Patents

Literature

103results about How to "Reduce radiative heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-additive agent modified high-strength wall self-thermal insulation material and preparing method thereof

InactiveCN101318796ANo need for high temperature calcinationReduce heat transferSolid waste managementCement productionPolymer scienceBrick

The invention discloses a nano additive modified high strength wall self heat preservation brick and a preparation method thereof. The method comprises the following steps: according to mass portion, 1 to 20 portions of bonding agent, 0.1 to 5 portions of admixture and 0.5 to 5 portions of nano additive are evenly mixed and added with admixtures, the weight of which is 0.001 to 0.1 times against the weight of the mixture, and evenly mixed again; and the mixture obtained is added with water and shaped. For the wall self heat preservation brick prepared by the method of the invention, the pressive strength is between 5 and 14MPa, the coefficient of thermal conductivity is between 0.1 and 0.2w / m.k, so that the brick is a highly efficient energy saving building material with superior performance.

Owner:浙江中联建设集团有限公司 +2

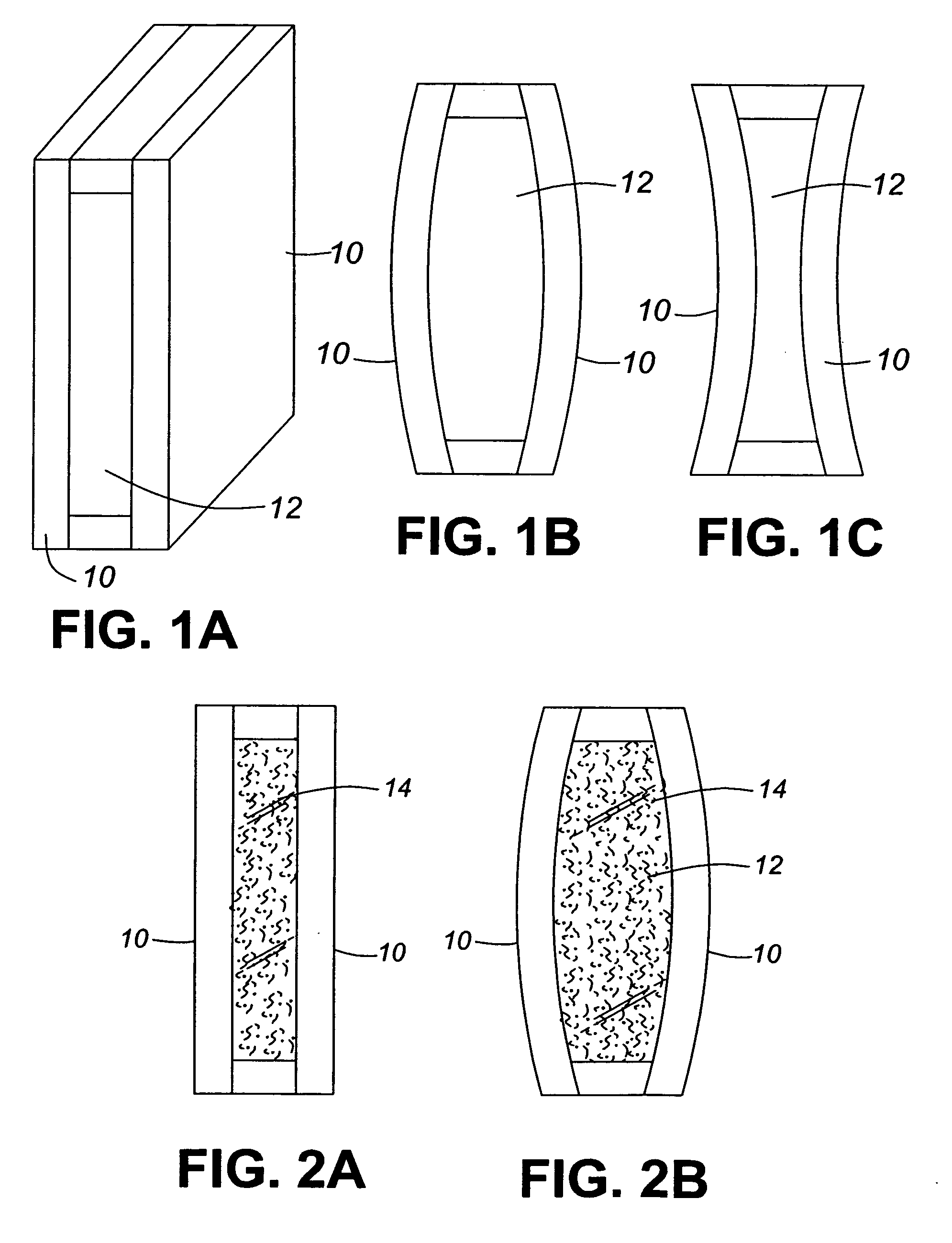

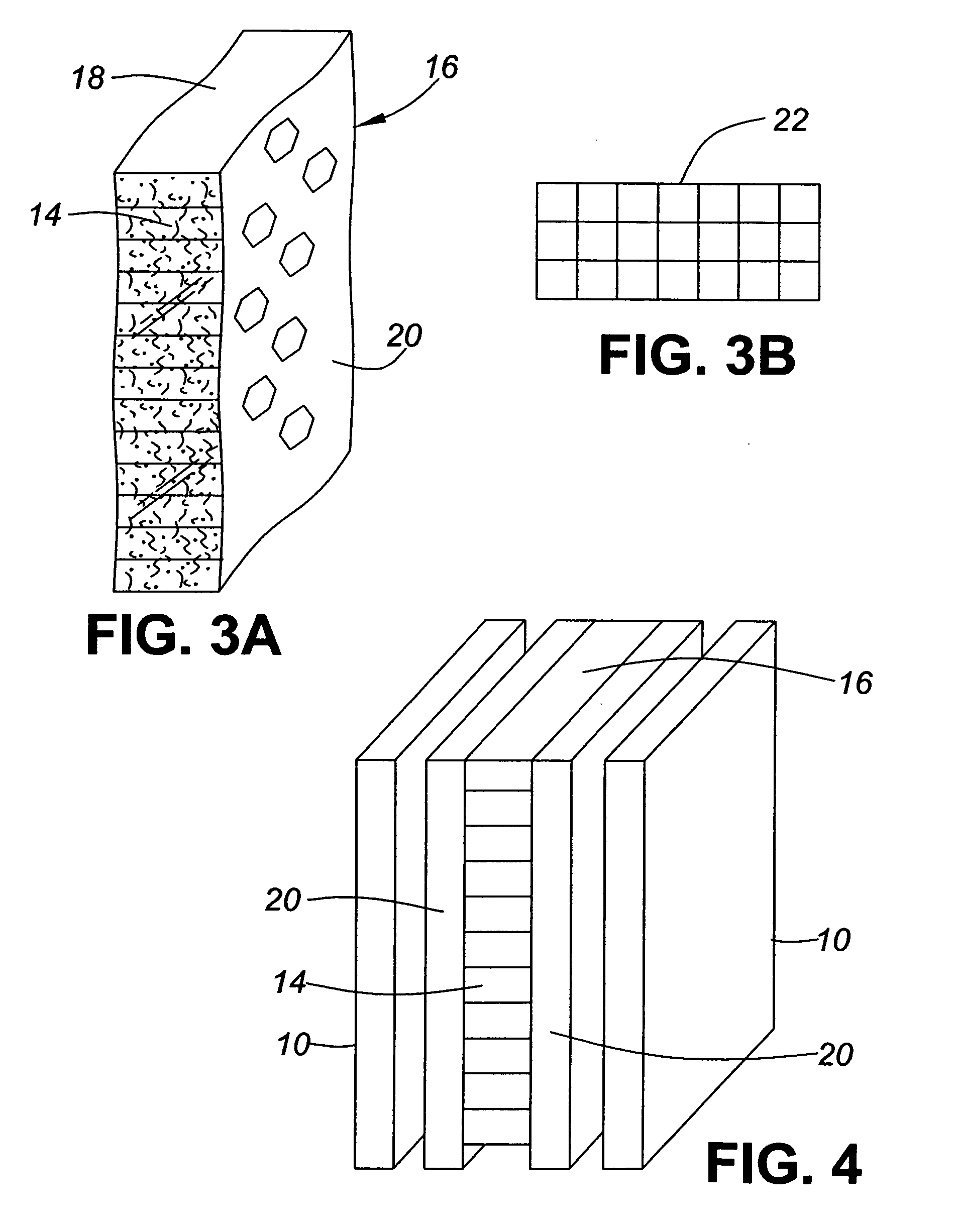

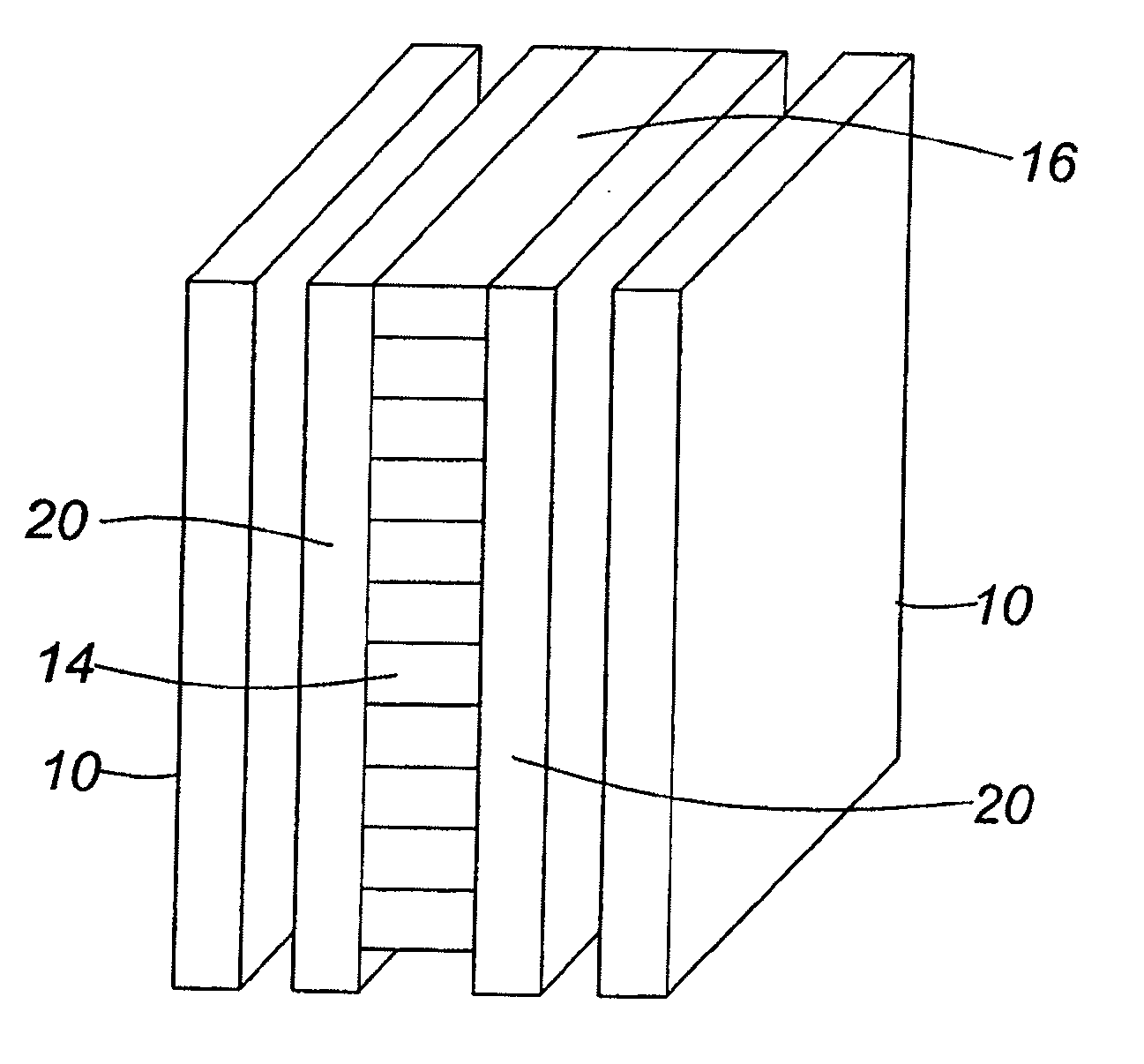

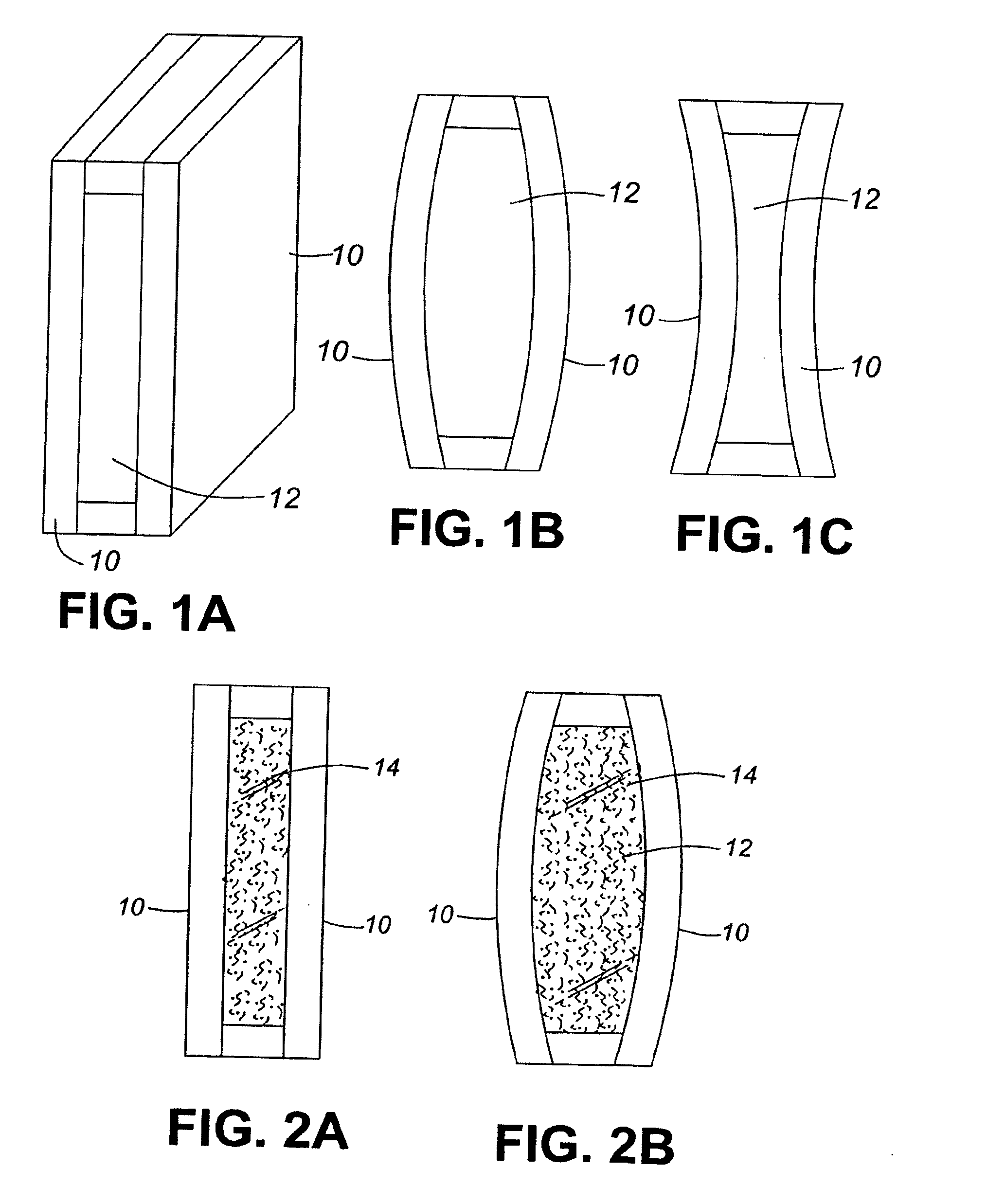

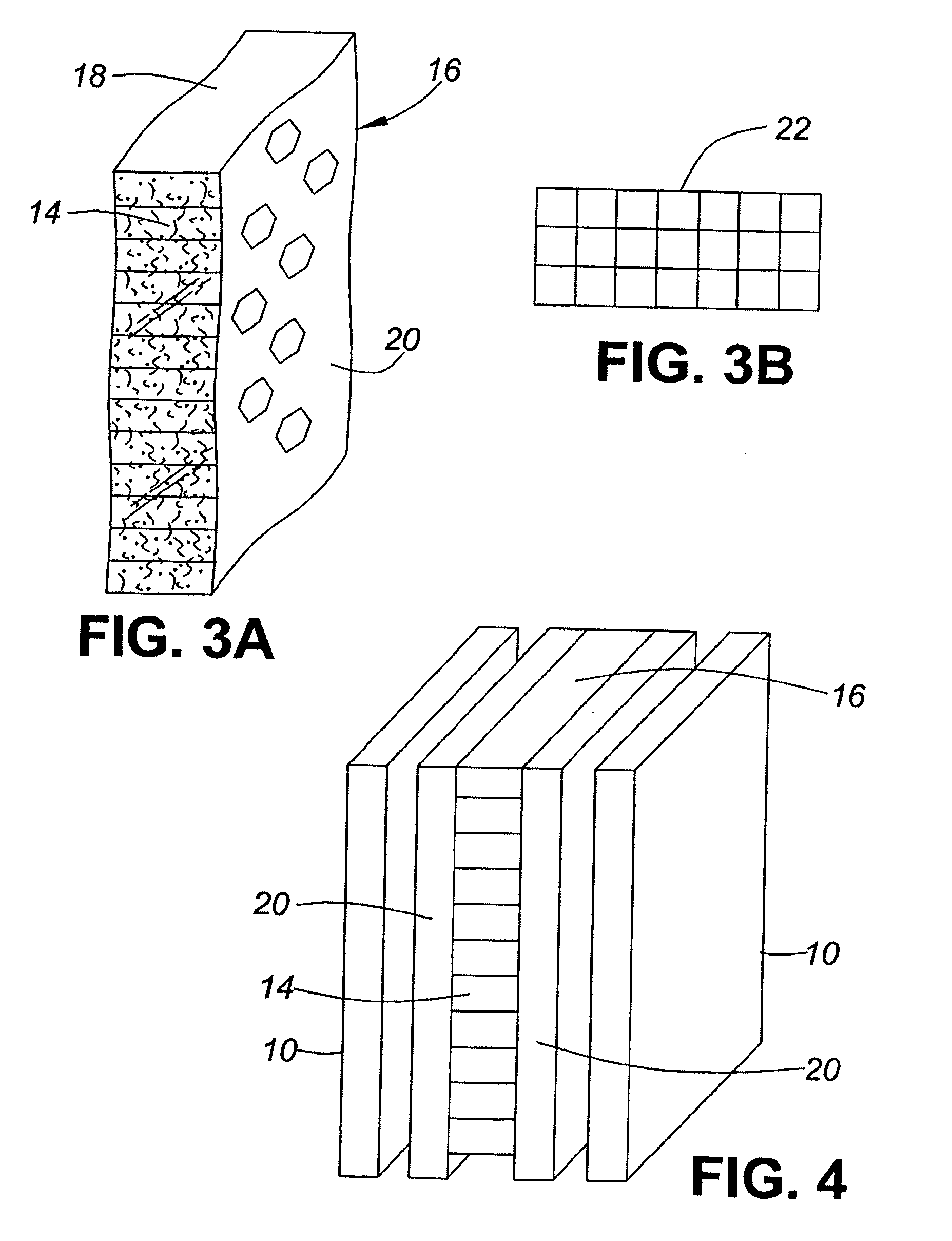

Glazing unit with transparent filler

ActiveUS20070122588A1Improve insulation effectReduce the amount requiredDoors/windowsClimate change adaptationHoneycombEngineering

A glazing unit has a at least one self-supporting insert of light-transmissive insulation material in the form of honeycomb arrangement of cells sandwiched in a gap between a pair of glass lites. A granular, light-transmissive, thermally insulating filler, such as silica aerogel, substantially fills the cells.

