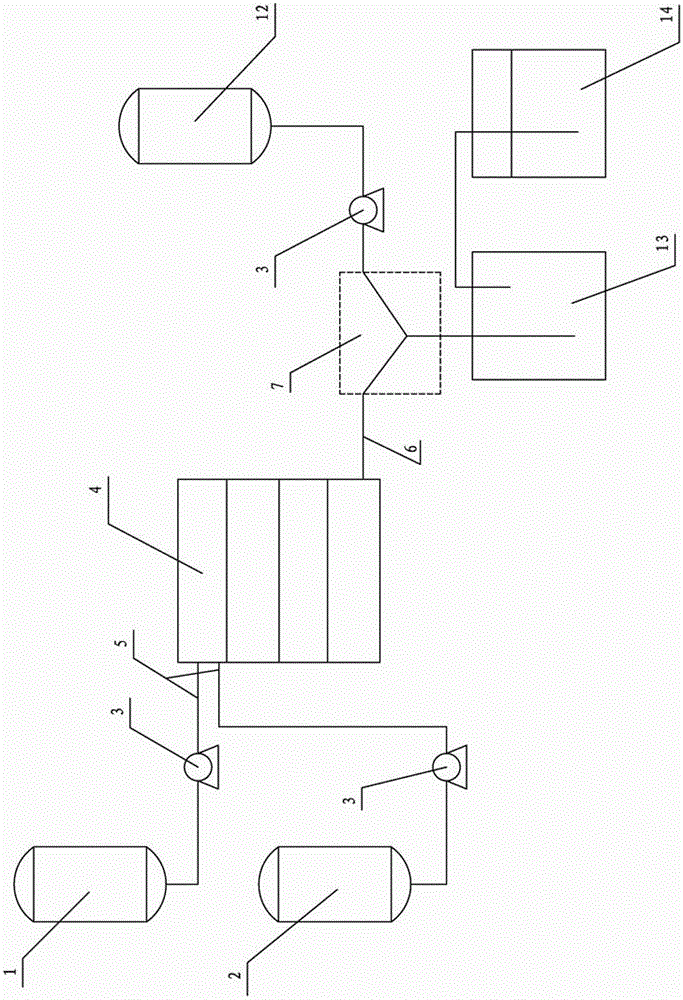

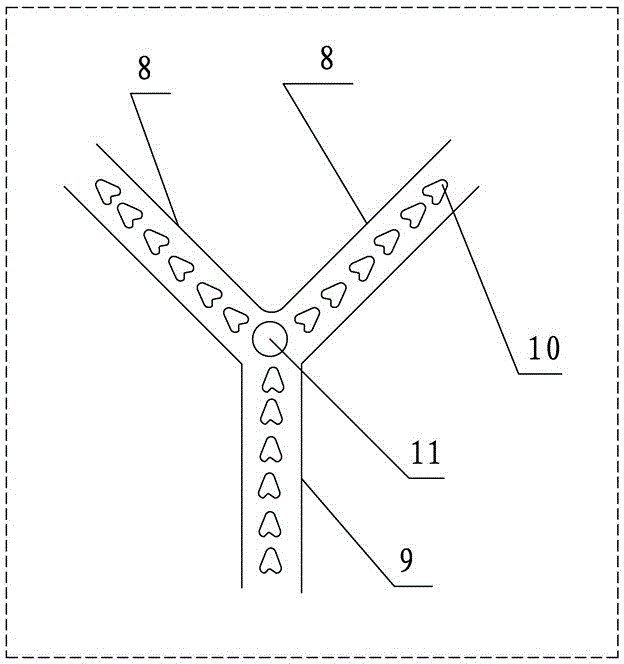

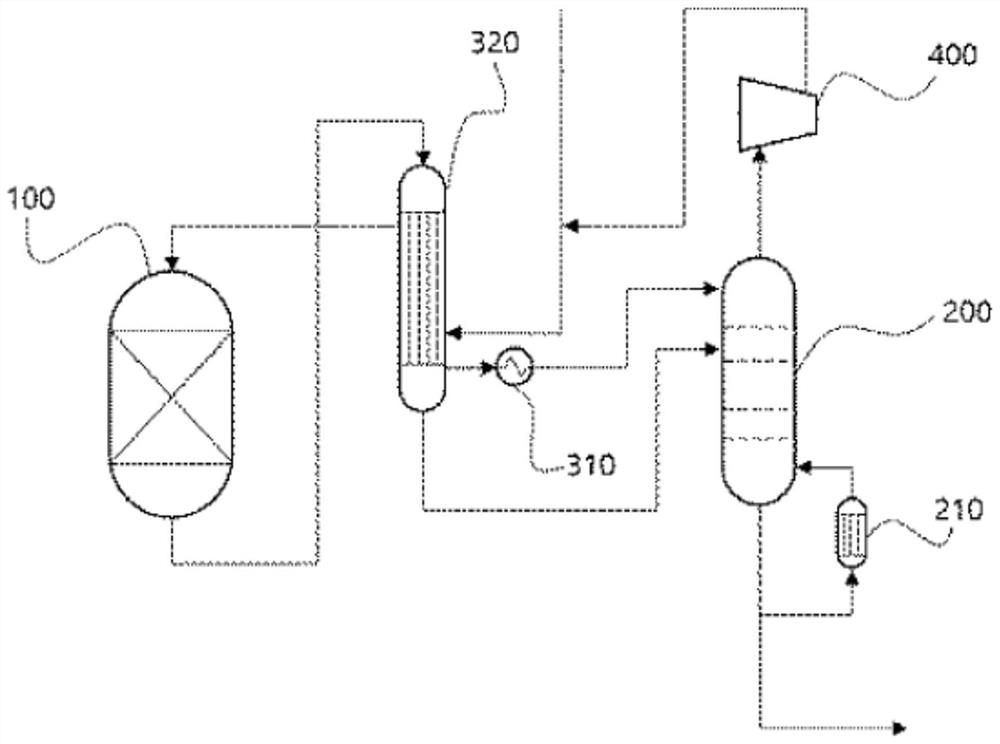

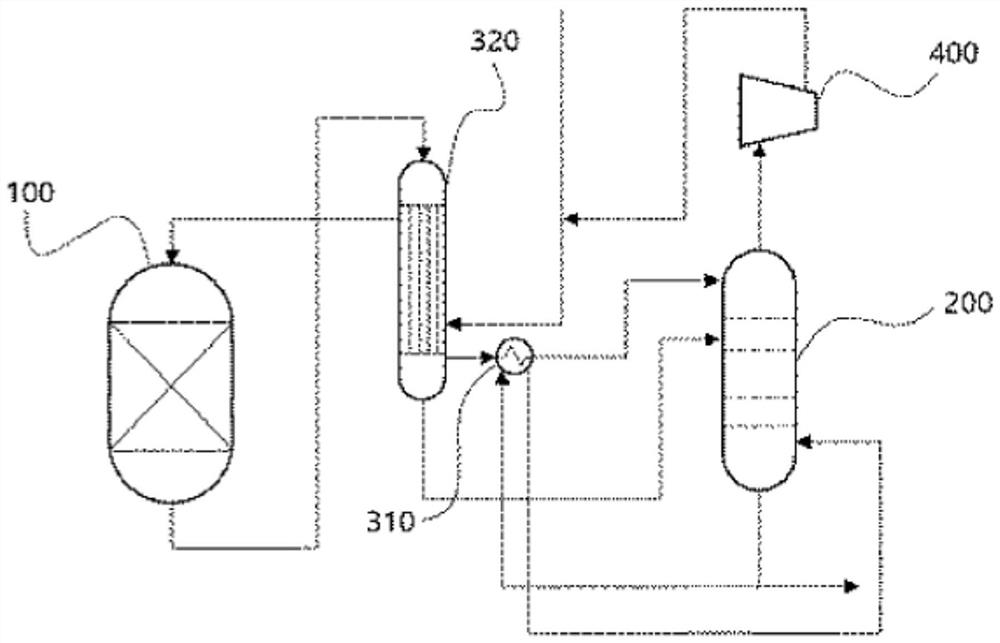

Continuous synthesis system and method of ethyl 4-chloroacetoacetate

InactiveCN106748764AHigh selectivityReduce manufacturing costPreparation from carboxylic acid halidesCarboxylic acid halides preparationEthyl acetateDiketene

The invention relates to a continuous synthesis system and method of ethyl 4-chloroacetoacetate. The method comprises the steps of adopting diketene, chlorine and ethyl alcohol as raw materials and inputting the raw materials into a micro-channel reactor through a metering pump; and carrying out chlorination and esterification and then synthesizing the ethyl 4-chloroacetoacetate. The reaction time is greatly shortened, and the produced product is high in content, low in cost, small in pollution and high in security and meets the requirements of industrial production.

Owner:JIANGSU CHENGXIN PHARMA

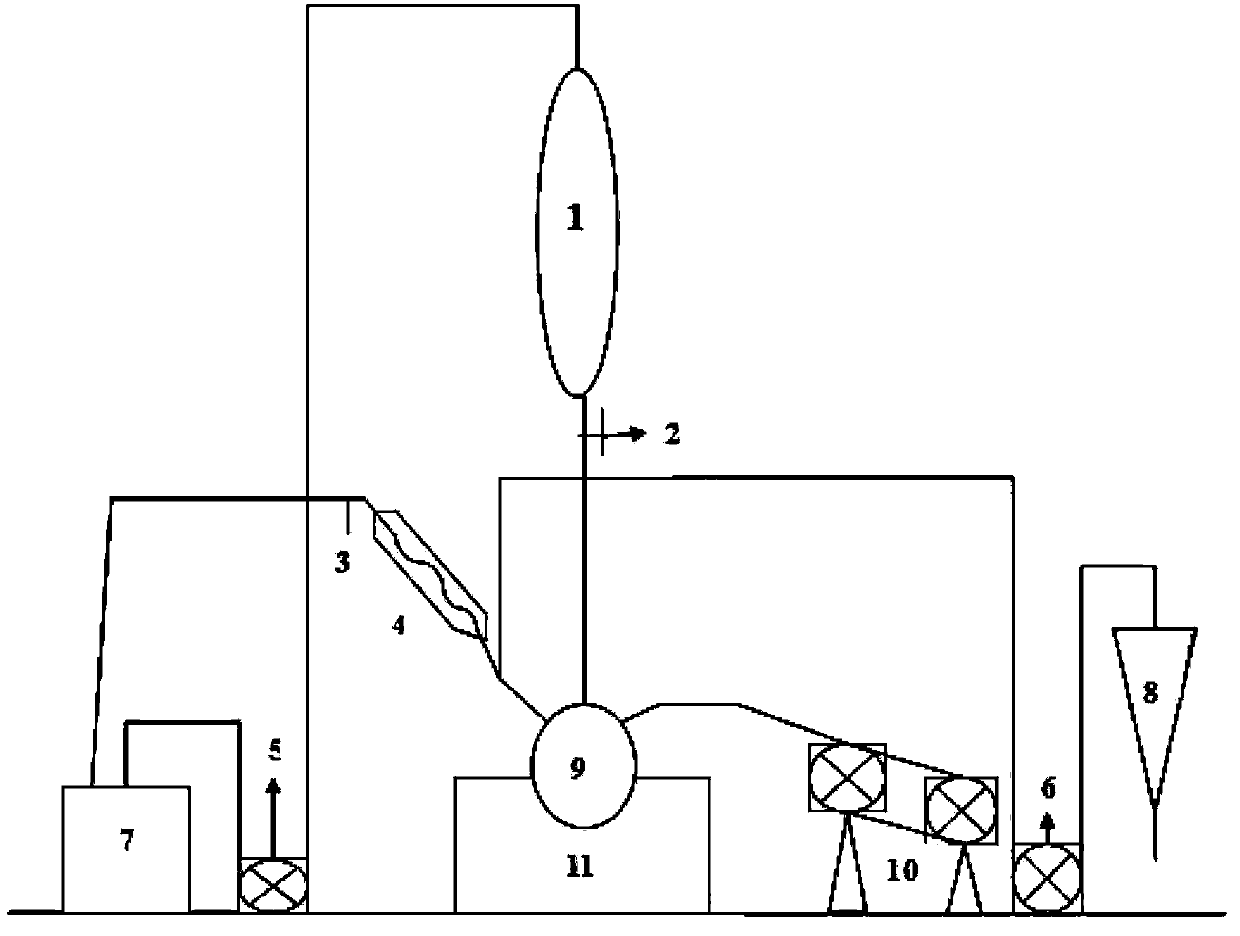

Method for preparing biodiesel by utilizing oil plant

ActiveCN103396883AHigh yieldEasy to synthesizeFatty acid esterificationBiofuelsTrans esterificationOil and grease

The invention belongs to the chemical field of bio oil, and in particular relates to a method for preparing biodiesel by utilizing oil plants. The invention discloses a method for preparing biological diesel by utilizing oil plants. The method utilizes the seeds oil plants as raw materials; an oil extraction solvent and a transesterification solvent form a double liquid phase mixed solvent; and in the presence of a solid base catalyst, the double liquid phase mixed solvent in different volumes is refilled for grease extraction and a transesterification reaction. The invention mainly solves the problem that one step synthesis of biodiesel by double liquid phase mixed solvent in the prior art has disadvantages of inhibition on the synthesis of biodiesel by reaction raw materials and inability to increasing yield, and provides a high-efficiency and high-yield method for synthesis of biodiesel.

