Heat-insulation and heat-preservation polyimide foam material and preparation method thereof

A polyimide and foam material technology, which is applied in the field of thermal insulation polyimide foam materials to achieve good mechanical properties, improve thermal insulation performance, and reduce gas convection heat transfer effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

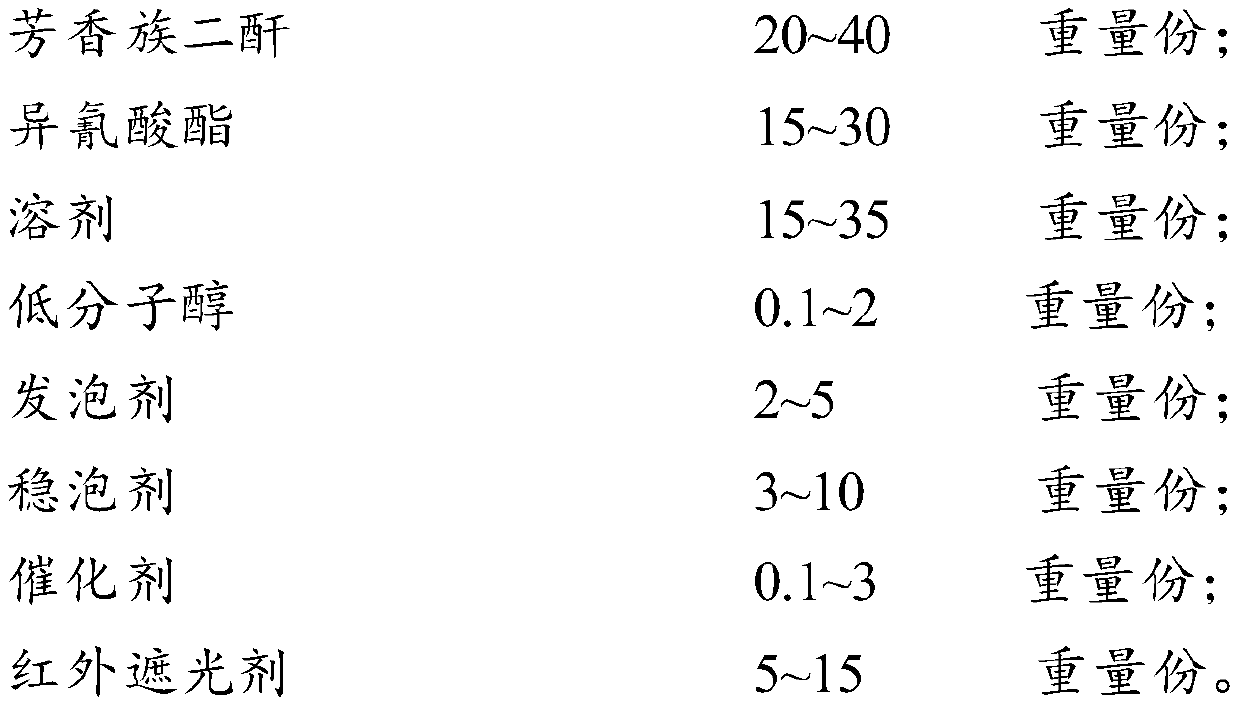

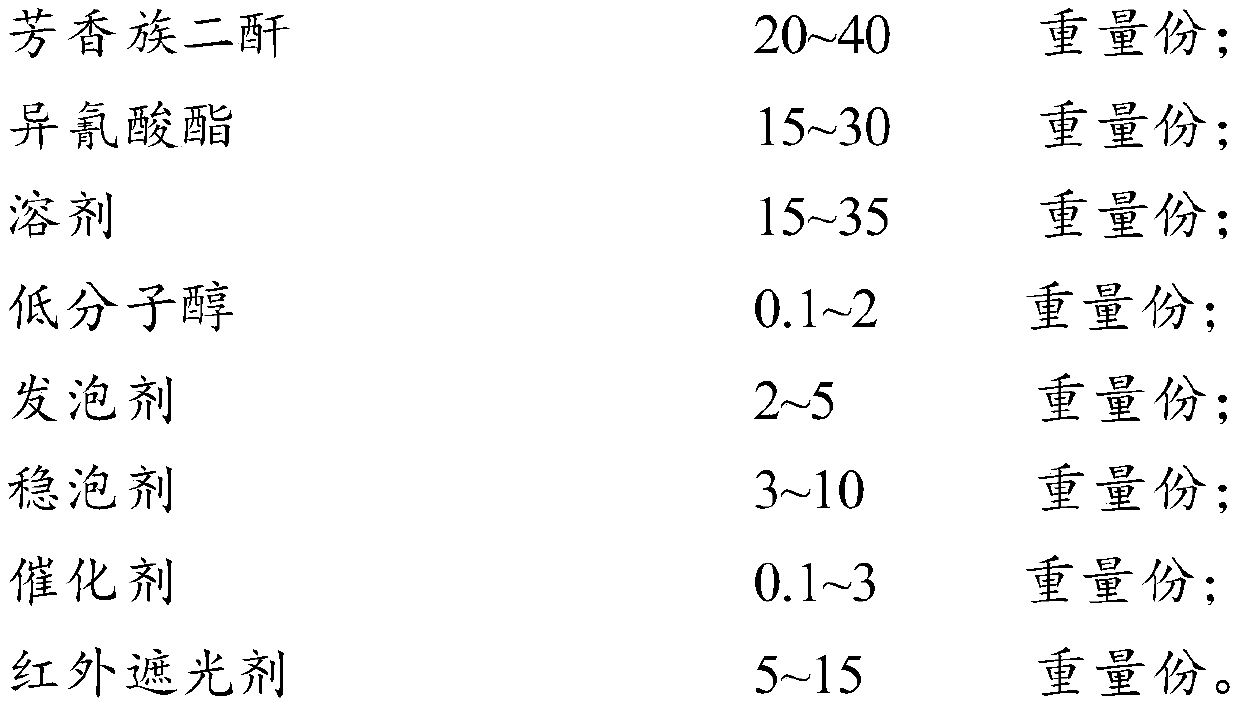

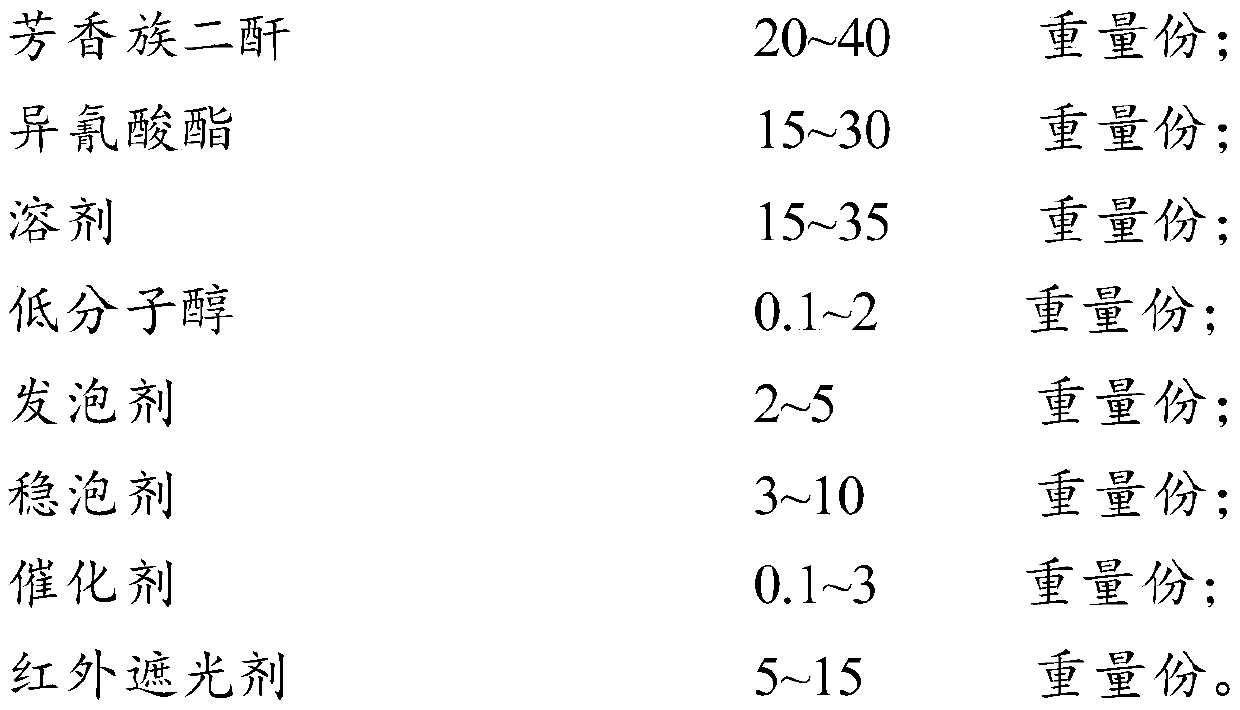

[0064] The present invention also provides a method for preparing the polyimide foam material according to any one of the above technical solutions, including the following steps:

[0065] 1) After reacting aromatic dianhydride, low molecular weight alcohol and solvent, a foaming precursor solution is obtained;

[0066] 2) After re-mixing the foam precursor solution, catalyst, blowing agent, foam stabilizer and infrared sunscreen obtained in the above steps, a mixed solution is obtained;

[0067] 3) The mixed solution obtained in the above steps and the isocyanate are finally mixed, and then subjected to free foaming molding in the mold, and then pre-curing and post-curing to obtain a polyimide foam material.

