Patents

Literature

172results about How to "Reduced insulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of foam concrete and preparation method thereof

The invention relates to a foamed concrete and a preparation method thereof. The foamed concrete adopts a chemical foaming method, and a foam stabilizer, an early strength agent, and a water reducer are respectively added to ordinary Portland cement slurry and stirred evenly, and then chemical foaming agent is added. The foaming agent is fully stirred evenly, then injection molded, cured at room temperature, and hardened. The dry apparent density range of the foamed concrete prepared by this method is 150-300kg / m3, the corresponding compressive strength is 0.10-0.50MPa, and the thermal conductivity is lower than 0.10W / mK. It can be used as roof insulation project, floor heating project, light Cushion material, especially suitable for external wall insulation system, energy-saving composite panels, etc. used in building energy-saving projects.

Owner:NANJING UNIV OF TECH

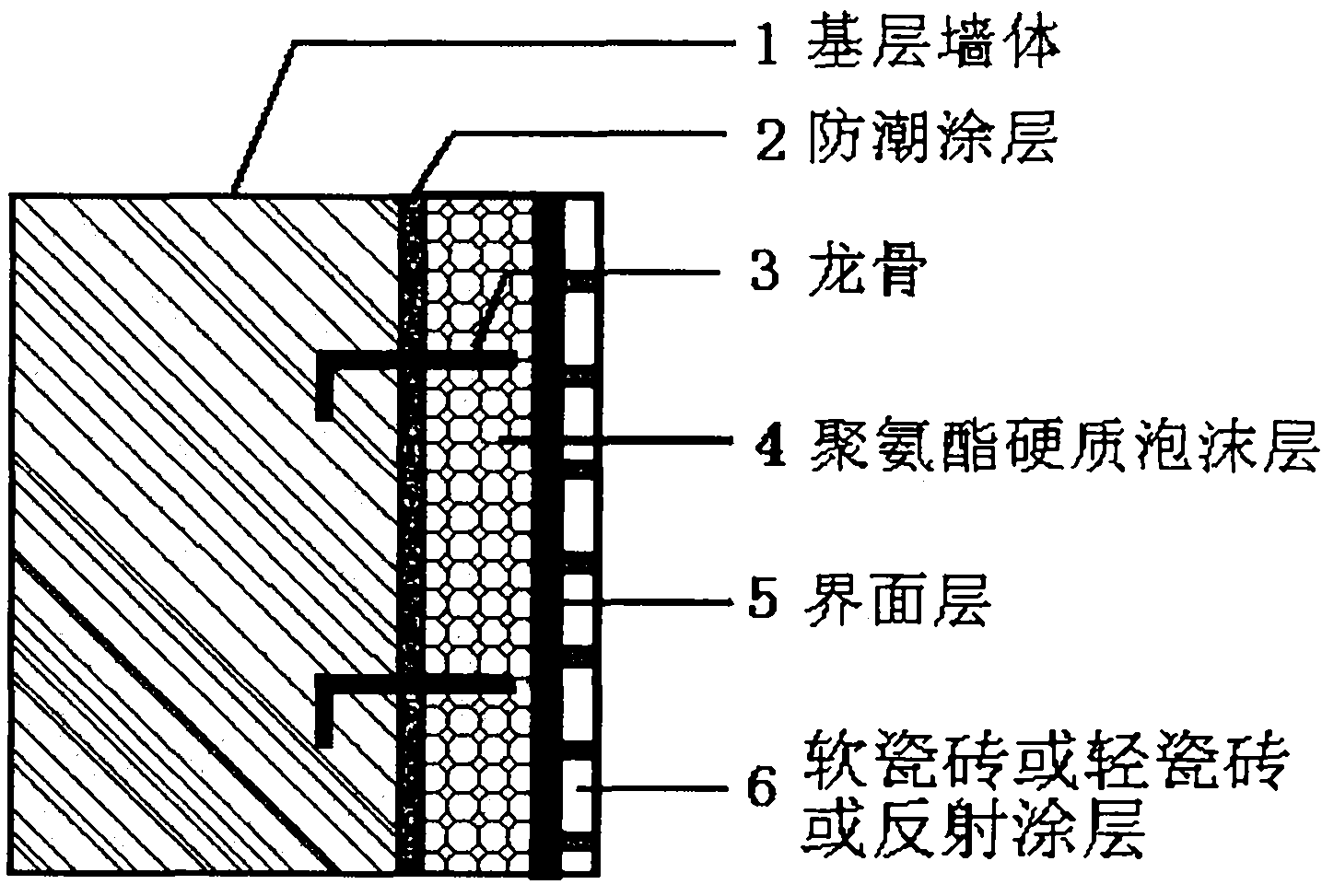

High flame retardant polyurethane rigid foam outer wall thermal insulation system

ActiveCN101956429AMeet the needs of beautificationImprove the problem of shrinkage and collapseHeat proofingBuilding material handlingWet bondingKeel

The invention discloses a high flame retardant polyurethane rigid foam outer wall thermal insulation system. From a basic unit wall provided with a keel and connecting pieces, a prime coat thickening layer, a polyurethane rigid foam layer, an interface layer, and soft tiles, light tiles or a reflective coating are arranged in turn. In the system, the prime coat thickening layer has high adhesion and good wet bonding strength for the basic unit wall and the polyurethane rigid foam; and the high flame retardant polyurethane rigid foam outer wall thermal insulation system is foamed by pure water, and is halogen-free, flame retardant, safe and environment-friendly. The vertical face of the wall is successfully foamed on site, and the polyurethane rigid foam can be directly sprayed and foamed on the basic unit wall which is treated by the prime coat thickening layer, can reach high adhesion to the basic unit wall after 24 to 48 hours, and has the coefficient of thermal conductivity of less than 0.03W / (m.K), the vertical burning reaching V-0 level, and the water absorption of less than 2.5 percent.

Owner:海聚高分子材料科技(广州)有限公司

Vitrified micro-bead heat preserving and insulating material and method of preparing same

InactiveCN101665343AImprove thermal insulation performanceOvercoming the Achilles heel of flammabilitySolid waste managementCrack resistanceNew energy

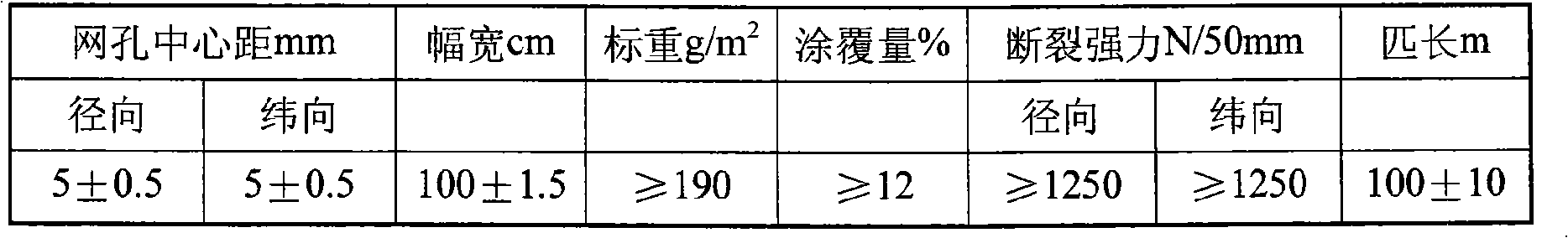

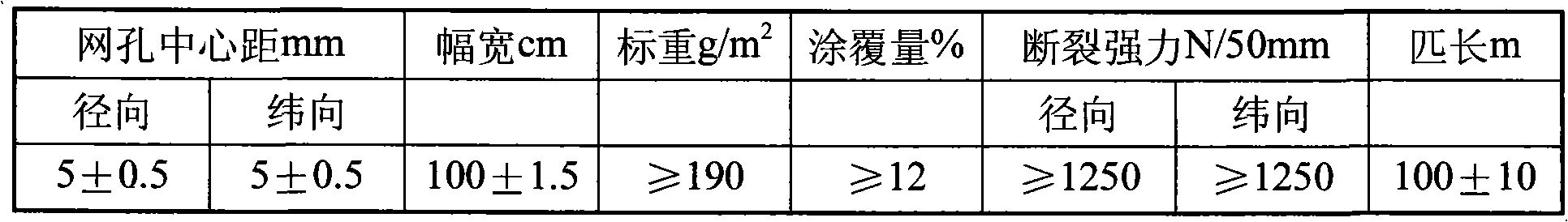

The invention relates to vitrified micro-bead heat preserving and insulating material, in particular to heat preserving and insulating material for the wall and the roof of a building and a method ofpreparing the same, belonging to the field of the building energy saving technology. The heat preserving and insulating material comprises dry vitrified micro-bead heat preserving and insulating power, flexible seepage-prevention and crack-resistance mortar and alkali-resisting glass-fiber mesh cloth or hot-dip galvanized electrically-welded mesh; the dry vitrified micro-bead heat preserving and insulating power comprises the following raw materials by weight portion: 38-50 portions of special cement, 2-5 portions of pulverized coal ash, 8-10 portions of master batch and 35-55 portions of vitrified micro-beads; the flexible seepage-prevention and crack-resistance mortar comprises the following raw materials by weight portion: 28-40 portions of common silica cement, 3-6 portions of pulverized coal ash, 7-10 portions of polymer and 45-60 portions of quartz sand. The invention provides the new energy-saving and consumption-reducing environmental-friendly building material which has low thermal conductivity, good heat preserving and insulating effect, high strength, seepage prevention effect, crack resistance, fire resistance and stable performance, is convenient to use and easy to popularize and can be widely used for preserving and insulating the heat of the wall and the roof of the civil and industrial building.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