Owner:黄耀江

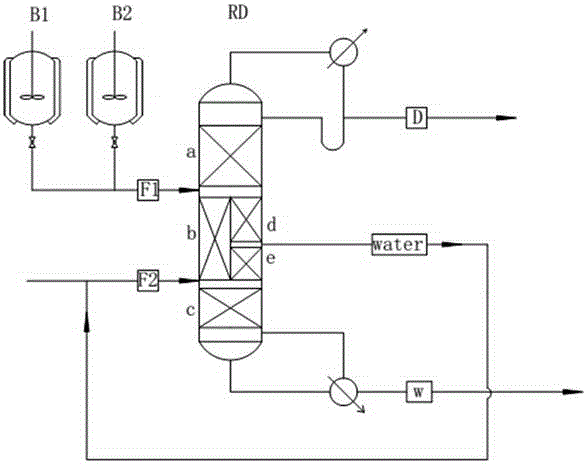

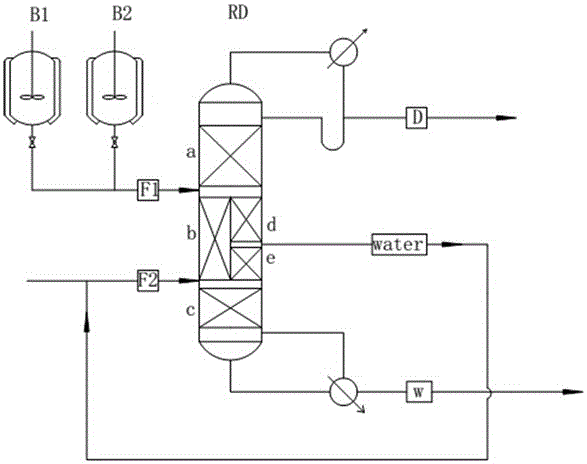

Intermittent reaction-continuous reaction rectification combined process for catalytic synthesis of oxalic acid

ActiveCN104892400AAvoid separabilityAvoid using effectsChemical industryPreparation from carboxylic acid esters/lactonesSide reactionBatch reaction

The invention discloses an intermittent reaction-continuous reaction rectification combined process for catalytic synthesis of oxalic acid. The process particularly comprises the following steps: (1) continuously feeding materials into a reactive dividing-wall rectification tower in a double batch reactor switching mode; (2) enabling dimethyl oxalate and water to enter a batch reactor to react primarily, wherein the equilibrium conversion rate reaches 50%-60%; and (3) continuously feeding reaction solution into a left-side reaction section ( zone b) of the reactive dividing-wall rectification tower from an upper feeding opening, continuously feeding normal-temperature water into the reactive dividing-wall rectification tower from a lower feeding opening of the zone b, and continuously discharging methyl alcohol produced in the reaction process from the tower top, wherein due to the discharging of methyl alcohol, the reaction proceeds to production of oxalic acid until dimethyl oxalate is completely hydrolyzed and the conversion rate can reach 99.5% or above. By virtue of the reactive dividing-wall rectification tower, the synthesis reaction and product separation and purification are implemented in the same tower, the existing process flow is simplified, and energy consumption and investment can be lowered. The intermittent reaction-continuous reaction rectification combined process for catalytic synthesis of oxalic acid has the characteristics of no addition of extra additives, high reaction speed, high conversion rate, low water-ester ratio, simple product separation operation, low energy consumption and the like.

Owner:FUZHOU UNIV

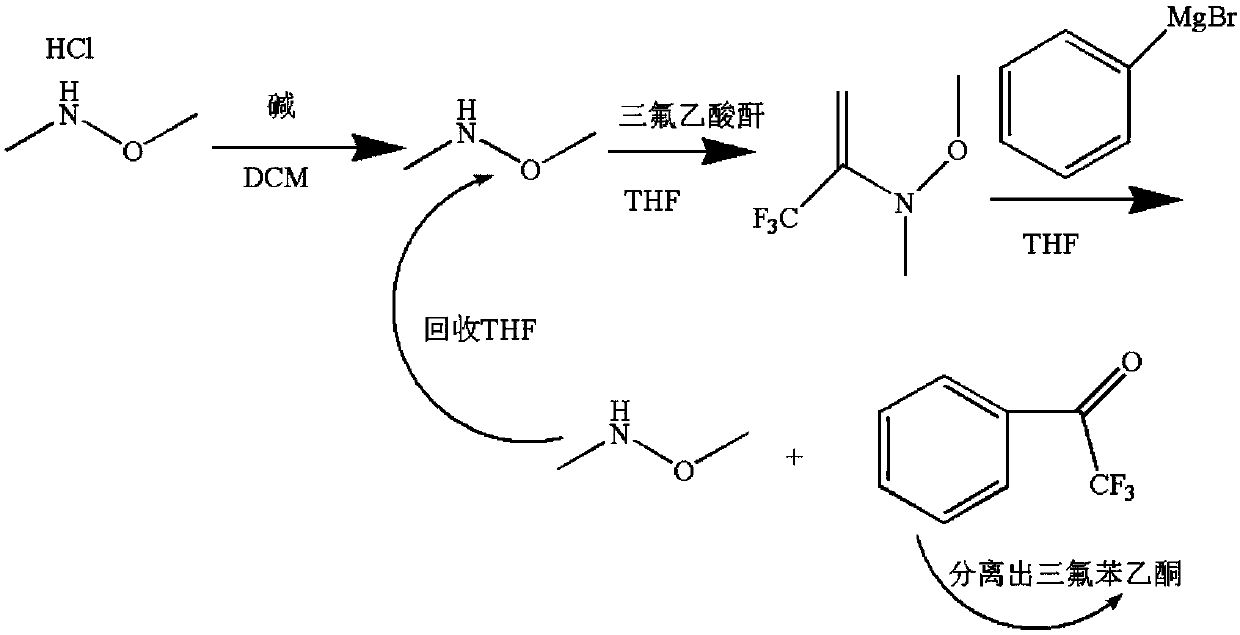

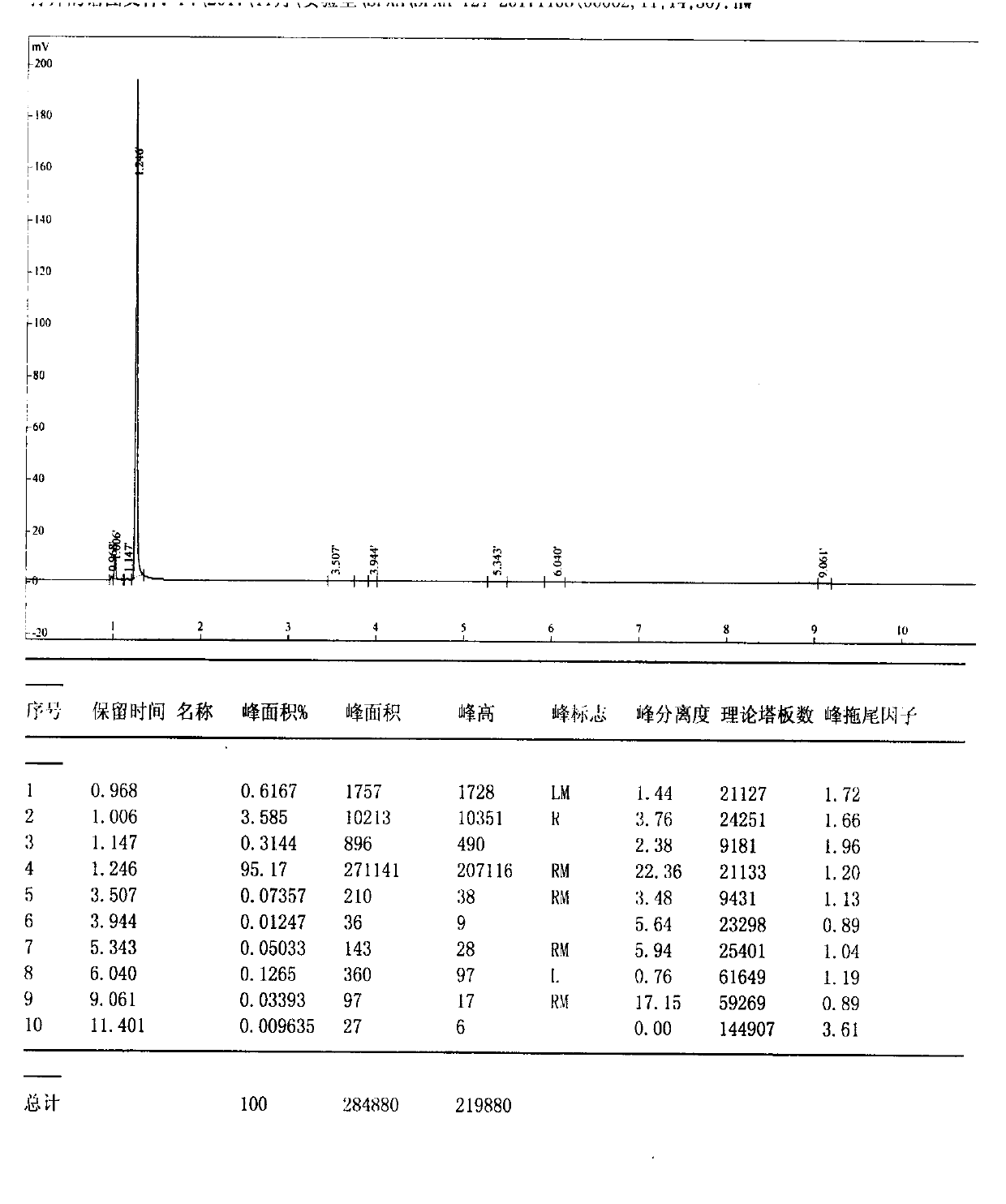

Clean and high-conversion-rate preparing method of 2,2,2-trifluroacetophenone

InactiveCN108047019AImprove conversion rateEfficient preparationPreparation by organometalhalide reactionOrganic compound preparationGrignard reagentSolvent

The invention discloses a clean and high-conversion-rate preparing method of 2,2,2-trifluroacetophenone. The method includes the following steps of S1, making N,O-dimethylhydroxylamine hydrochloride as the raw material react with organic alkali to obtain free N,O-dimethylhydroxylamine; S2, making trifluoroacetic anhydride react with free N,O-dimethylhydroxylamine to generate N,O-dimethyltrifluoroacetamide; S3, making a Grignard reagent react with N,O-dimethyltrifluoroacetamide to prepare trifluroacetophenone, recovering N,O-dimethylhydroxylamine generated in the step S1, applying N,O-dimethylhydroxylamine to the step S2, and recycling the reaction solvents used in the steps S1, S2 and S3. By means of the preparing method, prepared high-nucleophilicity N,O-dimethyltrifluoroacetamide reactswith the Grignard reagent, 2,2,2-trifluroacetophenone is efficiently prepared, meanwhile produced byproducts can be applied for preparing N,O-dimethyltrifluoroacetamide, and a recycling effect is achieved.

Owner:GUANGXI WANDE PHARMA

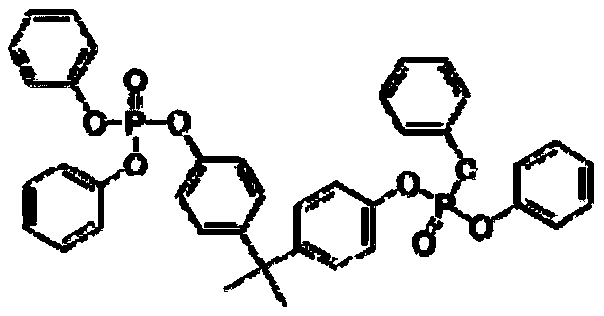

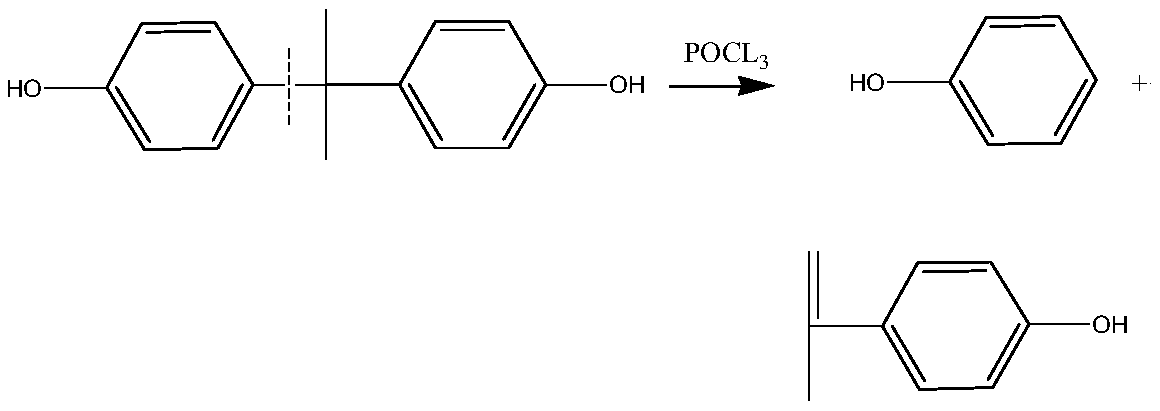

Preparation method of bisphenol A-bis(diphenyl phosphate)

InactiveCN110317228AEasy to operateReduce consumptionGroup 5/15 element organic compoundsDiphenyl phosphateDistillation

The invention relates to a preparation method of bisphenol A-bis(diphenyl phosphate). The preparation method comprises the following steps of 1, an esterification reaction, wherein phosphorus oxychloride is dropwise added into a bisphenol A solution containing a solvent, the esterification reaction is conducted in the presence of a Lewis catalyst, and reduced pressure distillation is conducted onthe phosphorus oxychloride after the reaction is completed; 2, an end-capping reaction, wherein end capping is conducted by using phenol, the phenol is recycled under reduced pressure to obtain a bisphenol A-bis(diphenyl phosphate) crude product; 3, refining of the crude product, wherein the crude product is washed with alkali and water, and then reduced pressure distillation is conducted to obtain the product. According to the method, the phosphorus oxychloride is dropwise added into the solution of bisphenol A and xylene or toluene, the method is convenient and reliable to use and easy to operate and does not need special equipment, the solvent can be recycled, the consumption is reduced, the quality of products in a batch production process is ensured, the yield is stable, and high-endproducts can be stably generated.

Owner:ZHEJIANG WANSHENG

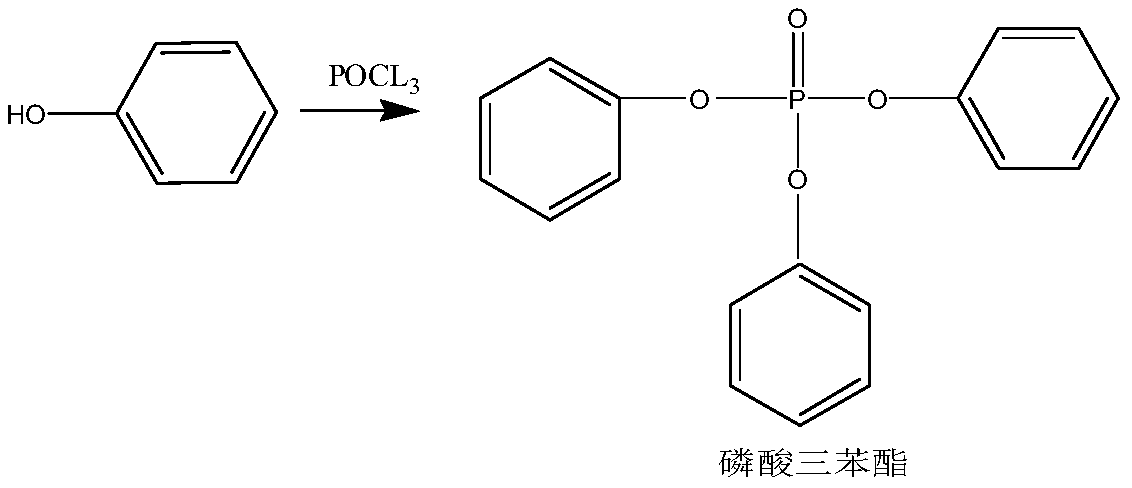

Process for preparing high-purity ethiprole through oxidation method

The invention discloses a process for preparing high-purity ethiprole through an oxidation method. The process comprises the following steps of: carrying out oxidation reaction on a right amount of raw material 5-amido-3-cyano-group-1-(2,6-dichloro-4-trifluoromethyl phenyl)-4-ethyl sulfinyl pyrazole (I) in an organic solvent with the participation of fatty acid and hydrogen peroxide; after the oxidation reaction is finished, adding a reducing agent and controlling the temperature of a system at the same time; then regulating the pH value of the system through an NaOH solution; then heating, refluxing, cooling, crystallizing and carrying out suction filtration to obtain a crude ethiprole product; purifying the crude ethiprole product (II) so as to obtain a qualified product, wherein the organic solvent is selected from at least one of chloroform, dichloromethane and dichloroethane. The production process disclosed by the invention has the advantages of simplicity, high efficiency, few by-products, bigger breakthrough on product yield and product purity, relatively low raw material toxicity, little environmental pollution and good production controllability.

