Decorative reflective coating and preparation method thereof

A reflective coating and decorative technology, applied in the direction of reflective/signal coatings, coatings, etc., can solve the problems of increasing the difficulty and cost of reflective coating preparation, poor heat insulation of reflective coatings, poor thermal isolation effect, etc., and achieve good thermal isolation effect , fast ionization speed, accelerated hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

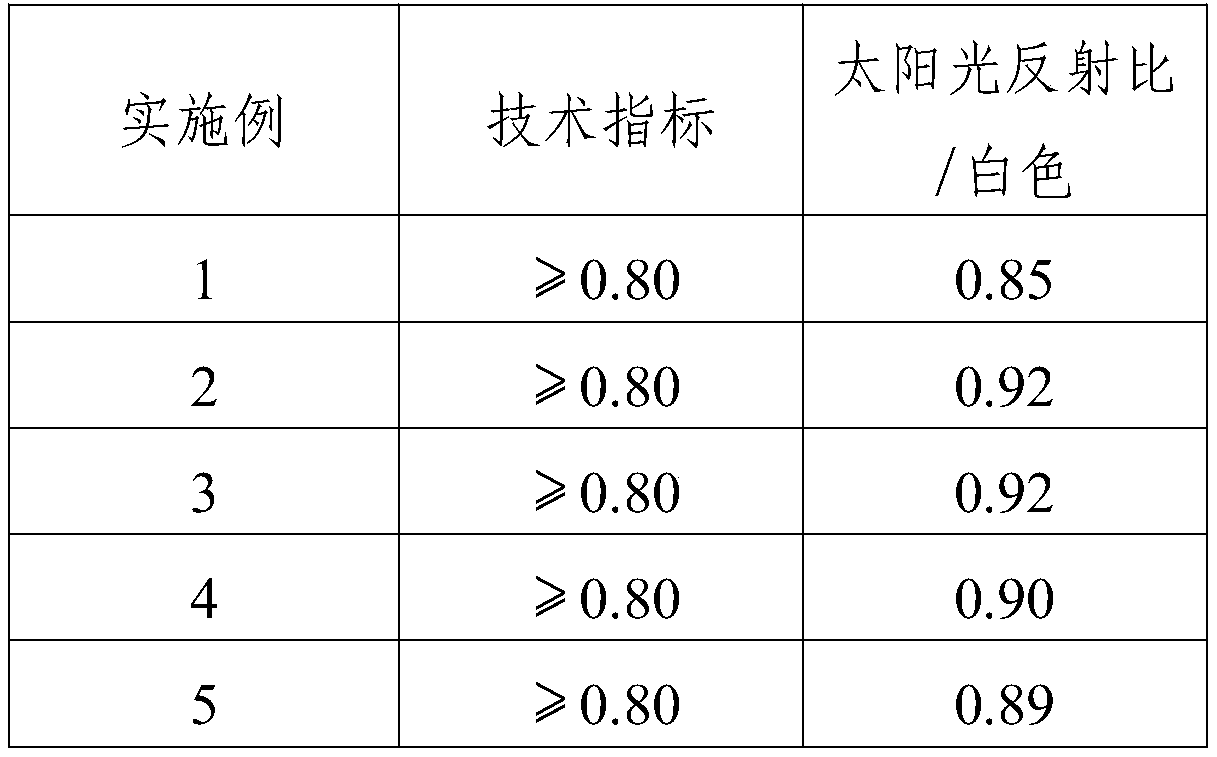

Examples

Embodiment 1

[0040] A decorative reflective paint, comprising the following raw materials in parts by weight: 5 parts of modified glass microspheres, 60 parts of acrylic resin, 5 parts of emulsifier, the emulsifier being sodium dodecylbenzenesulfonate, 2 parts of ceramic microspheres, nano 1 part of silicon dioxide, 1 part of phenolic resin, 10 parts of deionized water; modified glass microspheres are prepared by reacting hollow glass microspheres, surfactants, titanium tetrabromide and 15% potassium hydroxide, modified glass microspheres The parts by weight of the raw materials of the beads are as follows: 15 parts of hollow glass microspheres, 1.5 parts of surfactant, 20 parts of titanium tetrabromide, and 10 parts of potassium hydroxide.

[0041] A preparation method for a decorative reflective paint, specifically comprising the following steps:

[0042] (1) Mix hollow glass microspheres with distilled water and add a surfactant, stir evenly at high speed, and keep the water bath at a c...

Embodiment 2

[0048] A decorative reflective paint, comprising the following raw materials in parts by weight: 6 parts of modified glass microspheres, 65 parts of acrylic resin, 6 parts of emulsifier, the emulsifier being sodium dodecylbenzenesulfonate, 2 parts of ceramic microspheres, nano 1-2 parts of silicon dioxide, 1-2 parts of phenolic resin, 10-15 parts of deionized water; modified glass microspheres are prepared by reacting hollow glass microspheres, surfactants, titanium tetrabromide and 15% potassium hydroxide The parts by weight of the raw materials of the modified glass microspheres are as follows: 15-20 parts of hollow glass microspheres, 1.5-2 parts of surfactant, 20-30 parts of titanium tetrabromide, and 10-15 parts of potassium hydroxide.

[0049] A preparation method for a decorative reflective paint, specifically comprising the following steps:

[0050] (1) Mix hollow glass microspheres with distilled water and add a surfactant, stir evenly at high speed, and keep the wate...

Embodiment 3

[0056] A decorative reflective paint, comprising the following raw materials in parts by weight: 9 parts of modified glass microspheres, 70 parts of acrylic resin, 8 parts of emulsifier, the emulsifier being sodium dodecylbenzenesulfonate, 3 parts of ceramic microspheres, nano 1.5 parts of silicon dioxide, 1.5 parts of phenolic resin, 12 parts of deionized water; modified glass microspheres are prepared by the reaction of hollow glass microspheres, surfactants, titanium tetrabromide and 15% potassium hydroxide, modified glass microspheres The parts by weight of each raw material of beads are as follows: 18 parts of hollow glass microspheres, 2 parts of surfactant, 20 parts of titanium tetrabromide, and 12 parts of potassium hydroxide.

[0057] A preparation method for a decorative reflective paint, specifically comprising the following steps:

[0058] (1) Mix hollow glass microspheres with distilled water and add a surfactant, stir evenly at high speed, and keep the water bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com