A method for leaching copper from lead matte

A lead matte and leaching technology, which is applied in the field of leaching copper from lead matte, can solve the problems of lead smelting enterprises such as economic loss, low metal recovery rate, and low valuation coefficient, and solve the problems of large equipment investment, small air pollution, The effect of simple process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

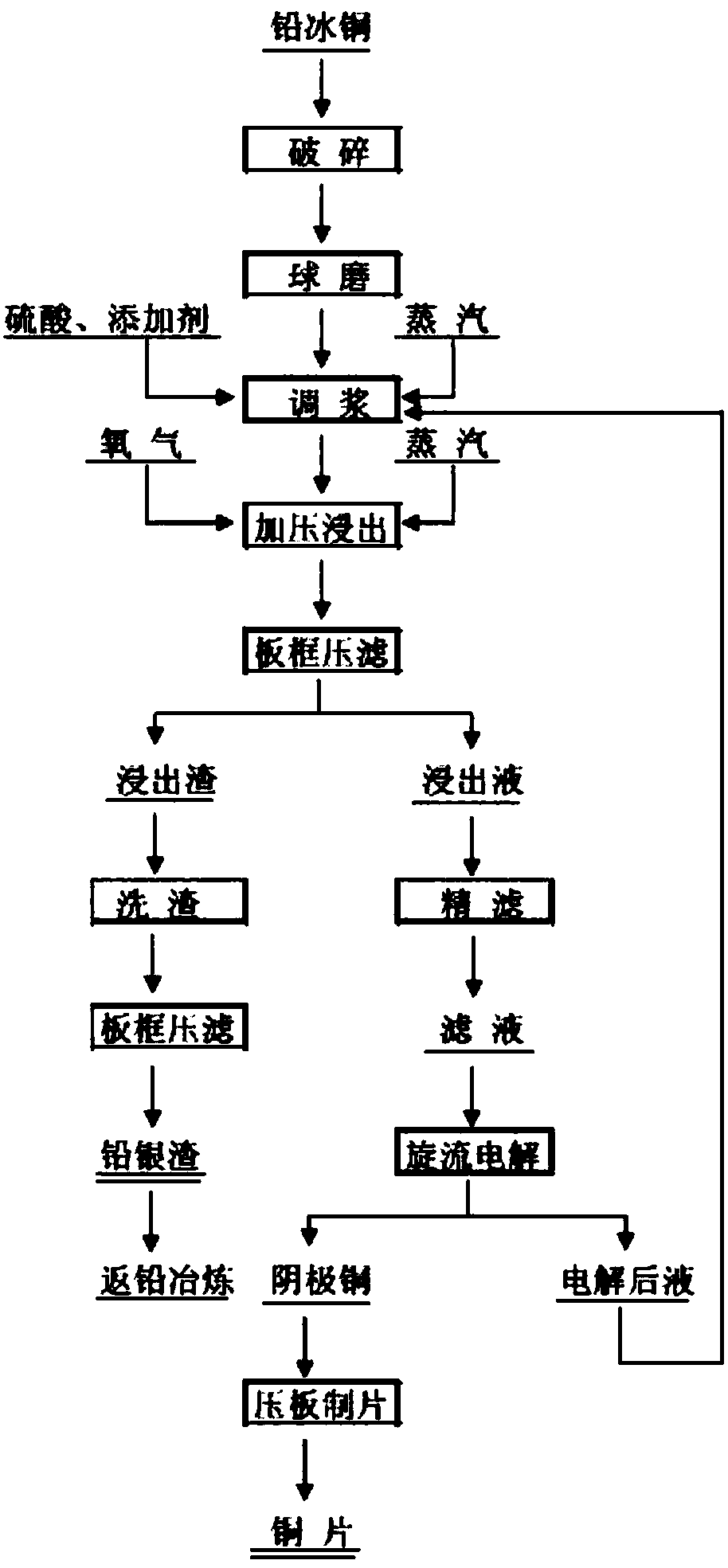

[0025] see figure 1 , which is a process flow diagram of leaching copper from lead matte according to an embodiment of the present invention. As an embodiment of the present invention, the method for leaching copper from lead matte includes the following steps.

[0026] 1) Weigh 2.3 tons of lead matte, after successively crushing by tiger's mouth and crushing by ball mill, lead matte powder is obtained; wherein, by weight, the lead matte composition is: Pb: 2.45%, S: 17.62%, Cu: 26.81 %, Fe: 21.16%.

[0027] 2) Add sulfuric acid to the lead matte powder, wherein the concentration of sulfuric acid is 150g / L, and the addition amount is 18.4 cubic meters, stir evenly to obtain a slurry; pass steam into the slurry to raise the temperature of the slurry to 60°C , while stirring for 1 hour; 2 minutes before pumping into the high-pressure reactor, add 30Kg calcium lignosulfonate to the slurry, stir evenly, and obtain a pulped material; it should be noted that this step can be carri...

Embodiment 2

[0035] see figure 1 , which is a process flow diagram of leaching copper from lead matte according to an embodiment of the present invention. As an embodiment of the present invention, the method for leaching copper from lead matte includes the following steps.

[0036] 1) Weigh 2.5 tons of lead matte, after successively crushing by tiger's mouth and pulverizing by ball mill, lead matte powder is obtained; wherein, by weight, the lead matte composition is: Pb: 6.34%, S: 9.35%, Cu: 24.24 %, Fe: 22.03%.

[0037] 2) Add sulfuric acid to the lead matte powder, wherein the concentration of sulfuric acid is 140g / L, and the addition amount is 17.5 cubic meters, and stir evenly to obtain a slurry; pass steam into the slurry to raise the temperature of the slurry to 65°C , while stirring for 1.2 hours; 1 minute before pumping into the autoclave, add 40Kg lignin to the slurry, and stir evenly to obtain a pulped material; it should be noted that this step can be carried out in a slurry...

Embodiment 3

[0045] see figure 1 , which is a process flow diagram of leaching copper from lead matte according to an embodiment of the present invention. As an embodiment of the present invention, the method for leaching copper from lead matte includes the following steps.

[0046] 1) Weigh 3 tons of lead matte, and successively pass through tiger's mouth crushing and ball mill pulverization to obtain lead matte powder; wherein, by weight, the lead matte composition is: Pb: 8.17%, S: 12.45%, Cu: 20.95 %, Fe: 19.87%.

[0047]2) Add sulfuric acid to the lead matte powder, wherein the concentration of sulfuric acid is 225g / L, the addition amount is 15 cubic meters, stir evenly to obtain a slurry; pass steam into the slurry to raise the temperature of the slurry to 70°C , while stirring for 1.5 hours; 3 minutes before pumping into the high-pressure reactor, add 60Kg sodium lignosulfonate to the slurry, stir evenly, and obtain a pulped material; it should be noted that this step can be carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com