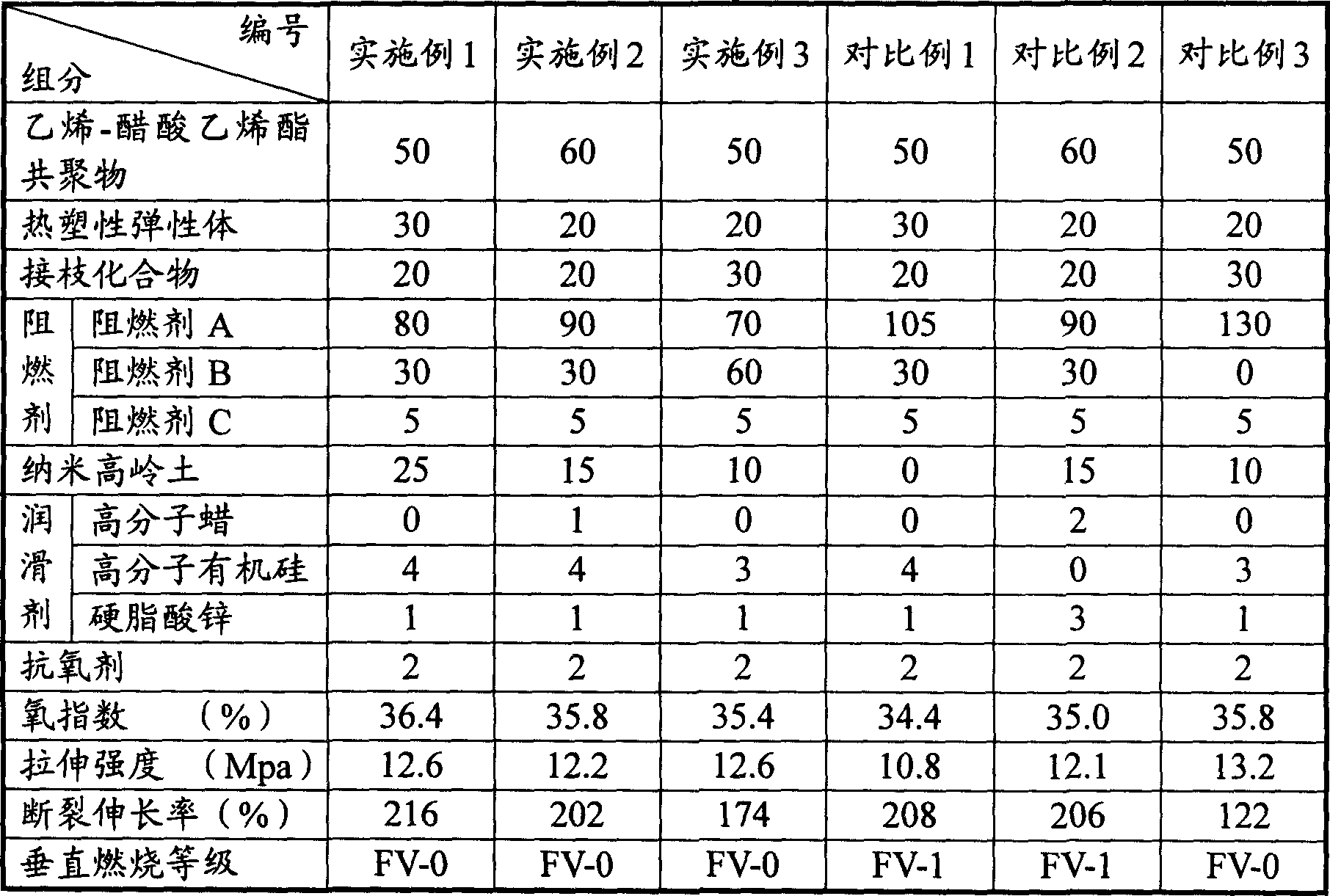

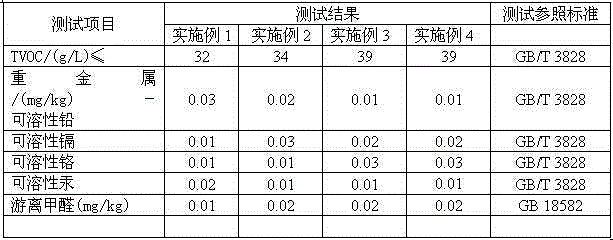

Nano kaoline fire-resistant synergistic halogen-free non-phosphor cable sheath material

InactiveCN1850899AHigh tensile strengthReduce spreadInsulated cablesInsulated conductorsPolymer chemistryEthylene-vinyl acetate

Owner:NINGBO SHIP PLASTIC CO LTD

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar

InactiveCN102690091AEliminate hot and cold bridgesEliminate hot and cold bridge phenomenonThermal insulationMicrosphere

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, especially a wall self-insulation system-matching hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, relate to a constuction energy-saving technology. The hollow microsphere masonry dedicated thermal insulation mortar comprises, by weight, 20-30% of special cement, 2-6% of coal ash, 20-35% of quartz sand, 5-8% of master batch, 35-45% of hollow microphere, and 3-6% of coarse whiting; and the hollow microsphere masonry dedicated surface mortar comprises, by weight, 28-40% of ordinary Portland cement, 3-6% of coal ash, 7-10% polymer, 40-55% of quartz sand, 10-16% of hollow microsphere, and 1-3% of coarse whiting. With a low heat conductivity coefficient, excellent thermal insulation effect, high compression strength, high bonding strength, low contractibility, environment-friendly and fire-proof properties and notable composite economic results, the wall self-insulation system-matching dedicated thermal insulation mortar and a dedicated surface mortar provided in the invention can be widely popularized and used in wall self-insulation system buildings.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

Heat-preserving composite foam concrete and preparation method thereof

InactiveCN101805203AImprove thermal insulationLight weightSolid waste managementCeramicwareFoam concreteFoaming agent

The invention discloses a formula of heat-preserving composite foam concrete, which comprises the following components based on parts by weight: 500-1000 parts of concrete, 500-1000 parts of admixture, 5-20 parts of additive, 1-30 parts of polyurethane grains, 5-20 parts of foaming agent and 500-900 parts of water. The preparation method the foam concrete comprises the following steps of: preparing foaming agent water solution, smashing the polyurethane into grains, and adjusting the sizes of the grains as required, wherein the diameters of the grains are 1-3mm; adding the polyurethane grains into the concrete, the residual water after preparing the foaming agent water solution, the additive and the admixture, and evenly stirring to obtain slurry; mixing and stirring the slurry with the foam prepared by the foaming agent water solution; and maintaining, pouring and shaping into the cast-in-situ foam concrete. The invention solves the problems of the coordination between the intensity of the foam concrete and the heat-conducting property and the treatment of the waste polyurethane. The foam concrete can guarantee the intensity and has better heat-insulating effect.

Owner:建研建材有限公司 +1

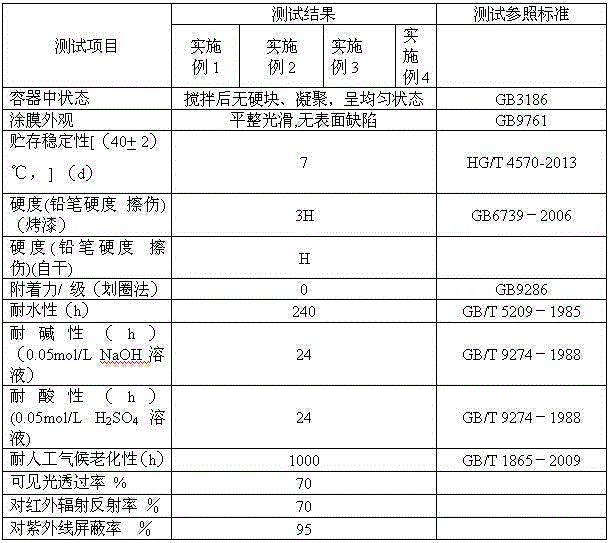

Aqueous colored transparent heat insulation coating, and preparation method and use method thereof

ActiveCN104151970AHigh hydroxyl contentImprove water resistanceReflecting/signal paintsMulticolor effect coatingsTin dioxidePolymer science

The invention discloses an aqueous colored transparent heat insulation coating, and a preparation method and a use method thereof. The aqueous colored transparent heat insulation coating is composed of a water-soluble hydroxy acrylic resin, an aqueous nanometer antimony-doped tin dioxide (ATO) slurry, an aqueous nanometer hydrotalcite slurry, an amino resin, an aqueous color paste, a film forming assistant, deionized water, a dispersant, a wetting agent, a pH adjusting agent, an antifoaming agent, an anti-settling slurry, a thickening agent, an adhesion accelerant and a leveling agent. The preparation method is characterized in that above substances are mixed under specific conditions to obtain the coating. The use method is characterized in that the addition amount of the amino resin is 4-8wt% when the coating is used as a single-component baking varnish; and the addition amount of the amino resin is 0 when the coating is used as a two-component air-dried paint. The coating has the advantages of very good adhesion, high hardness, excellent ageing resistance and good heat insulation effect on the surfaces of glass, plastic films and the like.

Owner:肇庆千江高新材料科技股份公司

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

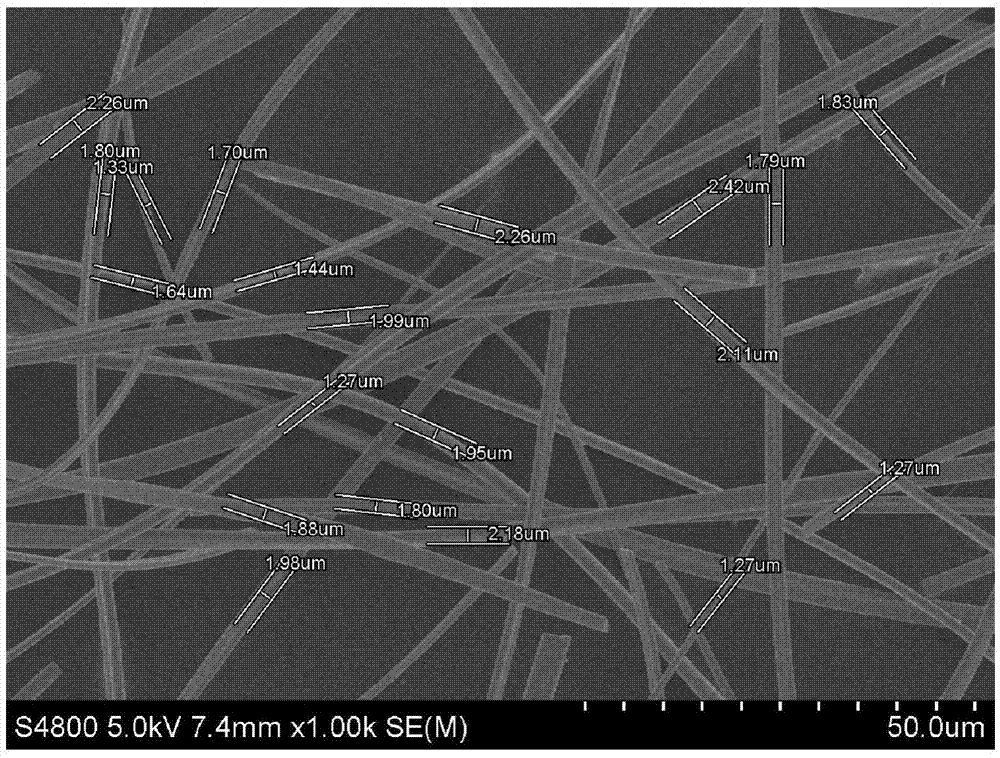

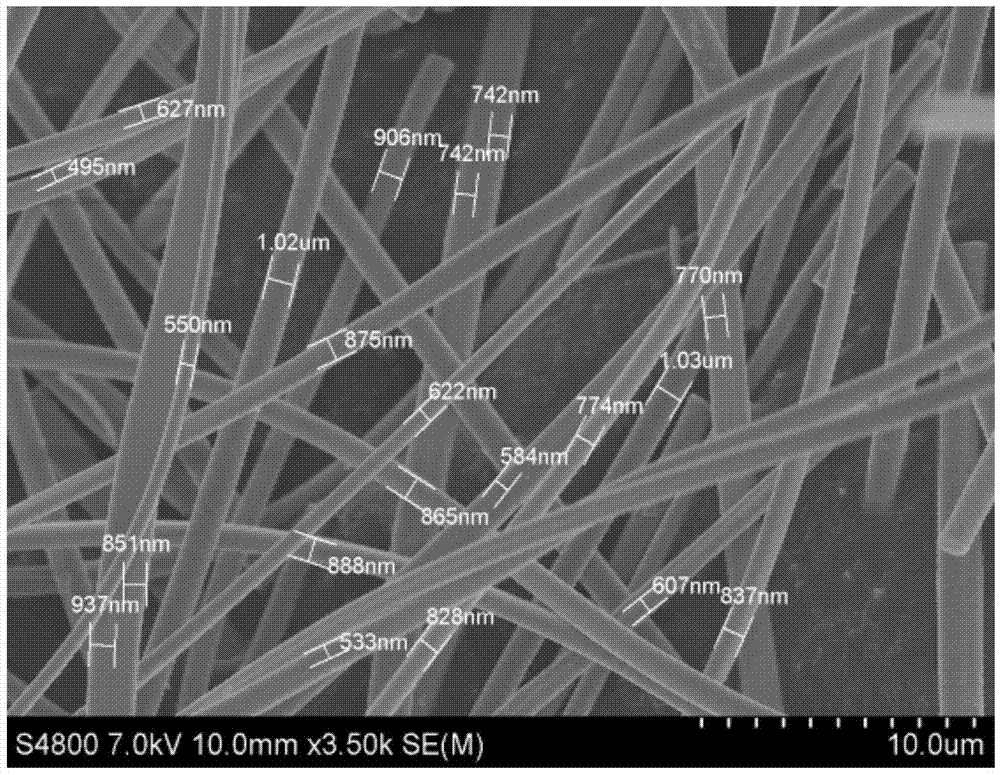

Method for preparing polyvinyl acetate zirconyl precursor sol spinning solution and sub-micron zirconium oxide crystal fibers