Owner:ADVANCED GLAZING TECH AGTL

Glazing Unit with Transparent Filler

ActiveUS20100163157A1Improve insulation effectReduce the amount requiredDoors/windowsClimate change adaptationFilling materialsHoneycomb

Disclosed is a method of making a glazing unit, comprising providing at least one self-supporting insert of light-transmissive insulation material in the form of honeycomb arrangement of cells, substantially filling the cells of said at least one self-supporting insert with a granular, thermally insulating, light transmissive filler material, and sandwiching said at least one insert between a pair of glass lites.

Owner:ADVANCED GLAZING TECH AGTL

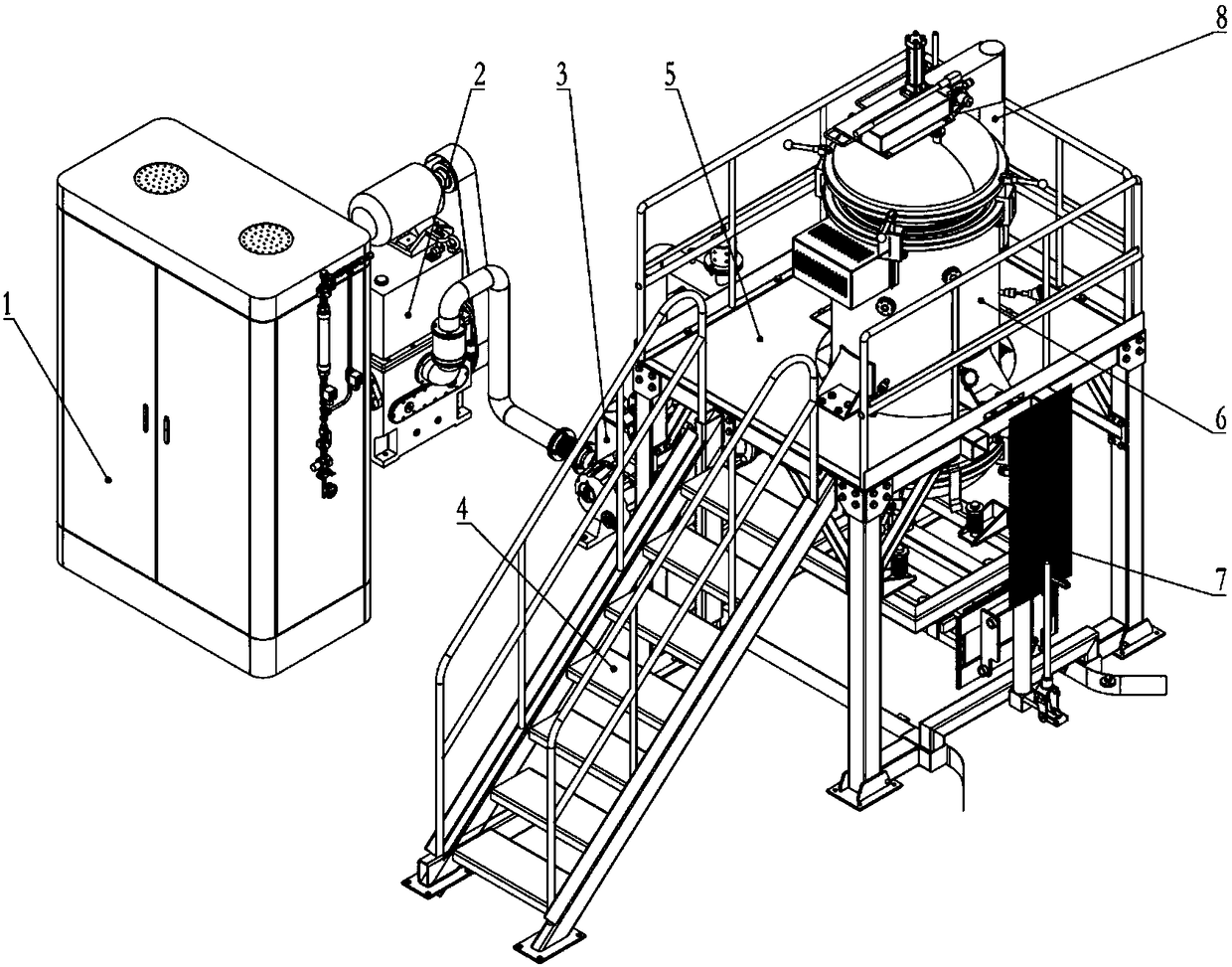

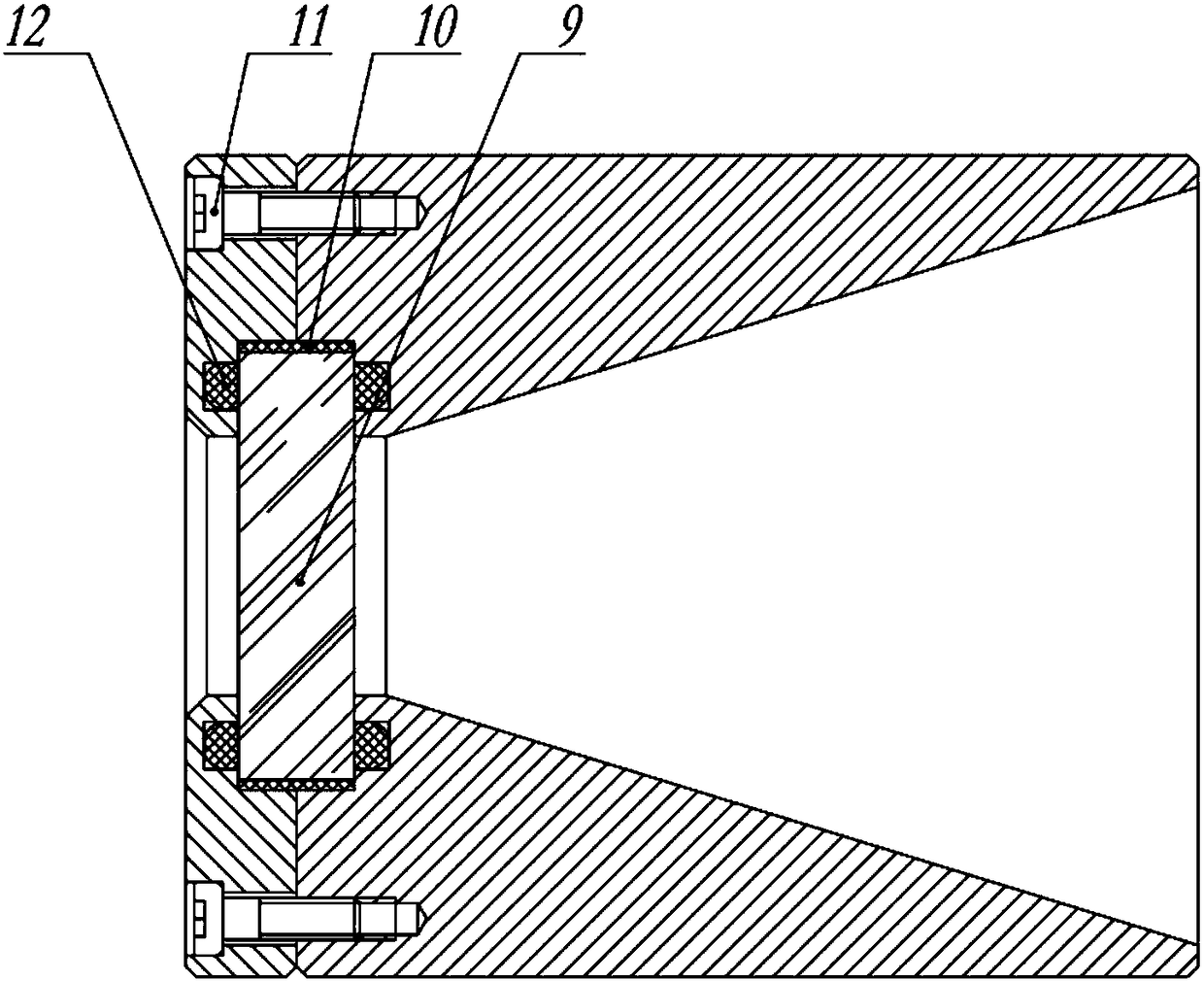

Visual experiment device for melting of nuclear reactor fuel rod and method

ActiveCN108447573ASimple structureOvercoming the inability to observe the exact process of fuel rod meltingNuclear energy generationNuclear monitoringNuclear reactorTest article

The invention provides a visual experiment device for melting of a nuclear reactor fuel rod and a method. The visual experiment device comprises a high-temperature melting furnace provided with a plurality of transparent windows, wherein a test article is vertically arranged in the high-temperature melting furnace; rhenium-molybdenum electrodes are arranged at the upper end and the lower end of the test article respectively and connected with copper electrodes penetrating the side wall of the high-temperature melting furnace; the test article comprises the fuel rod; a tungsten-rhenium heatingrod is arranged in the fuel rod; a cooling water circulation system used for cooling the high-temperature melting furnace is arranged outside the high-temperature melting furnace. By means of the cooling water circulation system for the high-temperature melting furnace, the temperature of the outer side of the furnace body is kept in safe limits, an external high-speed camera can work normally, and a core melting process under a severe accident of a reactor can be simulated realistically. Obtained experiment data can provide verification for the traditional numerical simulation method, and uncertainty of the existing severe accident analyzing procedure is reduced.

Owner:XI AN JIAOTONG UNIV

Modified PET polyester as well as preparation method and application thereof

ActiveCN107312166AFree from destructionShorten the replacement periodFlame-proof filament manufactureSilicon compoundsPolyethylene terephthalateSlurry

The invention relates to modified PET (Polyethylene terephthalate) polyester as well as a preparation method and application thereof, and belongs to the field of modified polyester. The modified PET polyester comprises aerogel particles and polyethylene terephthalate; the aerogel particles are dispersed between the molecular chains of the polyethylene terephthalate uniformly; the particle size of the aerogel particles is 2 to 3 microns; the content of the aerogel particles in the modified PET polyester is 1 to 10 percent by weight. Modified PET is prepared by the steps of adding the aerogel powder into glycol, putting into a grinding machine, grinding to prepare mixed slurry, mixing the mixed slurry and terephthalic acid, and performing esterification reaction and polymerization reaction. Modified PET fiber is prepared by slicing the modified PET, metering, spinning, cooling, applying oil, stretching, performing heat setting and performing winding formation. The aerogel particles are introduced before polymerization of the PET polyester, so the prepared PET has high spinnability, can produce modified PET fibers with various thickness, has wide application range and can meet the production requirement of various fabrics.

Owner:天津朗华科技发展有限公司

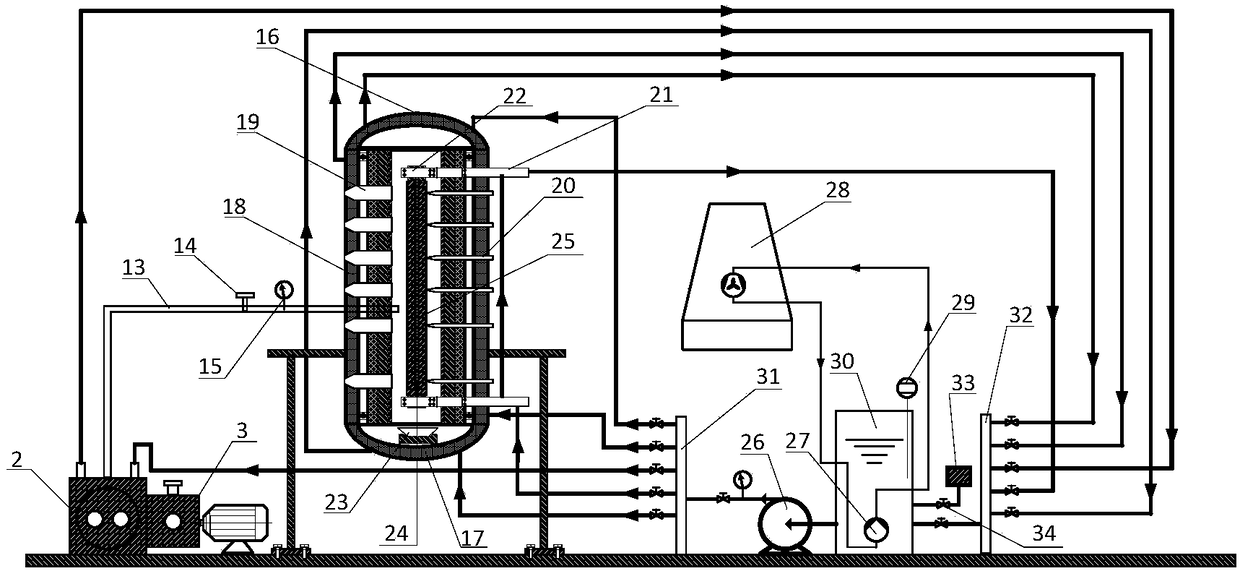

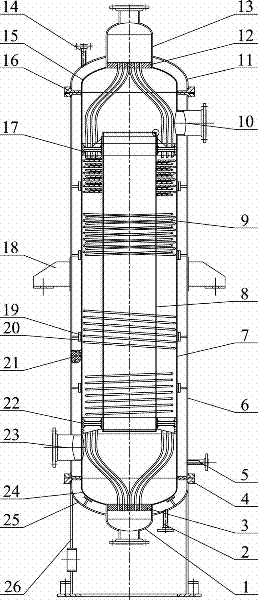

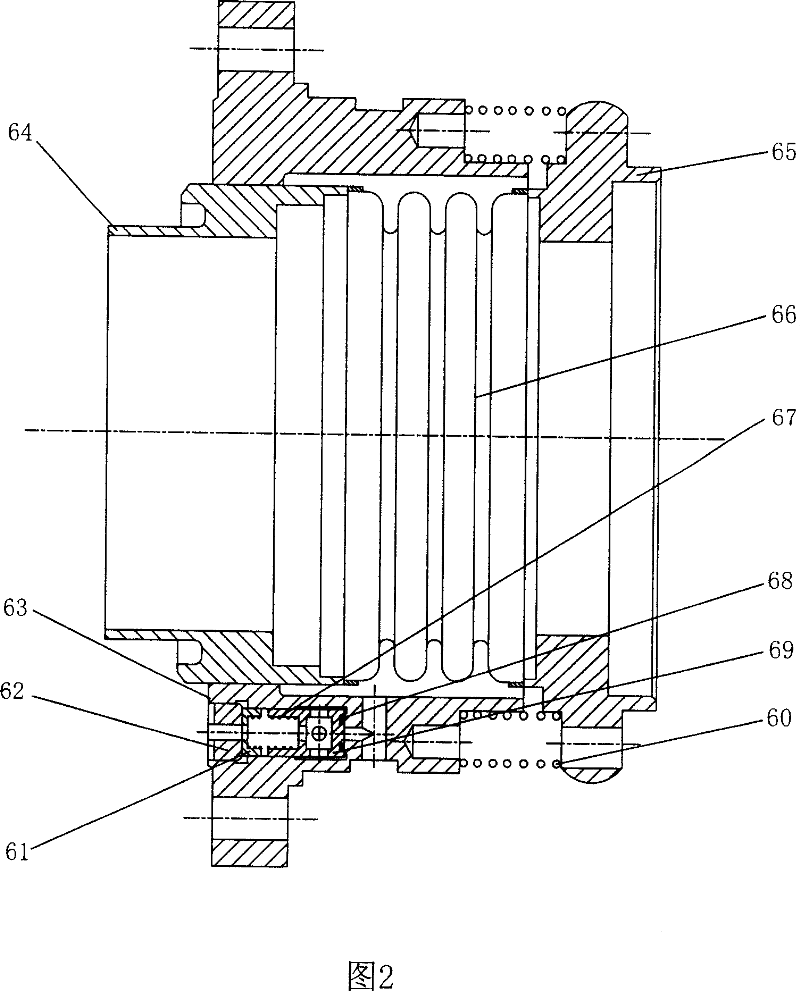

Single-flow low-temperature spiral winding tube type heat exchanger with vacuum heat-insulation effect

InactiveCN102564167AAvoid heat conductionHas low temperature heat transfer characteristicsStationary tubular conduit assembliesMathematical modelEngineering

A single-flow low-temperature spiral winding tube type heat exchanger with a vacuum heat-insulation effect mainly comprises a spiral winding tube bundle and a vacuum shell. A winding equation of a novel spiral tube bundle theory is applied, a mathematical model is built and applied to a numerical simulation process of a flow field, accordingly, a computation method of the tube bundle winding theory is obtained, and the spiral winding tube type heat exchanger is designed and manufactured. The vacuum heat-insulation technology is applied to the single-flow low-temperature spiral winding tube type heat exchanger, a vacuum structure consisting of an upper gland, a lower gland and a barrel which are independent from each other is adopted, and shortcomings that a traditional vacuum structure and a tube nest bundle are combined difficultly and inconvenient in manufacture, installation, detachment and maintenance and the like are overcome. The single-flow low-temperature spiral winding tube type heat exchanger is applicable to technical fields of gas purification and liquefaction separation including natural gas low-temperature liquefaction at the temperature of minus 161 DEG C, air low-temperature liquefaction separation at the temperature of minus 197 DEG C, low-temperature liquid-nitrogen washing at the temperature of minus 197 DEG C, low-temperature methanol washing at the temperature of minus 70 DEG C and the like, low-temperature heat exchange efficiency can be improved, and the single-flow low-temperature spiral winding tube type heat exchanger has the advantages that the single-flow low-temperature spiral winding tube type heat exchanger is compact in structure, heat transfer area of unit volume is large, heat expansion can be automatically compensated, the heat exchanger can be enlarged easily, the quantity of heat exchange equipment can be reduced, and the like.