Owner:ZHEJIANG HISUN CHEM

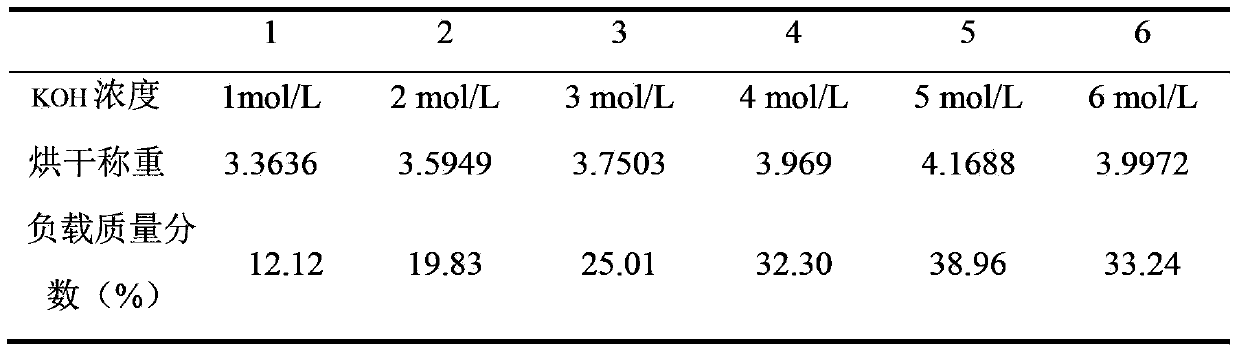

Super bright low-melting-point polyester biaxial oriented film and preparation method thereof

The invention belongs to the field of plastic film production processing and in particular relates to a super bright low-melting-point polyester biaxial oriented film and a preparation method thereof. The thickness of the low-melting-point polyester biaxial oriented film is 25-350 microns, and horizontal and longitudinal thermal shrinkage rates of 15 minutes at the temperature of 150 DEG C are respectively less than 1.5%. The preparation method comprises the following steps: firstly preparing a supported catalyst super bright modifier for a super bright supported catalyst by virtue of a sol-gel process, then beating terephthalic acid and ethylene glycol by utilizing the supported catalyst super bright modifier, so that beating liquid is obtained, then taking the beating liquid as a raw material to prepare an esterified product by virtue of an esterification process, then carrying out a pre-polycondensation process, so that super bright low-melting-point polyester is obtained, then pre-crystallizing the super bright low-melting-point polyester, and then preparing the super bright low-melting-point polyester biaxial oriented film by virtue of a biaxial orientation technology. The super bright low-melting-point polyester biaxial oriented film has excellent machinability and has broad application prospects in the industries of electronics, packaging, printing and the like.

Owner:JIANGSU YUXING FILM TECH

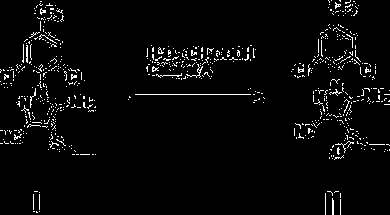

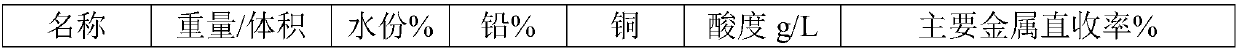

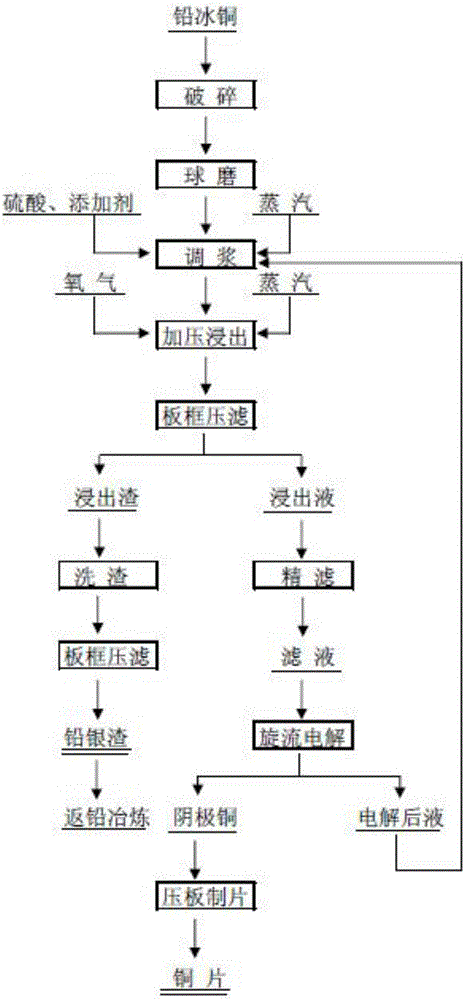

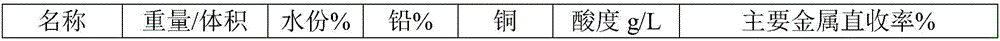

A method for leaching copper from lead matte

ActiveCN106756045BImprove leaching rateImprove recycling ratesProcess efficiency improvementAtmospheric pollutionMaterials science

The invention discloses a method for leaching copper out of lead matte. The method for leaching the copper out of the lead matte includes the steps that sulfuric acid is added into the lead matter, a sizing agent is obtained, and steam is introduced into the sizing agent to make the temperature of the sizing agent rise; an adding agent is added into the sizing agent, a slurrying material is obtained, it is stopped to introduce steam into the slurrying material, oxygen is introduced into the slurrying material to perform oxidizing leaching till the temperature of the slurrying material is not risen any more, a reaction product sizing agent is obtained and is filtered, and leaching residues and leaching liquid containing copper are obtained. According to the method for leaching the copper out of the lead matte, the lead matter serves as a raw material, the reaction condition is accurately controlled by means of steam heating, and therefore the leaching-out rate of the copper is increased. Thus, the method for leaching the copper out of the lead matte is high in raw material adaptability, and simple in procedure and operation, the copper leaching-out rate is high, pollution to the atmosphere is small, the recycling rate of the copper in the lead matter can be increased, and therefore waste of copper resources can be avoided.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

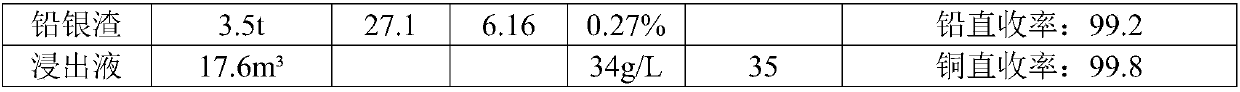

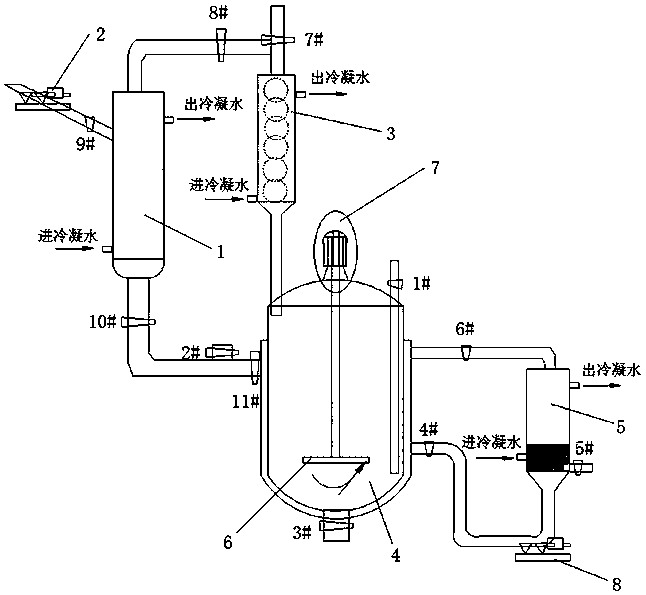

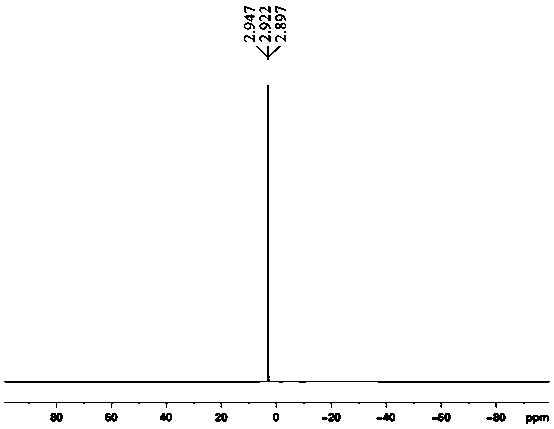

Methane reforming transformation separator based on ion membrane reactor

InactiveCN106744684AEfficient separationSolve the low separation efficiencyHydrogenHydrogen/synthetic gas productionCatalytic reformingMembrane reactor

The invention discloses a methane reforming transformation separator based on an ion membrane reactor. The methane reforming transformation separator comprises a quartz tube reactor (1), a catalyst bed (2), an ion membrane (3), a reaction gas inlet (4), a gas product outlet (5) and a gas separation product outlet (6). A catalytic reforming reactor is effectively combined with ion exchange membrane technology, voltage is applied to two sides of an ion exchange membrane during methane and carbon dioxide reforming reaction, protons and positive ions of hydrogen are driven to do directed migration and flow to the two sides of the ion exchange membrane respectively, reaction products are efficiently separated, forward reaction is timely promoted, the existing problems of low product separation efficiency, incomplete product research in a laboratory and industrial application limitation, methane and carbon dioxide reforming reaction is efficient, transformation and product separation are efficient, and the methane reforming transformation separator has the advantages of simplicity in operation, high separation efficiency, wide application prospect and the like.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

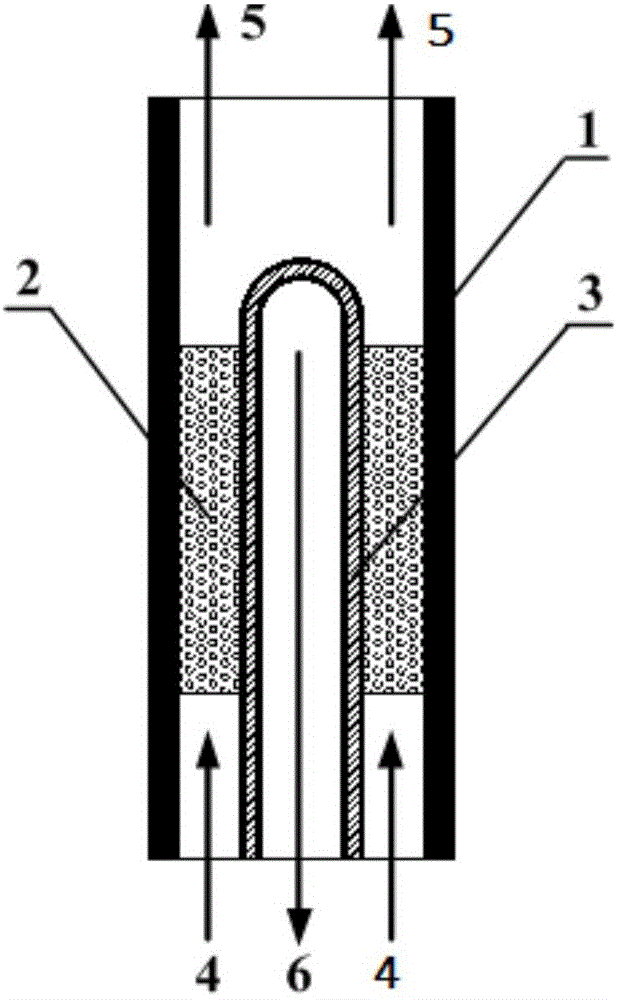

Preparation method of tert-butyl chloride

InactiveCN105399595AIncreased concentration of chloride ionsSolve the use problemHalogenated hydrocarbon preparationMetal chloridePtru catalyst

The invention discloses a preparation method of tert-butyl chloride. The tert-butyl chloride is synthesized through a chlorination reaction of tert-butyl alcohol under the catalysis of a metal chloride. The metal chloride is added as a catalyst in the preparation method, so the method has the advantages of simple production process, less device investment, realization of the reaction rate reaching 95% or above, and realization of the purity of a gas phase reaching 99.5% or above.

Owner:JINAN CHENGHUI SHUANGDA CHEM

Method for leaching copper out of lead matte

ActiveCN106756045AImprove leaching rateImprove recycling ratesProcess efficiency improvementPregnant leach solutionOxygen

The invention discloses a method for leaching copper out of lead matte. The method for leaching the copper out of the lead matte includes the steps that sulfuric acid is added into the lead matter, a sizing agent is obtained, and steam is introduced into the sizing agent to make the temperature of the sizing agent rise; an adding agent is added into the sizing agent, a slurrying material is obtained, it is stopped to introduce steam into the slurrying material, oxygen is introduced into the slurrying material to perform oxidizing leaching till the temperature of the slurrying material is not risen any more, a reaction product sizing agent is obtained and is filtered, and leaching residues and leaching liquid containing copper are obtained. According to the method for leaching the copper out of the lead matte, the lead matter serves as a raw material, the reaction condition is accurately controlled by means of steam heating, and therefore the leaching-out rate of the copper is increased. Thus, the method for leaching the copper out of the lead matte is high in raw material adaptability, and simple in procedure and operation, the copper leaching-out rate is high, pollution to the atmosphere is small, the recycling rate of the copper in the lead matter can be increased, and therefore waste of copper resources can be avoided.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

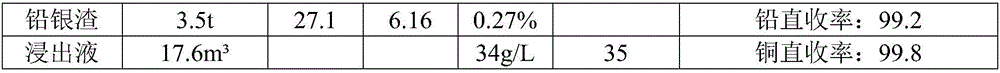

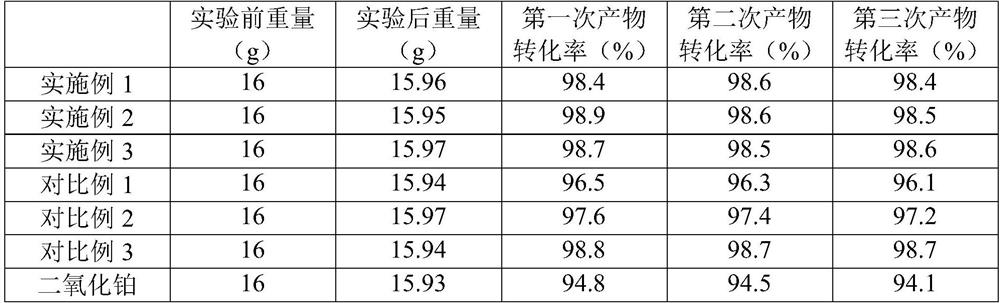

Non-toxic gold leaching agent and preparation method thereof

ActiveCN109971950AWide variety of sourcesSimple processProcess efficiency improvementGeneration rateChemical compound

The invention discloses a non-toxic gold leaching agent and a preparation method thereof. The non-toxic gold leaching agent is primarily prepared from the following components in parts by mass: 5-50 parts of a transitional metal compound, 1-10 parts of organic alkali, 20-100 parts of carbonate and 20-100 parts of an amide compound. The non-toxic gold leaching agent is wide in raw material source,easily available, simple in process and low in cost. By adding organic alkali to promote a positive reaction, the agent generation rate is improved and the agent consumption cost is lowered. In a preparation process, by adopting oxygen-enriching air, the oxygen potential of air in the reaction process can be improved, side reactions are inhibited, the reaction generation rate is improved, and thenon-toxic gold leaching agent is small in consumption of agents and good in gold leaching effect.