InactiveCN106929947AGood flexibilityGood heat insulationInorganic material artificial filamentsFilament/thread formingFiberMechanical property

The invention relates to a method for preparing polyvinyl acetate zirconyl precursor sol spinning solution and sub-micron zirconium oxide crystal fibers. The method mainly includes dissolving basic zirconium carbonate, glacial acetic acid, yttrium nitrate hexahydrate and spinning auxiliaries in absolute methanol according to certain proportions to obtain mixed solution and concentrating the mixed solution under reduced pressures at the temperatures of 30-40 DEG C to obtain the colorless, transparent and homogenous polyvinyl acetate zirconyl precursor sol spinning solution; acquiring polyvinyl acetate zirconyl precursor fibers by the aid of electrostatic spinning processes; carrying out pressure resolution on the precursor fibers to remove a ligand which is acetic acid, and then carrying out high-temperature treatment on the precursor fibers in a program-control sintering furnace. The method has the advantages that the diameters of the sub-micron zirconium oxide crystal fibers obtained byte ha id of the method range from 100 nanometers to 2.5 micrometers, and the sub-micron zirconium oxide crystal fibers are excellent in continuity, flexibility and heat-insulation and mechanical properties; the polyvinyl acetate zirconyl precursor sol spinning solution and the sub-micron zirconium oxide crystal fibers can be used at ultrahigh temperatures higher than or equal to 1800 DEG C for a long term.

Owner:山东德艾普节能材料有限公司

Fire retardant coating for underground coal seam of coal mine

ActiveCN101759407AIncrease flame retardancyNon-flammableSolid waste managementNon toxicityFire retardant

The invention provides fire retardant coating for an underground coal seam of a coal mine, comprising the following compositions in parts by weight: 74 to 140 parts of powder materials, and 15 to 56 parts of polymer emulsion. The powder materials comprise the following compositions in parts by weight: 30 to 50 parts of high quality cement, 7 to 10 parts of expanded perlite, 5 to 10 parts of expanded vermiculite, 10 to 25 parts of quartz sands, 10 to 15 parts of graphite powder, 0 to 10 parts of coal ash, 10 to 15 parts of aluminum hydroxide, and 2 to 5 parts of magnesium hydroxide. The method for preparing the fire retardant coating comprises the following steps: uniformly mixing the power materials in proportion, and packaging the materials independently; mixing the polymer emulsion with water, and adding the powder material in the mixture in a proportion of the polymer emulsion, the water and the powder materials to be 0.2-0.4:0.15-0.55:1; and uniformly mixing the mixture by a mortar mixer. The coating has the advantages of fire proofing, static resistance, good caking property with coal, good water resistance, good elasticity, non toxicity, easy construction, low cost and the like.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

High-strength nanoporous ceramizable ablation heatproof composite material and preparation method thereof

ActiveCN110951210AImprove tensile propertiesImprove bending resistancePolymer scienceUltimate tensile strength

The invention relates to a high-strength nanoporous ceramizable ablation heatproof composite material and a preparation method thereof. The composite material comprises 20-60 wt% of hybrid resin and 40-80 wt% of a fiber reinforcement, the hybrid resin comprises silicone hybrid phenolic resin, the thickness of the composite material is 2-50 mm, the density of the composite material is 700-1400 kg / m<3>, and the nanopore diameter is 50-1000 nm. The preparation method comprises the following steps: (1) preparing a hybrid resin sol; (2) impregnating the sol; (3) carrying out a sol-gel reaction; and(4) drying the composite material to obtain the composite material. Compared with like materials in the prior art, the composite material of the invention has the advantages of large binding force ofthe resin and fiber interface, high compression modulus, high bending strength, high tensile strength, ceramization at a high temperature, low thermal conductivity and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Fiber composite aerogel material as well as preparation method and application thereof

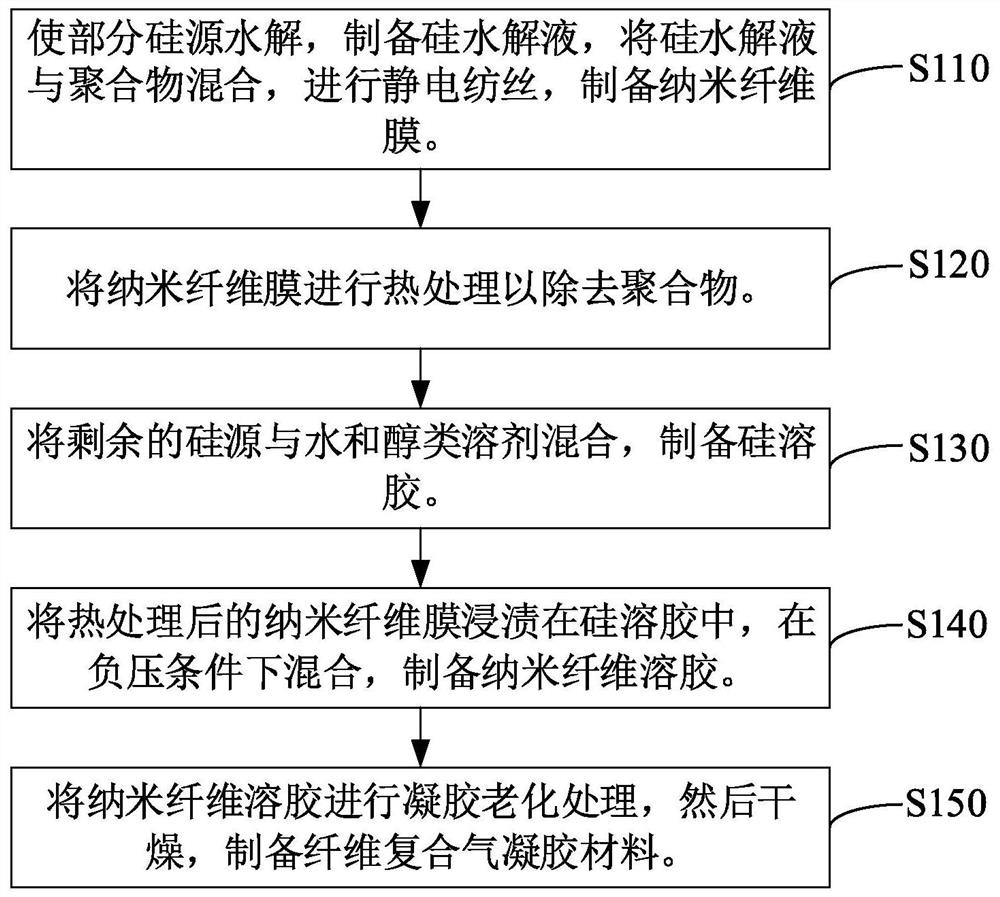

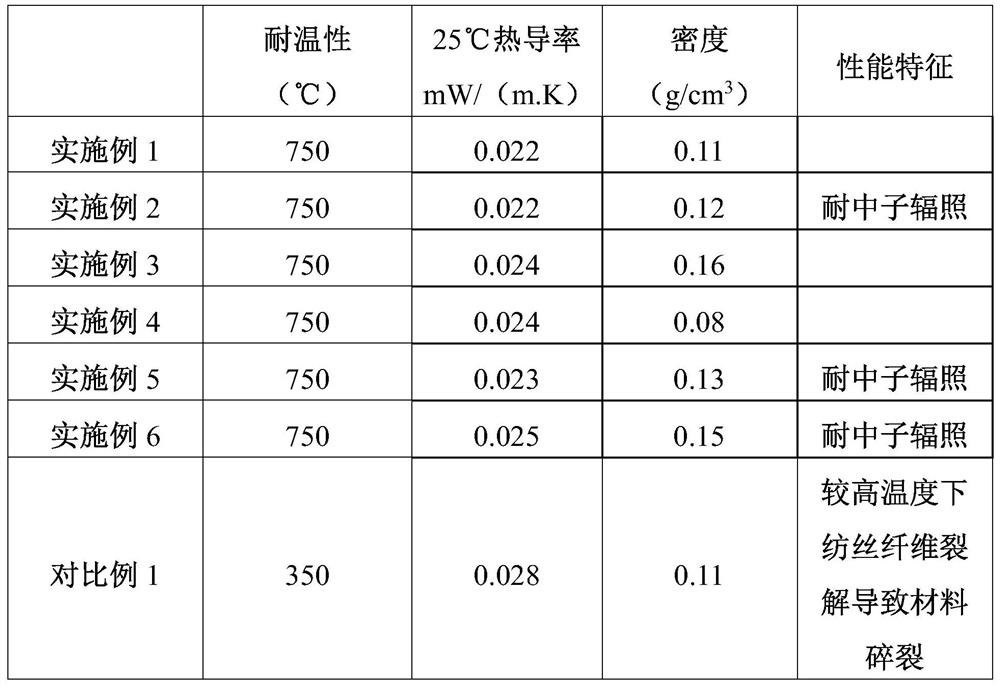

The invention relates to a fiber composite aerogel material as well as a preparation method and application thereof. The preparation method of the fiber composite aerogel material comprises the following steps: hydrolyzing part of a silicon source to prepare a silicon hydrolysate, mixing the silicon hydrolysate with a polymer, and carrying out electrostatic spinning to prepare a nanofiber membrane; thermally treating the nanofiber membrane to remove the polymer; mixing the remaining silicon source with water and an alcohol solvent to prepare silica sol; soaking the nanofiber membrane subjected to heat treatment in silica sol, and mixing under a negative pressure condition to prepare nanofiber sol; and carrying out gel aging treatment on the nanofiber sol, and then drying to prepare the fiber composite aerogel material. According to the preparation method of the fiber composite aerogel material, the thermal insulation property and the flexibility of the fiber composite aerogel material can be improved at the same time, and powder does not fall off.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

Foamed rubber sealing material and manufacturing method thereof

The invention relates to a foamed rubber sealing material and a manufacturing method thereof. The foamed rubber sealing material is composed of 100 parts of main material, 6-8 parts of reinforcing colorant, 20-40 parts of plasticizer, 1-2 parts of dispersing agent, 8-12 parts of foaming agent, 8-10 parts of vulcanizing agent, 1-2 parts of stearic acid, 1-2 parts of accelerator, 3-6 parts of protective agent and 60-80 parts of filler. The main material CR:EPDM:NR ratio is 70:(10-20):(10-20), the plasticizer brown ointment:naphthenic oil ratio is 1:3, the accelerator DETU:TMTM ratio is 1:1, and the protective wax:anti-aging agent 445:anti-aging agent ODA ratio is 1:1:1. The manufacturing method comprises the following steps: rubber mixing, powder mixing, discharging, primary vulcanizing and foaming, secondary vulcanizing and foaming, and normal-temperature natural cooling for 10-15 days. The foamed rubber sealing material has the advantages of low density, high toughness, low thermal conductivity, water resistance, favorable aging resistance, excellent elasticity, excellent shock-absorbing capacity, excellent flame retardancy, environmental protection and no toxicity.