Owner:张周卫

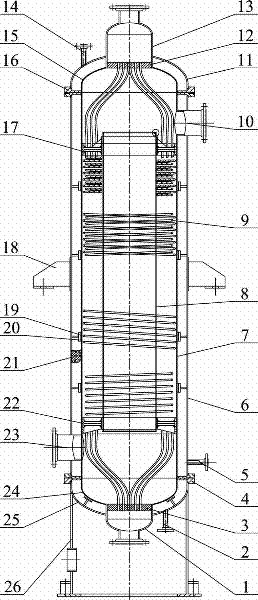

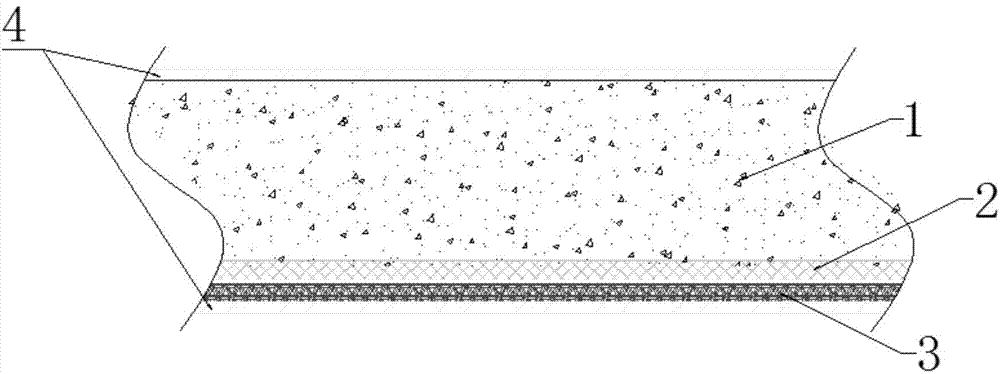

Aerogel composite heat insulation plate and preparation method thereof

The invention provides an aerogel composite heat insulation plate. The aerogel composite heat insulation plate is prepared from the following raw materials in parts by mass: 100 parts of ceramic fiber, 3 to 8 parts of an organic bonding agent, 5 to 15 parts of an inorganic bonding agent, 10 to 30 parts of aerogel powder and 0 to 15 parts of an infrared light shielding agent, wherein the aerogel powder is prepared from 5 weight percent to 15 weight percent of structural water. According to the aerogel composite heat insulation plate provided by the invention, the aerogel containing the partialstructural water is used as a filling material of a ceramic fiber plate and part of micron-pore structure in the ceramic fiber plate is changed into a nano-pore and micron-pore composite structure sothat the convection and conduction heat transfer of the ceramic fiber plate are reduced; the infrared light shielding agent is selectively added and is used as an infrared non-transparent substance inthe ceramic fiber plate, so that the radiation heat transfer of the ceramic fiber plate at high temperature is reduced.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

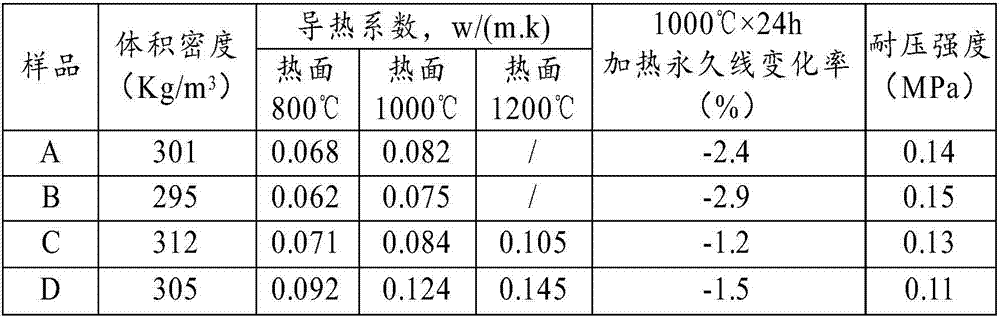

Thermal switch based on negative thermal expansion

InactiveCN105304409ASimple structureLarge running strokeThermal switch detailsMaterials scienceThermal load

The invention discloses a thermal switch based on negative thermal expansion. The thermal switch comprises a negative thermal expansion element and a conductive element. The negative thermal expansion element is made of a negative thermal expansion material. The negative thermal expansion element is connected with the conductive element. When the temperature of the negative thermal expansion element is above a predetermined threshold, the conductive element and a thermal load are disconnected. When the temperature of the negative thermal expansion element is below the predetermined threshold, the conductive element and the thermal load are connected. According to the invention, the thermal switch based on negative thermal expansion is simple in structure and only has two parts; the running stroke of the thermal switch is large; a large gap caused by a large stroke can reduce an angle coefficient between two end faces of the gap; radiation heat transfer can be reduced; and disconnected thermal resistance is increased.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

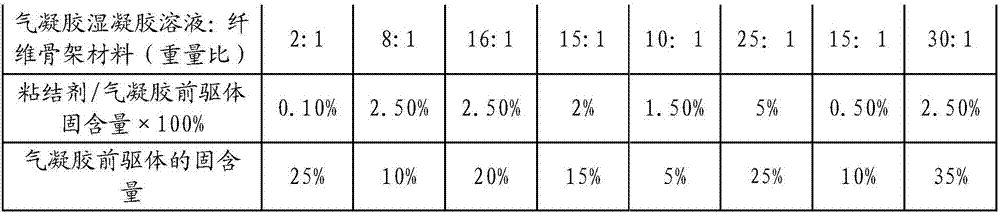

Powder removal prevention aerogel composite insulation felt and preparation method thereof

ActiveCN107140938AShorten the replacement periodImplement reflectionSynthetic fibresCarbon fibresFiberMaterials science

The invention belongs to the technical field of energy-saving and environment-friendly materials, and particularly relates to powder removal prevention aerogel composite insulation felt used for building and industrial energy saving and insulation. The insulation felt comprises an aerogel wet gel solution and a fiber framework material at a weight ratio of (2-30):1. A preparation method of the insulation felt comprises the steps of immersing the fiber framework material into the aerogel wet gel solution according to the aerogel wet gel solution and the fiber framework material at the weight ratio of (2-30):1 to achieve saturation adsorption of the aerogel wet gel solution by the fiber framework material, and then performing drying to obtain the insulation felt. The insulation felt overcomes the problems of high cost and easy powder removal of the existing insulation felt, and is better in performance and more environment-friendly.

Owner:天津朗华科技发展有限公司

Nano miroporous heat-insulating material

InactiveCN102976710AReduce radiative heat transferHigh mechanical strengthCeramicwareFiberSilicon dioxide

The invention relates to a heat-insulating material in a nano miroporous structure. A method for preparing the heat-insulating material comprises the following steps of: (1) stirring and mixing raw materials including nanoscale silica, an infrared opacifier, reinforced fibers and a refractory material to obtain a mixture; and (2) enabling the mixture obtained in the step (1) to be subjected to dry pressing, and sintering at 800 DEG C for at least 1 hour to obtain a target object. The nanoscale silica accounts for 40-80% of the total weight of the raw materials, the infrared opacifier accounts for 10-30%, the reinforced fibers account for 5-15%, and the refractory material accounts for 5-15%. The heat-insulating material provided by the invention has good excellent heat insulating properties and mechanical strength and can be used for a long time at a high temperature.

Owner:EAST CHINA UNIV OF SCI & TECH +1

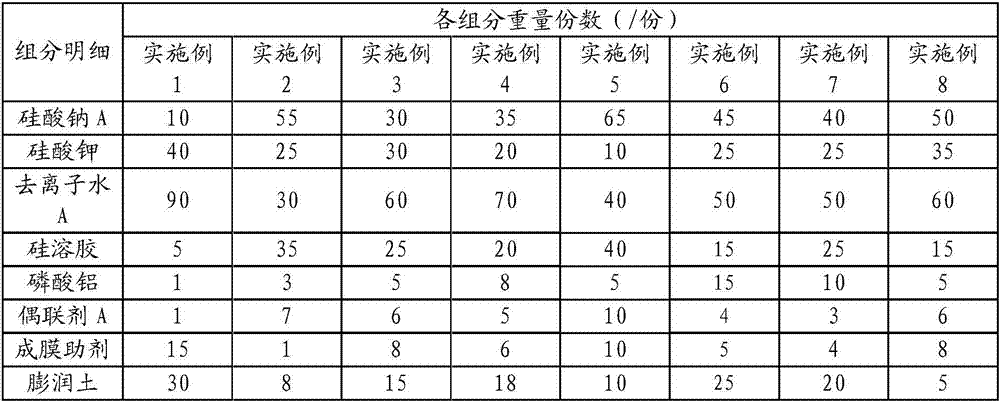

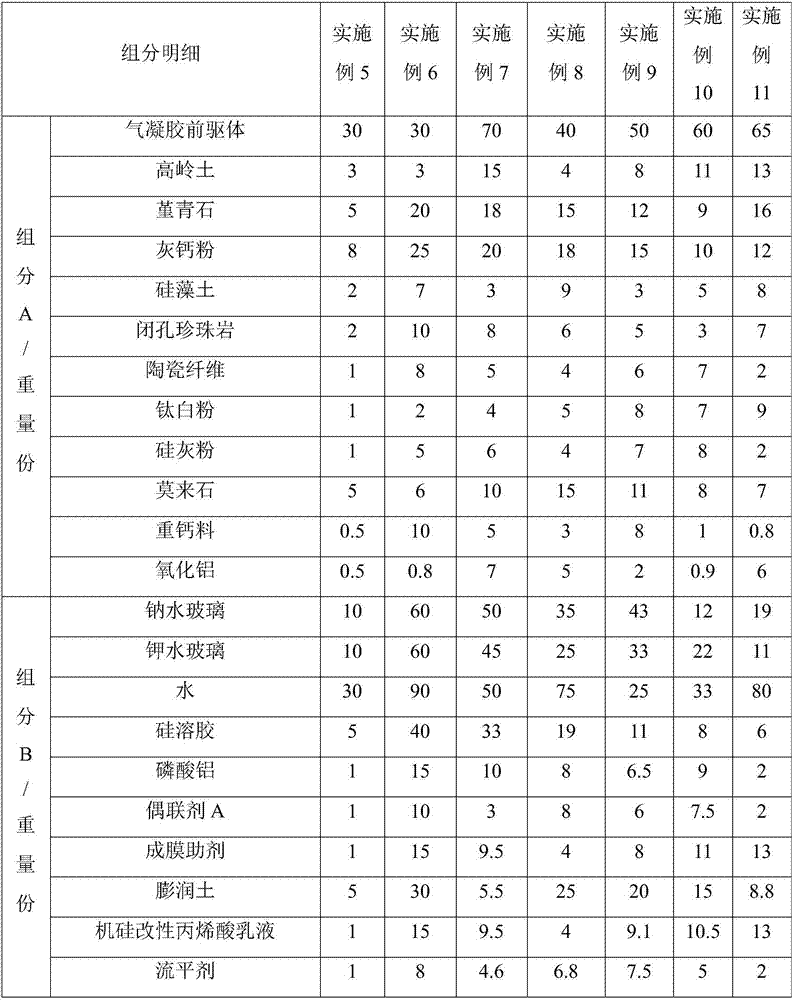

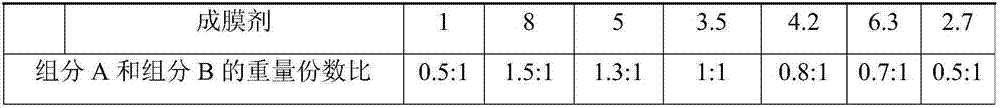

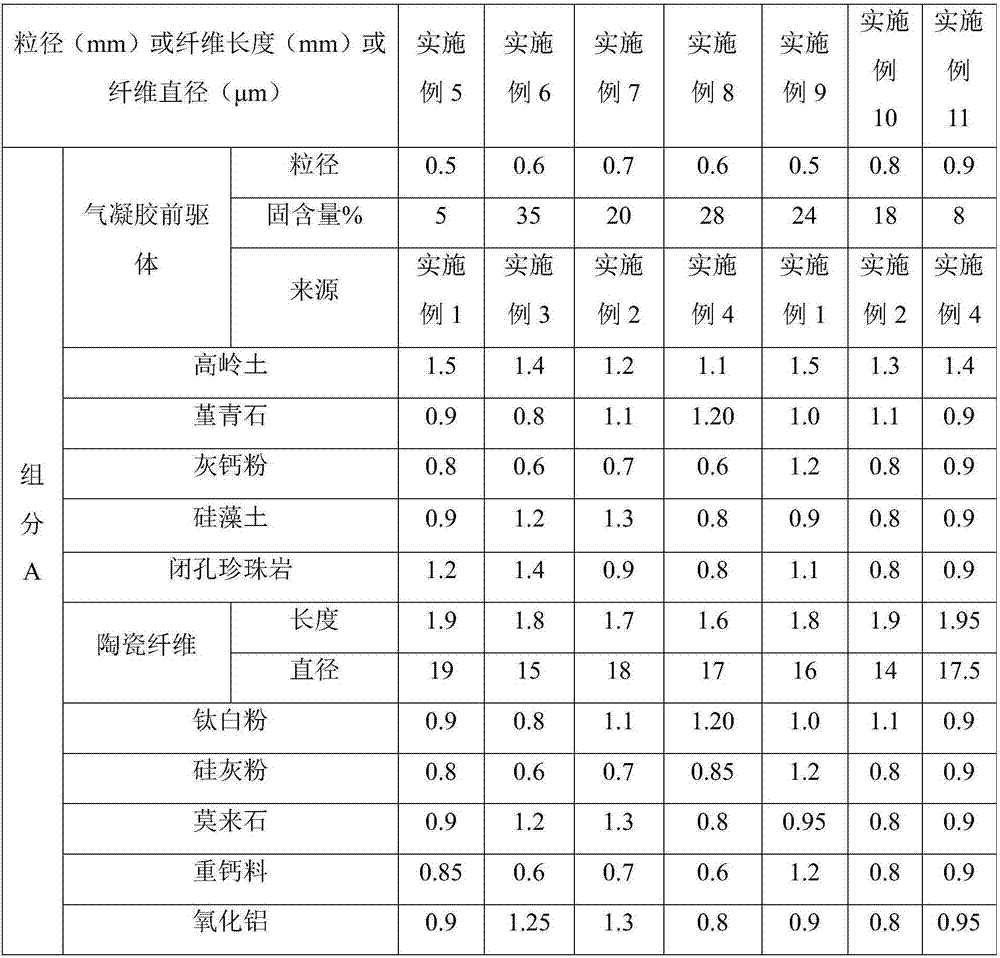

Ultrathin fireproof aqueous coating and preparation method thereof

ActiveCN107254204ADelay the heating processEnhanced Fire DurabilityFireproof paintsAlkali metal silicate coatingsThermal insulationThermal radiation

The invention belongs to the field of aqueous coatings and in particular relates to an ultrathin fireproof aqueous coating and a preparation method thereof. When the ultrathin fireproof aqueous coating is prepared, a component A and a component B are added, the component A comprises an aerogel precursor, stepless powder and the like, and the component B is used as a binding agent. The aerogel precursor is adopted as a core raw material to prepare the fireproof aqueous coating; as an aerogel material is of a nano three-dimensional structure and has characteristics that a solid heat conduction route is effectively prolonged, gas convective heat transfer is inhibited and thermal radiation is reduced, an aerogel fireproof coating made of the aerogel material has a thermal insulation property which is incomparable by conventional materials; after being applied to a steel material and dried, the ultrathin fireproof aqueous coating provided by the invention is relatively high in mechanical strength, achieves a fireproof grade A1, additionally has relatively good advantages of being waterproof and low in cost, and provides a novel material for buildings, environmental protection and industrial energy conservation.

Owner:天津朗华睿博科技有限公司

Nanometer micropore heat insulation board and manufacturing method thereof

ActiveCN103807568AImprove thermal stabilityReduce heat transferThermal insulationLayered productsInsulation layerRadiation temperature

The invention relates to a nanometer micropore heat insulation board. Structurally, an insulation layer, an anti-radiation layer and an enhancement layer are arranged from the cold face to the hot face in sequence. When the nanometer micropore heat insulation board is used, the enhancement layer close to the hot face has strong high-temperature resistance and a strong mechanical property, the insulation layer far away from the hot face has good insulation and heat insulation properties, furthermore, opacifying agent components are added into the anti-radiation layer serving as the middle layer, the radiative heat transferring of the anti-radiation layer is reduced by reducing the overall extinction coefficient, and the insulation and heat insulation properties of the insulation board are intensified. Due to the fact that different opacifying agents have different extinction coefficients and a wide anti-radiation temperature range can be shown, the nanometer micropore heat insulation board can keep the good insulation and heat insulation properties under the high-temperature condition.

Owner:桐乡市中元建材科技有限公司

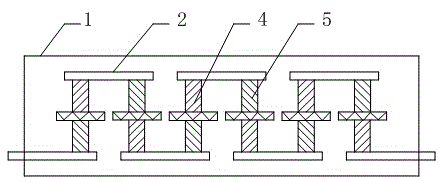

Multi-cascade thermoelectric device and manufacturing method thereof

ActiveCN105006517AAvoid the influence of temperature distributionReduce radiative heat transferThermoelectric device manufacture/treatmentContact methodEngineering

A multi-cascade thermoelectric device includes a packaging sleeve and a power generating unit. Conductive wire and ceramic substrates are disposed on the upper end and the lower end of the power generating unit. The power generating unit is formed by P-type and N-type multi-cascade thermoelectric arms that are arranged alternatively. Each multi-cascade thermoelectric arm includes more than two thermoelectric columns that adapt to various temperature conditions and that are sequentially connected through thermal shield layers. The low-temperature end of each multi-cascade thermoelectric arm is connected to the conductive wires through soldering. The high-temperature end of each multi-cascade thermoelectric arm is in mechanical cooperation with the conductive wires through flexible conductive materials. A connecting place of each conductive wire and one corresponding high-temperature end is provided with a groove through milling, flake graphite and an annular cushion are sequentially placed in the groove, and the high-temperature end is disposed in the annular cushion and is in contact with the flake graphite. A mechanical contact method is adopted to achieve thermal conduction, and flexible conductive graphite is adopted to realize positioning and flexible fixing effects, so thermal mismatch stress is eliminated, and materials are prevented from being destroyed. Moreover, all processing machines of the device are low in price, and then the production cost is reduced.

Owner:珠海莲腾清洁能源有限公司

Nano micropore thermal-insulation board and production method thereof

InactiveCN109734460AImprove insulation performanceReduce thermal radiation heat transferLayered productsCeramicwareCompression moldingLithium oxide

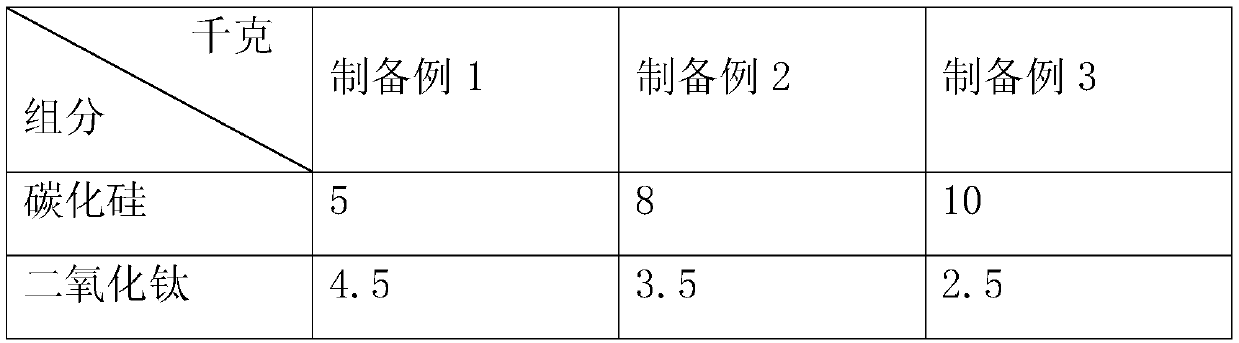

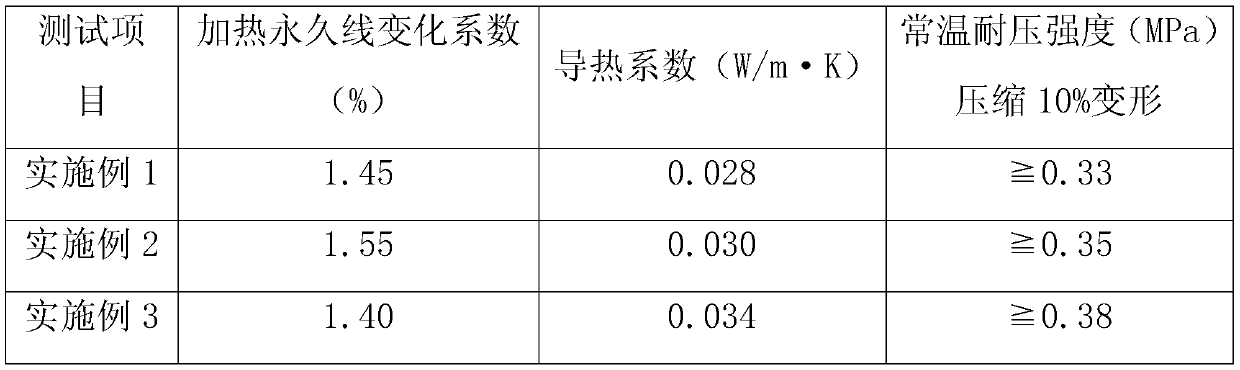

The invention discloses a nano micropore thermal-insulation board and a production method thereof. The nano micropore thermal-insulation board comprises fumed silica, diatomite, micron lithium oxide,reinforcing fibers and infrared radiation opacifying agent, wherein the reinforcing fibers comprises high-silica glass fibers and ceramic fiber cotton; the infrared radiation opacifying agent comprises silicon carbide and titanium dioxide. The production method includes the steps of S1, preparing materials according to the proportion; S2, feeding in a layered manner; S3 stirring and mixing; S4, performing compression molding; S5, packaging. The nano micropore thermal-insulation board is low in heat conduction coefficient, good in high-temperature stability and good in thermal-insulation performance.

