Heat insulation composition

A composition and material technology, applied in the field of industrial upgrading and thermal insulation composition, can solve the problems of increasing bulk density of thermal insulation materials, etc., and achieve the effects of reducing bulk density, improving thermal protection performance, and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

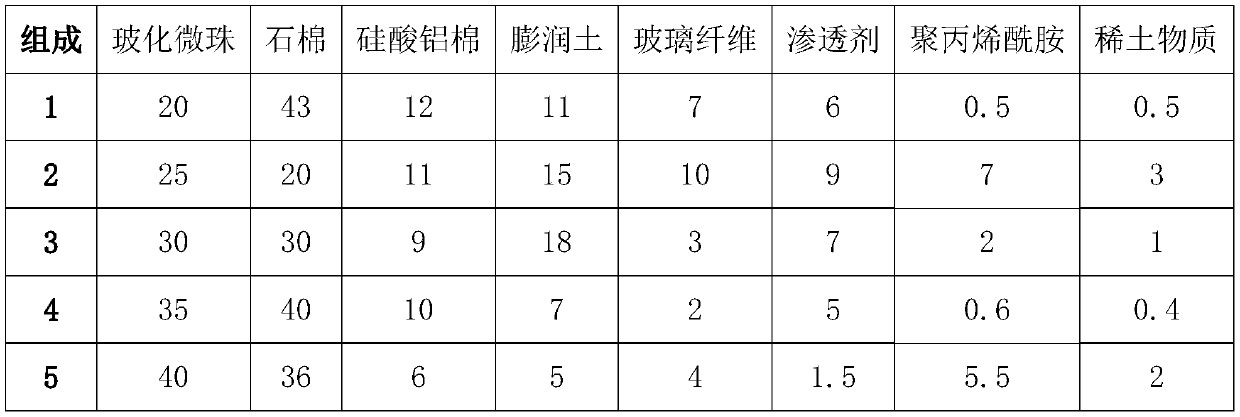

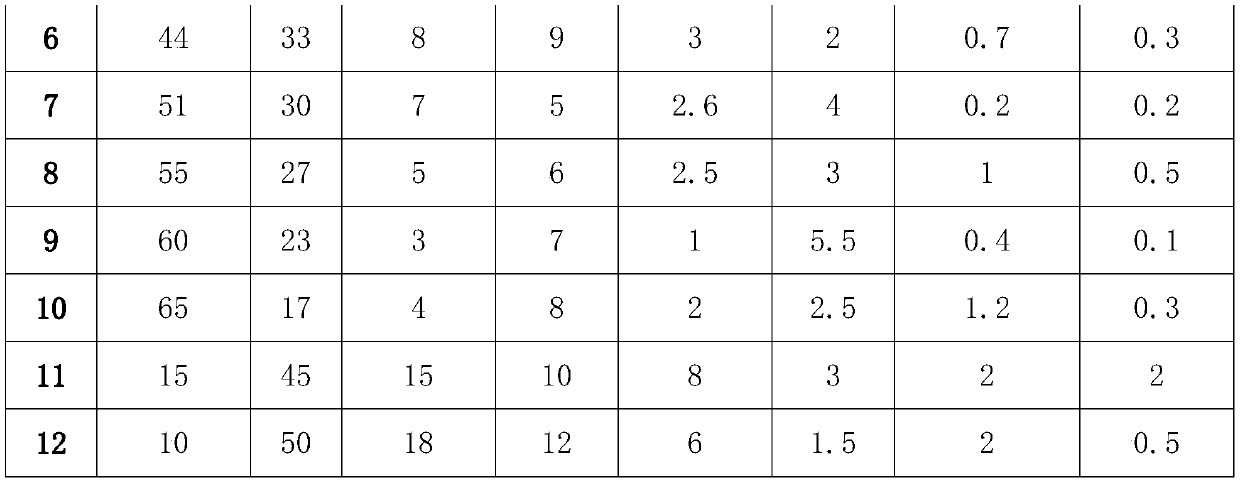

[0034] A thermal insulation composition, the raw material composition is as follows:

[0035] The proportion of vitrified microbeads in the insulation material is 10-65 wt%, preferably 20-65 wt%. The vitrified microbeads used in the present invention are intuitively micro-circular particles, have a reflective continuous vitrified smooth outer surface, have obvious capillary adsorption and compressive strength, have high strength, low water absorption, high strength, and mixing. Good and easy to disperse. In the present invention, the particle size of the vitrified microbeads is preferably 15-100 mesh.

[0036] Asbestos, the proportion of the thermal insulation material is 10-50wt%, preferably 10-45wt%. In the present invention, it is preferably serpentine or Qi cotton. Serpentine asbestos, also known as serpentine asbestos, is also called chrysotile asbestos. It is a variant of serpentine and is a magnesium silicate mineral. The fibers of serpentine asbestos are rolled up in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com