Owner:扬州动易运动用品有限公司

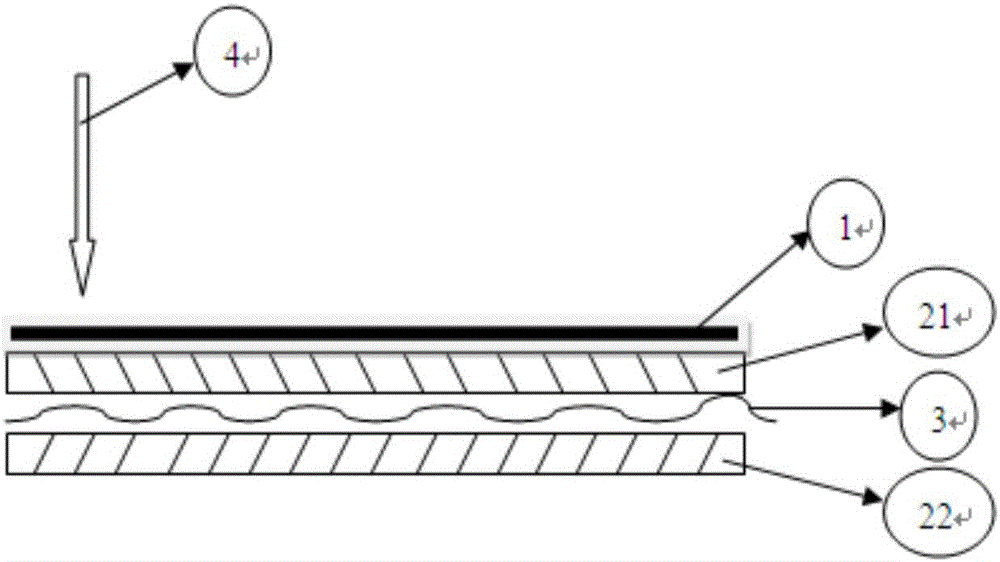

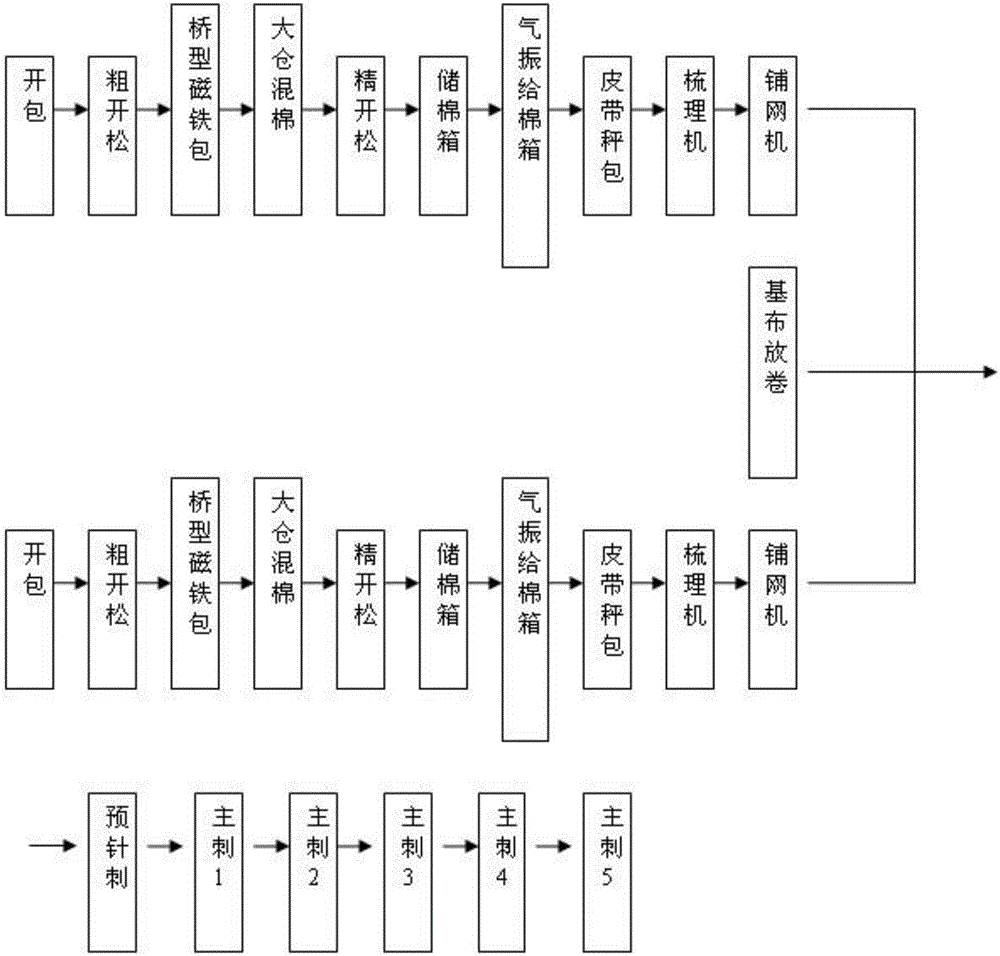

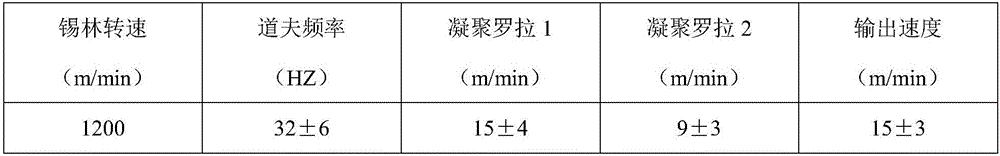

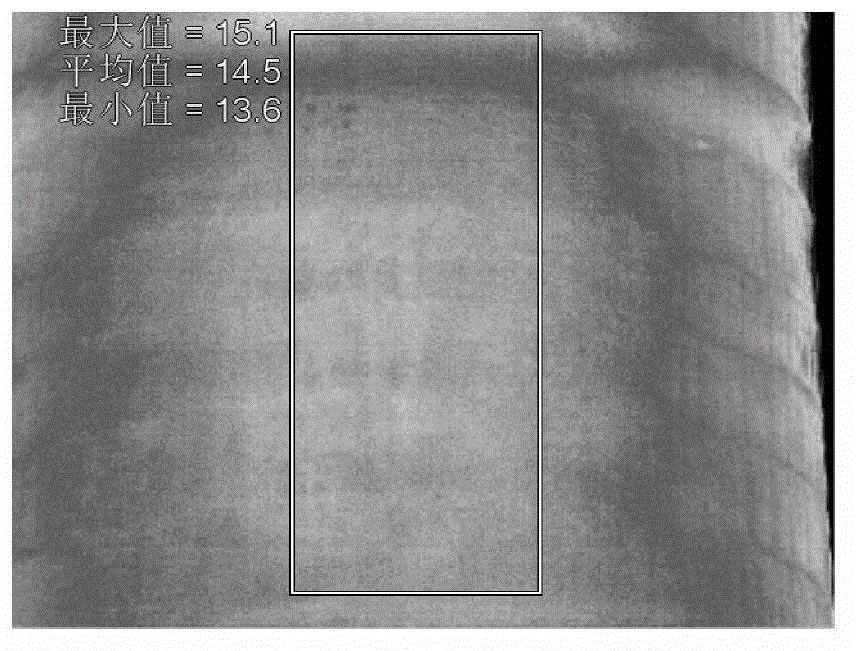

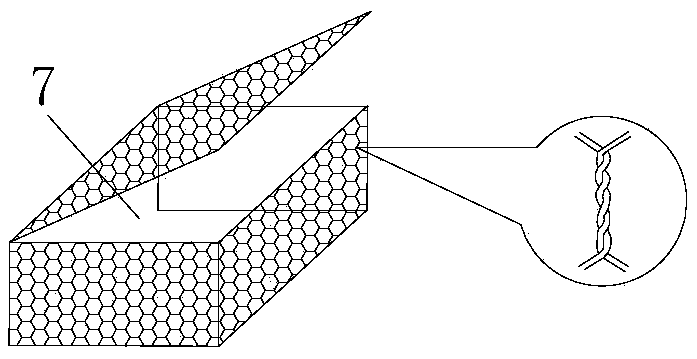

Flue gas purifying filter material for semi-dry desulphurization and preparation method thereof

ActiveCN106582112AGood dimensional stabilityImprove antioxidant capacityHuman health protectionGas treatmentFiltrationCorrosion

The invention discloses a flue gas purifying filter material for semi-dry desulphurization and a preparation method thereof. The flue gas purifying filter material for semi-dry desulphurization is compounded by an expanded polytetrafluoroethylene micropore thin layer and a blended needled felt layer; the blended needled felt is compounded by a blended composite dust facing surface layer, a corrosion resisting enhanced base cloth layer and a blended composite gas cleaning surface layer which are connected in order, wherein the expanded polytetrafluoroethylene micropore thin layer and the blended composite dust facing surface layer are connected. The flue gas purifying filter material for semi-dry desulphurization has warp and weft strength which are higher than 900N / 50mm, warp and weft elongation at break which are less than 15%, and high dimension stability; the filter material can tolerate high temperature which is 250 DEG C or above, and application temperate is wide; corrosion resistance is good, and inoxidizability is good; the polytetrafluoroethylene film has smooth surface, and dust-cleaning efficiency is high and reaches 99.999%; the filter material has the advantages of low friction, flame retardancy, insulating properties, and heat insulation property; the material has long service life; and the material has high filtering efficiency, high filtration accuracy, water resistance and corrosion resistance.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Method for sticking vacuum thermal insulation slabs and method for producing incubator internally comprising vacuum thermal insulation slabs

The invention discloses a method for sticking vacuum thermal insulation slabs and a method for producing an incubator internally comprising the vacuum thermal insulation slabs. The method for sticking vacuum thermal insulation slabs comprises the steps as follows: firstly, stirred polyurethane foaming materials are sprayed on the surface of a stuck substance, or the polyurethane foaming materials are mixed on the surface of the stuck substance under an atmospheric environment; the parameters of the polyurethane foaming materials in weight portions are as follows: isocyanate to polyether polyol is equal to 1-1.8 to 1; the non-sticky time of foams is 10-360s; and the density of the foams is 10-100kg / m3; and secondly, the vacuum thermal insulation slabs are paved on the surfaces of the polyurethane foaming materials in a non-sticky time after the polyurethane foaming materials are initiated; and the vacuum thermal insulation slabs are stuck on the surface of the stuck substance by the generated polyurethane foams.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Preparation method of aluminum oxide-silicon oxide aerogel composite material

ActiveCN113716572ASimple preparation processEasy to operateAerogel preparationSilicon compoundsThermal insulationSilicon oxide

The invention belongs to the field of thermal insulation materials, and discloses a preparation method of an aluminum oxide-silicon oxide aerogel composite material, wherein after preparing silicon dioxide gel is prepared, the surface of the silicon dioxide gel is continuously impregnated with an aluminum sol mixed solution, and compounding is carried out by using a method of coating the silicon dioxide aerogel with aluminum oxide aerogel; Si-OH and Si-OR bonds (wherein R is alkyl) on the surface of the silicon dioxide gel can react with -Al-O- bonds to form a silicon and aluminum aerogel composite network structure, a silicon dioxide aerogel network framework can play a role in supporting an aluminum oxide aerogel framework, the situation that the aluminum oxide aerogel structure collapses at the high temperature at present is reduced, and meanwhile, the aluminum oxide aerogel skeleton also improves the mechanical property of the silicon dioxide aerogel. Besides, the aluminum oxide aerogel is arranged on the outermost layer of the composite gel, approximately forms a gradient structure and can well protect the silicon dioxide aerogel network structure at high temperature, and the aluminum oxide aerogel and the silicon dioxide aerogel cooperate with each other to jointly improve the heat insulation and mechanical properties of the composite material.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

