Nuclear-grade modular thermal insulation layer and preparation method thereof

An insulating layer, nuclear-grade technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of difficult processing of special-shaped parts, uneven bulk density, large weight, etc., to ensure the performance of equipment or systems, the broad market Application prospects, the effect of reducing convective heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

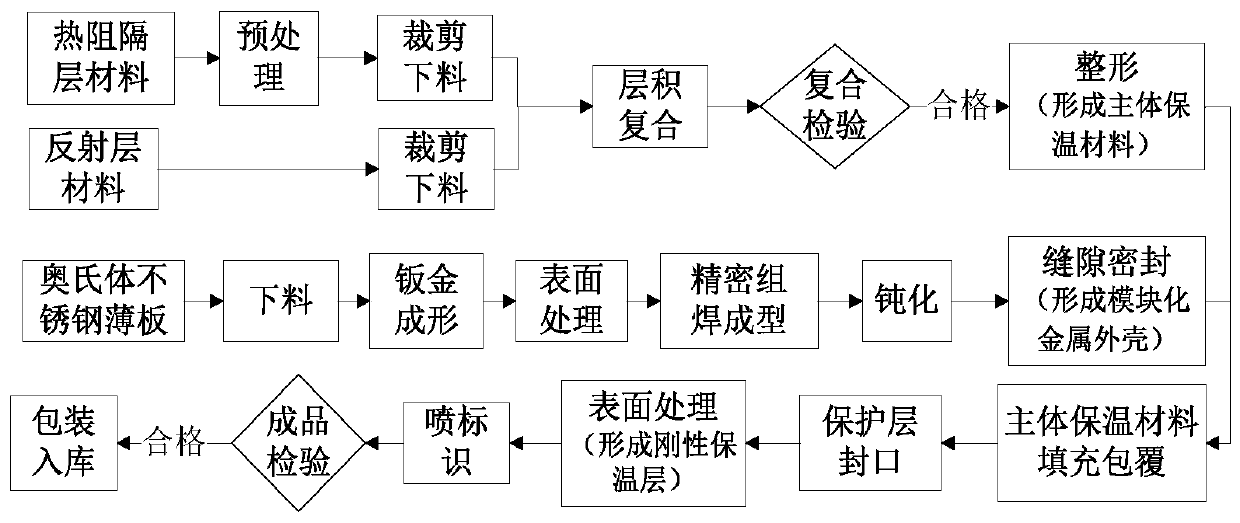

Embodiment 1

[0022] The maximum temperature on the surface of a valve is 200°C, the thickness of the insulation layer is 30mm, and a rigid insulation layer is used. The thermal resistance layer material in the main insulation material is a radiation-resistant ceramic fiber insulation composite material with a thickness of 3mm, and the reflective layer material is a 25μm-thick PI film coated with 50nm Thick 316L stainless steel, thermal resistance layer and reflective layer materials are compounded according to the designed lamination method, and then shaped through the valve mold to form the main insulation material of the valve insulation layer. The material of the outer protective layer is a 304 stainless steel sheet with a thickness of 0.5mm. After cutting and blanking, sheet metal forming, surface treatment, precision assembly and welding, passivation, gap sealing and other processes, an outer protective shell is formed. Fill and cover the main body insulation material, and finally carr...