Owner:南通中保节能科技有限公司

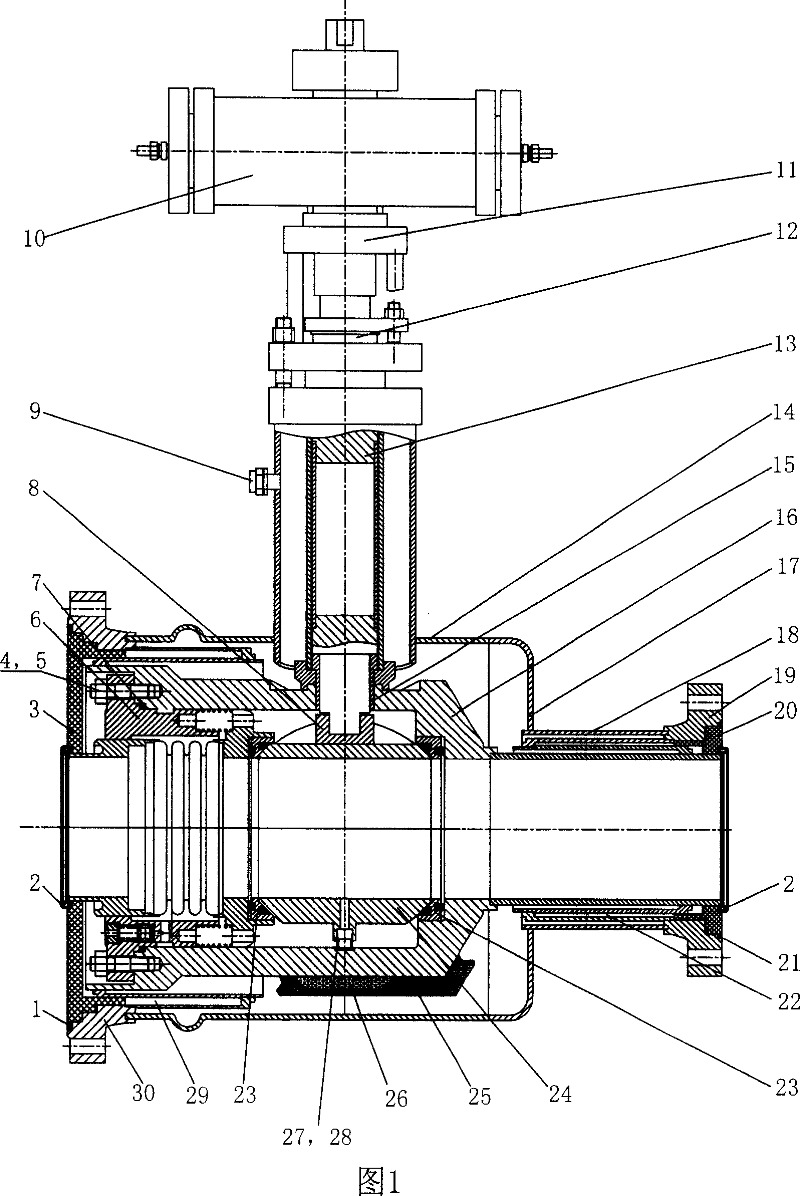

Vacuum low-temperature ball valve

The vacuum low temperature ball valve comprises the clamping part, seal part and the drive part, with the clamping part composed of inlet flange, outlet flange and the outside shell connected in the middle, the seal structure composed of the valve inside the jacket with both ends fixed on the inlet and outlet flanges, fixed on the spring valve base at the inlet end of the valve through the screw bolt and nut and two seal bases with seal cushion embedded at both sides, with one connected to the spring valve base and the other connected to the valve. The drive part comprises the ball floating inside the valve, both sides of the ball contacting with two seal base, sliders on the top of the ball, with spring base and spring connected to the valve at the bottom of the ball. There are valve bar, guide sleeve and drive mechanism on the slider. It has good seal feature, high reliability, less cold loss, and long working cycle.

Owner:中国航天科技集团公司第一研究院第一〇一研究所

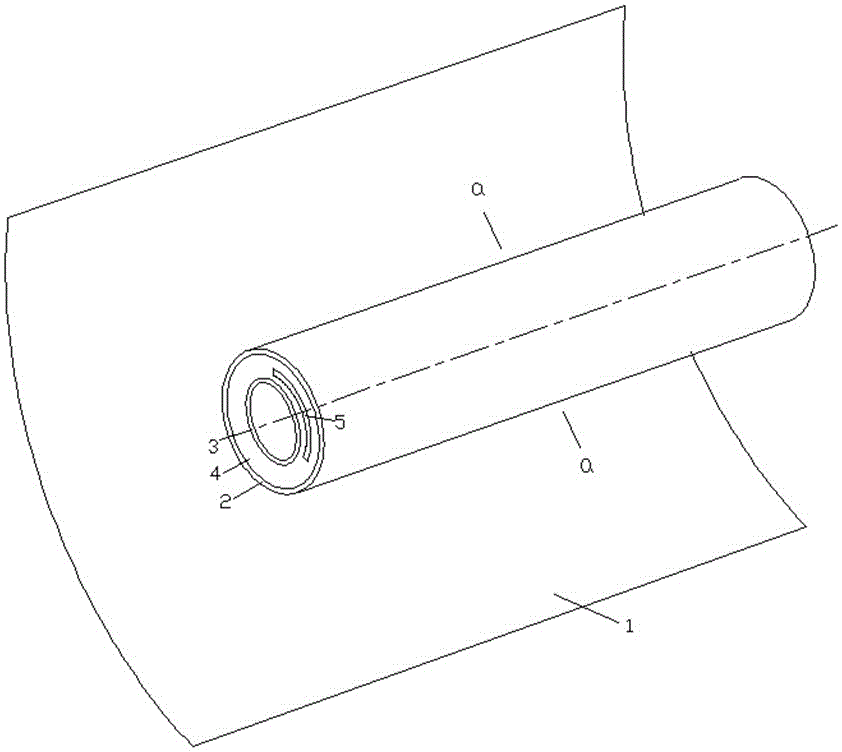

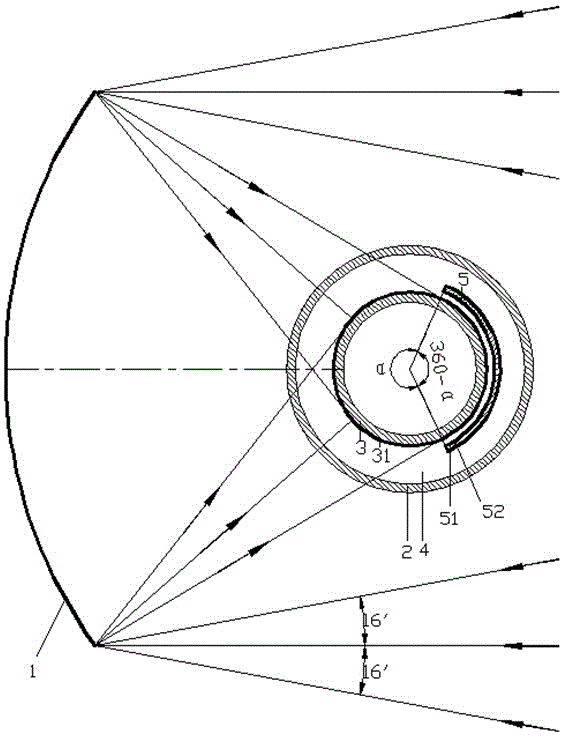

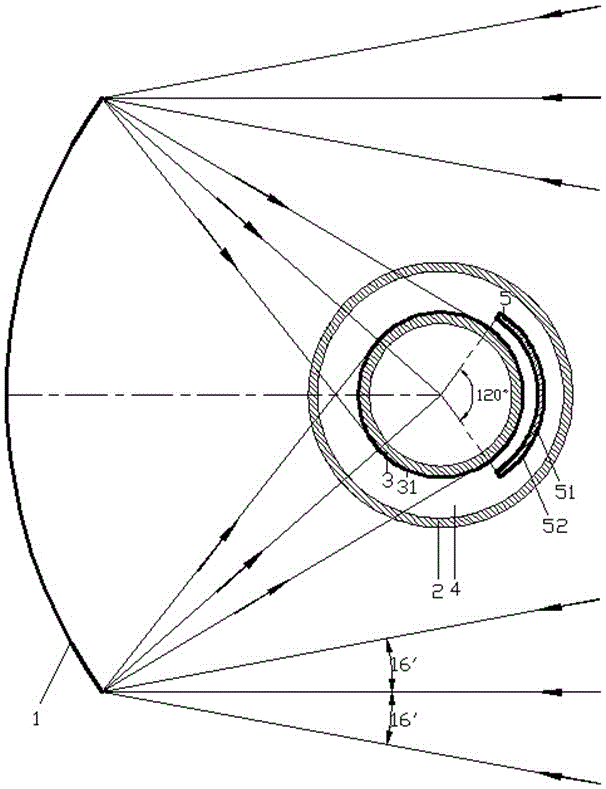

Slot type light gathering type solar vacuum heat collecting pipe

InactiveCN105157257AReduce lossReduce external heat lossSolar heat devicesSolar thermal energy generationGlass coverLow emissivity

The invention relates to a slot type light gathering type solar vacuum heat collecting pipe. The slot type light gathering type solar vacuum heat collecting pipe comprises an outer glass cover pipe and an inner heat absorbing pipe. An inner pipe coating is arranged on the outer cylindrical face of the inner heat absorbing pipe. A cavity between the outer glass cover pipe and the inner heat absorbing pipe is vacuum annular space. A heat shielding plate is arranged in the vacuum annular space. The side face, corresponding to the inner heat absorbing pipe, of the heat shielding plate is a reflection face, and the side face, corresponding to the outer glass cover plate, of the heat shielding plate is an absorption face. The inner surface of the heat shielding plate has the properties of high reflectivity and low emissivity in an infrared band, the outer surface of the heat shielding plate is coated with a selective absorption coating and has the properties of high absorptivity in the solar radiation wave band of 0.2-3 microns and low emissivity in the infrared wave band larger than 3 microns. The external radiation heat loss of the inner pipe of the vacuum heat collecting pipe under the medium-high temperature heat collecting situation can be greatly reduced, and the heat collecting efficiency is improved.

Owner:UNIV OF SCI & TECH OF CHINA

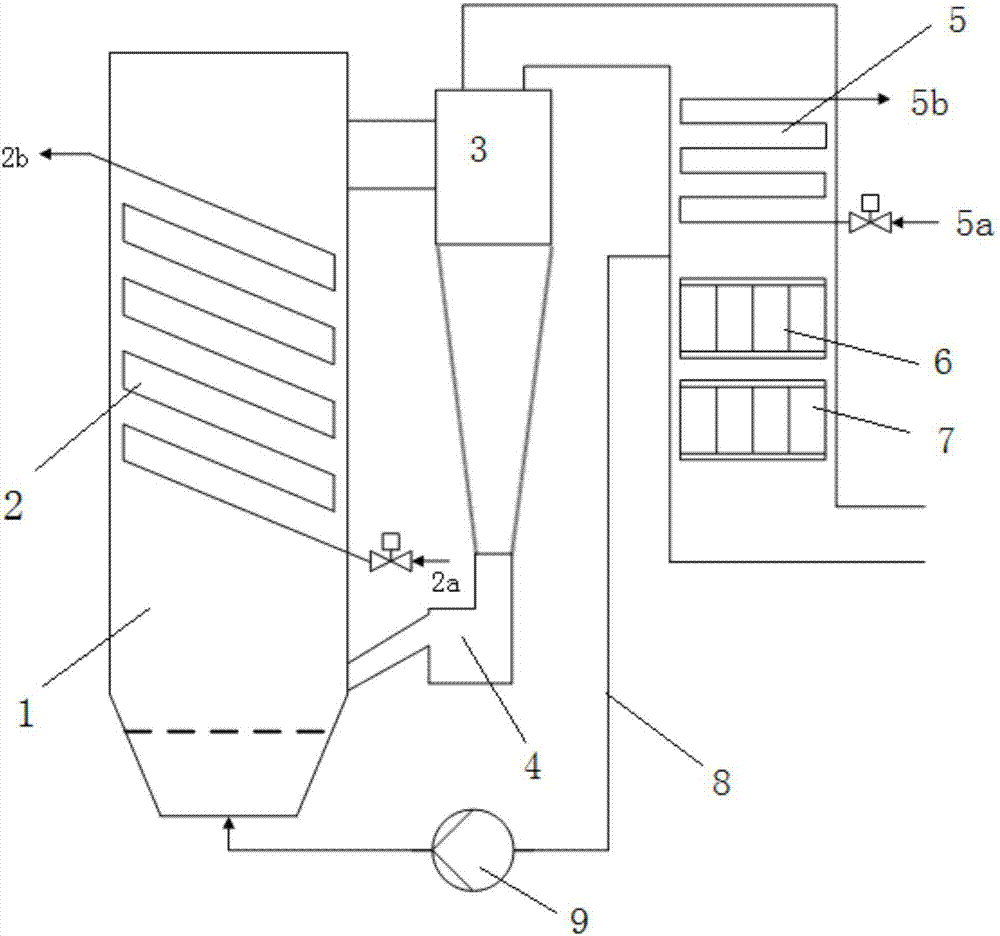

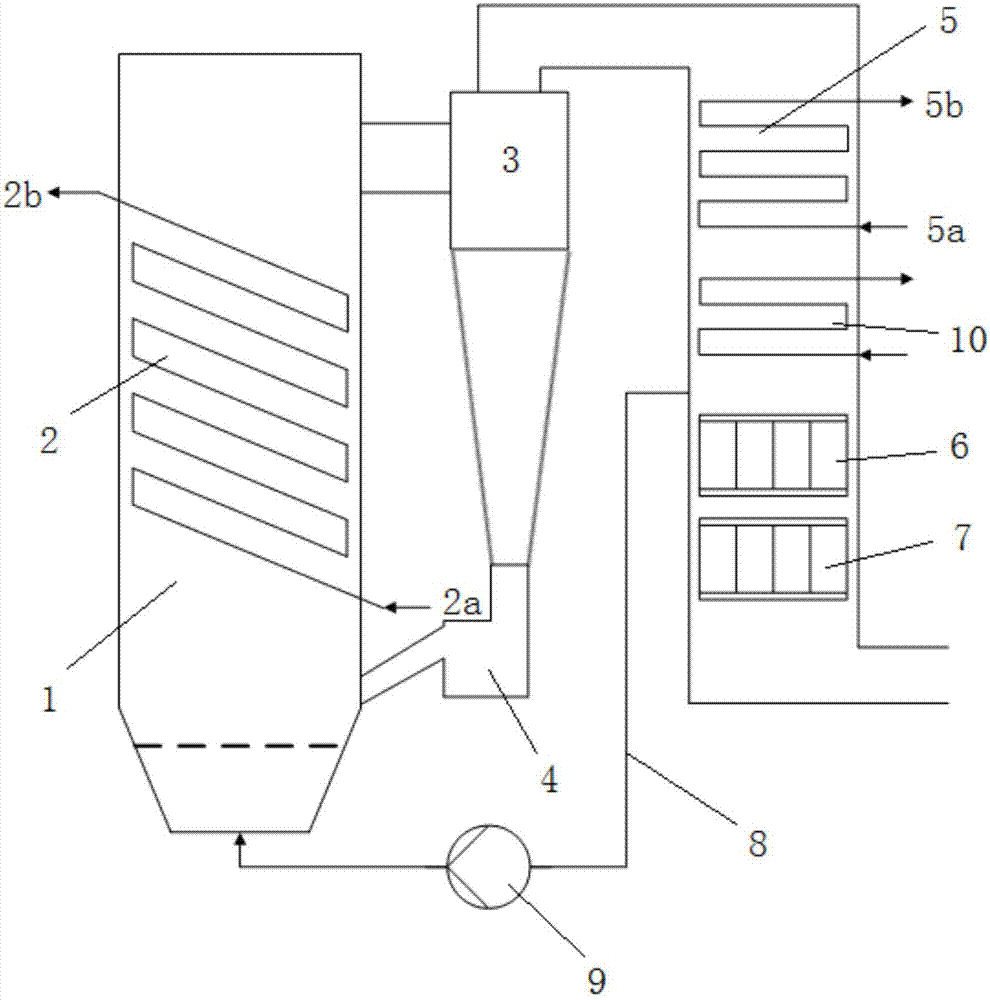

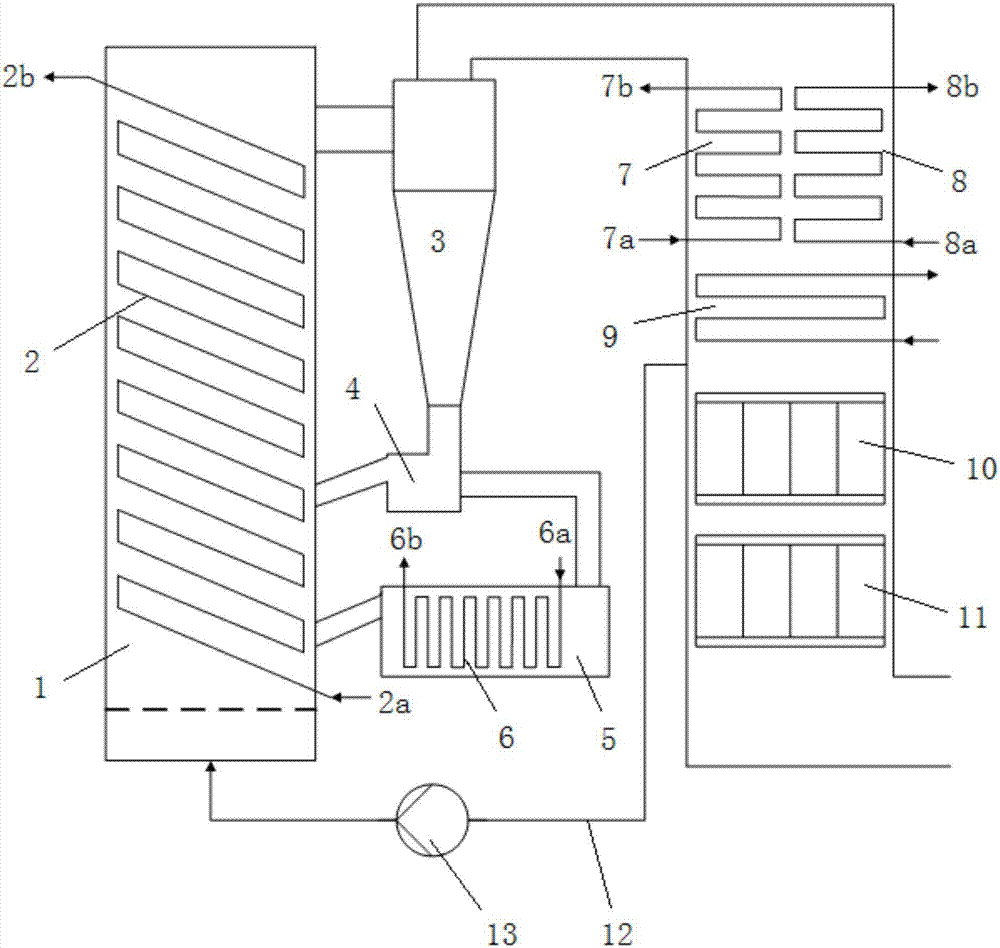

Supercritical-carbon-dioxide circulating fluidized bed boiler heating system and heating method

ActiveCN107120642AEasy to adjustAvoid Overheating ProblemsFluidized bed combustionIndirect carbon-dioxide mitigationSolid particleEngineering

The invention discloses a supercritical-carbon-dioxide circulating fluidized bed boiler heating system and a heating method. The supercritical-carbon-dioxide circulating fluidized bed boiler heating system comprises a boiler, a spiral tube coil super-heater, a classifier, a gas pass and a convection super-heater, wherein the spiral tube coil super-heater is mounted in a boiler chamber of the boiler, and of a spiral tube coil structure, and a spiral tube coil provides a supercritical-carbon-dioxide circulating channel; the convection super-heater is mounted in the gas pass, and provides a supercritical-carbon-dioxide circulating channel; the upper end of the boiler chamber communicates with an inlet of the classifier, an smoke outlet of the classifier communicates with one end of the gas pass, and an solid-particle outlet of the classifier communicates with the boiler chamber of the boiler through a refeed valve; and the spiral tube coil super-heater and the convection super-heater are arranged in parallel or in series.