Owner:ZIJIN MINING GROUP

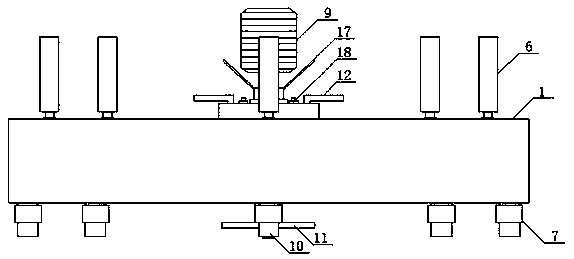

Preparation method of methyltrialkoxysilane

InactiveCN107868101APromote positive responseHigh yieldGroup 4/14 element organic compoundsFertilizerChemistry

The invention provides a method for preparing methyltrialkoxysilane. Anhydrous alcohol is added into reaction vessel A, one end of the airway is connected below the liquid level of reaction vessel A, and the other end of the airway is connected to a In the container B of chlorosilane; heat the absolute alcohol in the reaction container A to 55-63 °C, heat the methyltrichlorosilane in the container B to 62-68 °C, and pass N2 into the container B to react The mixed solution in container A is heated to 75-88°C, refluxed and incubated for 1-4h; after refluxed and incubated for 1-4h, the heating is stopped to obtain the product, which is neutralized with ammonia gas until the pH is 8-9 to obtain methyl trialkoxysilane. In the present invention, under normal pressure and low temperature conditions, feeding dry neutral gas and adopting ammonia gas as a neutralizing agent, the process equipment is simple, easy to operate, low in price, high in yield, and the ammonium chloride produced after neutralization can be It is used as fertilizer and is conducive to green production.