[0068] In the above-mentioned polyimide foam material of the present invention, the selection and ratio of the raw materials and the preferred range thereof are preferably consistent with the selection and ratio of the raw materials in the polyimide foam material and the preferr...

Embodiment 1

[0100] Material A is isocyanate;

[0101] The raw materials of B material are aromatic dianhydride, solvent and ethanol;

[0102] C material raw materials are blowing agent, foam stabilizer, catalyst and infrared sunscreen.

[0103] Stir 0.5 parts of ethanol and 20 parts of N,N'-dimethylformamide to raise the temperature to 50°C, add 25 parts of pyromellitic dianhydride, continue to heat up to 80°C, react for 3h, and cool to room temperature to obtain material B; Add material C including 2 parts of water, 5 parts of TEGOSTAB B2470A, 0.2 parts of PC-T, 0.2 parts of IPAS-1, and 5 parts of carbon black to material B and mix evenly; add material A to 4,4'-diphenylmethane diisocyanate , The isocyanate content is 30%, then add the above solution to the above solution and stir at a high speed of 2000r / min for 15s, pour it into the mold, and foam and shape at room temperature; then microwave the foam for 15min under 500W power, and then in an oven at 200℃ In the middle, bake for 3 hours; h...

Embodiment 2

[0105] Stir 0.8 parts of ethanol and 23 parts of dimethyl sulfoxide to 55°C, add 28 parts of 3,3',4,4'-diphenyl ether tetraacid dianhydride, continue to heat up to 70°C, react for 3.5h, cool At room temperature, obtain material B; add material C including 1.5 parts methanol, 6 parts CONCENTROL STB PU 1231, 0.15 parts DY-20, 0.3 parts T9, 0.25 parts DABCO 33, and 10 parts carbon black into material B and mix evenly; The material is isophorone diisocyanate, the content of isocyanate is 32%, then add to the above solution, stir at high speed at 2500r / min for 12s, inject it into the mold, foam and shape at room temperature; then put the foam under 500W power, microwave 20min, and then bake in an oven at 220°C for 3h; heat-press the peeled foam at a pressure of 12MPa and a temperature of 220°C for 45s to prepare the thermal insulation polyimide foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com