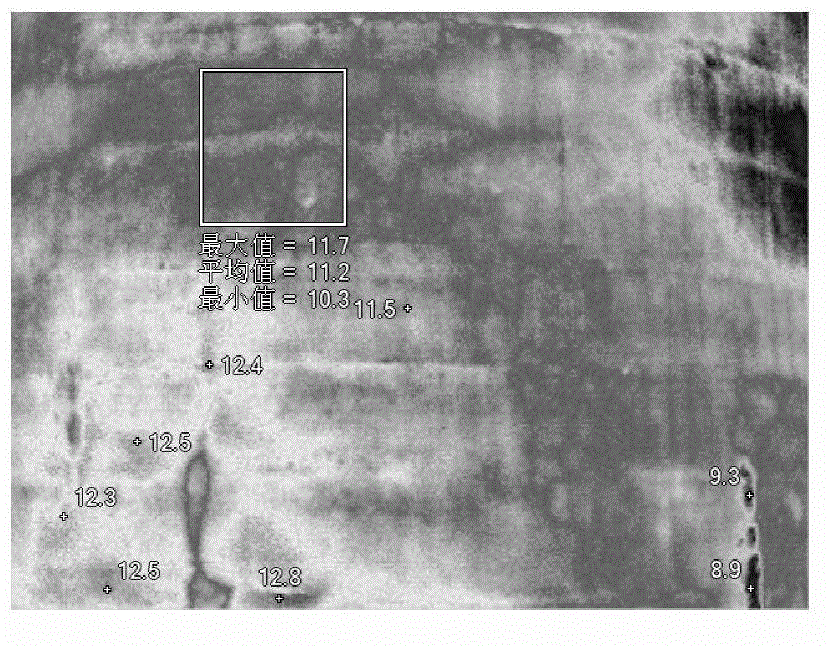

Measuring method of corrosion degree of desulfuration flue gas to chimney

The invention discloses a measuring method of corrosion degree of desulfuration flue gas to a chimney. The method is characterized by detecting the corrosion degree of the chimney through a thermal infrared imager, and comprises the following steps that (1) an internal temperature ti of the chimney is confirmed according to a chimney temperature control device; (2) an external air temperature t0 of the chimney is measured actually by a thermometer; an external surface temperature tw0 of the chimney is measured actually by the thermal infrared imager; (3) entire thermal resistance R0 of walls of the chimney is confirmed according to material composition and thickness of the chimney; (4) a uniform temperature part is found out from a thermogram of a certain section of the walls of the chimney to serve as a reference area; external surface thermal exchange resistance Rw of the walls of the chimney is computed by a formula; and (5) thermal resistance R01 of an individual abnormal temperature point is computed; and the corrosion thickness of the internal wall of the chimney is computed according to variation of the thermal resistance. The method detects the chimney by utilizing the thermal infrared imager, and can infer whether defects exist in a detected object, and the magnitude of a defect range after temperature variation is tested.

Owner:北京恺岚科技发展有限公司 +2

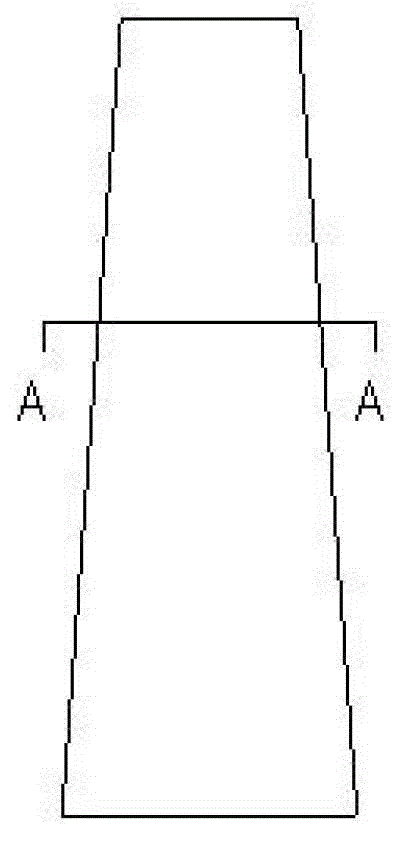

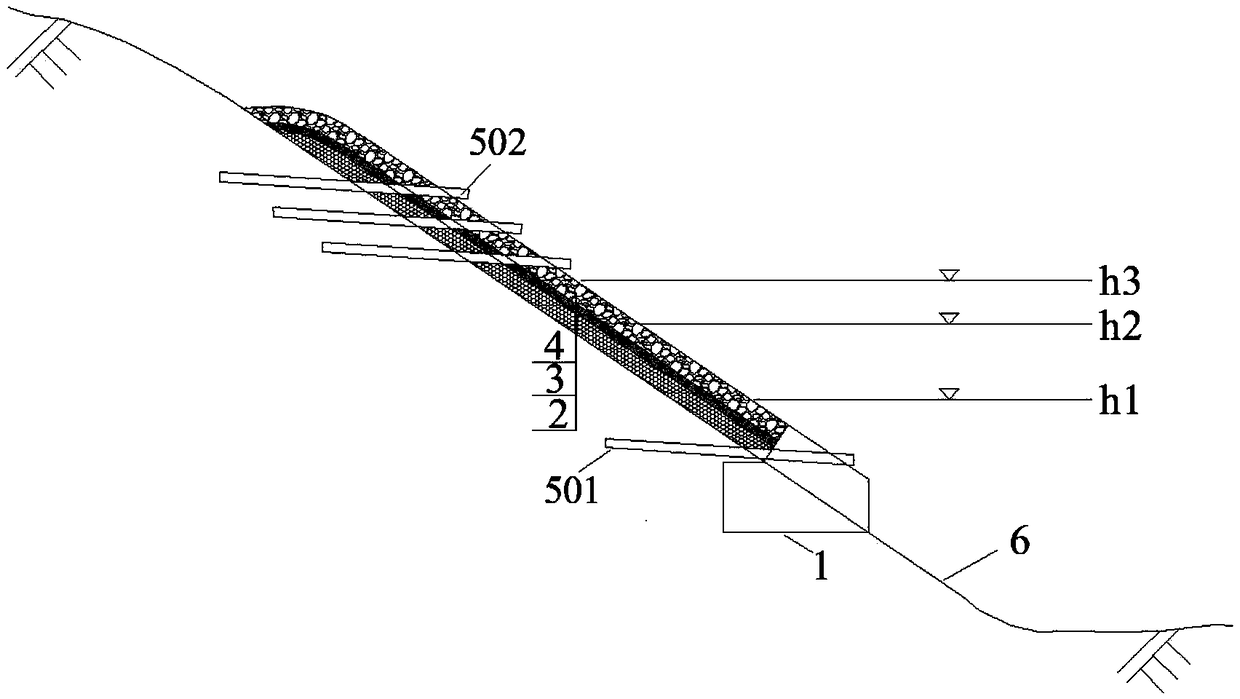

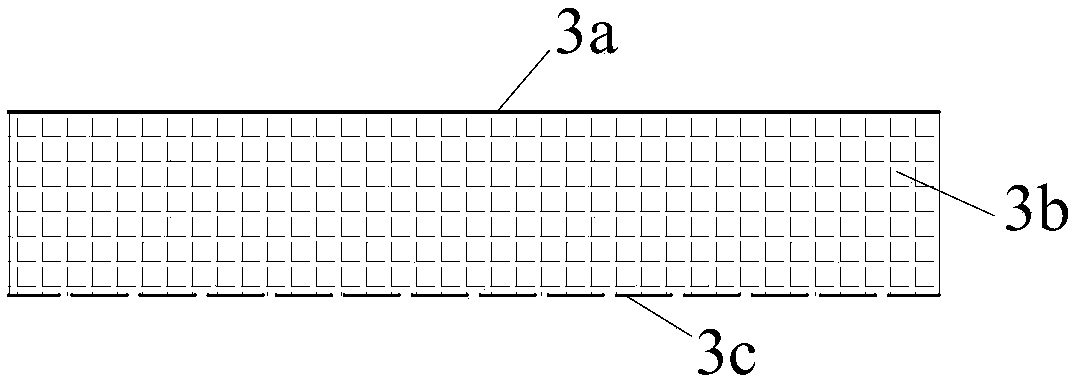

Anti-seepage and anti-freezing protection system for bank and side slopes of reservoir in cold region and construction method thereof

PendingCN109024487APrevent seepage damageAvoid destructionCoastlines protectionSoil preservationAnti freezingEngineering

The invention belongs to the field of side slope and bank slope protection engineering, and discloses an anti-seepage and anti-freezing protection system for bank and side slopes of a reservoir in a cold region. The anti-seepage and anti-freezing protection system comprises a foundation embedded in the side slope. A gravel cushion layer, a composite anti-drainage plate and a Renault protection padare sequentially laid from inside to outside on the slope surface of the side slope from the foundation to a set height of the side slope, wherein the set height of the side slope is higher than a surge water level. The anti-seepage and anti-freezing protection system further comprises one-way drainage pipes, wherein the one-way drainage pipes comprise a bottom one-way drainage pipe and a top one-way drainage pipe. The water inlet section of the bottom one-way drainage pipe penetrates through the foundation and extends into the side slope. The water inlet section of the top one-way drainage pipe penetrates through the Renault protection pad, the composite anti-drainage plate and the gravel cushion layer sequentially and extends into the side slope. The invention further discloses a construction method of the anti-seepage and anti-freezing protection system for the bank and side slopes of the reservoir in the cold region. The anti-seepage and anti-freezing protection system is simple in structure, reliable in function, convenient to construct, long in service life, and capable of effectively preventing erosion damage and seepage damage to the bank and side slopes of the reservoir,greatly weakening freezing and thawing damage to the side slope, and ensuring long-term stability of the bank and side slopes of the reservoir.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