Owner:青岛九洲千和机械有限公司

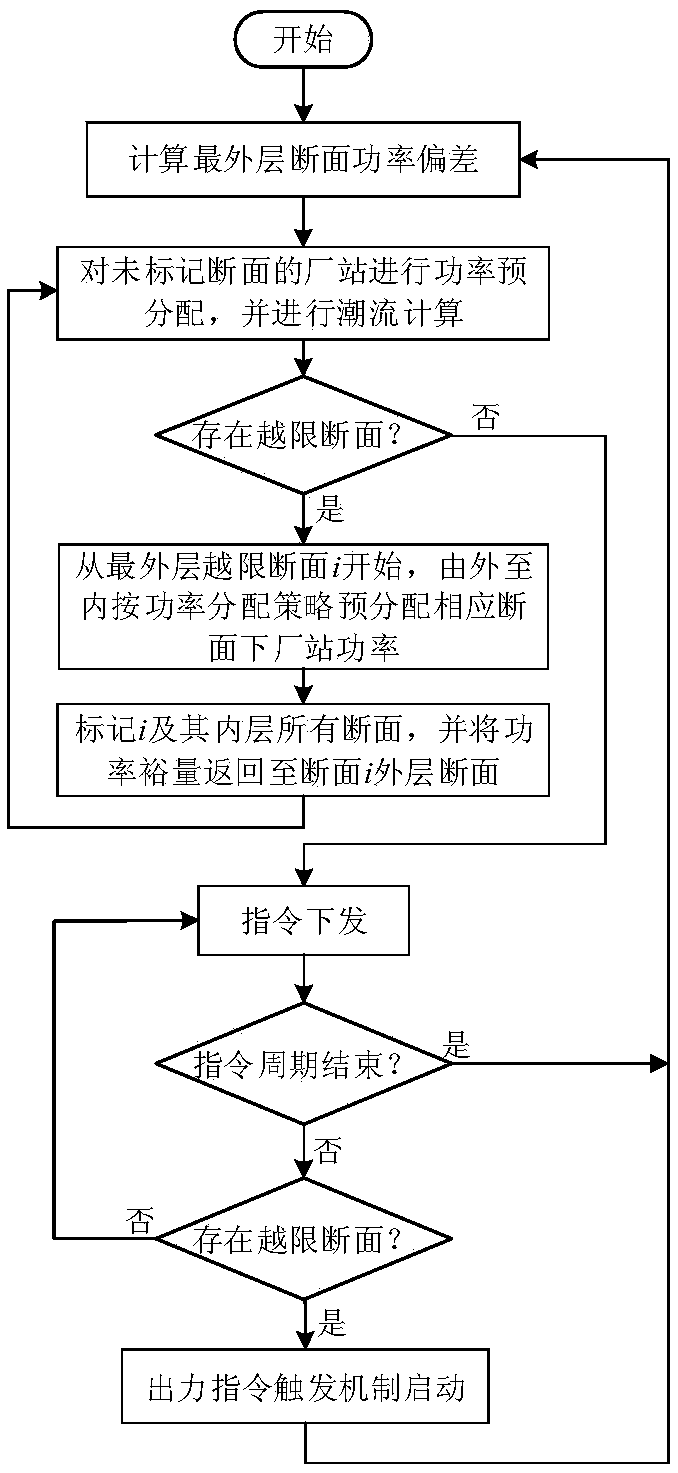

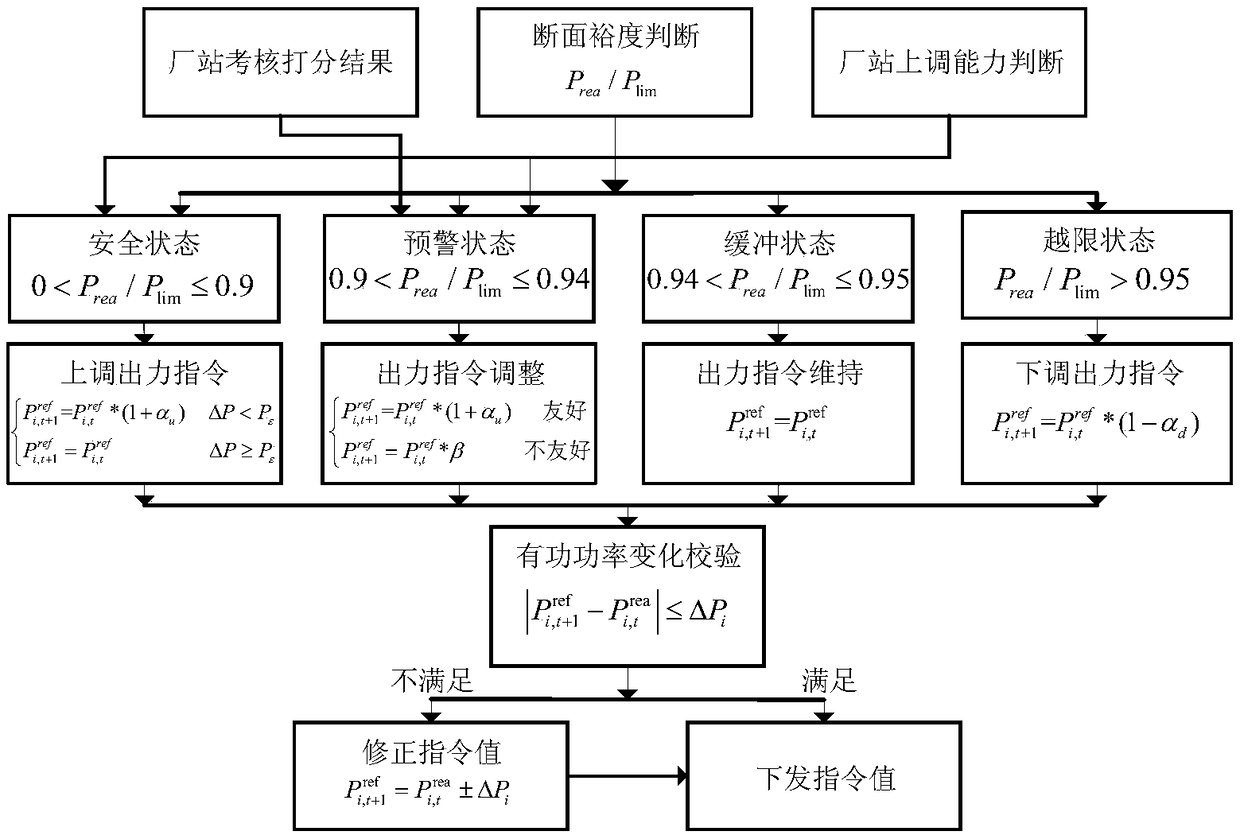

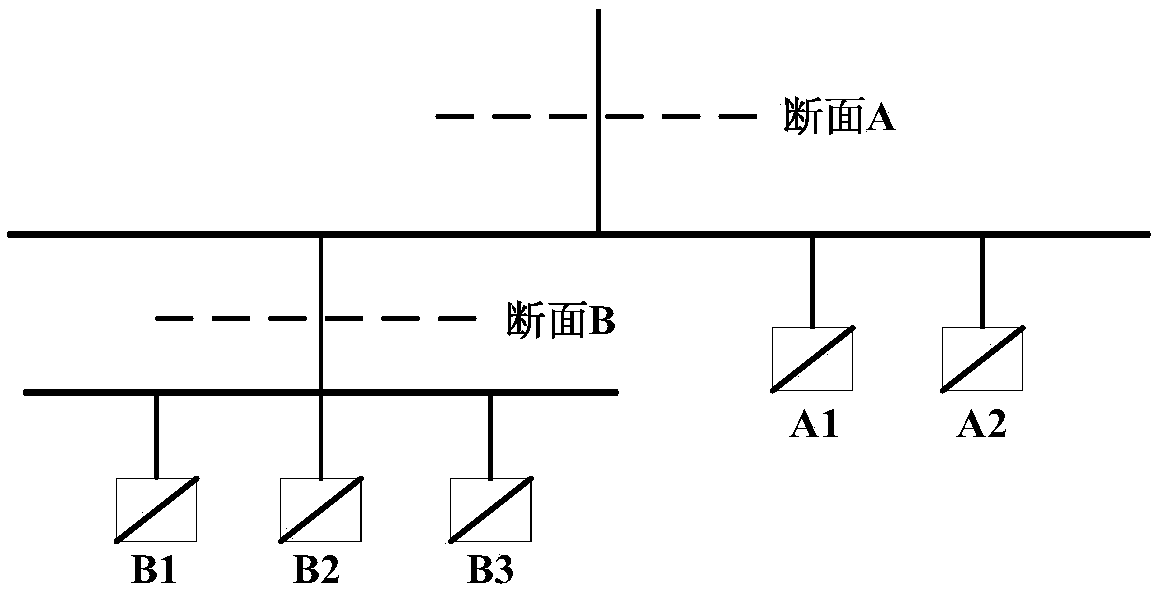

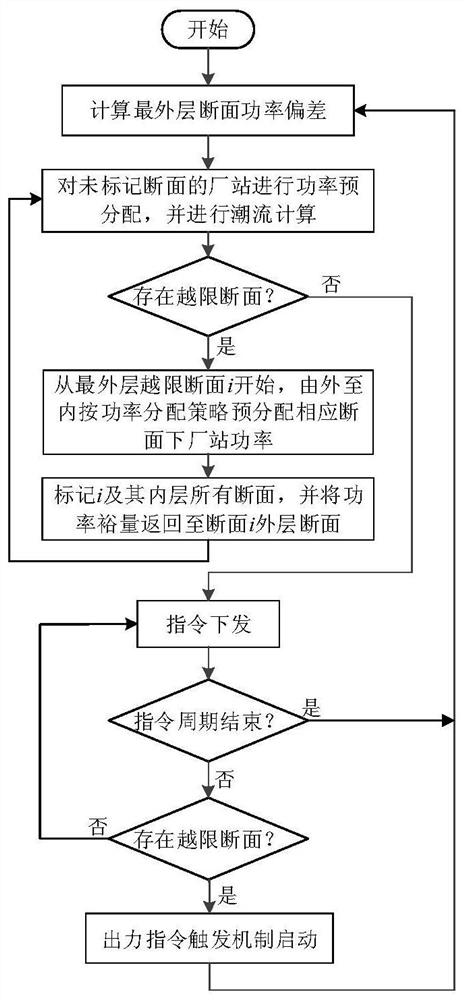

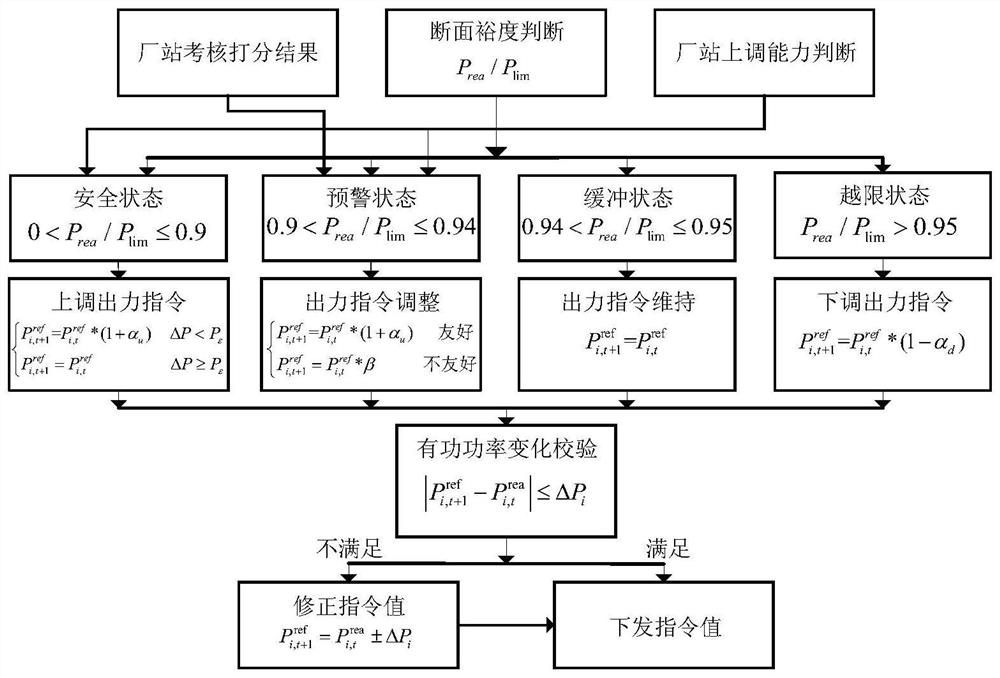

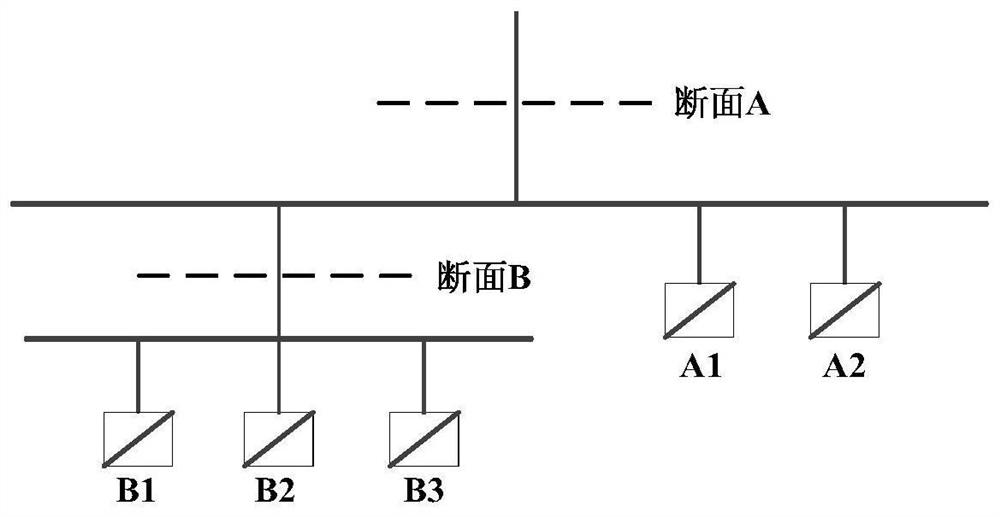

High permeability wind-solar-hydropower active power control method based on sectional safety constraint

ActiveCN108879800AFacilitate responsiveness and fair schedulingEliminate section violationsSingle network parallel feeding arrangementsInstruction cyclePenetration rate

The invention belongs to the technical field of power system economic dispatch, and particularly relates to a high-permeability wind-solar-hydropower active power control method based on a section safety constraint. The control method divides the section into four states: safety, warning, critical buffer and over-limit. The establishment of the critical buffer state can avoid the over-limit causedby factors such as the inaccurate response of the plant station, so as to maximize the output of the plant with the full utilization of the section. At the same time, factory stations access unfriendly can be punished and factory stations access friendly can be rewarded combined with the assessment score of the power station, so as to promote the positive response and fair scheduling of the plantto the instructions. High permeability wind-solar-hydropower active power control method based on sectional safety constraints also considers the trigger mechanism for emergencies, eliminates sectionover-limit due to various events, without waiting for the end of the instruction cycle. A large-scale fair scheduling under multiple nested sections can be ensured by section search method "from outside to inside".

Owner:CHUXIONG POWER SUPPLY BUREAU OF YUNNAN POWER GRID CO LTD

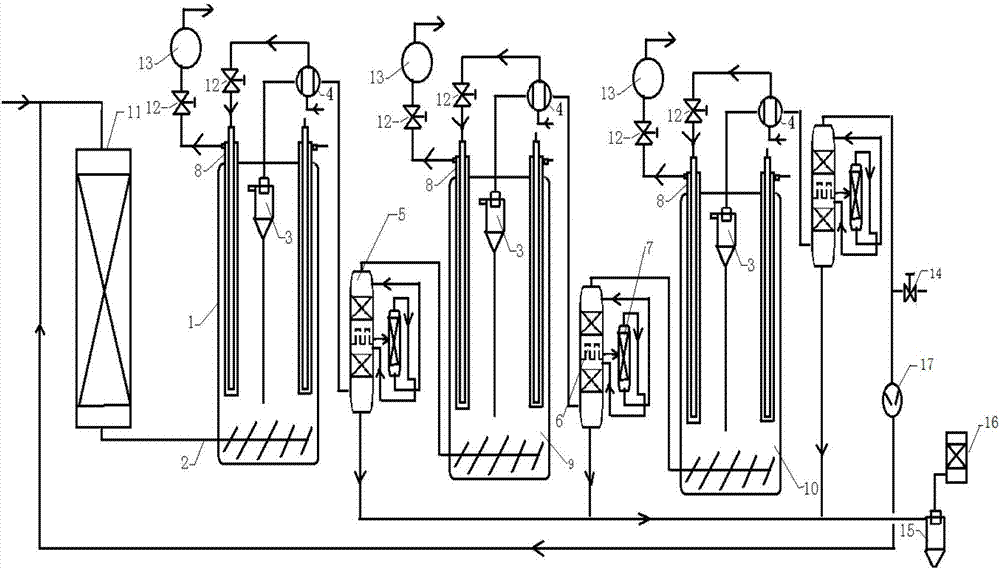

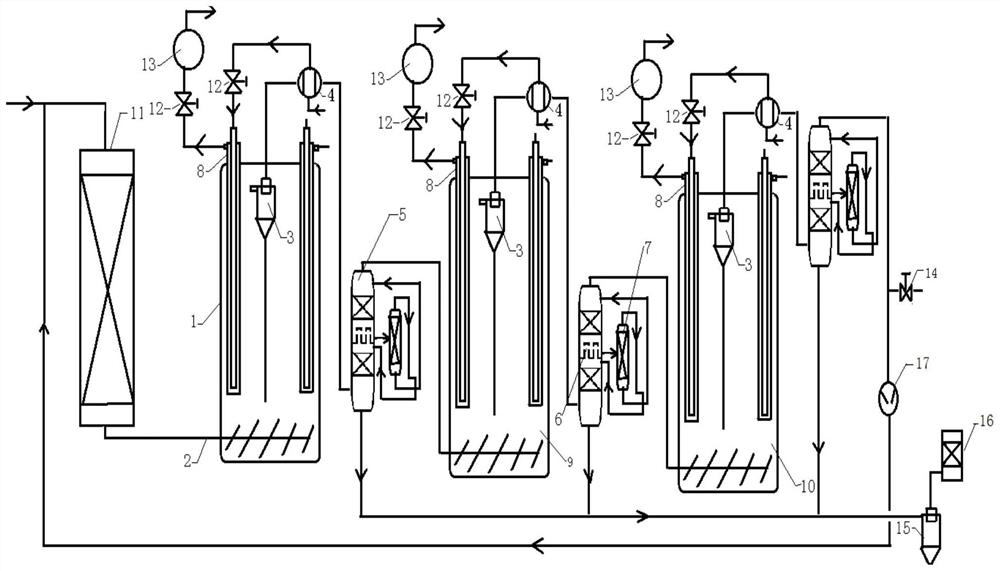

Process using synthetic gas and fluidized bed to prepare methanol based on interstage absorption and separation

ActiveCN107235826AIncrease conversion rate per passIncrease the effective cross-sectional area of the reactionOrganic compound preparationHydroxy compound preparationFixed bedImpurity

The invention provides a process using synthetic gas and fluidized beds to prepare methanol based on interstage absorption and separation. The process is characterized in that a reaction system comprises a methanol fixed bed pre-reactor and the two-stage or multi-stage serially-connected methanol fluidized bed reactors, the purified synthetic gas with the ratio of CO to H2 being 1:2 after conversion is allowed to enter the first-stage fluidized bed reactor with a cooler tube through the methanol fixed bed pre-reactor, part of CO and H2 has average-temperature methanol synthetic reaction with micro-powder methanol catalyst through the cooler tube under 200-280 DEG C and 3.0-7.0Mpa, a gas-solid separator is used to remove the catalyst of the product gas, and the product gas is cooled by a water cooler and enters a methanol absorption and separation tower; the product gas enters the subsequent-stage methanol fluidized bed reactors with cooler tubes after methanol removing, and the process above is repeated; part of separated tail gas is discharged and part of the separated gas is pressurized and returned to serve as the synthetic gas raw material; methanol-rich absorption liquid on the upper section of the absorption tower is subjected to depressurization and flash evaporation to recycle methanol, and the methanol is used as the absorption agent of the lower section of the tower to absorb the methanol and remove fine powder; the methanol discharged from the bottom of the tower is collected and subjected to impurity removing and enters a rectification system.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

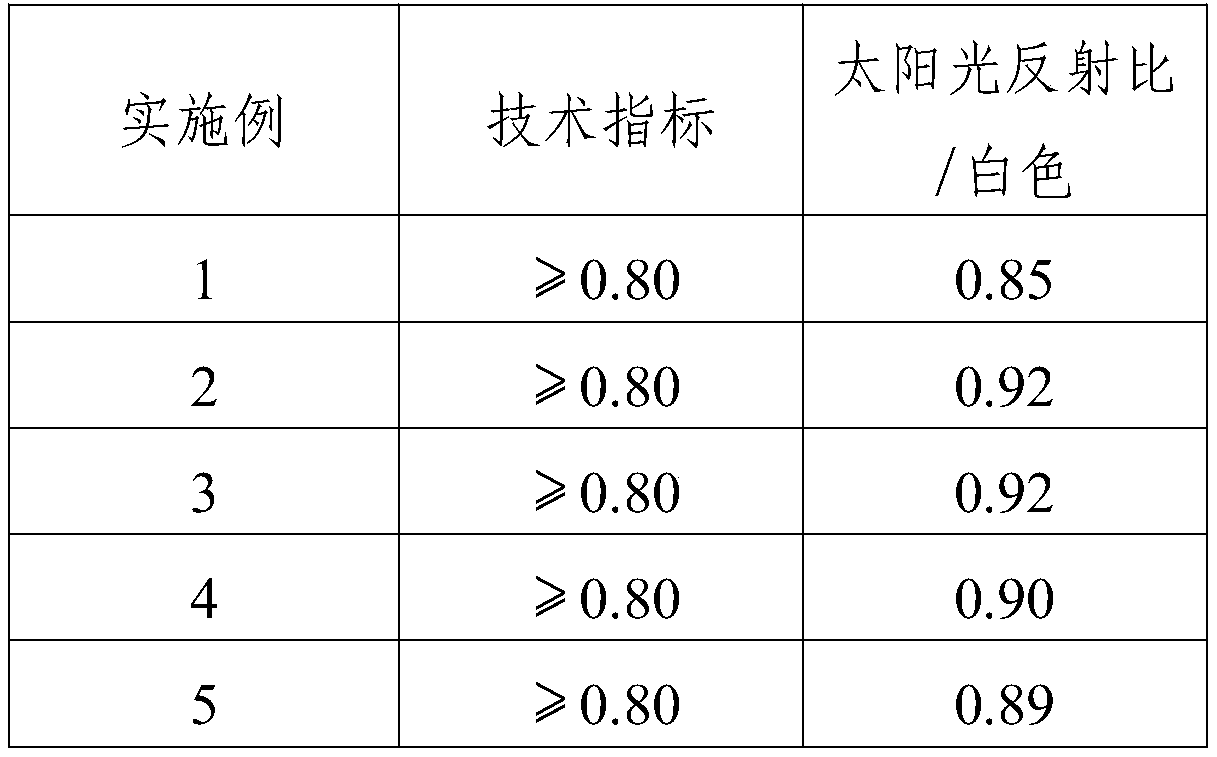

Decorative reflective coating and preparation method thereof

InactiveCN111100517AIncrease deposition rateGood synergyReflecting/signal paintsAcrylic resinLight reflection

The invention provides a decorative reflective coating and a preparation method thereof. The decorative reflective coating comprises the following components in parts by weight: 5-10 parts of modifiedglass beads, 60-80 parts of acrylic resin and 5-10 parts of an emulsifier, the emulsifier being sodium dodecyl benzene sulfonate, 2-3 parts of ceramic beads, 1-2 parts of nano silicon dioxide, 1-2 parts of phenolic resin and 10-15 parts of deionized water, wherein the ratio of the modified glass beads to the ceramic beads is (2-3):1. According to the invention, the hollow glass beads and titaniumtetrabromide react to obtain the modified glass beads; the modified glass beads are coated with a layer of titanium oxide, the titanium oxide has a good thermal isolation effect, so that the coatinghas good light reflection and heat preservation properties at the same time, the added ceramic beads and the modified glass beads act together, the reflection and isolation effects are brought into full play, and the performance of the coating is improved.