Owner:SHANDONG UNIV

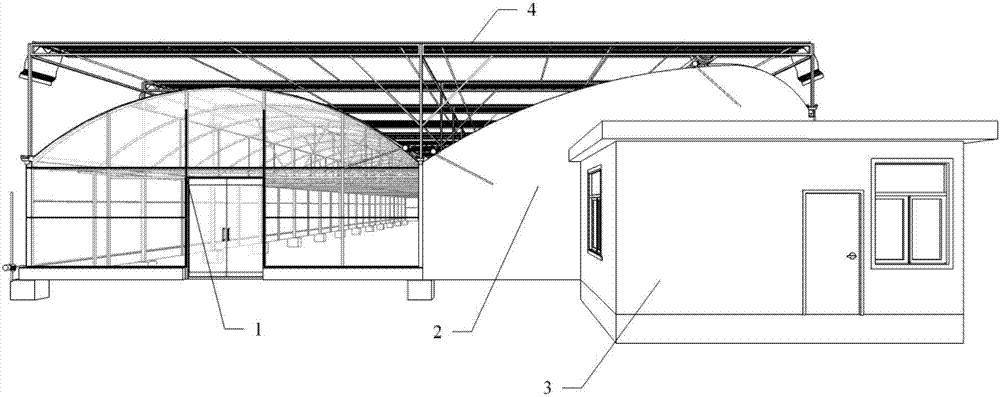

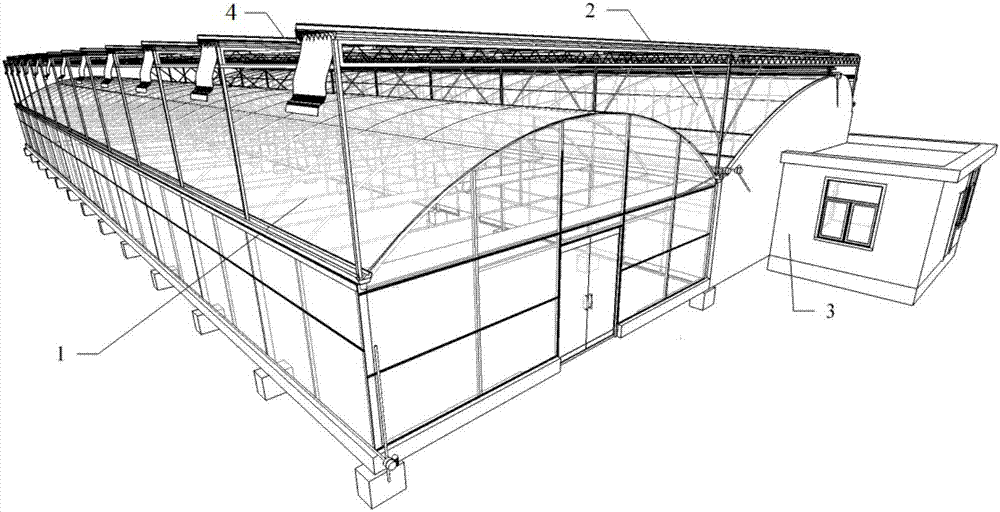

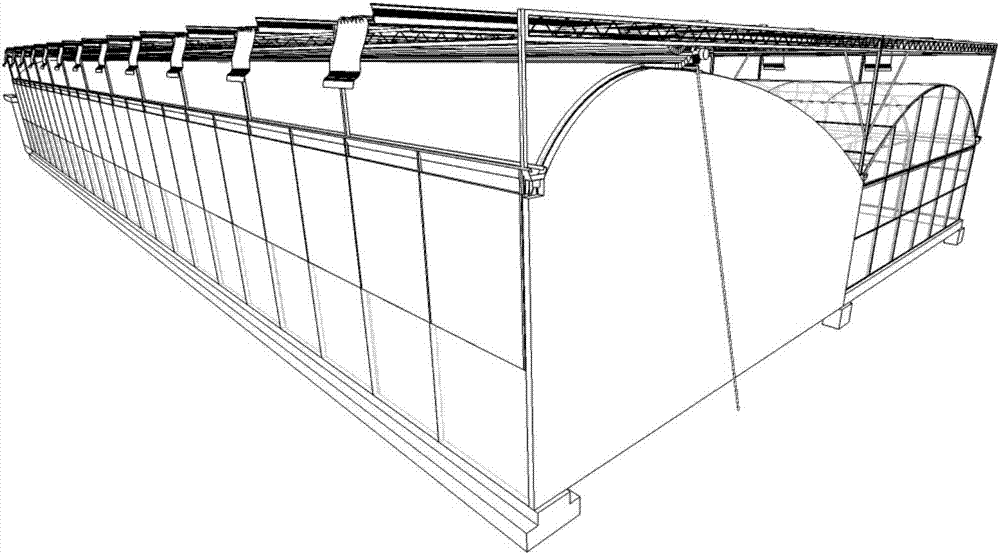

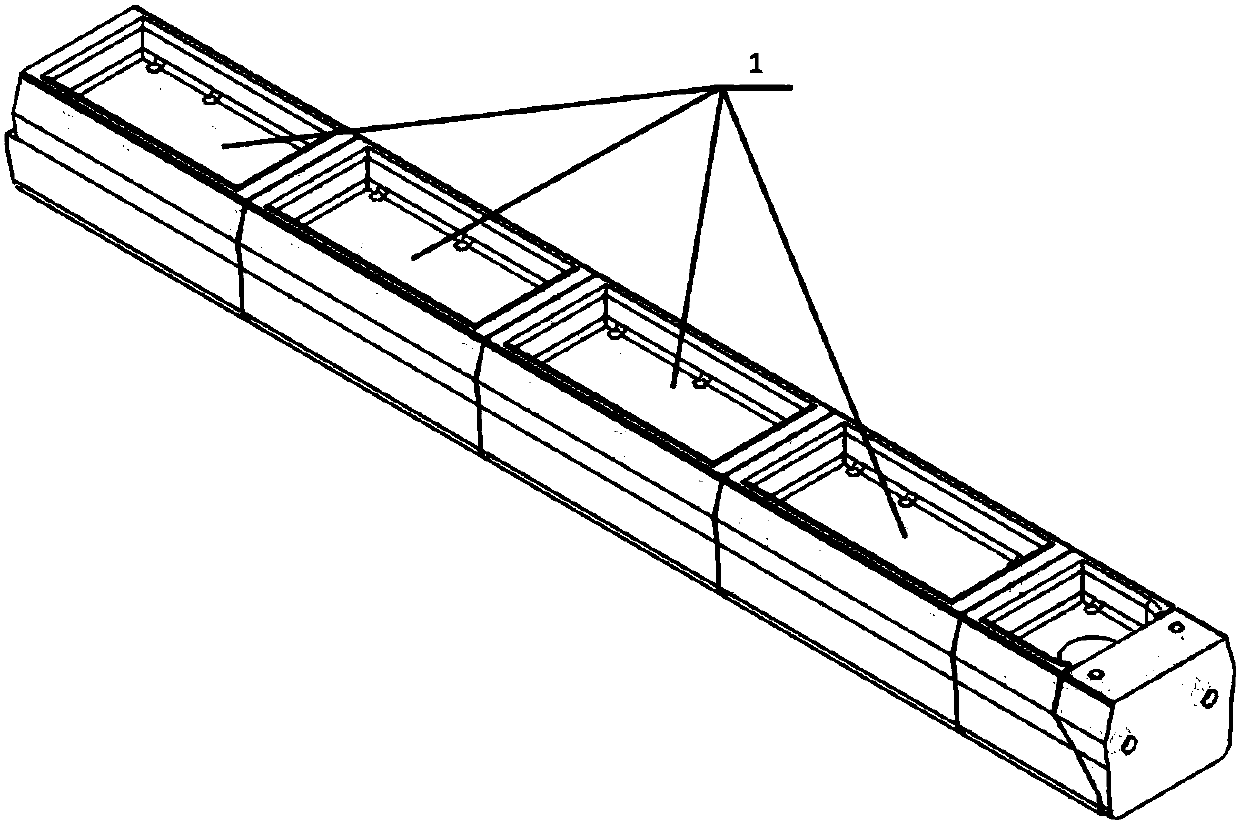

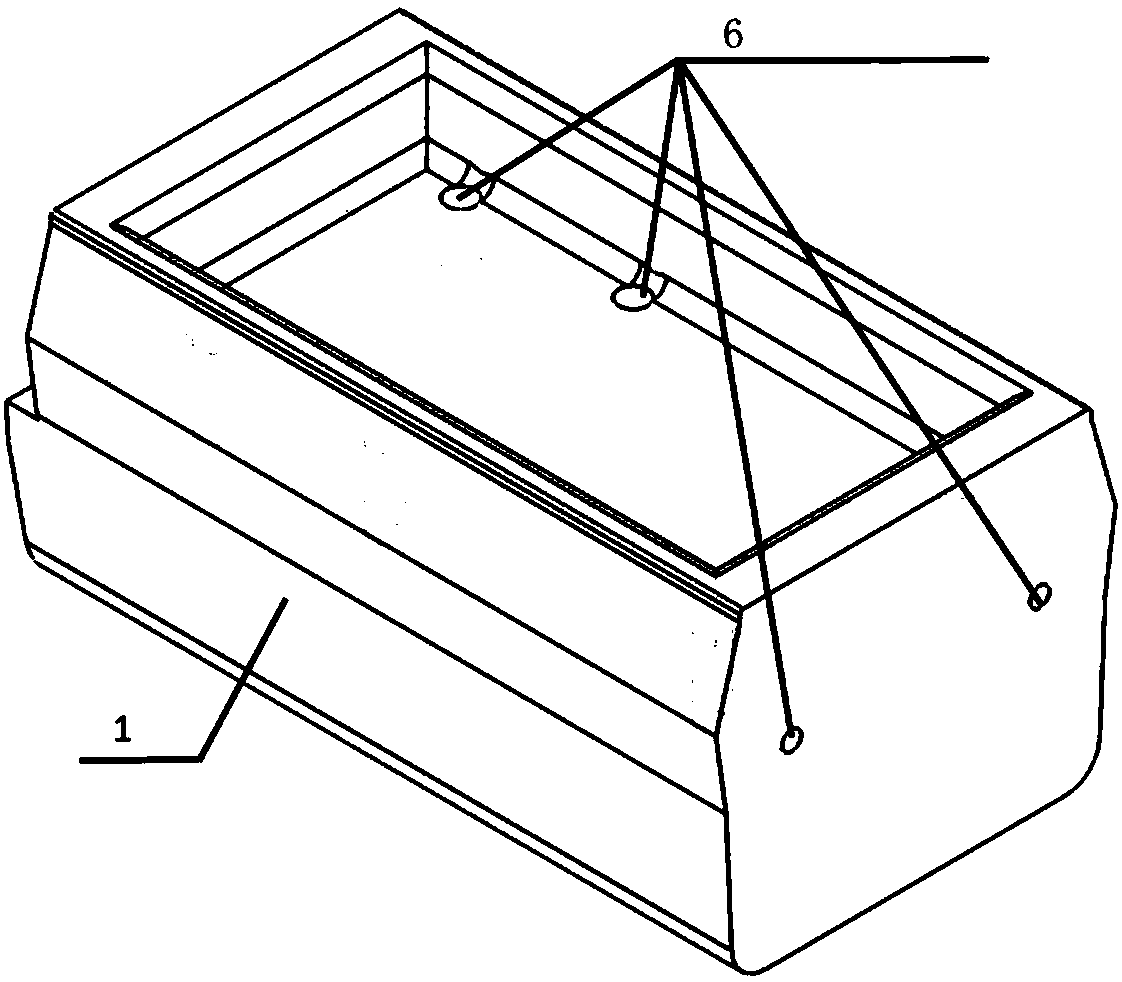

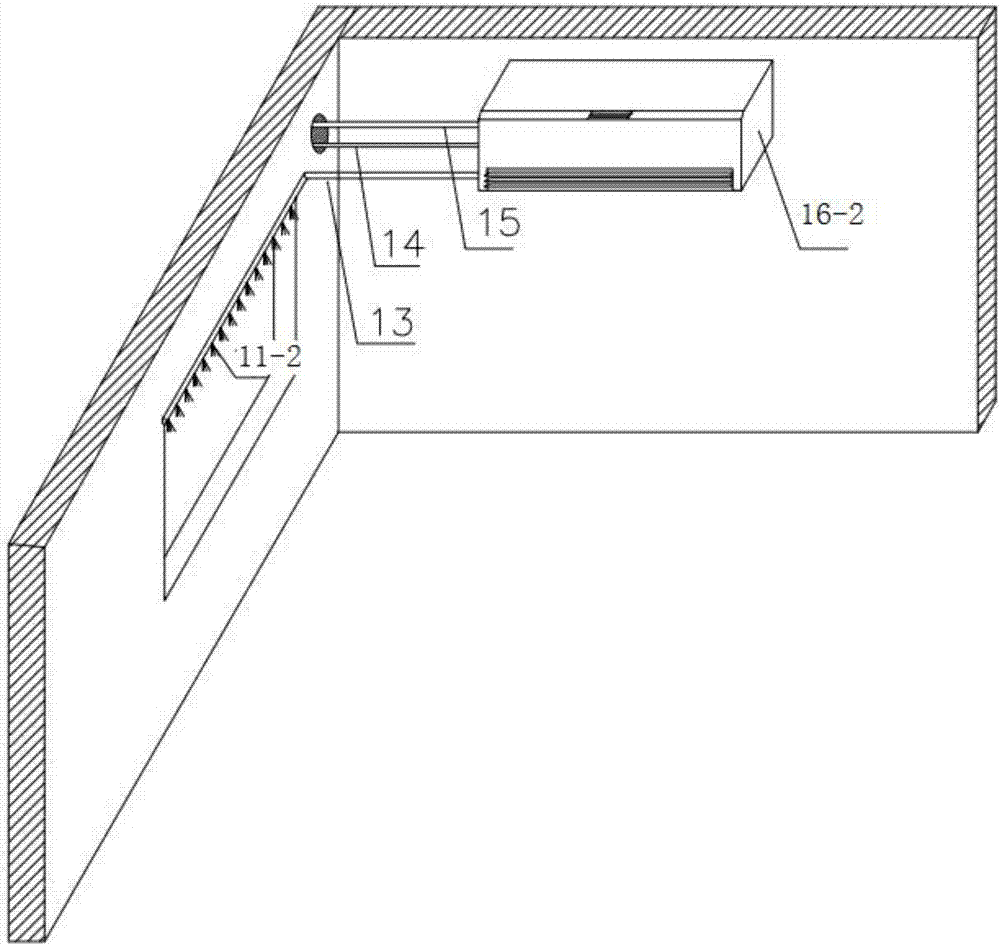

Multi-span solar greenhouse used for annual production in Yangtze River basin region

InactiveCN106962067AEasy constructionEasy maintenanceClimate change adaptationRenewable energy machinesDaylightEngineering

The invention discloses a multi-span solar greenhouse used for annual production in the Yangtze River basin region. The greenhouse comprises a circular-arch-shaped greenhouse body, a sunlight greenhouse body and a workshop. The circular-arch-shaped greenhouse body and the sunlight greenhouse body are connected side by side in the length direction and isolated from each other by a plastic thin film; an outer shading system is arranged above the circular-arch-shaped greenhouse body and the sunlight greenhouse body, a first inner heat preserving system is arranged in the circular-arch-shaped greenhouse body, and a second inner heat preserving system is arranged in the sunlight greenhouse body. Greenhouse framework structures are installed in an assembled mode, time and labor are saved, construction and maintenance are convenient, and the greenhouse can be transferred to a different place to be installed for repeated use. The greenhouse overcomes defects that common plastic greenhouses and dual-layer thin film greenhouses are poor in heat preservation and sunlight greenhouses are high in temperature and humidity in summer, a wall is good in heat preservation and heat storage property, solar energy is fully used, a rear wall can increase the light-permeating area, and light is fully used. The greenhouse is high in compatibility and suitable for regions to the south of the Huaihe River.

Owner:NANJING AGRICULTURAL UNIVERSITY

An energy-saving door lining brick for a coke oven

The invention relates to a door structure of a coke oven, and particularly relates to an energy-saving door lining brick for a coke oven. The door lining brick includes a lining brick main body, a glaze surface, a web and fastening members. The lining brick main body is provided with at least one concave type hollow structure, and is provided with fastening member connecting holes. The glaze surface is hung on the external surface, in contact with coke, of the lining brick main body. The wed covers the concave type hollow structure. The upper surface of the lining brick main body is in close contact with the web. The web and the lining brick main body are fastened through the fastening members so that the concave type hollow structure becomes a sealed cavity. The bottom of the web is coated with a coating. Heat-reflecting coating having high reflectivity is adopted by the coating. The lining brick is a fire-resistant precast block lining brick, and has a height of 500-2000 mm. The lining bricks are arranged into a row up and down and are tightly mounted inside an oven door frame. The lining brick can greatly reduce the present oven door thickness, reduce the temperature of the external wall of an oven door, reduce heat loss and save energy.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Heat-insulation and heat-preservation polyimide foam material and preparation method thereof

The invention provides a polyimide foam material. The polyimide foam material comprises the following raw materials: 20-40 parts by weight of aromatic dianhydride, 15-30 parts by weight of isocyanate,15-35 parts by weight of a solvent, 0.1-2 parts by weight of low molecular alcohol, 2-5 parts by weight of a foaming agent, 3-10 parts by weight of a foam stabilizer, 0.1-3 parts by weight of a catalyst and 5-15 parts by weight of an infrared opacifying agent. According to the invention, the infrared opacifying agent is added into the polyimide foam material, and the scattering and absorption effects of the infrared opacifying agent are utilized to reduce radiation heat transfer and the heat conductivity coefficient of a material; and by using of the infrared opacifying agent, the heat conductivity coefficient of the polyimide foam material is obviously reduced at a high temperature. The addition ratio of the infrared opacifying agent is regulated and controlled, and the addition ratio ofraw materials is combined, so the polyimide foam material with specific composition and formula is finally obtained. The foam material prepared by using the method provided by the invention has low heat conductivity coefficient, and has excellent heat resistance and mechanical properties at the same time.