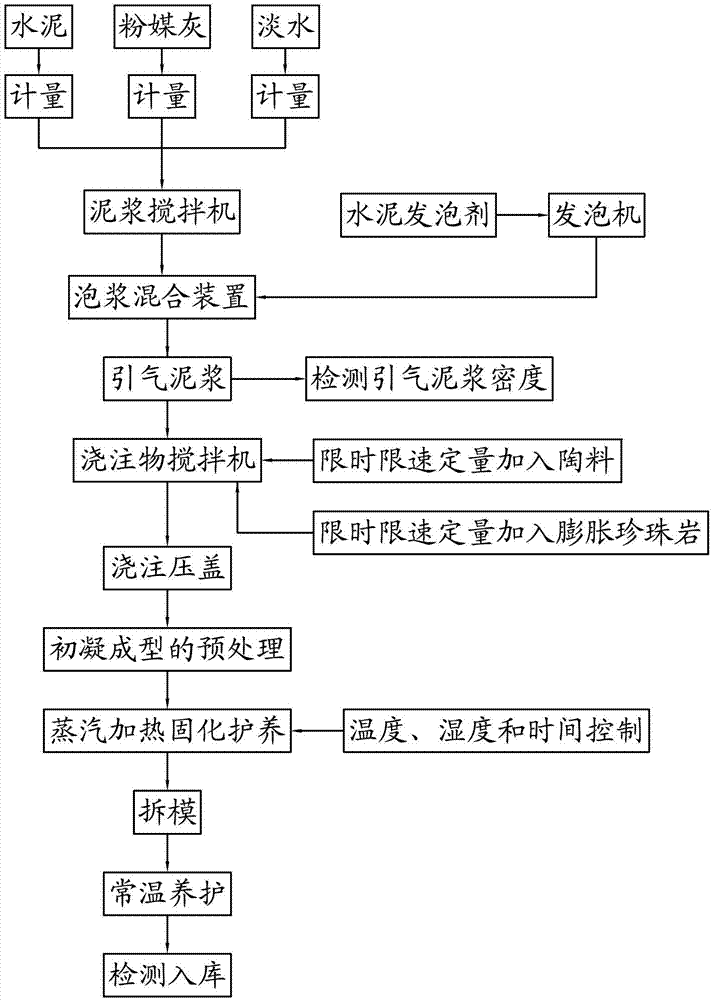

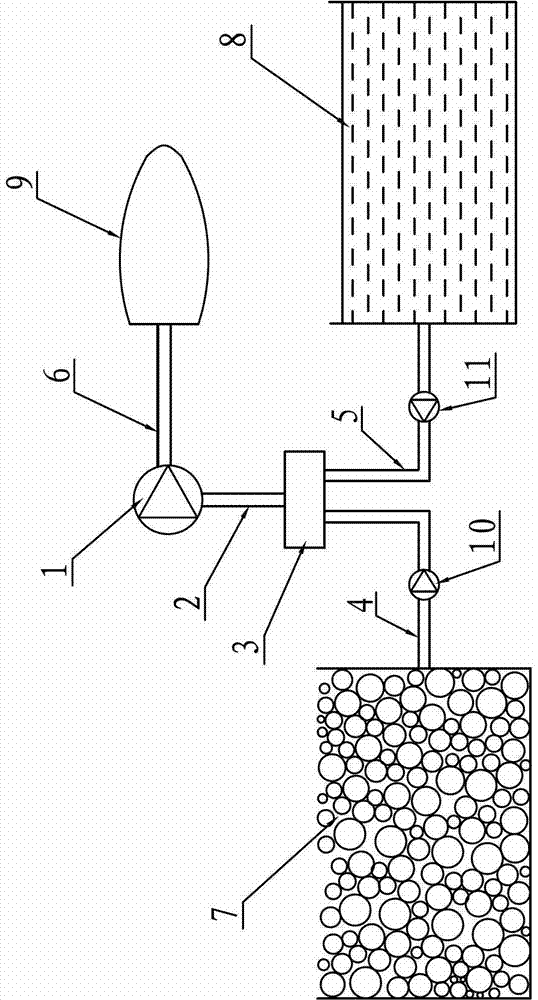

Heat-insulation sound-insulation light-weight high-strength aerated concrete building block and producing method thereof

The invention discloses a heat-insulation sound-insulation light-weight high-strength aerated concrete building block and a producing method thereof. The building block is made from special concrete materials by molding, pouring and curing; the the special concrete materials include the following components in percentage by weight: 25-30 parts of cement, 26-31 parts of coal ash, 15-25 parts of ceramsite, 5-8 parts of expanded perlite, 18-25 parts of fresh water and 2-3 parts of cement foaming agent; and the green body of the aerated concrete building block is prepared by the steps of preparation of slurry, preparation of aerated concrete pouring material, pre-solidification molding of a pouring gland, pretreatment after pre-solidification molding, steam heating solidification and maintenance and removal of the die. A foam-slurry mixing device is used for mixing foams with primary slurry to form entraining slurry, the density of the entraining slurry is controlled by adjusting the input quantity of foams, and ceramisite and expanded perlite are added regularly and quantitatively to obtain the pouring material; furthermore, pouring is completed in the stirring state, therefore, the strength of the produced product is equivalent to that of the existing products, but the sound-insulation, heat-insulation and density performance indexes are prior to those of the existing products, and the dispersion is small.

Owner:CHANGZHOU MICROTEK SELF THERMAL INSULATION WALL MATERIAL

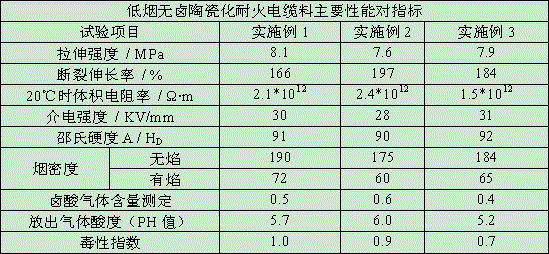

Low-smoke zero-halogen ceramic fireproof cable material and preparation method thereof

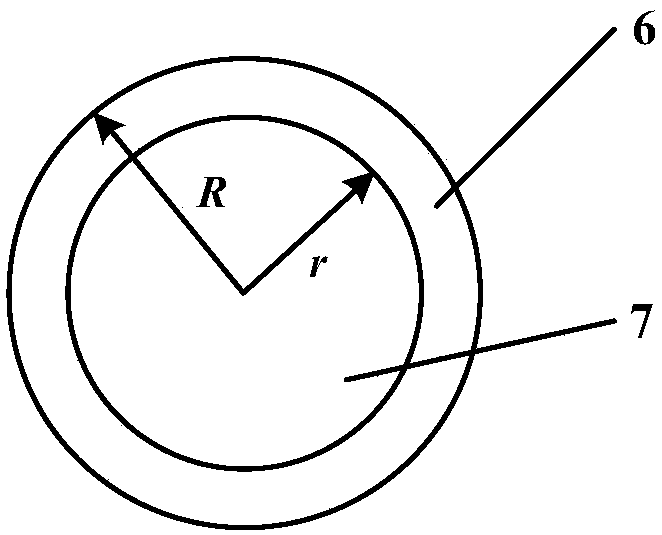

InactiveCN105131416ACrust temperature is lowReduced insulation effectPlastic/resin/waxes insulatorsOcteneCarvacryl acetate

The invention relates to a low-smoke zero-halogen ceramic fireproof cable material and a preparation method thereof. The low-smoke zero-halogen ceramic fireproof cable material is prepared from the following materials in parts by weight: an ethylene-vinyl acetate copolymer, an ethylene-alpha-olefin copolymer, maleic anhydride-grafted amorphous polyolefin, mica powder, ceramic powder, glass powder, magnesium hydroxide, calcium oxide, zinc oxide, melamine cyanurate, an antioxidant 1010, a silane coupling agent A-172, and lubricant silicone master batch; the ethylene content of the ethylene-vinyl acetate copolymer is 28-40%, and the melt flow rate is 3-5g / 10min; the ethylene-alpha-olefin copolymer is a mixture of one or two of an ethylene-alpha-propylene copolymer and an ethylene-alpha-octene copolymer which are mixed according to any ratio by weight; the glass powder is low-melting-point glass powder having the melting point of 500-800 DEG C. The low-smoke zero-halogen ceramic fireproof cable material is porcelainized to change into a hard ceramic protection layer after ignition at high temperature and has certain mechanical strength, thereby ensuring normal operation of a wire and cable line.

Owner:中广核三角洲(苏州)高聚物有限公司

Thermal insulation building paint containing nanoparticles and preparation method of paint

InactiveCN107189596ANon-combustibleEasy to useFireproof paintsCellulose coatingsAdhesiveThermal insulation

The invention discloses thermal insulation building paint containing nanoparticles. The thermal insulation building paint containing the nanoparticles comprises, by weight, 60-90 parts of nanoparticles, 30-50 parts of sepiolite, 20-30 parts of diatomite, 10-30 parts of talcum powder, 40-50 parts of filler, 20-30 parts of glass hollow microspheres, 8-24 parts of desulfurization rubber powder, 10-20 parts of acrylic emulsion, 6-18 parts of high-temperature resin, 5-15 parts of polyethylene glycol, 12-18 parts of defoaming agent, 5-8 parts of adhesive, 5-10 parts of thickening agent, 8-16 parts of mildew preventive, 9-12 parts of bactericide, 2-8 parts of flame retardant and water. The thermal insulation building paint containing the nanoparticles and prepared through the method is convenient to use, has low heat conductivity, heat preservation and flame retardancy, and is environmentally friendly and good in chemical stability.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Fireproof expanded vermiculite and preparation method thereof

ActiveCN109321021AImprove airtightnessImprove insulation performanceFireproof paintsFoaming agentSolvent

The invention relates to fireproof expanded vermiculite and a preparation method thereof. The preparation method comprises the following steps: (1) incomplete expansion calcining is carried out on vermiculite: impurities of a vermiculite material are removed, the vermiculite material is poured into a rotary furnace with the temperature of 500 DEG C to 1000 DEG C and heated for expanding for 10 to20 seconds, and after discharge, incompletely expanded vermiculite, the bulk density of which is 800 kg / m<3> to 1200 kg / m<3>, is obtained; (2) the incompletely expanded vermiculite is added into a solvent, sufficiently stirred and ultrasonically dispersed for 20 to 40 minutes, so that a vermiculite suspension is obtained; (3) the vermiculite suspension is added with a fireproof modifier and ultrasonically dispersed for 40 to 60 minutes, wherein the fireproof modifier consists of a low-molecular carbon source, a char-forming catalyst, and a foaming agent; (4) the solution obtained in step (3) is centrifugally separated, and the precipitate is preliminarily dried, so that the fireproof expanded vermiculite is obtained. The fireproof expanded vermiculite has good fireproof performance and smoke suppression property.