Owner:湖南太子化工涂料有限公司

Preparation method and preparation device of lithium difluoro(oxalato)borate

InactiveCN111533763ASolve the complicated purification processEfficient conversionGroup 3/13 element organic compoundsRe crystallizationLithium electrode

The invention discloses a preparation method and a preparation device of lithium difluoro(oxalato)borate, and belongs to the technical field of lithium ion battery electrolyte. The method comprises the following steps: 1) mixing a boron trifluoride complex, a solvent and lithium oxalate, and reacting at 40-110 DEG C for 2-12 hours; 2) carrying out primary vacuum distillation on the reaction liquidcontaining lithium tetrafluoroborate and lithium difluoro(oxalato)borate until the solvent amount is reduced by 1 / 3-1 / 2; 3) condensing and crystallizing the obtained primary distillation residual liquid; 4) mixing the primary distillate with oxalic acid and a catalyst, reacting at 35-110 DEG C for 4-8 hours, carrying out secondary vacuum distillation, and distilling until the primary distillate is reduced by 1 / 3-1 / 2; 5) condensing and crystallizing the secondary distillation residual liquid, and 6) recrystallizing a primary crude product and a secondary crude product of lithium difluoro(oxalato)borate to obtain lithium difluoro(oxalato)borate. The method provided by the invention can reduce side reactions and the number of times of recrystallization, and has the advantages of high yield and high raw material utilization rate.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

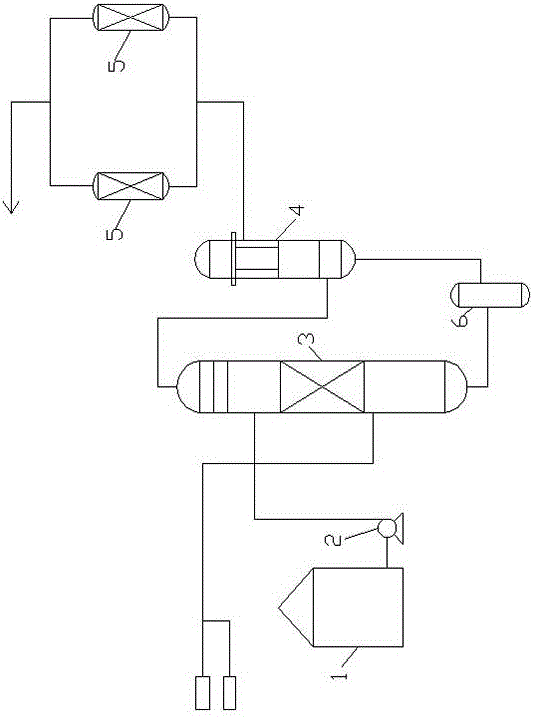

Anthracene oil hydrogenating circulating hydrogen recycling and purifying device

InactiveCN106315511AReduce wasteImprove recycling ratesHydrogen separation using liquid contactDispersed particle separationHydrogen puritySolvent

The invention relates to an anthracene oil hydrogenating circulating hydrogen recycling and purifying device. The device comprises a desulphurization mechanism and a variable pressure adsorption mechanism, wherein the desulphurization mechanism comprises a desulphurization solvent slot, a solvent circulating pump and a desulphurization tower, the desulphurization solvent slot is connected with the upper part of the desulphurization tower by virtue of the solvent circulating pump, an inlet in the lower part of the desulphurization tower is connected with an anthracene oil discharging hydrogen pipeline and a fluidized bed discharging hydrogen pipeline, an outlet in the bottom of the desulphurization tower is connected with a filter, the variable pressure adsorption mechanism is composed of a deep freezer and two variable pressure adsorption tanks which are connected in parallel, a gas outlet in the top of the desulphurization tower is communicated with the deep freezer, an outlet of the deep freezer is connected with the variable pressure adsorption tank which are connected in parallel, and an outlet in the bottom of the deep freezer is connected with the filter. The anthracene oil hydrogenating circulating hydrogen recycling and purifying device greatly improves anthracene oil hydrogenating circulating hydrogen recovery utilization rate, raw material hydrogen amount of a hydrogenating device is saved through recycling, and hydrogen purity of a reaction system is improved, intra-system hydrogen partial pressure is guaranteed, forward reaction of a catalyst is promoted, and the device provided by the invention has the advantages of reasonable design, easy operation, energy conservation and environmental protection.

Owner:HEBEI XINQIYUAN ENERGY TECH DEV

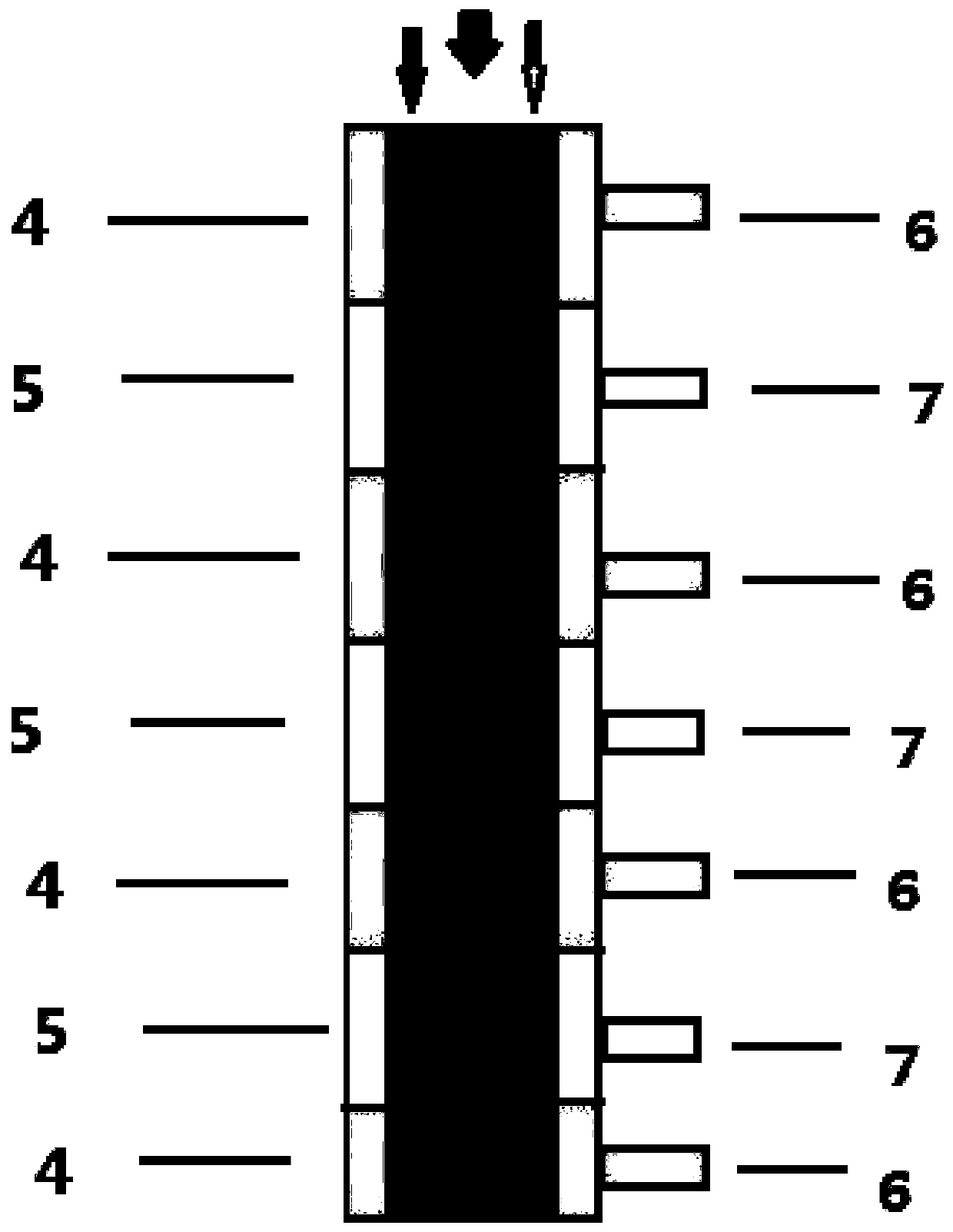

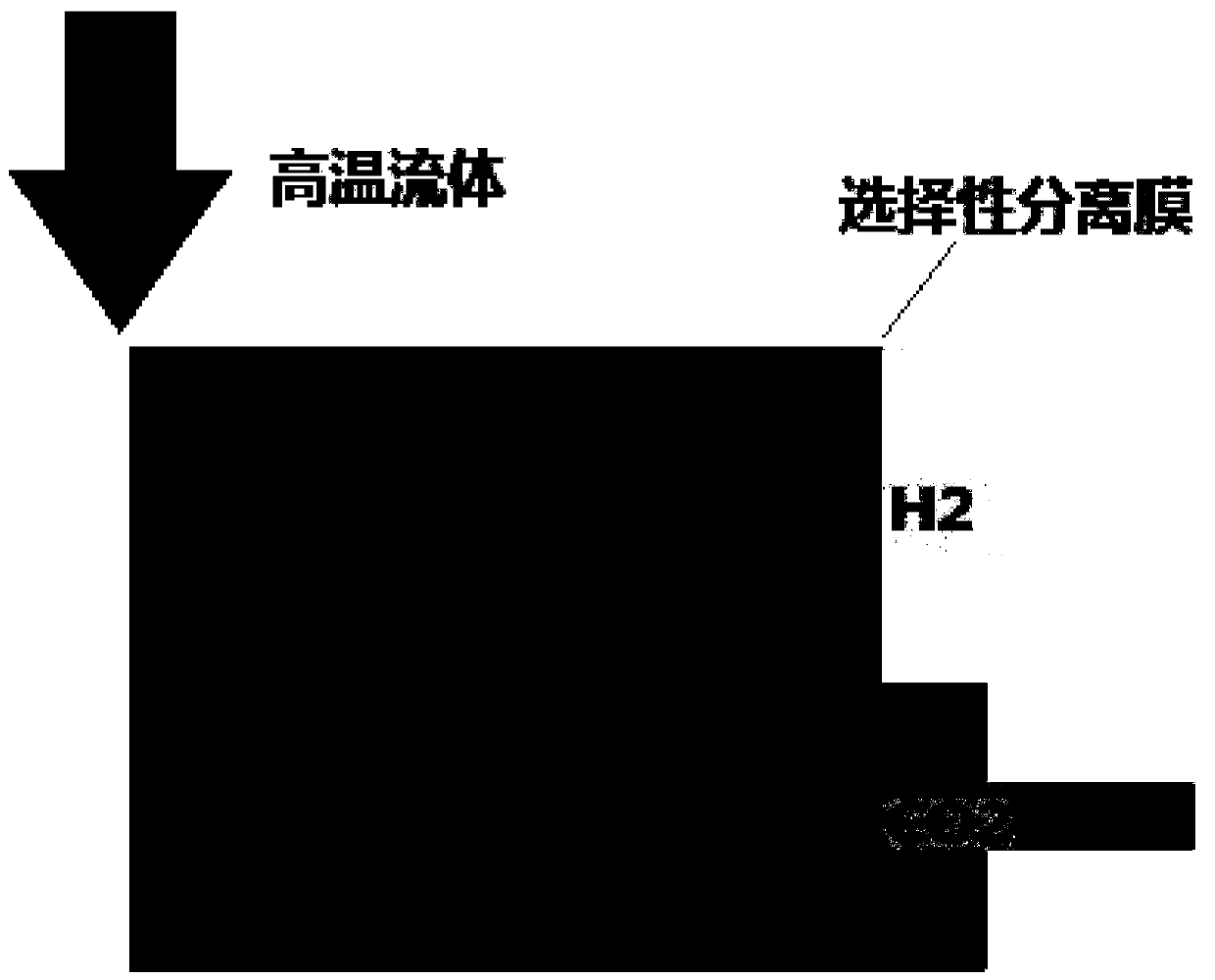

Online separation reforming hydrogen production method capable of enhancing reaction efficiency and device for realizing method

InactiveCN110902652AReduce volumeReduce weightHydrogen/synthetic gas productionHydrogen separation by diffusionPtru catalystEngineering

The invention discloses an online separation reforming hydrogen production method capable of enhancing reaction efficiency and a device for realizing the method. A reactor of the method is composed ofinner, middle and outer concentric circular tubes made of three different materials, an upper end cover and a lower end cover, the three concentric circular tubes form three cavity channels, namely an inner cavity, a middle cavity and an outer cavity, and the upper end cover and the lower end cover are installed on the upper portion and the lower portion of the cavity channels. The lower end cover seals the lower ends of the middle cavity and the outer cavity, and the upper end cover is provided with a plurality of holes for providing a high-temperature fluid inlet for the inner cavity and providing an air inlet for the middle cavity. A high-temperature fluid flows into the inner tube to provide energy for reaction. The outer wall surface of the inner tube is coated with a catalyst. A reactant gas is introduced into the middle cavity channel; and the reactant gas and the catalyst are subjected to catalytic reaction. The middle tube is prepared by adopting different separation membranes, so that a gas product is separated into the outer cavity. And the outer cavity channel is correspondingly isolated into different gas product areas. By adopting the method provided by the invention, the conversion rate of the reactant can be remarkably improved, and the volume and weight of the whole reforming reaction system are reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

