Basalt fiber thermal insulation decorative integrated plate and preparation method thereof

A technology of basalt fiber and integrated board, which is applied in the field of building materials, can solve the problems of poor thermal insulation performance of thermal insulation boards, achieve the effects of highlighting the ability to shield infrared radiation, reduce gas convective heat transfer, and improve thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

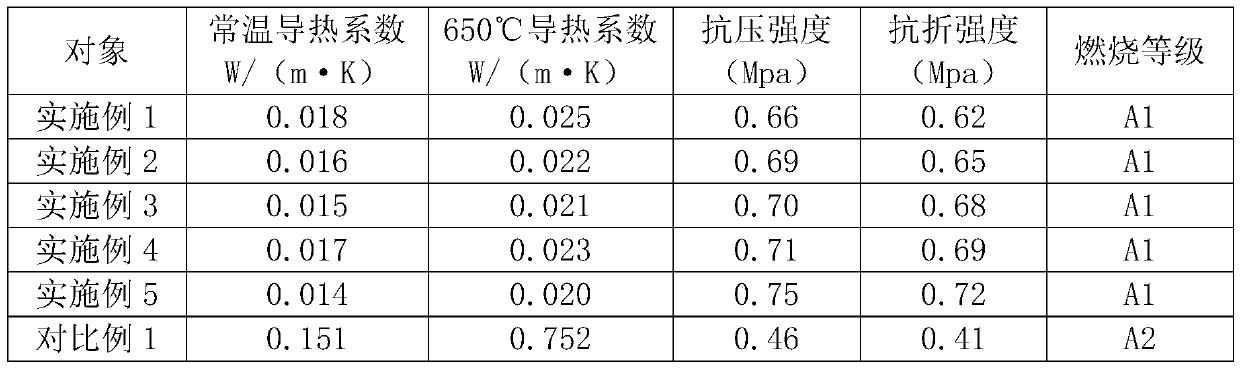

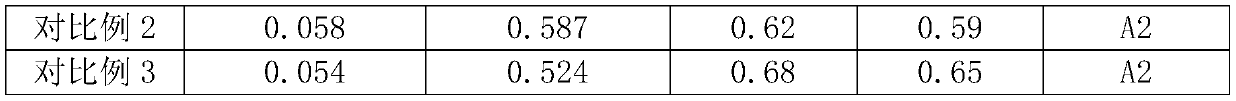

Examples

Embodiment 1

[0030] The basalt fiber thermal insulation and decoration integrated board of this embodiment includes: a thermal insulation layer and a facing layer; wherein, the thermal insulation layer includes: in parts by weight, 20 parts of basalt fiber, 30 parts of carbon fiber, modified SiO 2 5 parts of airgel, 100 parts of inorganic filler, 50 parts of adhesive and 10 parts of auxiliary agent.

[0031] The above modified SiO 2 The airgel has a pore size of 10 nm, which is prepared by the following steps:

[0032](1) Mix ethyl silicate, ethanol and deionized water, then adjust the pH value of the solution to 2 with hydrochloric acid, and stir for 15 minutes in a water bath at 30°C to obtain a silica sol; mix the silica sol with the Mix the mixed solution of potassium hexatitanate whiskers and tetrabutyl zirconate, continue to stir and adjust the pH value to 2 with hydrochloric acid to obtain a composite sol; then add ammonia water dropwise to the composite sol to adjust the pH value ...

Embodiment 2

[0045] The basalt fiber thermal insulation and decoration integrated board of this embodiment includes: a thermal insulation layer and a facing layer; wherein, the thermal insulation layer includes: in parts by weight, 40 parts of basalt fiber, 10 parts of carbon fiber, modified SiO 2 30 parts of airgel, 60 parts of inorganic filler, 20 parts of adhesive and 30 parts of auxiliary agent.

[0046] The above modified SiO 2 The airgel has a pore size of 20nm, which is prepared by the following steps:

[0047] (1) Mix ethyl silicate, ethanol and deionized water, then adjust the pH value of the solution to 3 with hydrochloric acid, and stir for 10 minutes in a water bath at 40°C to obtain a silica sol; mix the silica sol with the Mix the mixed solution of potassium hexatitanate whiskers and tetrabutyl zirconate, continue stirring and adjust the pH value to 3 with hydrochloric acid to obtain a composite sol; then add ammonia water dropwise to the composite sol to adjust the pH value...

Embodiment 3

[0060] The basalt fiber thermal insulation and decoration integrated board of this embodiment includes: a thermal insulation layer and a facing layer; wherein, the thermal insulation layer includes: in parts by weight, 25 parts of basalt fiber, 25 parts of carbon fiber, modified SiO 2 10 parts of airgel, 90 parts of inorganic filler, 30 parts of adhesive and 15 parts of auxiliary agent.

[0061] The above modified SiO 2 The airgel has a pore size of 15nm, which is prepared by the following steps:

[0062] (1) Mix ethyl silicate, ethanol and deionized water, then adjust the pH value of the solution to 2.5 with hydrochloric acid, and stir for 12 minutes in a water bath at 35°C to obtain a silica sol; mix the silica sol with the Mix the mixed solution of potassium hexatitanate whiskers and tetrabutyl zirconate, continue to stir and adjust the pH value to 2.5 with hydrochloric acid to obtain a composite sol; then add ammonia water dropwise to the composite sol to adjust the pH va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com