Owner:河北辰翔实业有限公司

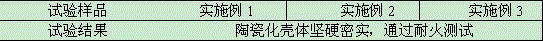

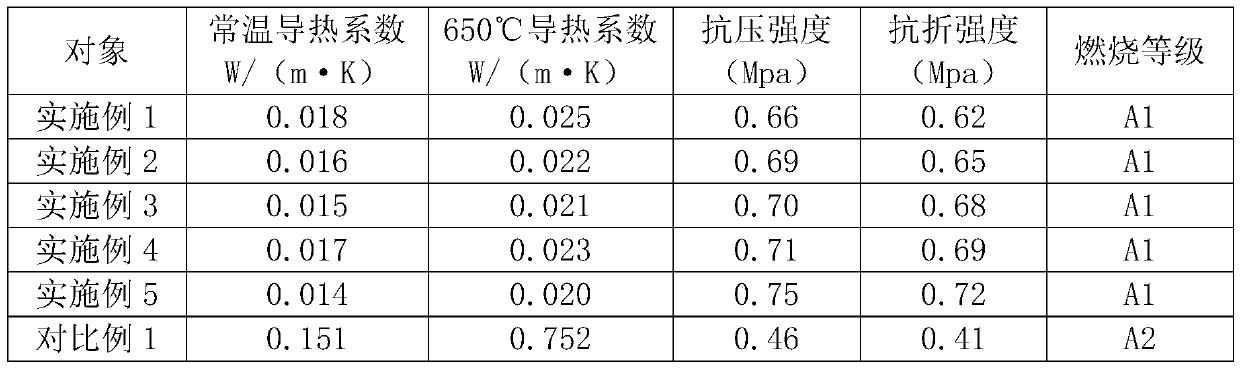

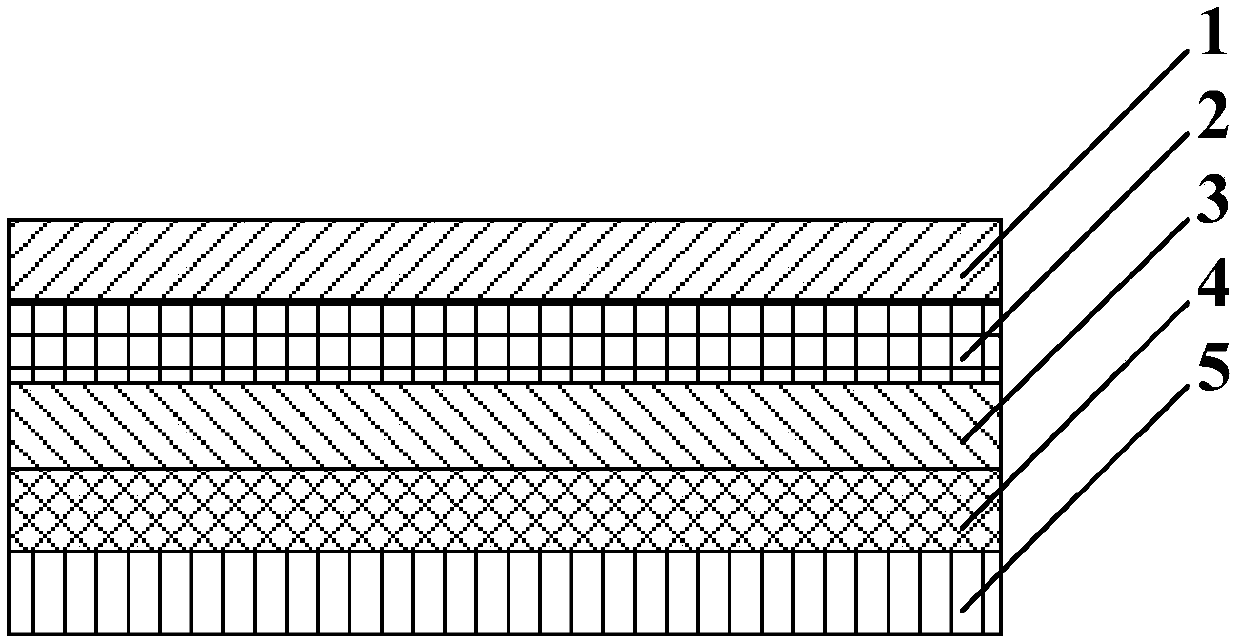

Basalt fiber thermal insulation decorative integrated plate and preparation method thereof

ActiveCN110357566AReduce convective heat transferImprove insulation effectCarbon fibersThermal insulation

The invention discloses a basalt fiber thermal insulation decorative integrated plate and a preparation method thereof, belonging to the technical field of building materials. According to the invention, carbon fiber and basalt fiber are taken as framework structural materials, modified SiO2 aerogel is taken as a heat insulation functional material, and inorganic fillers, adhesives and additives are combined to form the basalt fiber heat insulation decorative integrated plate. The basalt fiber thermal insulation decorative integrated plate can be used below 650 DEG C, has a thermal conductivity of about 0.02 W / (mK), is three to five times that of the traditional inorganic thermal insulation material, and can greatly improve the thermal insulation effect and high-temperature resistance.

Owner:中科华坤(北京)科技有限公司

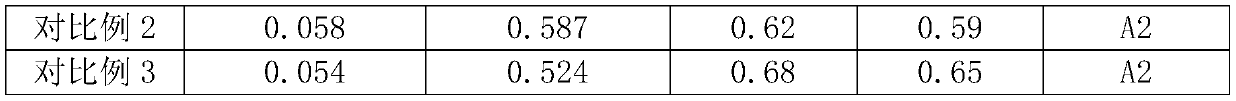

Polyurethane foam heat insulation and decoration integrated board and preparation method thereof

ActiveCN110256107AImprove fire performanceStable mechanical propertiesCovering/liningsCeramicwarePolymer scienceFireproofing

The invention discloses a polyurethane foam heat insulation and decoration integrated board and a preparation method thereof, and belongs to the technical field of building materials. The polyurethane foam heat insulation and decoration integrated board is obtained through a reaction among modified basalt fibers, modified SiO2 aerogel and a polyurethane composite. The modified basalt fibers are added to the polyurethane material; excellent fireproofing performance, high-temperature resistance, stable mechanical properties at a high temperature, water resistance, acid resistance and normal-temperature alkaline resistance of the modified basalt fibers are utilized; the modified basalt fibers can serve as reinforcements to improve the toughness and strength of the polyurethane composite board, and can also enable the polyurethane composite board to serve as a heat-insulating building material in severe weather conditions. The modified SiO2 aerogel with excellent heat insulation properties can serve as a filler. The polyurethane foam heat insulation and decoration integrated board has excellent mechanical properties, high-temperature resistance and flame retardancy, and can maintain thermal stability at a high temperature.

Owner:展宏节能科技有限公司

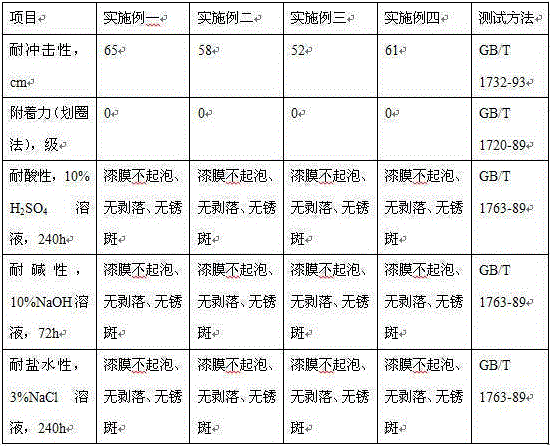

Epoxy anticorrosive coating

InactiveCN105348988AImprove mechanical propertiesImprove erosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention discloses an epoxy anticorrosive coating. The coating comprises the following components in percentage by mass: 55-65% of resin, 23-28% of pigments and packing and 12-17% of auxiliary agents, wherein the resin comprises the following components in percentage by mass: 40-50% of oil modified epoxy resin, 5-10% of oil soluble phenolic resin and 5-10% of hexamethoxymethylmelamine resin. The epoxy anticorrosive coating disclosed by the invention can form a 200-400 [mu]m-thick coating by primary coating, has excellent water resistance, saline water resistance, oil resistance and chemical resistance, has a stiff coating film, has excellent physical properties such as adhesive force, wear resistance, impact resistance and the like, and is suitable for using as a long anticorrosive coating for chemical equipment, an inner wall of a high press water pipe and a steel member exposed to a corrosive environment.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Efficient thermal insulation cellucotton felt and production method thereof

ActiveCN104534224AHigh porosityLow thermal conductivityThermal insulationPipe protection by thermal insulationPorosityFiber

The invention discloses an efficient thermal insulation cellucotton felt and a production method thereof. According to the efficient thermal insulation cellucotton felt, the porosity is larger than 93%, the thickness is 5mm-20mm, the fiber monofilament diameter is smaller than or equal to 3mum, and closed vacuum balls that are smaller than 20nm in diameter are uniformly distributed on fiber monofilaments. According to the efficient thermal insulation cellucotton felt and the production method thereof, the porosity of the cellucotton felt is greatly improved, the thermal conductivity of the cellucotton felt is lowered, any binding agent is not added in the felt, the felt has the advantages that the felt is free of toxicity, resistant to high temperature, flexible in texture, small in volume density and reusable between high temperature and low temperature and the thermal insulating property is not remarkably reduced though the felt is used at the high temperature, the maximum using temperature can reach 1000 DEG C, and the felt can be widely applied to fire prevention and thermal insulation of high temperature devices and especially applied to heat preservation and thermal insulation of devices that are usually required to be switched between high and low temperatures.

Owner:南玻院(宿迁)新材料有限公司

Light composite baking-free brick for nitrogen kiln and its preparing method

The invention discloses a nitrogen kiln using light compounding unburned brick and the manufacture method. It includes working layer, and identity layer. Working layer, which is made up of 40-50% light aggregate, 2-10% silicon fine powder, 44-54% sintering alumina powder, and 0.3-1% paper pulp powder, occupies 1 / 4-1 / 2, and identity layer, which is made up of 40-50% light aggregate, 50-60% sintering alumina powder, 0.3-1% paper pulp power, occupies 1 / 2-3 / 4. When adding material, using clapboard to separate off, adding material into working layer and identity layer, removing the clapboard, taking shaking pressing or machine pressing molding, baking at 150-250 degree centigrade, the product would be gained. The invention would enhance the thermal shock resistance, and high or low temperature combination intensity of light brick.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