Owner:常州福隆科技新材料有限公司

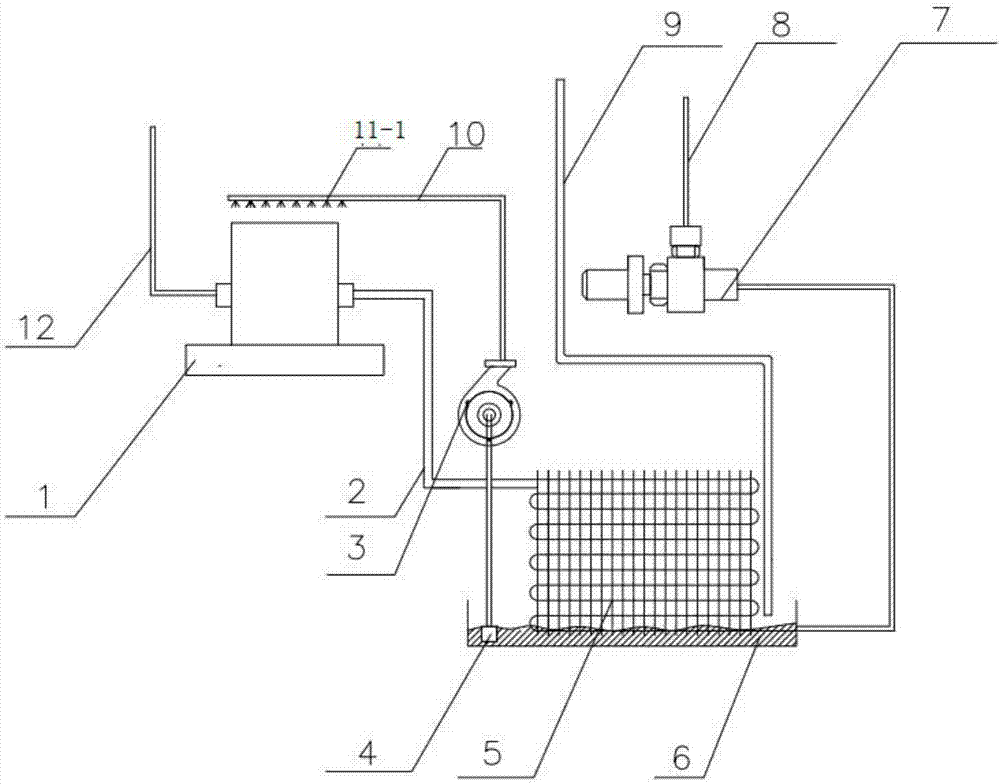

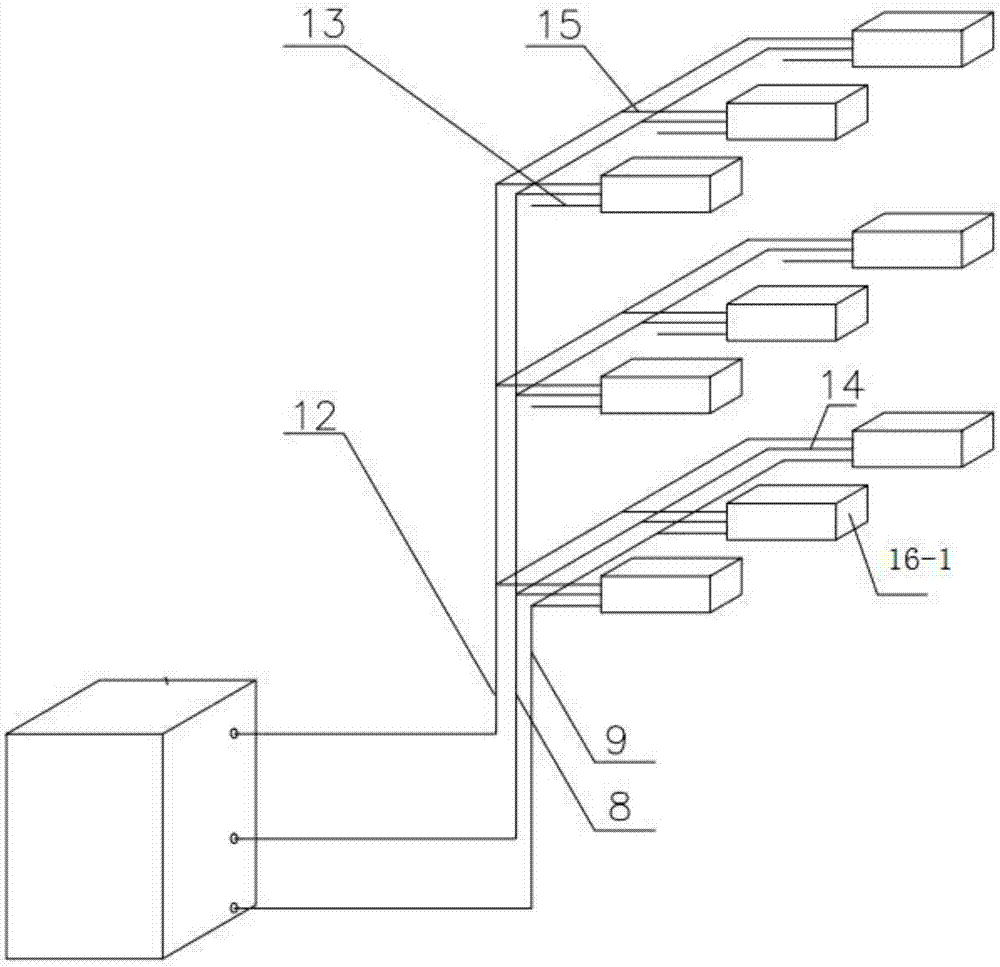

Condensed water utilizing system of multi-split air conditioner

PendingCN106969488AAvoid random emissionsAvoid lostCondensate preventionLighting and heating apparatusLevel sensorEngineering

The invention discloses a multi-line condensed water utilization system. Condensed water utilization system 1 of the present invention includes evaporator 1, condensed water drain pipe, water tank and spraying device 1; the condensed water discharged from evaporator 1 on the first floor enters the water tank pair below the condenser through the condensed water drain pipe The condenser is used for cooling, and a liquid level sensor is installed in the water tank. The drain pipe installed with the drain pump and the liquid level sensor is connected to the spray device 1 installed above the compressor; a set of condensed water utilization is installed on each floor of the second floor and above System 2, each set of condensed water utilization system 2 includes an evaporator, pipeline and atomizing device 2; the condensed water discharged from the evaporator 2 is discharged from the pipeline respectively, and the pipeline is connected to the atomizing device 2, and the condensed water is introduced into the window edge spraying device 2 . The system is simple in structure and easy to install, and has good versatility. At the same time, the condensed water above the second floor does not need to be collected on the first floor, but is discharged to the nearest window to save pipelines.

Owner:TIANJIN UNIV OF COMMERCE

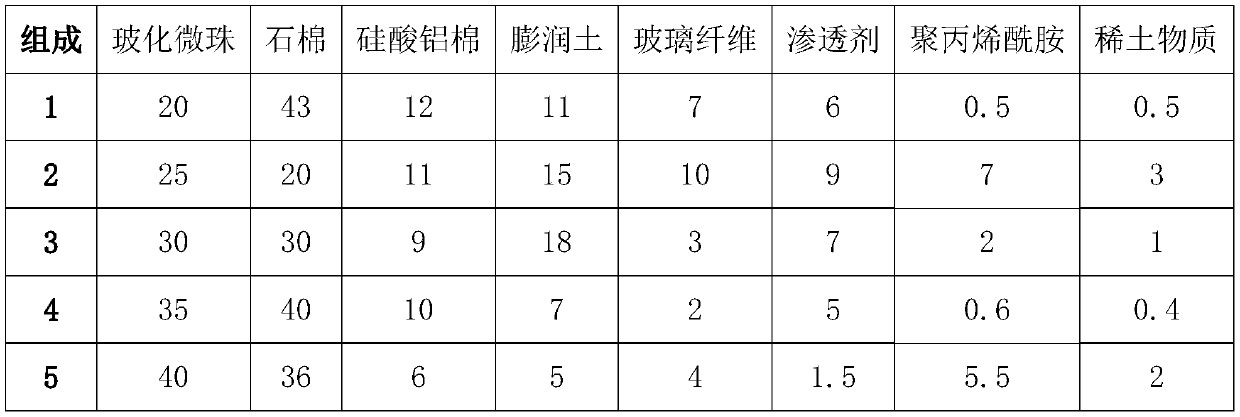

Heat insulation composition

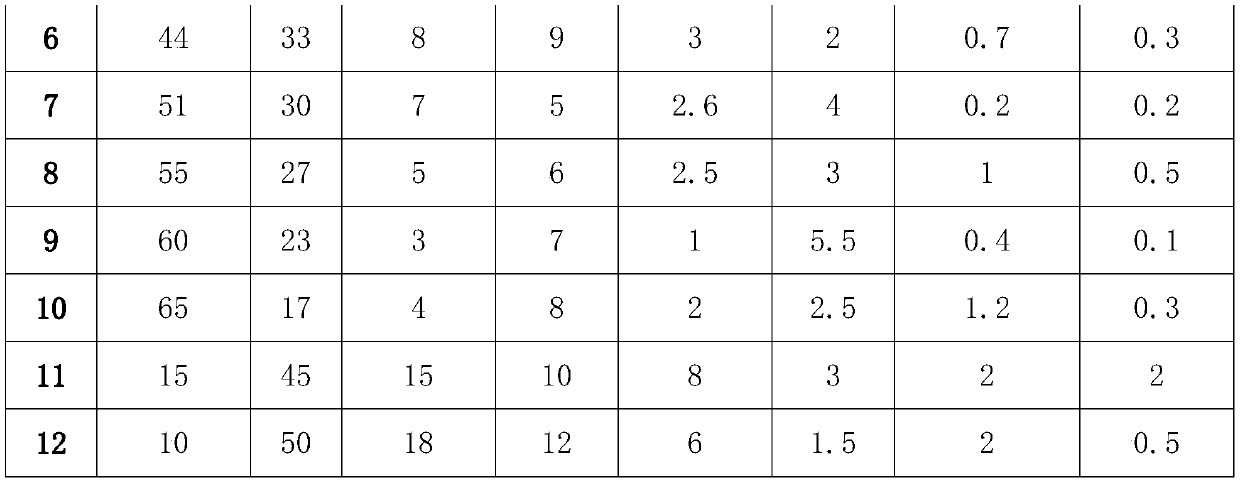

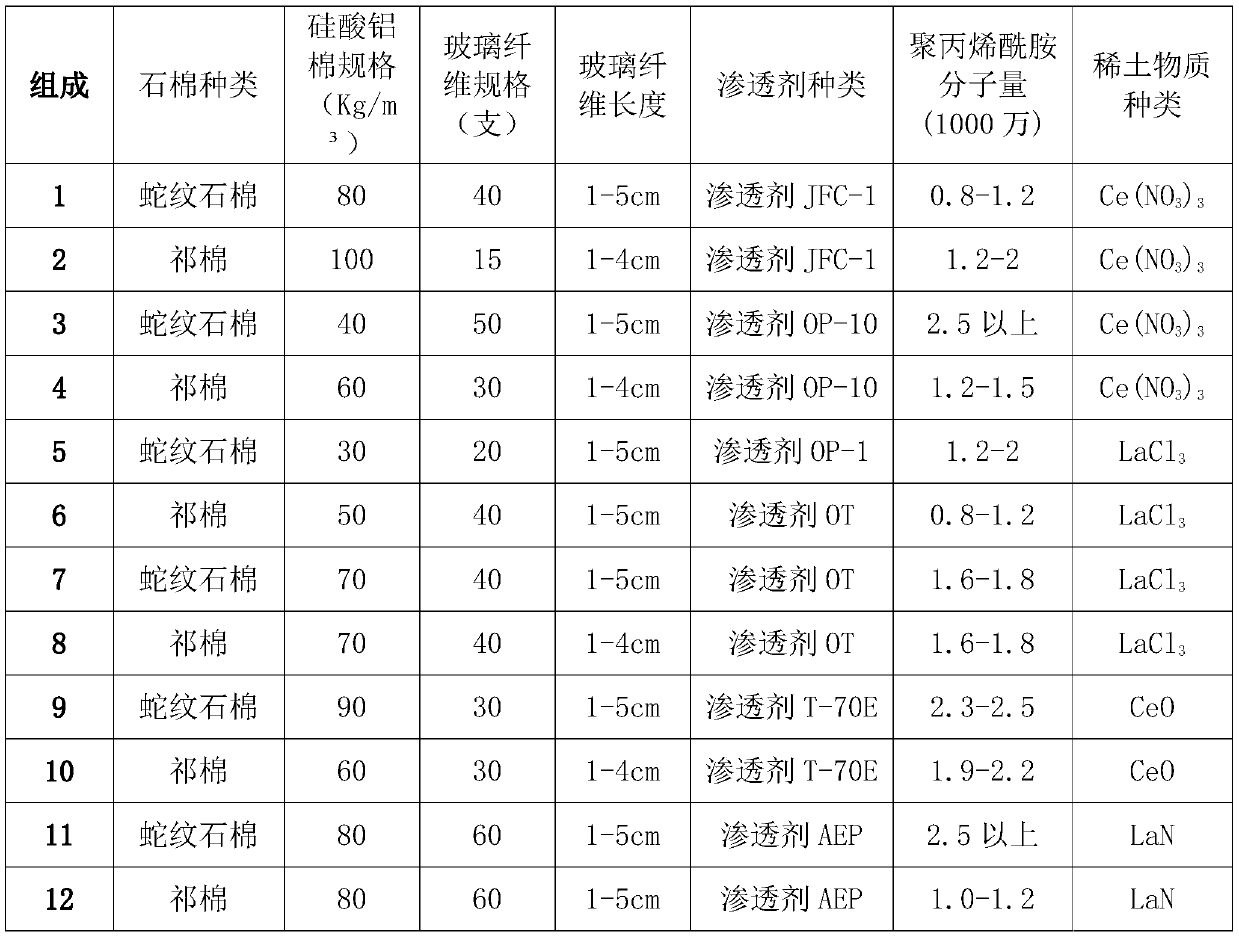

PendingCN110498636AExtended heat conduction pathLow thermal conductivityGlass fiberAluminum silicate

The invention discloses a heat insulation composition with a heat insulation effect. The problem that the volume weight of the heat preservation composition is large when the heat insulation effect isimproved in the prior art is solved. The heat insulation composition comprises 10-65 wt% of vitrified microbeads, 10-50 wt% of asbestos, 1-20 wt% of aluminum silicate wool, 5-20 wt% of bentonite, 1-10 wt% of glass fibers and 1-10 wt% of a penetrant. The heat insulation composition has the advantages of excellent heat insulation performance, low volume weight, reduction of the thickness by 50% orabove under a condition that the surface temperature is same to that of the aluminum silicate wool, and remarkable energy-saving effect due to great reduction of the heat dissipation area, so the adiabatic temperature range is greatly expanded, and the working temperature range can reach -40-1000 DEG C.

Owner:刘永平

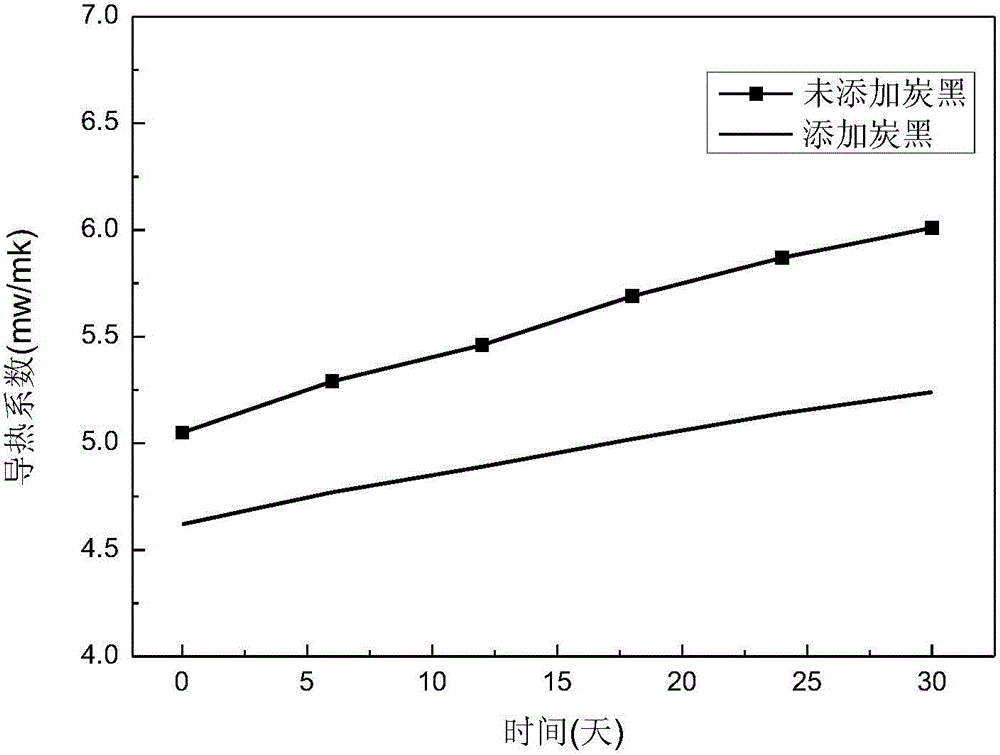

Preparation method of fumed silica and nanoscale carbon black composite material

The invention discloses a preparation method of a fumed silica and nanoscale carbon black composite material. The prepared composite material can be used as a core material of a vacuum insulated panel. According to the composite material, with fumed silica as a main raw material, the compressive strength and the heat-insulating property of the product are improved by adding a short fiber, an opacifying agent and the like; the uniformly dispersed composite material is prepared by a mechanical high-speed mixing method; the effects on the heat-conducting property and the ageing effect of the composite material caused by the nanoscale carbon black as an additive are further researched; a plurality of groups of products are prepared by adjusting the adding amount of the nanoscale carbon black; a test shows that the composite material has the optimal heat-insulating property when the adding amount of the carbon black is 3%-15%, and the heat conductivity coefficient can reach 0.0040-0.0048w / mk. The composite material has the positive effects of being simple in preparation process, cheap and available in used raw materials and suitable for large-scale production, and is mixed by a dry method; the prepared product is excellent and stable in property and good in ageing property; and application energy consumption of household appliances such as refrigerators can be reduced.