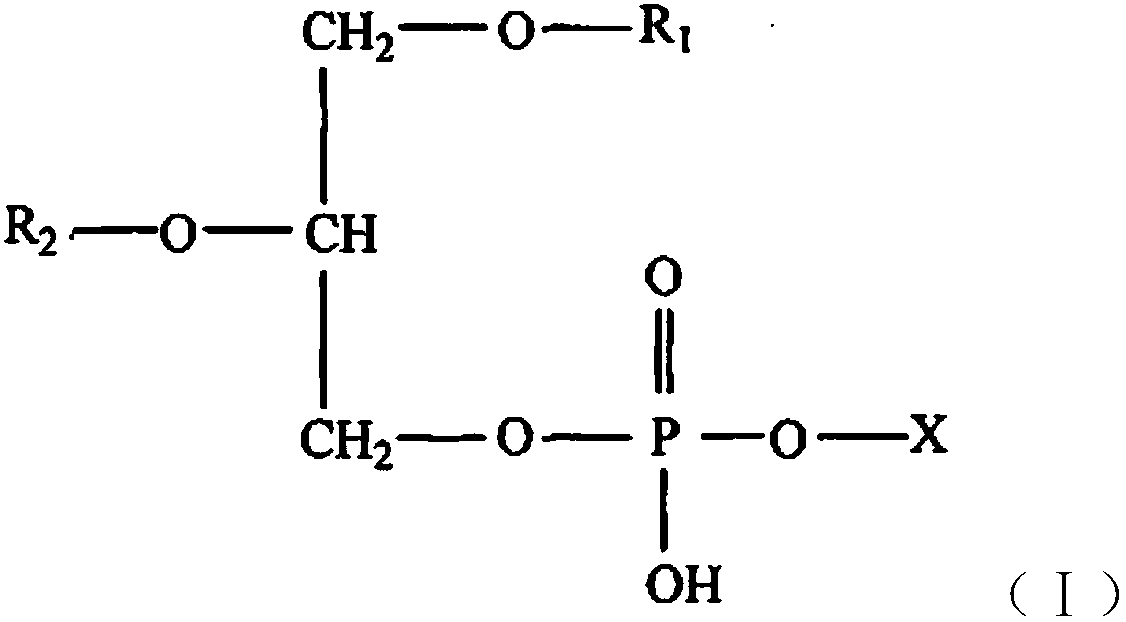

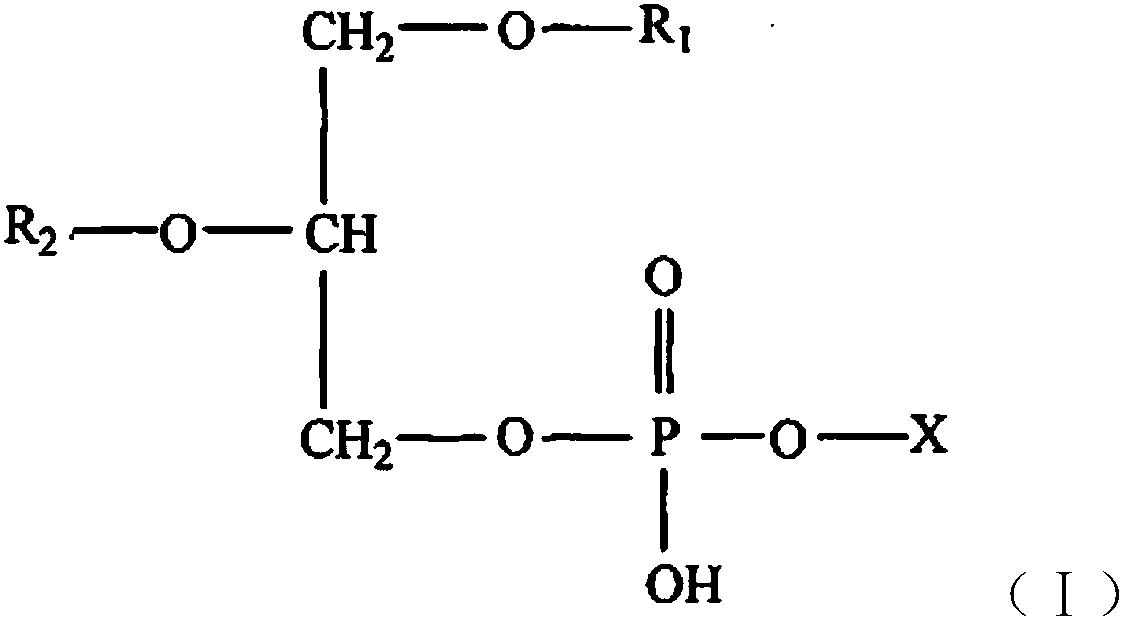

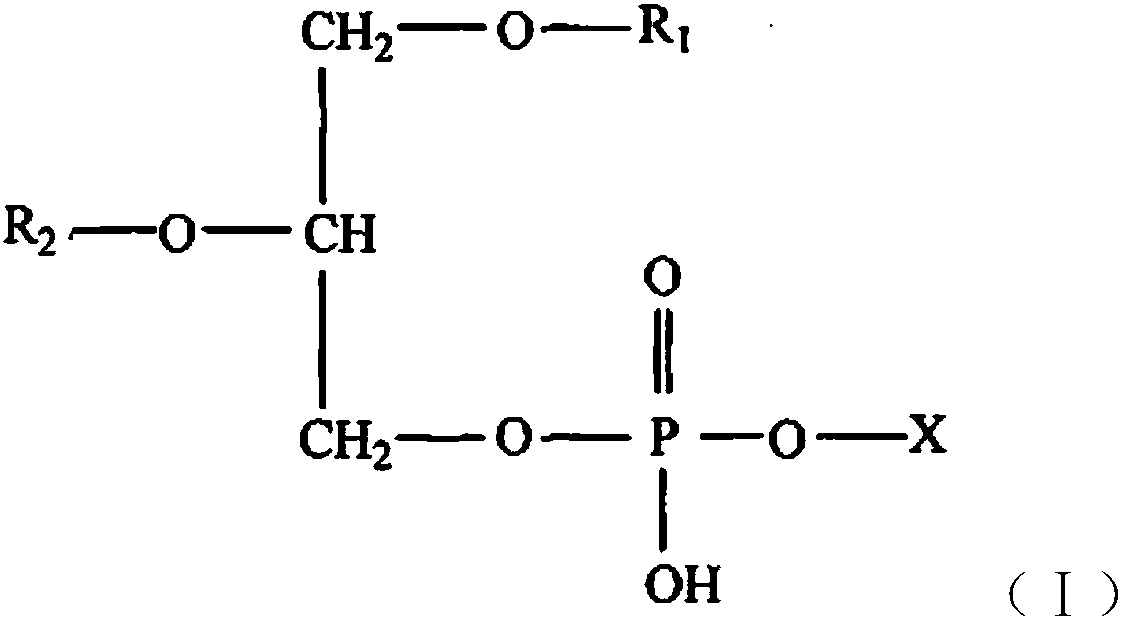

Phospholipid substance containing Omega-3 fatty acid and preparation method thereof

InactiveCN109280060APhysiological function is clearGood application effectGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsFood additiveIodo fatty acid

The invention provides a phospholipid substance containing Omega-3 fatty acid and a preparation method thereof. In the phospholipid substance, the content of phospholipid is more than 80%. Main fattyacid in the phospholipid is one of DHA or EPA, wherein the content of the main fatty acid is 50-90% and the content of the other one is less than 1%. The phospholipid substance is high in phospholipidcontent, high in Omega-3 fatty acid purity in the phospholipid, single in composition and clear in function, and can be applied in the field of specific medicine, dietary supplements and food additives. Meanwhile, the invention also provides a method for preparing the phospholipid substance. The method is simple in process and low in cost, is suitable for industrial production, and makes up for shortcomings of conventional preparation methods.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Synthetic gas fluidized bed methanol production process based on interstage absorption and separation

ActiveCN107235826BIncrease conversion rate per passIncrease the effective cross-sectional area of the reactionOrganic compound preparationHydroxy compound preparationPtru catalystFluidized bed

The invention provides a synthetic gas fluidized bed methanol production process based on interstage absorption and separation. The reaction system is composed of a methanol fixed bed pre-reactor and a two-stage or multi-stage methanol fluidized bed reactor in series. The converted CO / H 2 The 1:2 purified syngas passes through the methanol fixed-bed pre-reactor and then enters the first-stage methanol fluidized-bed reactor with heat extraction pipes, part of CO and / H 2 With the fine powder methanol catalyst at 200-280℃ and 3.0-7.0Mpa, the homogeneous methanol synthesis reaction occurs through the heat exchange of the heat pipe. After the product gas is passed through the gas-solid separator to remove the catalyst, it is cooled by a water cooler and enters the methanol absorption and separation tower. ; After demethanolization, the product gas enters the methanol fluidized bed reactor with heat pipes at subsequent stages, and repeats the above process; finally, part of the separated tail gas is held and partly pressurized and returned as a raw material for synthesis gas; the upper part of the absorption tower is rich in methanol The absorption liquid is depressurized and flashed to recover methanol, which is used as an absorbent in the lower section of the tower to absorb methanol and remove fine powder; methanol is removed from the bottom of the tower and collected to remove impurities before entering the rectification system.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

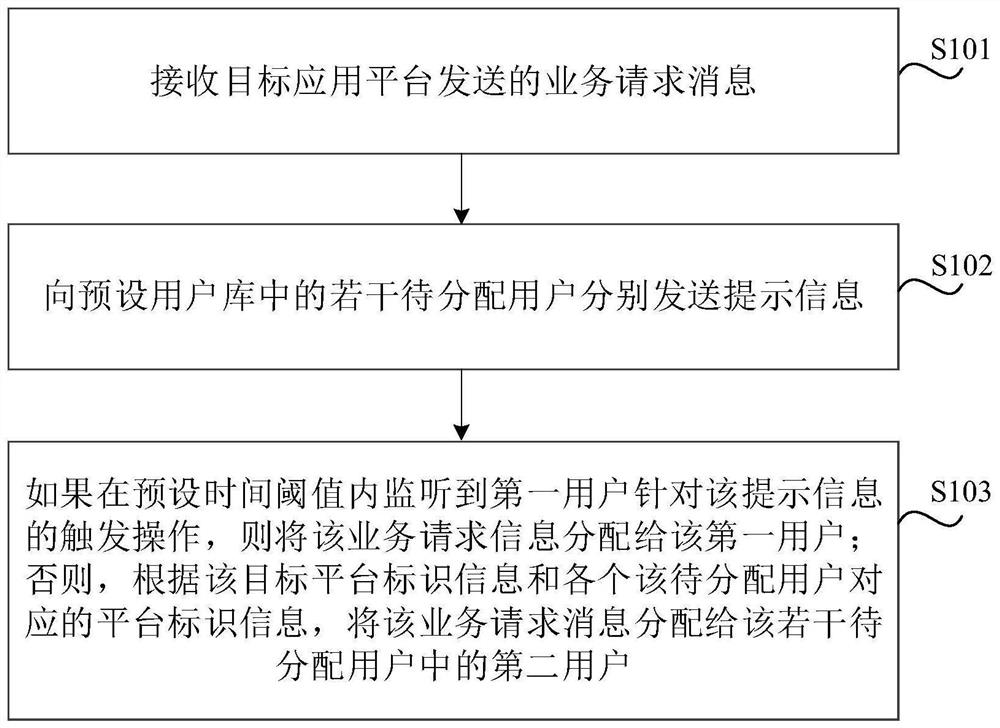

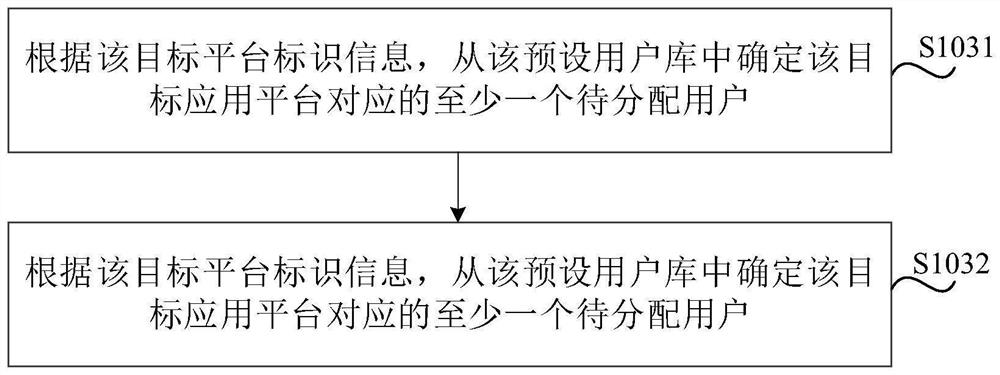

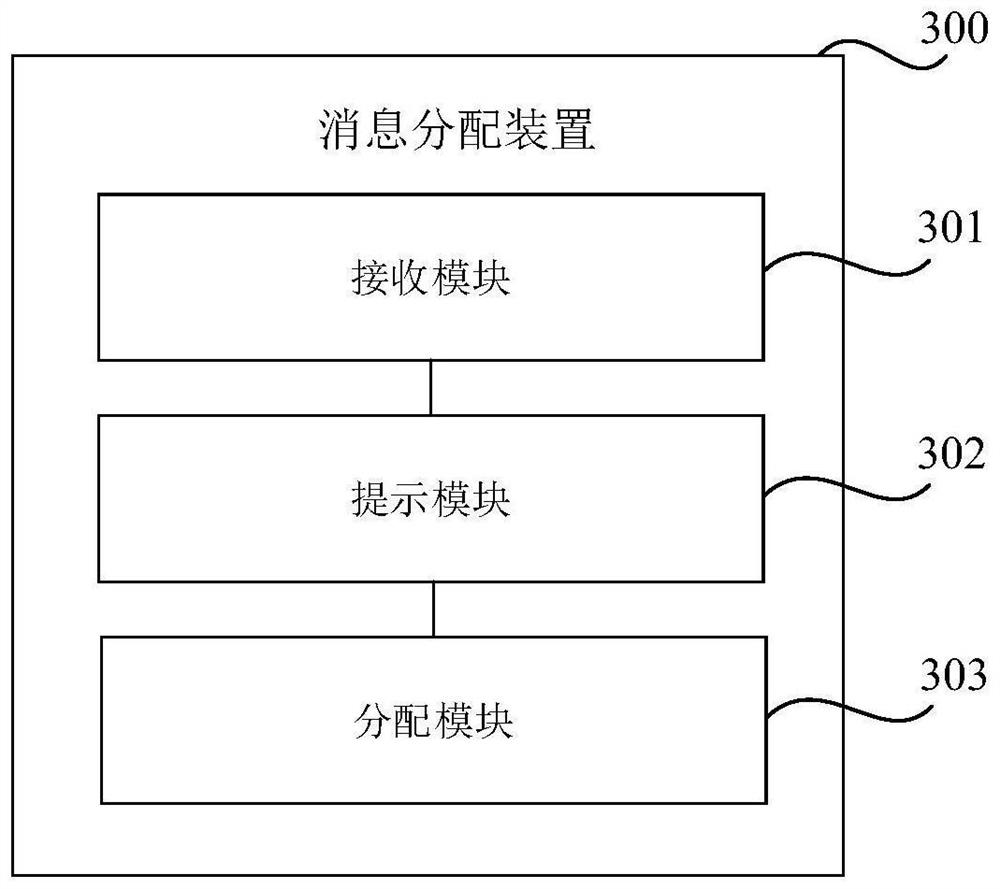

Message distribution method and device, electronic equipment and storage medium

PendingCN114296968AImprove processing efficiencyTimely processingInterprogram communicationDistribution methodEngineering

The invention relates to a message distribution method and device, electronic equipment and a storage medium, and the method comprises the steps: receiving a service request message sent by a target application platform, and the service request message comprises the target platform identification information of the target application platform; respectively sending prompt information to a plurality of to-be-distributed users in a preset user library; the preset user library comprises a plurality of to-be-distributed users and platform identification information corresponding to the to-be-distributed users; if a trigger operation of a first user for the prompt information is monitored within a preset time threshold, distributing the service request information to the first user; and otherwise, allocating the service request message to a second user in the plurality of users to be allocated according to the target platform identification information and the platform identification information corresponding to each user to be allocated.

Owner:BEIJING JINTI TECH CO LTD

Catalytic Synthesis of Oxalic Acid Combined Process of Batch Reaction and Continuous Reaction Rectification

ActiveCN104892400BAvoid using effectsEasy to operateChemical industryPreparation from carboxylic acid esters/lactonesSide reactionDimethyl oxalate

The invention discloses an intermittent reaction-continuous reaction rectification combined process for catalytic synthesis of oxalic acid. The process particularly comprises the following steps: (1) continuously feeding materials into a reactive dividing-wall rectification tower in a double batch reactor switching mode; (2) enabling dimethyl oxalate and water to enter a batch reactor to react primarily, wherein the equilibrium conversion rate reaches 50%-60%; and (3) continuously feeding reaction solution into a left-side reaction section ( zone b) of the reactive dividing-wall rectification tower from an upper feeding opening, continuously feeding normal-temperature water into the reactive dividing-wall rectification tower from a lower feeding opening of the zone b, and continuously discharging methyl alcohol produced in the reaction process from the tower top, wherein due to the discharging of methyl alcohol, the reaction proceeds to production of oxalic acid until dimethyl oxalate is completely hydrolyzed and the conversion rate can reach 99.5% or above. By virtue of the reactive dividing-wall rectification tower, the synthesis reaction and product separation and purification are implemented in the same tower, the existing process flow is simplified, and energy consumption and investment can be lowered. The intermittent reaction-continuous reaction rectification combined process for catalytic synthesis of oxalic acid has the characteristics of no addition of extra additives, high reaction speed, high conversion rate, low water-ester ratio, simple product separation operation, low energy consumption and the like.

Owner:FUZHOU UNIV

A method and device for improving the desulfurization reaction rate of ore pulp by using surfactant

ActiveCN111229009BGood suspensionReduce usageGas treatmentDispersed particle separationActive agentReaction rate

Owner:KUNMING UNIV OF SCI & TECH

A high-permeability wind-solar-hydropower active power control method based on cross-section safety constraints

ActiveCN108879800BFair scheduling implementationPromote positive responseSingle network parallel feeding arrangementsPower stationElectricity system

The invention belongs to the technical field of power system economic dispatching, and specifically relates to a high-permeability wind-light-hydropower active power control method based on cross-section safety constraints. The control method divides the cross-section into four states: safety, early warning, critical buffer and limit violation , where the establishment of the critical buffer state can avoid over-limits caused by factors such as inaccurate response of the plant and station, so as to realize the maximum output of the plant and station under the fully utilized section; at the same time, combined with the evaluation and scoring of the power plant and station, it can punish the inappropriate access Friendly factories and stations, and rewards for accessing friendly factories and stations, so as to promote positive response and fair scheduling of factories and stations to instructions; this method also considers the trigger mechanism of emergencies, eliminating the cross-section limit caused by various events, without waiting The end of the instruction cycle ensures the safety of the section; the "outside-to-inside" section search method is adopted to ensure a large-scale fair scheduling under multiple nested sections.