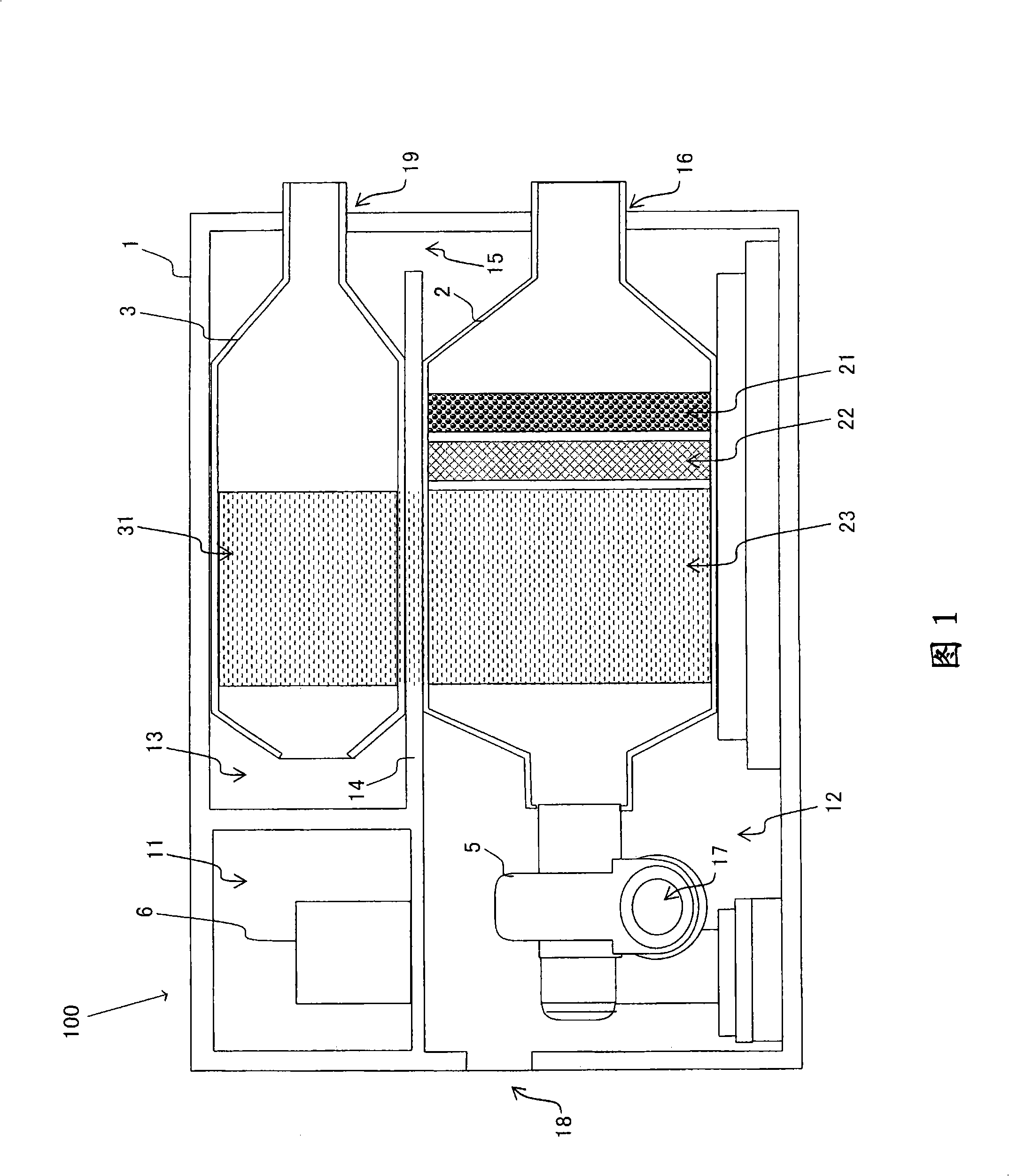

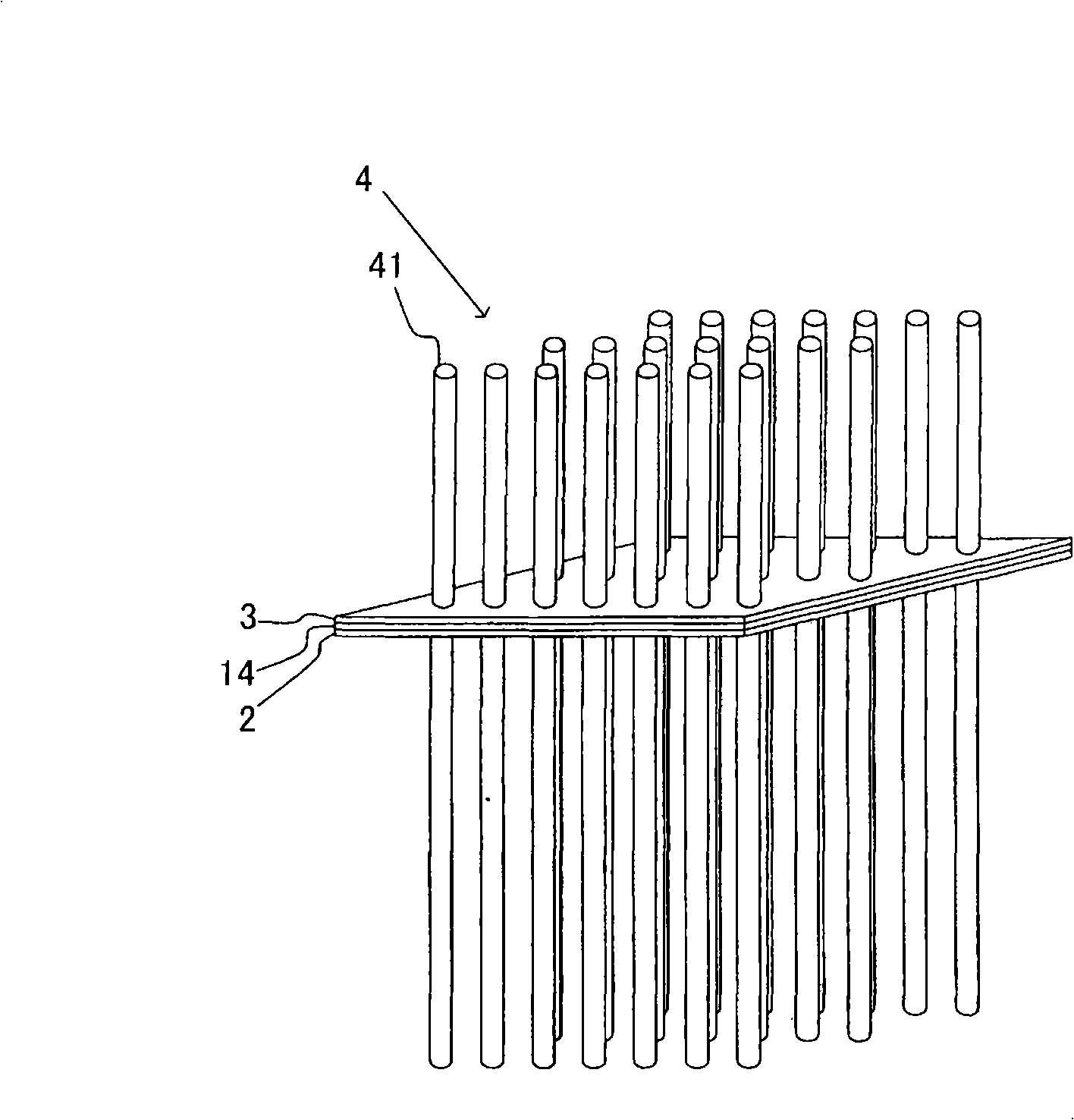

Heat recovering device

ActiveCN101319789AImprove heat recovery efficiencyReduced insulation effectCombustion processIncreasing energy efficiencyEngineering

The invention provides a heat recovery device. Compared with the prior heat recovery device, the heat recovery device can improve heat recovery efficiency and control manufacturing costs at the same time. The heat recovery device (100) comprises a heat exchange unit (4), a main preheating chamber (12) and a secondary preheating chamber (13). The main preheating chamber (12) is provided with a high temperature chamber (2). The secondary preheating chamber (13) is provided with a low temperature chamber (3). The heat exchange unit (4) recovers heat from the high temperature chamber (2) and emits the recovered heat to the low temperature chamber (3). The secondary preheating chamber (13) is positioned at the front section of the low temperature chamber (3) in a passage of low temperature gases, and the main preheating chamber (12) is positioned at the front section of the secondary preheating chamber (13) in the passage of low temperature gases. In the main preheating chamber (12), the low temperature gases suck the heat emitted from the high temperature chamber (2).

Owner:KOYO THERMO SYST CO LTD

Aerogel gradient thermal insulation material containing endothermic opacifying agent

ActiveCN107696630ASolve the strength problemSolve the fragileLayered productsFiberThermal insulation

The invention provides an aerogel gradient thermal insulation material containing an endothermic opacifying agent. The aerogel gradient thermal insulation material comprises 3-5 layers of thermal insulation layers, wherein each layer is composed of a SiO2 aerogel, reinforcing fiber doped therein and a core-shell structure opacifying agent. Specifically, the opacifying agent shell is an opacifyingmaterial, and the core is a phase-change material. The aerogel matrix has low thermal conductivity and can suppress heat conduction. The opacifying shell can inhibit radiative heat transfer. The phase-change material absorbs heat in the melting process and improves the thermal inertia of the material. Therefore, the material has the characteristics of low thermal conductivity, low radiation heat transfer capacity, large apparent specific heat and the like, greatly improves the high-temperature and short-acting heat insulation performance of SiO2 aerogel, can meet the high-temperature and short-acting heat insulation requirements of aerospace, military use and the like, and also meets the long-acting heat insulation requirements of industrial high temperature thermal protection and the like. By adding the fiber and endothermic opacifying agent, the aerogel gradient thermal insulation material provided by the invention solves the low strength, phase-change material leakage after melting,high thermal conductivity, infrared light transmission and the like in existing latent heat type thermal insulation materials, and has strong practicability.

Owner:XI AN JIAOTONG UNIV

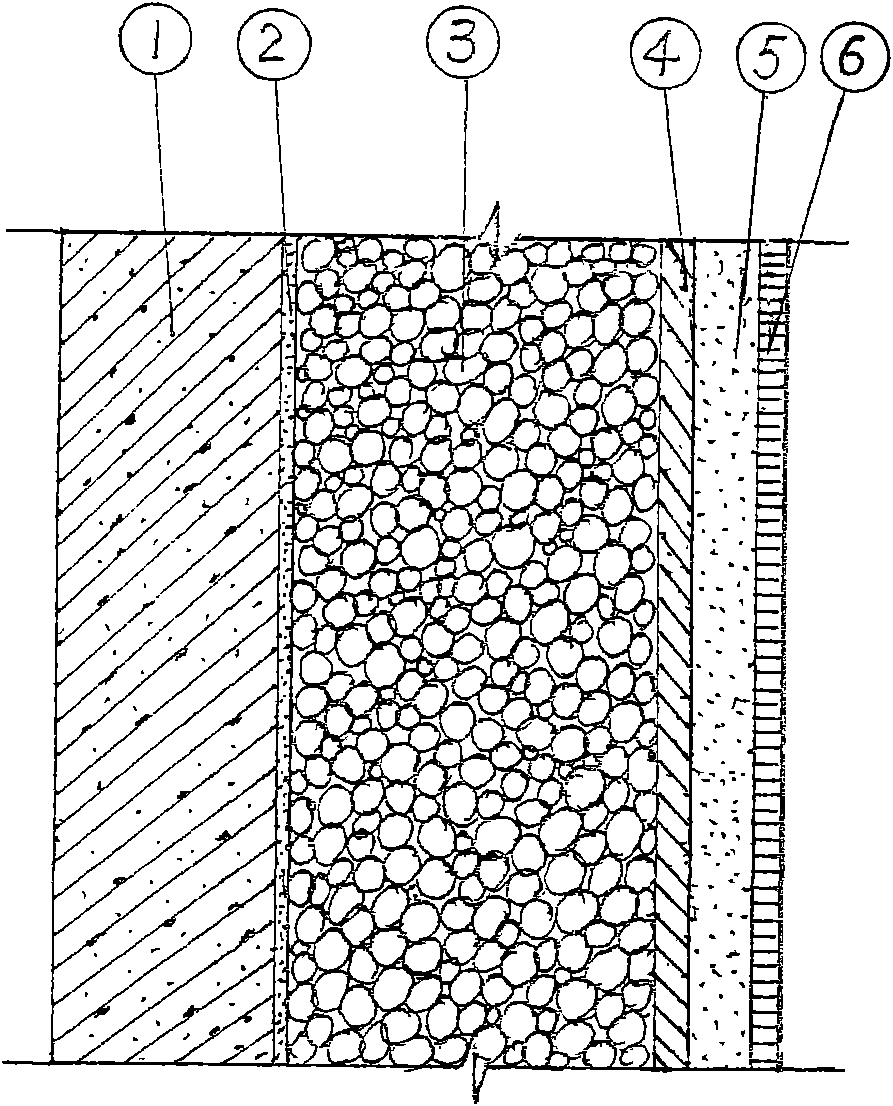

Composite block equipped with metal net and/or reinforced bar plasterer, and its bonding construction method

InactiveCN101319547AIncrease stiffnessLose weightConstruction materialCovering/liningsRebarCement mortar

The invention relates to a composite member provided with a metal gauze and / or a reinforced coating, which relates to a building composite member and aims to solve the problems of heavy weight of a concrete floor and so on. The composite member comprises a cement mortar layer, a core layer, and the metal gauze and / or reinforcing steel bars in the cement mortar layer, wherein, the cement mortar layer is arranged outside the core layer. The primary cementation is as follows: an interface agent is coated on the surface of the core layer, and the core layer is bonded with a cement mortar coating into a whole when the interface agent is wet. The secondary cementation is as follows: after the interface agent coated on the core layer for the first time is dried, the interface agent is coated on the core layer for the second time, and the core layer is bonded with the cement mortar coating into a whole when the interface agent coated for the second time is wet. The tertiary cementation is as follows: the interface agent is coated on mutual seams of the massive or platy core layers, and the core layers coated with the interface agent are bonded with each other for assembly; or the interface agent is coated on walls of holes passing through the core layers, and the cement mortar layer running through the core layers is bonded with the walls of the holes in the core layers through the wet interface agent. The composite member has the advantages of lightening of the weight of the building member, good heat-insulating property, low manufacturing cost and convenient construction.

Owner:吴淑环

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com