Owner:CHUZHOU YINXING NEW MATERIAL TECH CO LTD

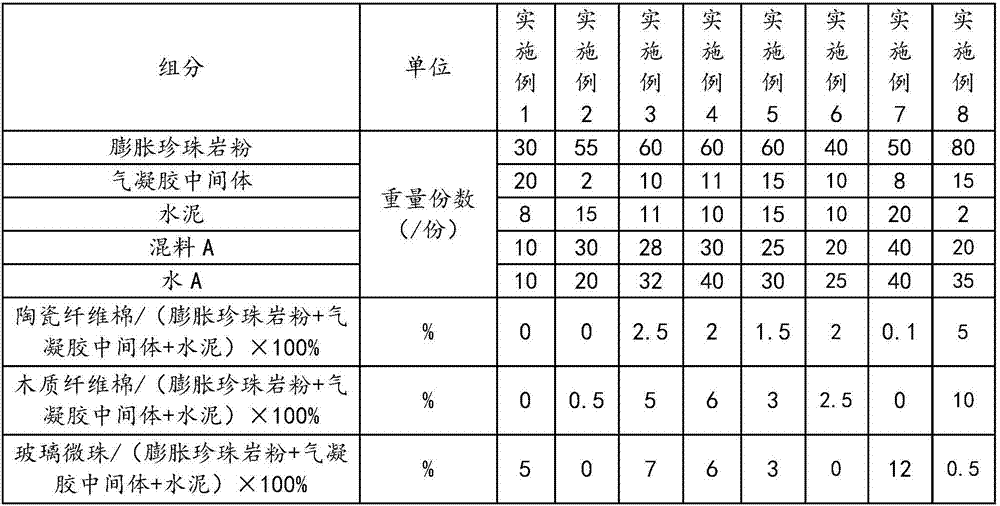

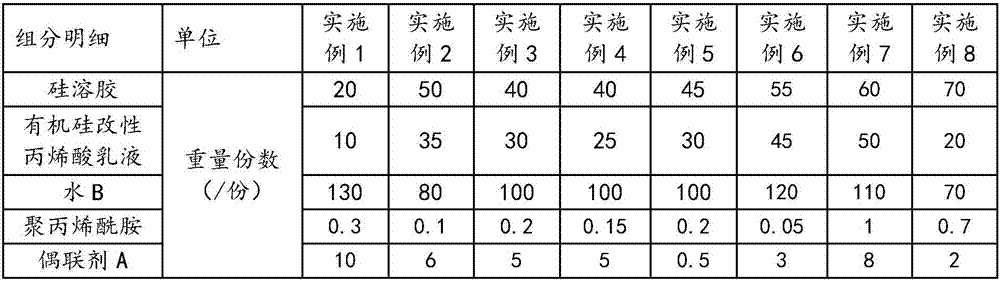

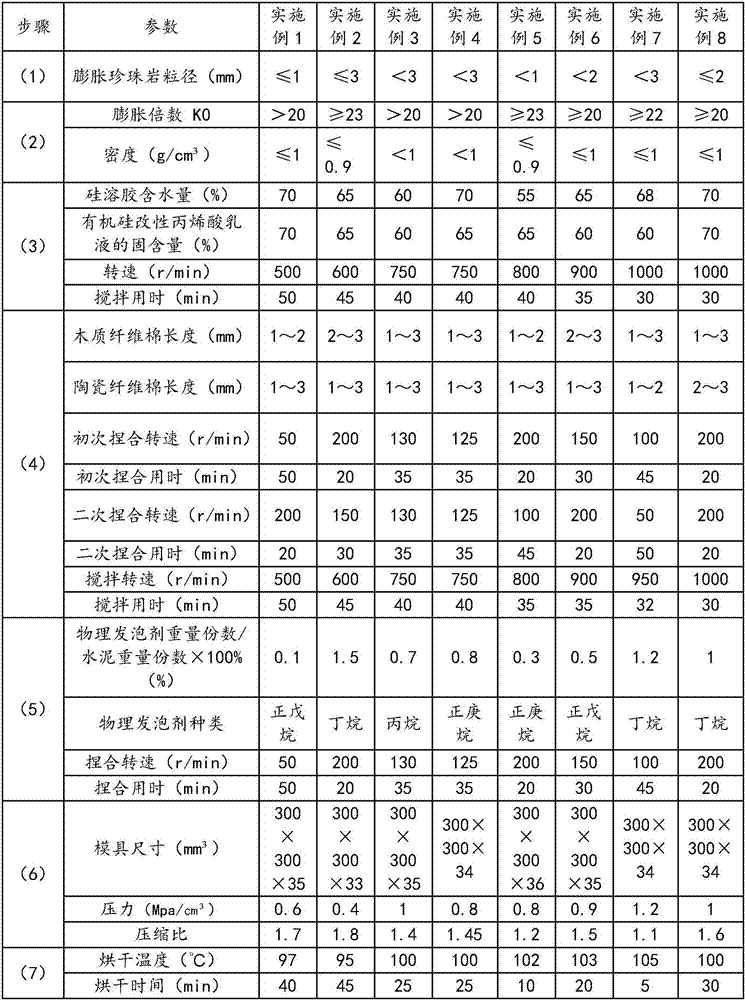

Aerogel modified expanded perlite heat preservation plate and preparing method thereof

ActiveCN107089810AFree from destructionShorten the replacement periodCeramicwareFiberPolymer science

The invention belongs to the technical field of energy-saving and environment-friendly materials, and particularly relates to an aerogel modified expanded perlite heat preservation plate for architecture and industrial energy conservation and heat preservation. The aerogel modified expanded perlite heat preservation plate is prepared from one or two expanded perlite powder, an aerogel intermediate, cement, a mixing material A, water, ceramic fiber cotton and wood fiber cotton. The preparing method comprises the steps of evenly mixing one or two in the expanded perlite powder, the aerogel intermediate, the cement, the ceramic fiber cotton and the wood fiber cotton, adding water to conduct even stirring, adding the mixing material A, after conducting even stirring, adopting a mold to conduct press forming, and conducting airing after conducting drying till full dryness is achieved. According to the aerogel modified expanded perlite heat preservation plate, the thermal conductivity and moisture content of the expanded perlite heat preservation plate product are drastically lowered, and the bending resisting strength and tensile resisting strength are both drastically improved.

Owner:天津朗华科技发展有限公司

Supercritical carbon dioxide boiler heating system and heating method

ActiveCN107101187AAvoid Overheating ProblemsSolve the lack of layout spaceIndirect carbon-dioxide mitigationSteam superheatersFlue gasEngineering

The invention discloses a supercritical carbon dioxide boiler heating system and a heating method. The supercritical carbon dioxide boiler heating system comprises a boiler, a spiral tube coil superheater, a separator, an external heat exchanger, an external reheater, a flue, a convection superheater and a convection reheater. The spiral tube coil superheater is installed inside a hearth of the boiler and is of a spiral tube coil structure, and a spiral tube coil provides a supercritical carbon dioxide circulating channel. The external reheater is installed inside the external heat exchanger. The convection superheater and the convection reheater are installed inside the flue. The upper end of the hearth communicates with an inlet of the separator. A flue gas outlet of the separator communicates with one end of the flue. A solid particle outlet of the separator communicates with an inlet of the external heat exchanger, and an outlet of the external heat exchanger communicates with the hearth of the boiler. The spiral tube coil superheater and the convection superheater are arranged in parallel. The external reheater and the convection reheater are arranged in parallel.

Owner:SHANDONG UNIV

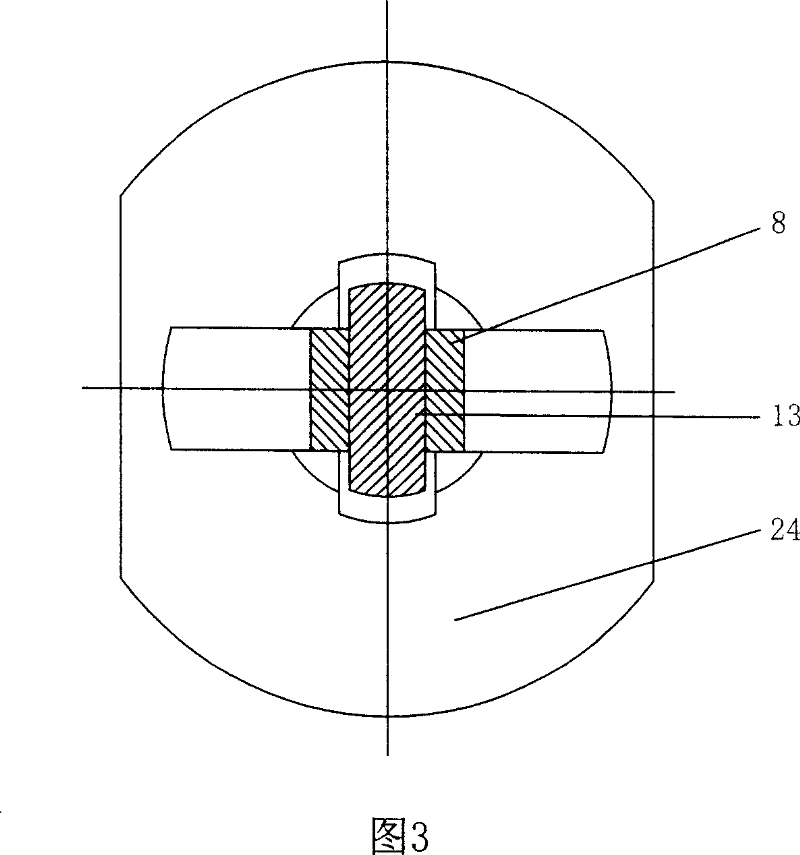

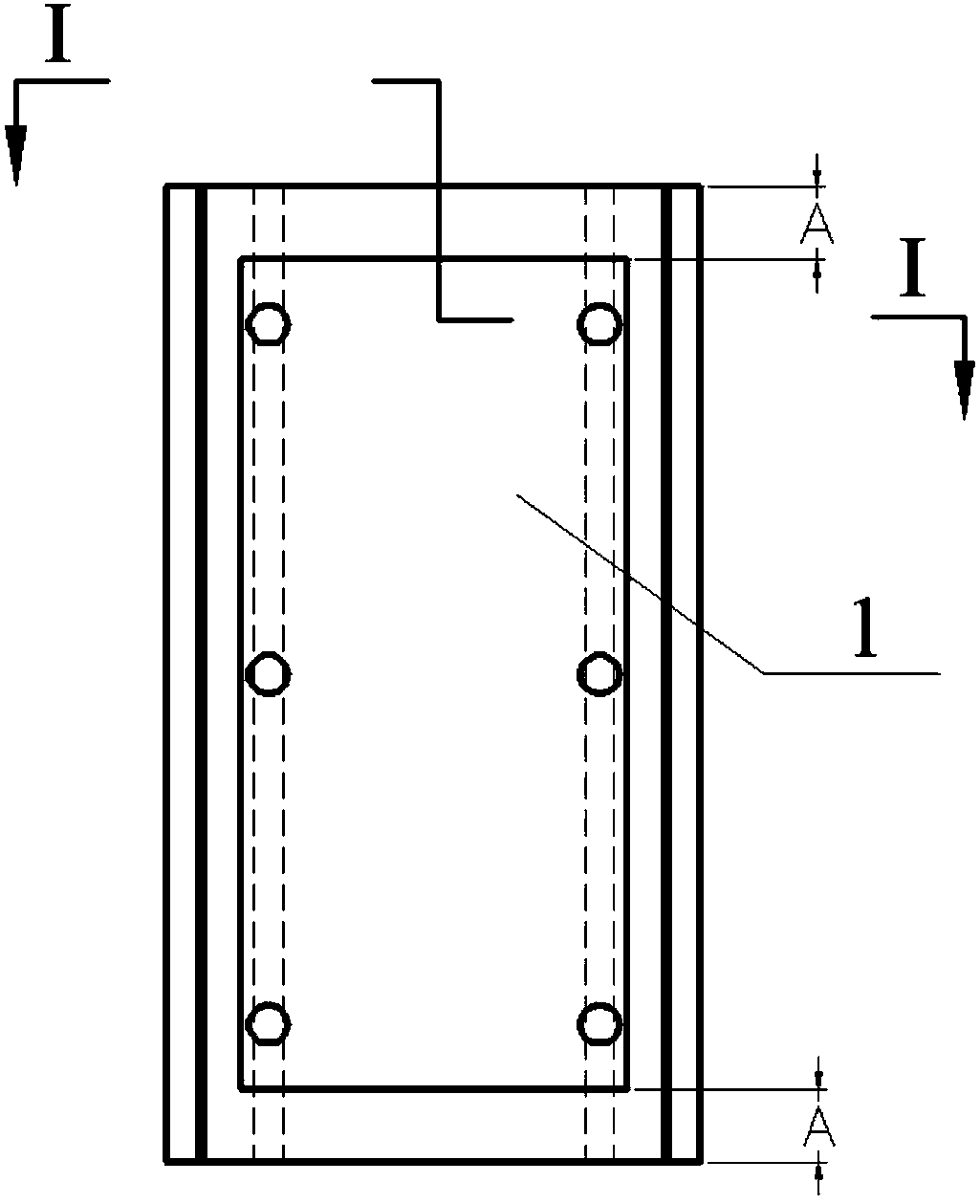

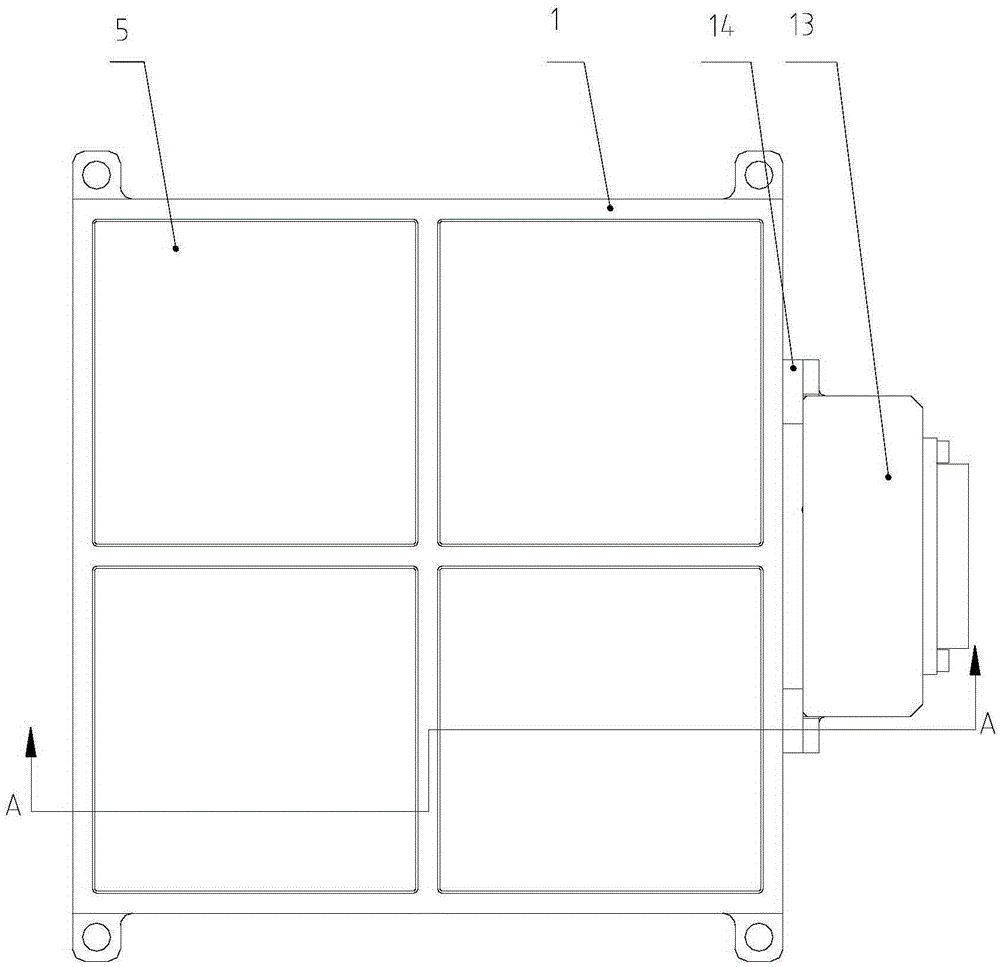

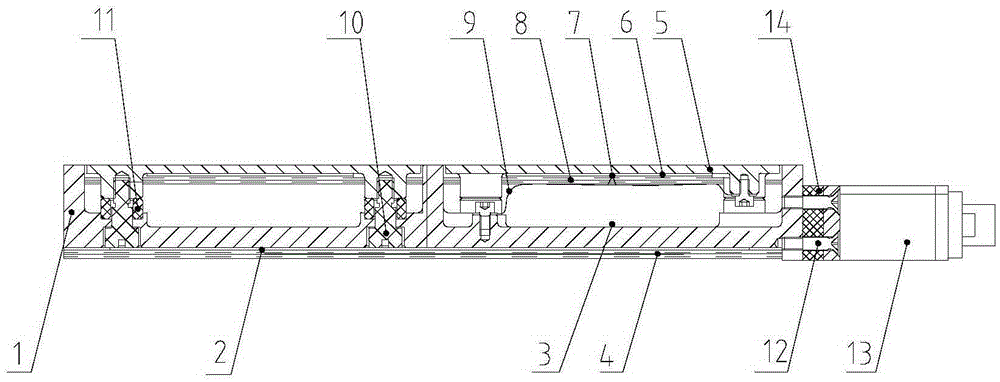

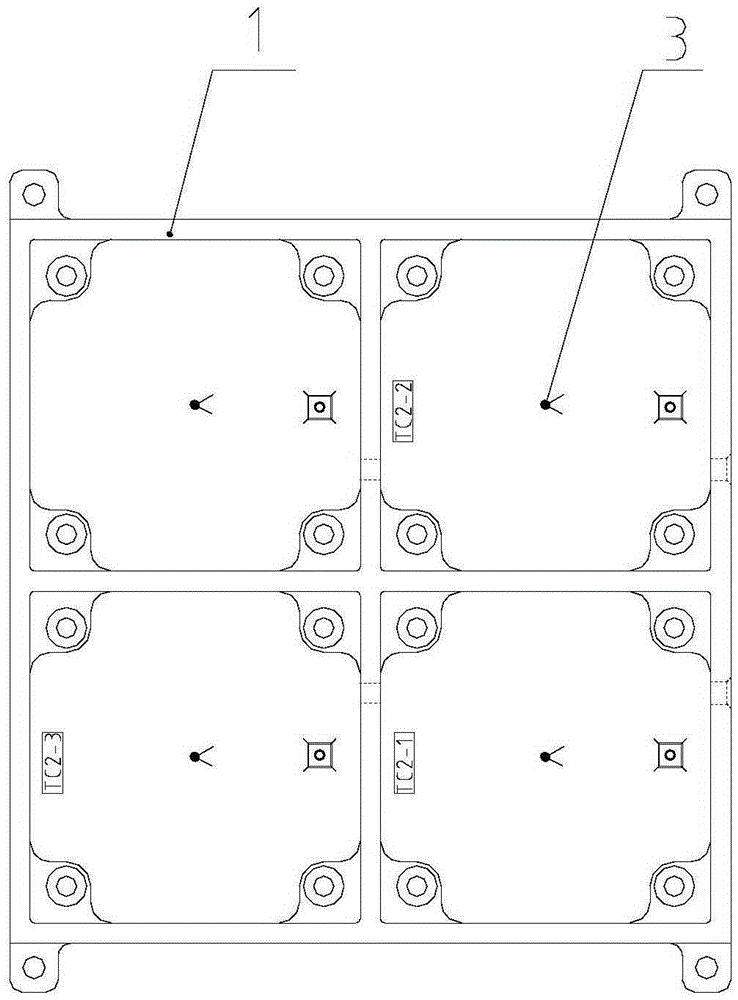

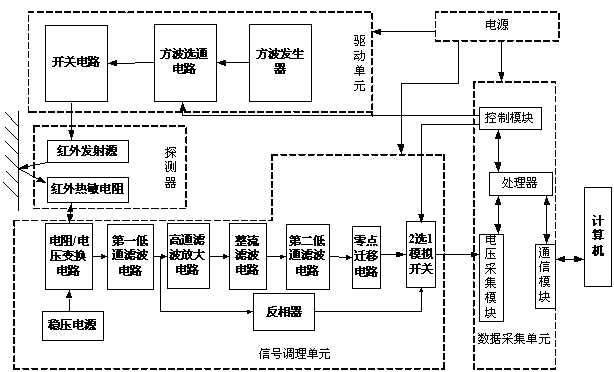

On-orbit thermal control coating radiation parameter measuring device

ActiveCN105319237AGood isothermThe connection relationship is simpleMaterial heat developmentMeasurement deviceThermistor

The invention relates to the technical field of spacecraft thermal control measurement, in particular to an on-orbit thermal control coating measuring device, and discloses an on-orbit thermal control coating radiation parameter measuring device which comprises a cup body (1), a cup body heating sheet (2), a cup body thermistor (3), a cup body heat-proof component (4), a sensitive sheet (5), a sensitive sheet heating sheet (6), a sensitive sheet thermistor (7), a sensitive sheet heat-proof component (8), a sensitive sheet grounding component (9), a countersunk head polyimide screw (10), a polyimide heat-proof pad (11), an electric connector countersunk head screw (12), an electric connector (13), and an electric connector polyimide heat-proof pad (14). The on-orbit thermal control coating radiation parameter measuring device has the advantages that the structure is flat, so that the cup body is excellent in isothermality; the cup body and the sensitive sheet are simply connected with each other, so as to simplify the heat transmission route and effectively control heat leakage; the size of the sensitive sheet is enlarged, so that relative error caused by heat leakage and measurement is reduced, and the measuring accuracy is improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