Embodiment 2

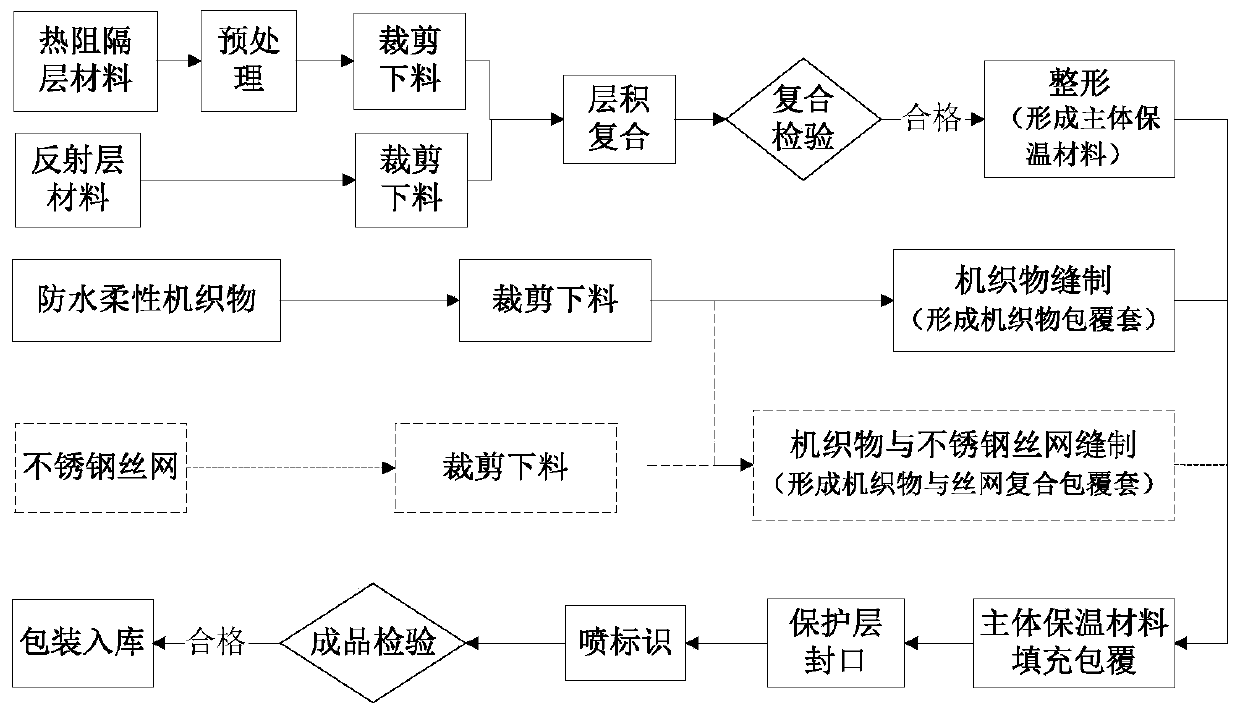

[0025] The maximum temperature on the surface of a cylindrical device is 400°C, the thickness of the insulation layer is 85mm, and the outer protective layer is a flexible insulation layer of woven fabric. The material of the thermal resistance layer in the main insulation material is 6mm radiation-resistant ceramic fiber insulation composite material. The layer material is 316L stainless steel foil with a thickness of 0.03mm. The heat resistance layer and reflective layer materials are laminated according to the design, and then shaped by cylindrical tooling to form the main insulation material of the cylindrical equipment insulation layer. The material of the outer protective layer is a waterproof flexible woven fabric with a thickness of 0.8mm, which is cut by an automatic cutting system, and then made into a woven fabric covering sleeve after sewing. Finally, the main body insulation material is filled and coated in the coating sleeve, and the protective layer is sealed to ...

Embodiment 3

[0028] The maximum temperature on the surface of a pipeline is 280°C, and the thickness of the insulation layer is 50mm. The outer protective layer is a flexible insulation layer composed of woven fabric and wire mesh. The thermal resistance layer material in the main insulation material is 6mm radiation-resistant ceramic fiber insulation composite material. The material of the reflective layer is 316L stainless steel foil with a thickness of 0.03mm. The thermal resistance layer and the material of the reflective layer are combined according to the designed lamination method and then shaped by pipeline tooling to form the main thermal insulation material of the pipeline thermal insulation layer. The 0.4mm waterproof flexible woven fabric and the 0.07mm, 120-mesh 316L stainless steel wire mesh were cut, blanked, and compositely sewed to form a composite covering. Finally, the main body insulation material is filled and coated in the composite coating sleeve, and the protective l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com