Owner:CHUXIONG POWER SUPPLY BUREAU OF YUNNAN POWER GRID CO LTD

Preparation method of isopropanol

ActiveCN114173895AImprove separation efficiencySave energyEntertainmentOrganic compound preparationIsopropanololPhase reaction

The present invention relates to a method for producing isopropanol, the method comprising: supplying a supply stream comprising a propylene monomer and water to a reaction unit to cause the propylene monomer and water to react with each other, thereby producing a reaction product comprising isopropanol, propylene monomer and water; feeding each of a first discharge stream comprising a gas-phase reaction product discharged from the reaction unit and a second discharge stream comprising a liquid-phase reaction product discharged from the reaction unit to a stripping column; and separating from the stripping column a top drain stream comprising propylene monomer and a bottom drain stream comprising water and isopropanol wherein the first drain stream is condensed through a first heat exchanger and fed to the stripping column in a liquid phase.

Owner:LG CHEM LTD

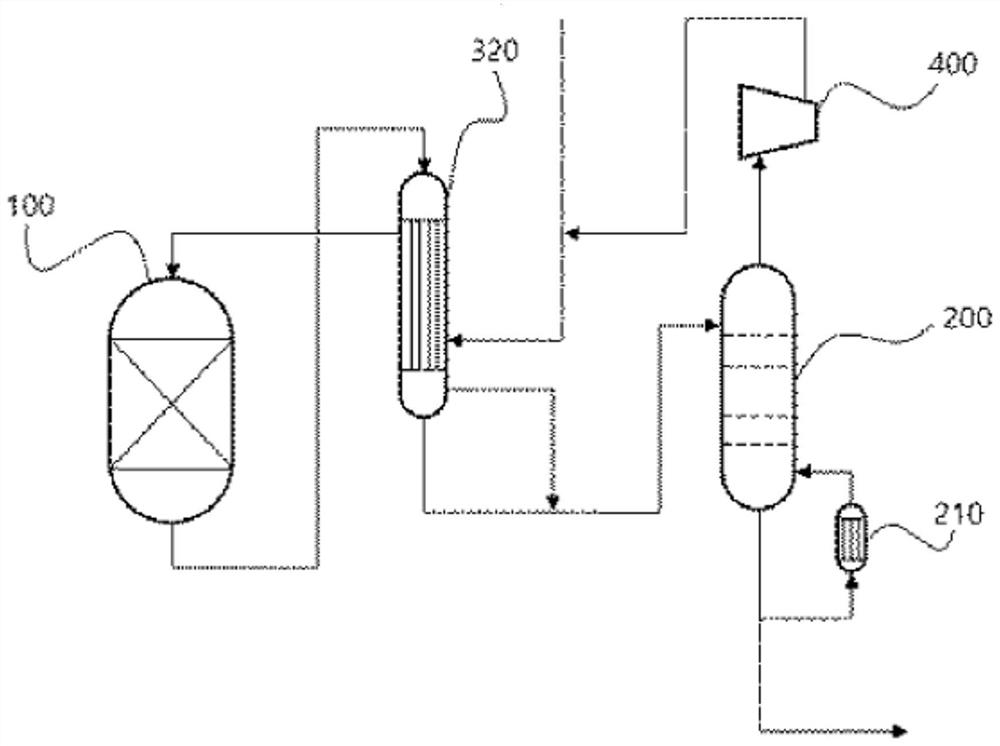

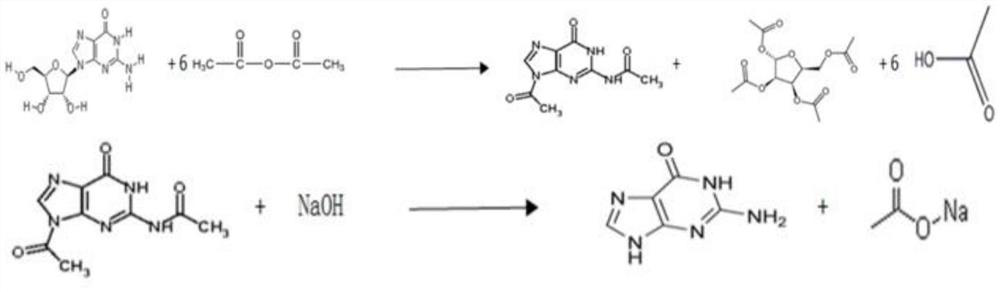

A kind of method utilizing guanosine to synthesize guanine

ActiveCN111440170BMild conditionsImprove securityEsterified saccharide compoundsSugar derivativesAcetic acidAcetic anhydride

The invention belongs to the field of organic synthesis, and in particular relates to a method for synthesizing guanine by using guanosine. In the present invention, acetic anhydride, guanosine and boric acid are reacted to obtain diacetylguanine and tetraacetylribose; diacetylguanine is reacted under alkaline conditions to obtain guanine; the method has mild conditions when preparing diacetylguanine, and guanine When reacting with acetic anhydride, guanosine needs to absorb heat when breaking the chain, and release heat instantly when breaking the chain. This scheme neutralizes the exotherm, improves safety, mid-term distillation, steams acetic acid, promotes positive reaction, increases yield, and evaporates solvent reduced solubility. The invention utilizes guanosine to synthesize guanine, wherein the yield of guanine is over 95%, and the purity is over 99.5%. The yield of tetraacetyl ribose reaches over 95%, and the purity is over 99.5%.

Owner:通辽德胜生物科技有限公司

Method and device for increasing ore pulp desulfurization reaction rate by using surfactant

ActiveCN111229009AGood suspensionReduce usageGas treatmentDispersed particle separationMass transfer resistanceFlue gas

The invention discloses a method and device for improving the ore pulp desulfurization reaction rate by using a surfactant. The method comprises the following steps: S1, preparing phosphoric ore pulpwith a liquid-solid ratio of 30-50%, and uniformly mixing the surfactant in the phosphoric ore pulp to obtain absorption slurry; and S2, uniformly mixing flue gas to be desulfurized with oxygen, fullymixing the mixed gas with the absorption slurry obtained in the step S1 for reaction, and discharging the treated flue gas. The phosphorus ore pulp mixed with the surfactant is used for flue gas desulfurization, turbulence resistance reduction can be achieved, mass transfer resistance of SO2 absorption is reduced, the suspension property of the ore pulp is enhanced, and therefore the reaction ispromoted, and the desulfurization reaction rate and desulfurization efficiency are remarkably improved. The device provided by the invention has the advantage of rapid reaction, has an automatic deslagging function, does not influence flue gas treatment, and is convenient and efficient to operate.

Owner:KUNMING UNIV OF SCI & TECH

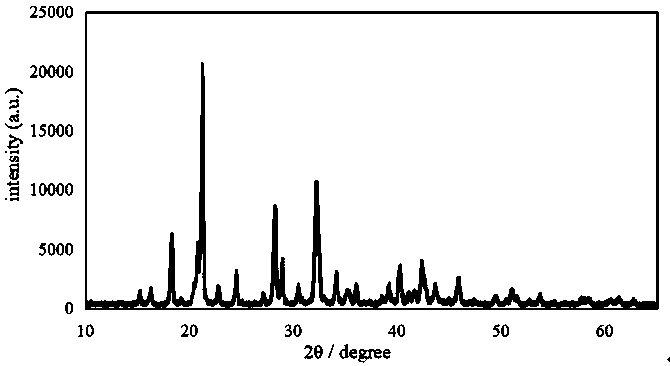

A kind of graphene catalyst supported by metal particles and preparation method thereof

InactiveCN112536030BReduce generationPromote positive responseCatalyst protectionOrganic compound preparationDoped graphenePtru catalyst

The invention discloses a graphene catalyst supported by metal particles and a preparation method thereof, belonging to the technical field of catalysts. The present invention adds platinum dioxide, graphene, diphenylamine, bromobenzene, and carbon nanotubes, wherein platinum dioxide and carbon nanotubes are doped, and graphene is combined with diphenylamine and triphenylamine after halogenation. Graphene and carbon nanotubes were hot pressed to form a new catalyst. In the present invention, the combination of carbon nanotubes and graphene is selected on the carrier, which increases the contact area between the catalyst and the two reaction substances. On the other hand, it can increase the thermal stability of the catalyst. Platinum dioxide is selected as the catalyst in the design. Added diphenylamine and halogen, on the one hand, can enhance the activity of platinum dioxide, on the other hand, can increase the stability of the catalyst, and improve the life and effect of the catalyst.

Owner:浙江胜烯环境科技有限公司

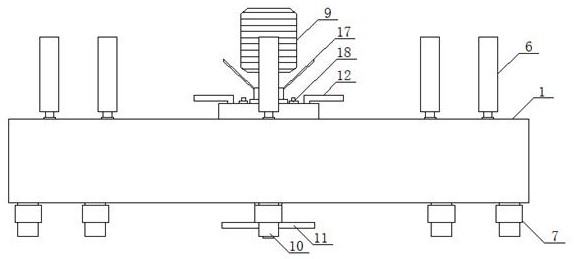

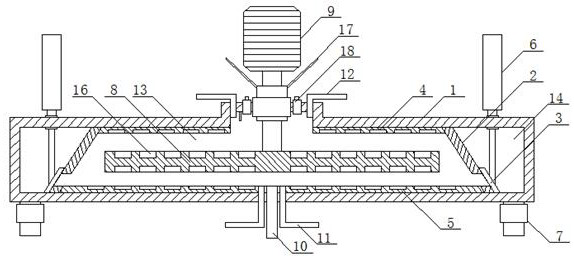

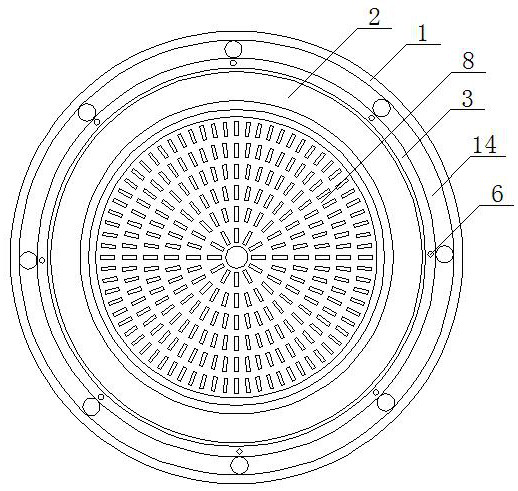

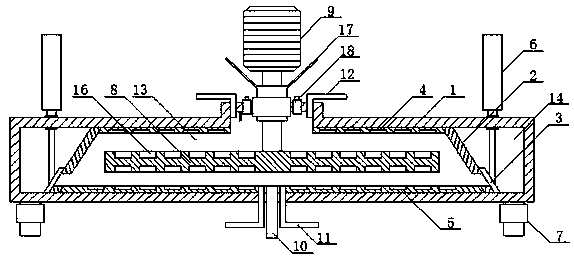

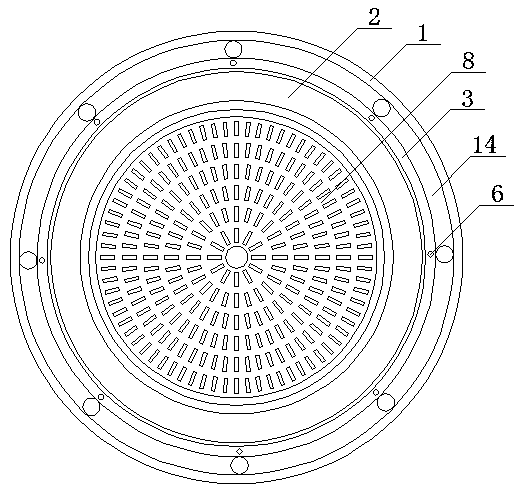

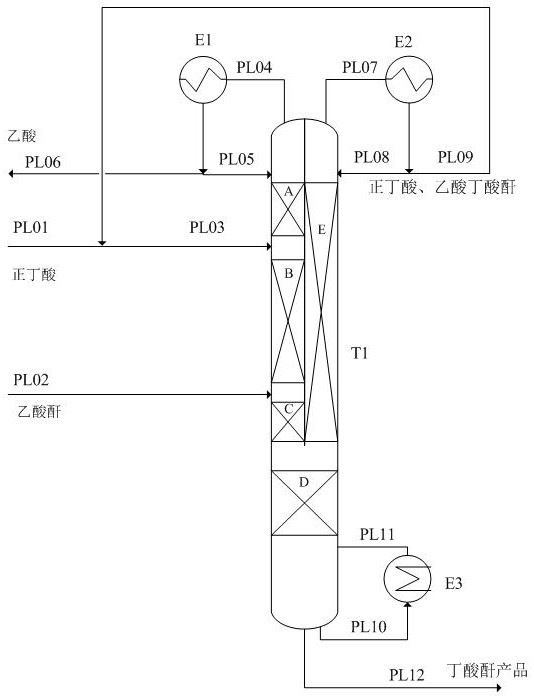

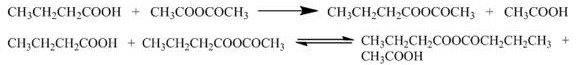

Production method for producing butyric anhydride through dividing wall reaction rectification

PendingCN114805057APromote positive responseReduce energy consumptionOrganic compound preparationCarboxylic acid anhydrides preparationAcetic acidN-Butyric acid

The invention relates to a production method for producing butyric anhydride through dividing wall reaction rectification, which comprises the following steps of: feeding a raw material n-butyric acid from an upper feeding hole of a main tower of a dividing wall reaction rectification tower, and feeding a raw material acetic anhydride from a lower feeding hole of the main tower of the dividing wall reaction rectification tower; the raw materials n-butyric acid and acetic anhydride are subjected to acylation reaction in the middle of the main tower of the partition reaction rectifying tower and vapor-liquid mass transfer; condensing mixed steam of n-butyric acid and a small amount of acetic acid-butyric anhydride obtained at the top of the auxiliary tower of the dividing wall reaction rectifying tower through a condenser, and reacting at a feeding hole in the main tower of the dividing wall reaction rectifying tower; the butyric anhydride product is discharged from the tower kettle of the dividing wall reaction rectifying tower. According to the invention, the acylation reaction and the light component removal of the product are integrated into the same tower, and the equipment has the advantages of high conversion rate, high selectivity, low energy consumption, low equipment investment and the like.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com