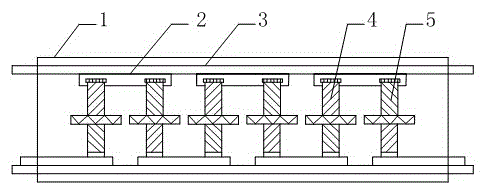

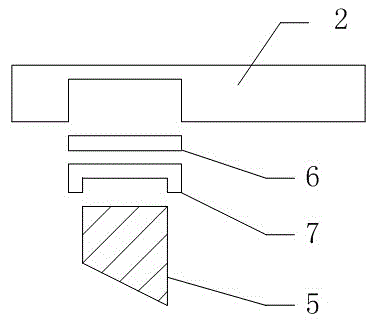

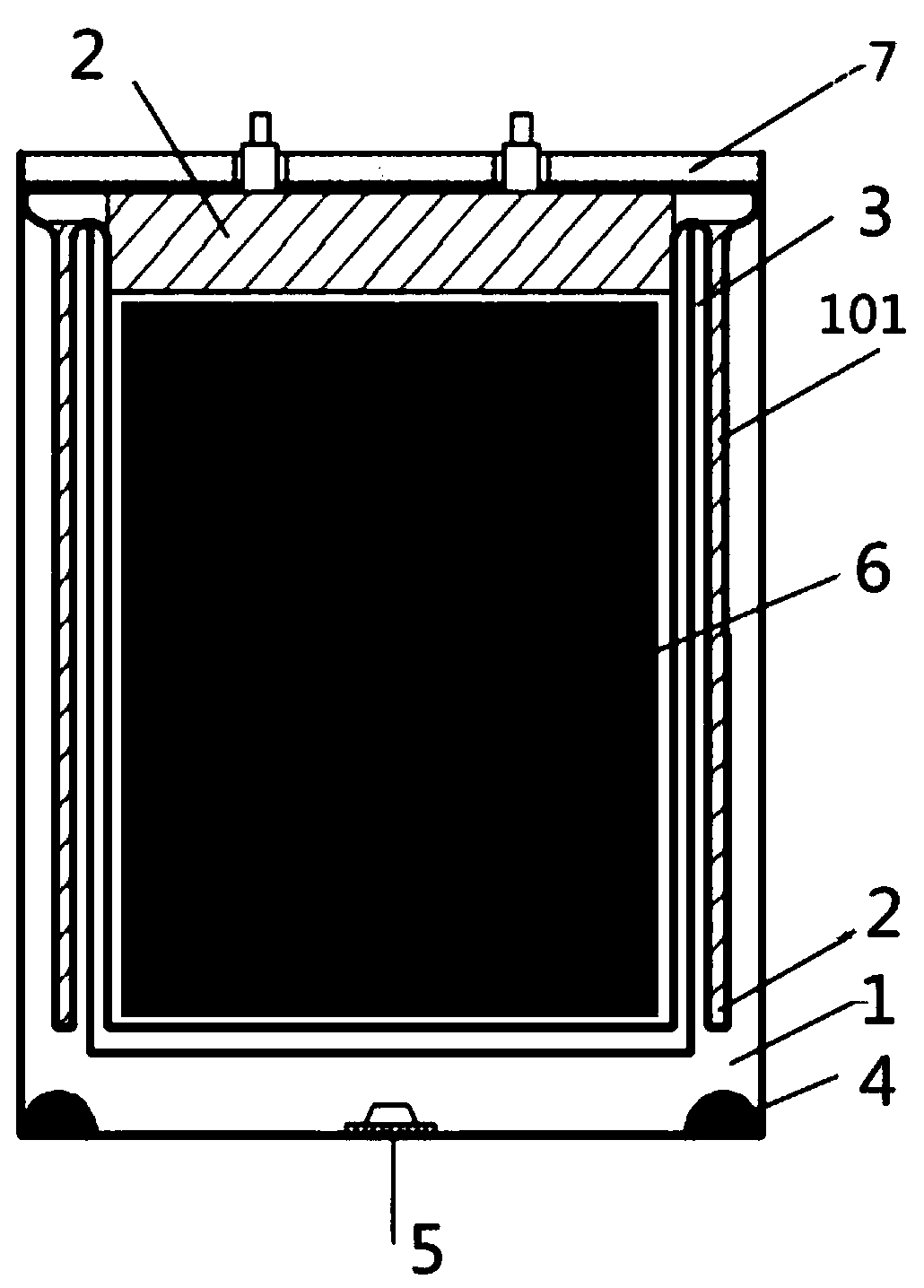

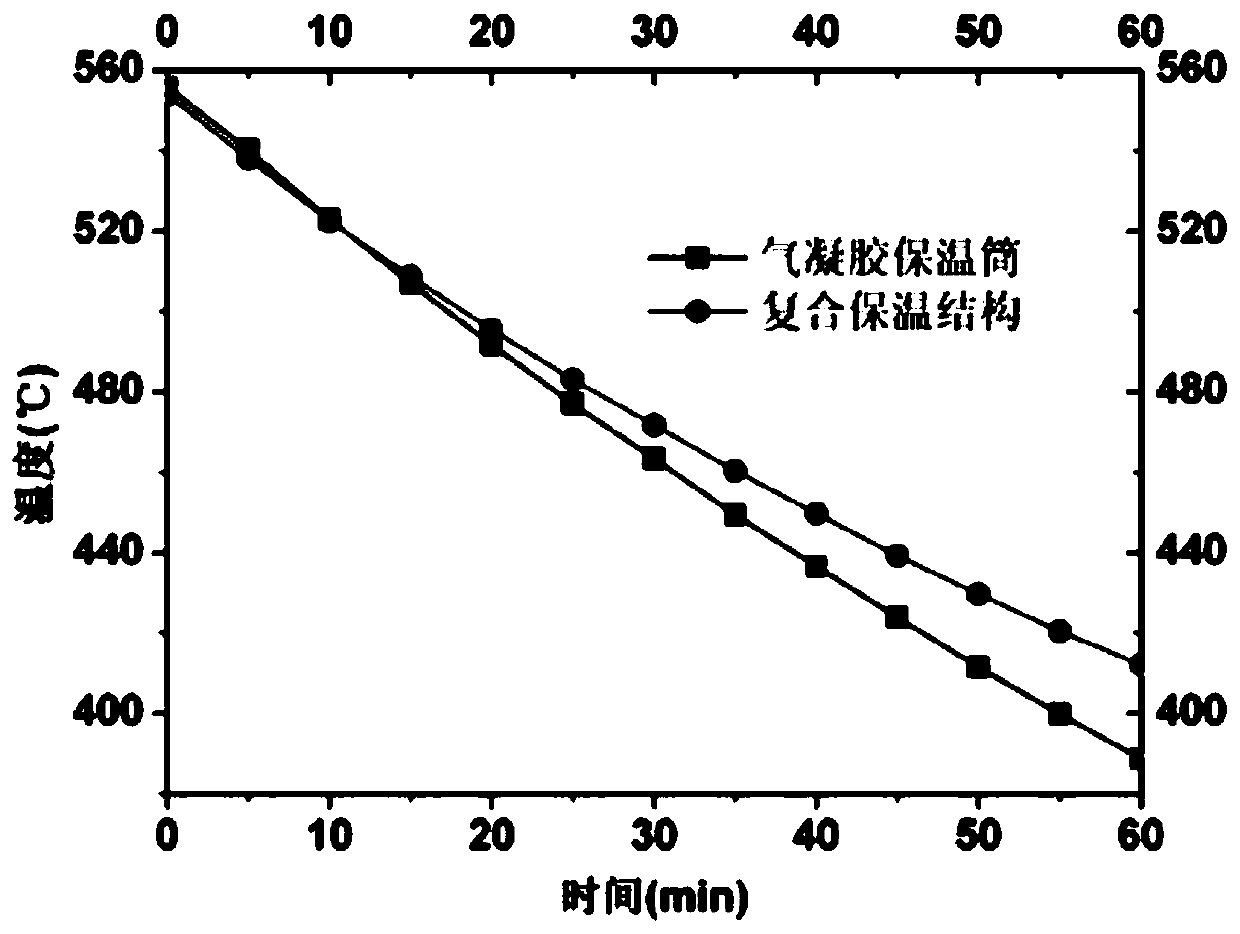

Composite thermal insulation structure of thermal battery and application of composite thermal insulation structure in thermal battery preparation

ActiveCN110544809AReduce radiative heat transferGood insulation effectDeferred-action cellsSecondary cellsThermal insulationGetter

The invention discloses a composite thermal insulation structure of a thermal battery and an application of the composite thermal insulation structure in the preparation of the thermal battery. The composite thermal insulation structure comprises a vacuum thermal insulation cavity, an aerogel thermal insulation layer, a reflection infrared radiation layer, a getter material and a battery cover plate, wherein a groove is formed in the side wall of the shell of the vacuum heat insulation cavity; the groove is formed in the upper end of the vacuum heat insulation cavity; the aerogel heat preservation layer is arranged in the groove and at the upper end of the vacuum heat insulation cavity; the reflection infrared radiation layer is arranged in the vacuum heat insulation cavity; the solution material is arranged at the bottom in the vacuum heat insulation cavity, and the battery cover plate is arranged at the upper ends of the vacuum heat insulation cavity and the aerogel heat insulation layer. The composite thermal insulation structure of the thermal battery provided by the invention can obviously delay the reduction of the temperature of an electric pile in the working process of thethermal battery and prolong the thermal life of the thermal battery.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Nano-silica particle packed bed super thermal insulation material and preparation method thereof

ActiveCN107879761AThe thermal conductivity of the solid phase decreasesLow thermal conductivityCeramicwareSilica particleThermal insulation

The invention discloses a nano-silica particle packed bed super thermal insulation material and a preparation method thereof. The method comprises the steps as follows: nano-silica particles A with the particle size of 10-40 nm and nano-silica particles B with the particle size of 50-100 nm are placed in a ball mill in the mass ratio being (5:5)-(8:2) at the room temperature, nano-silica mixed particles A are obtained after uniform mixing and then transferred to an ultrasonic dispersion machine, an infrared shielding agent is added to the ultrasonic dispersion machine for ultrasonic dispersionfor 50-70 min, and nano-silica mixed particles B are obtained, wherein the mass ratio of the infrared shielding agent to the nano-silica mixed particles A is (1:10)-(1:4); the nano-silica mixed particles B are pressed at the room temperature and the nano-silica particle packed bed super thermal insulation material is obtained. The production process can be simplified, the production cost can be reduced and the environmental pollution can be reduced on the basis that the prepared material has high-temperature resistance and excellent mechanical performance.

Owner:CHINA UNIV OF MINING & TECH

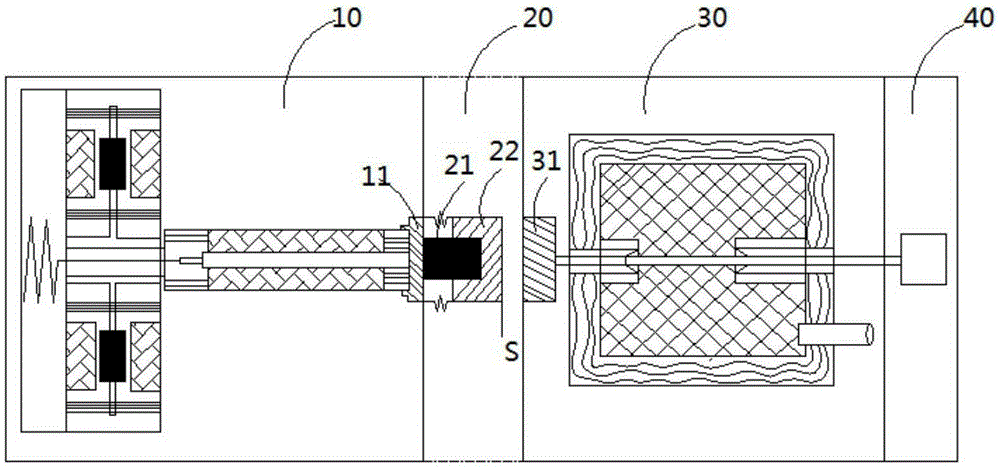

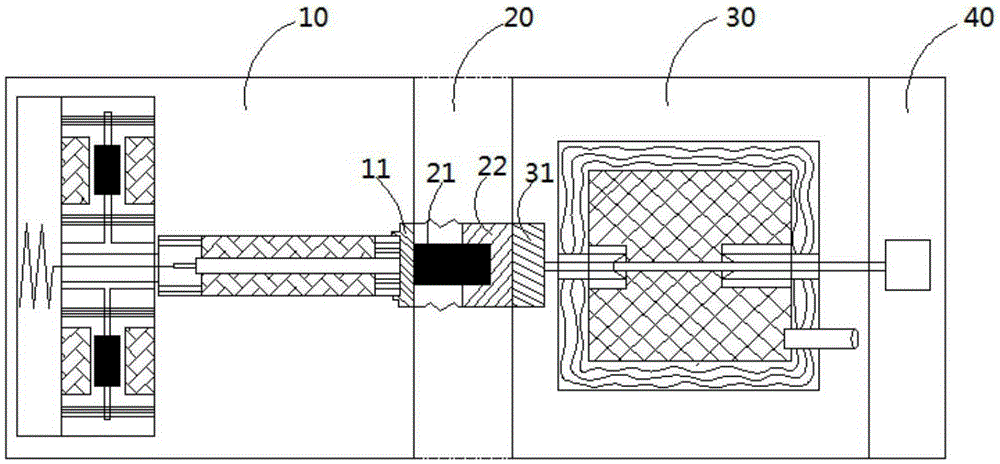

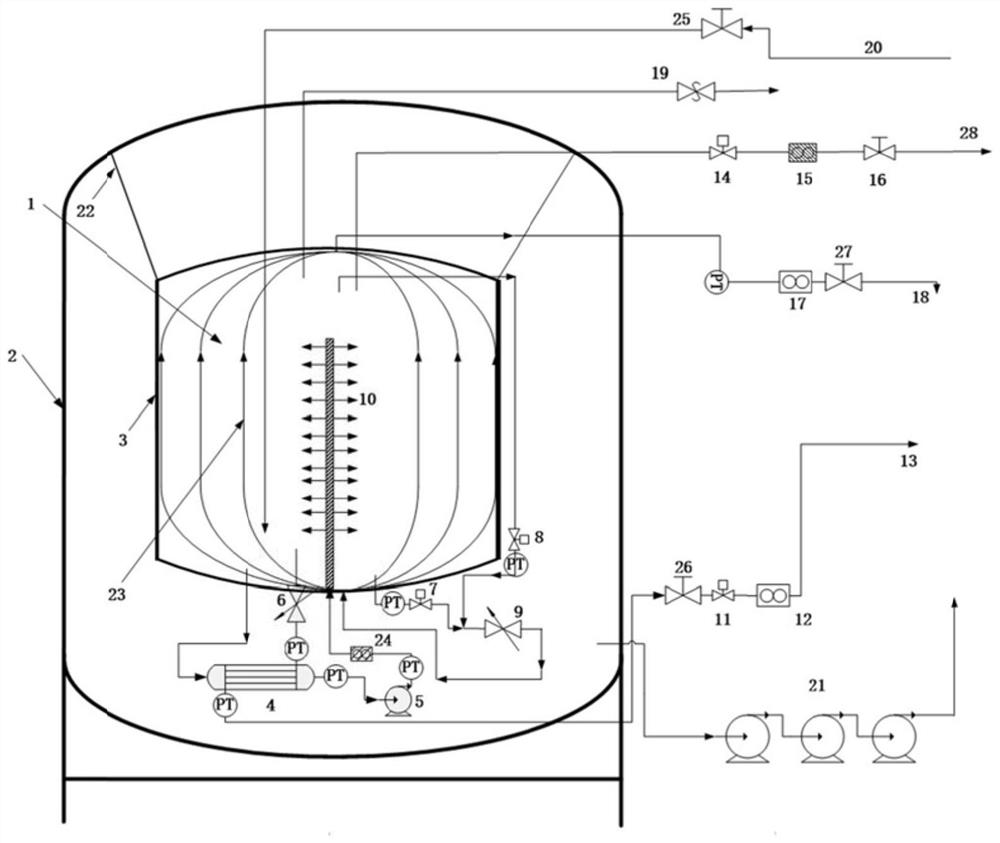

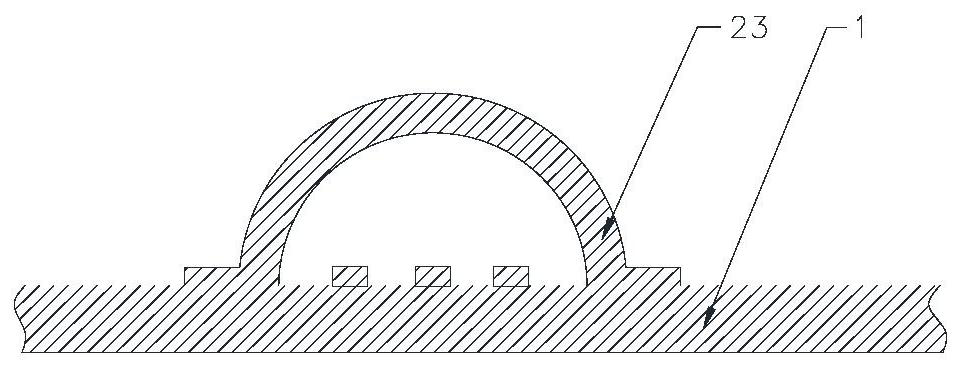

Ground integration test device and method for cryogenic propellant thermodynamic exhaust system

ActiveCN112550779AImprove stabilitySimple structureCosmonautic condition simulationsEngineeringPumping vacuum

The invention provides a cryogenic propellant thermodynamic exhaust system ground integration test device and method, the cryogenic propellant thermodynamic exhaust system ground integration test device comprises a storage tank (1), a vacuum container (2), an active thermodynamic exhaust system and a passive thermodynamic exhaust system, the storage tank (1) is located in the vacuum container (2)and is fixedly connected with the inner wall of the vacuum container (2); an interlayer between the storage tank (1) and the vacuum container (2) is vacuumized through a vacuum unit (21) to simulate the outer space environment. According to the ground integration test device and method, various exhaust schemes and combinations thereof can be tested, most test structural parts in each scheme are arranged outside the storage tank, maintenance is convenient, and the design reliability is improved; structural parts such as a jet mixing device arranged in the storage tank are simple in structure and high in stability.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

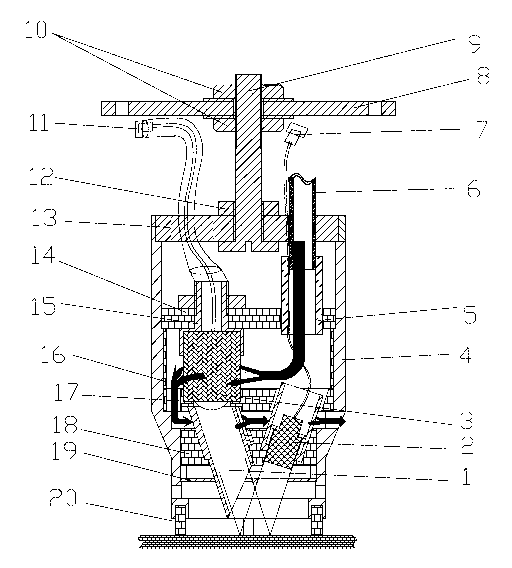

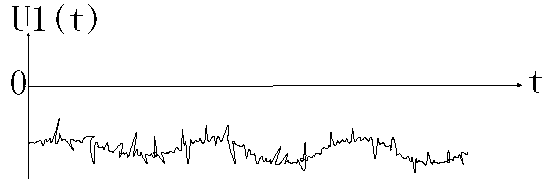

Surface emissivity tester

ActiveCN103175783ASmall sizeStrong vibration resistanceMaterial analysis by optical meansElectrical resistance and conductanceEmissivity

The invention relates to a surface emissivity tester, which is composed of a detector, a circuit part, a computer and a power supply, the detector sends an infrared thermistor voltage signal which reflects the surface emissivity to the circuit part, the circuit part sends the conditioned signal to the computer for processing, the power supply is partial power supply for circuit, the detector comprises a housing, an infrared emission source, an optically focused cylinder and an infrared thermistor, the infrared emission source and the infrared thermistor are respectively fixed in the housing, the lower transverse plane of the infrared thermistor is connected to the optically focused cylinder, the optical path emitted by the infrared emission source is symmetrical to the central axis of the optically focused cylinder by relative to the housing central axis, the leading-out wire of the infrared thermistor and the infrared emission source control line are respectively passed through a housing top cover and connected to the circuit part. The surface emissivity tester has the advantages that the surface emissivity tester can perform temperature compensating on non-linear characteristic of the thermistor, can eliminate the error brought by partial drift of the circuit, and increase the test precision. The surface emissivity tester can be conveniently used on different object surfaces for on-line real-time dynamic test of emissivity.

Owner:AECC SHENYANG ENGINE RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com