Structure for improving heating efficiency of cathode heater assembly and preparation method thereof

A heating efficiency and cathode technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of weak support strength of the heat shield tube to the cathode, failure to meet the environmental test conditions, and reduction of heat shield material strength and other issues, to achieve the effect of reducing heat sub-power consumption, prolonging heat conduction path, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

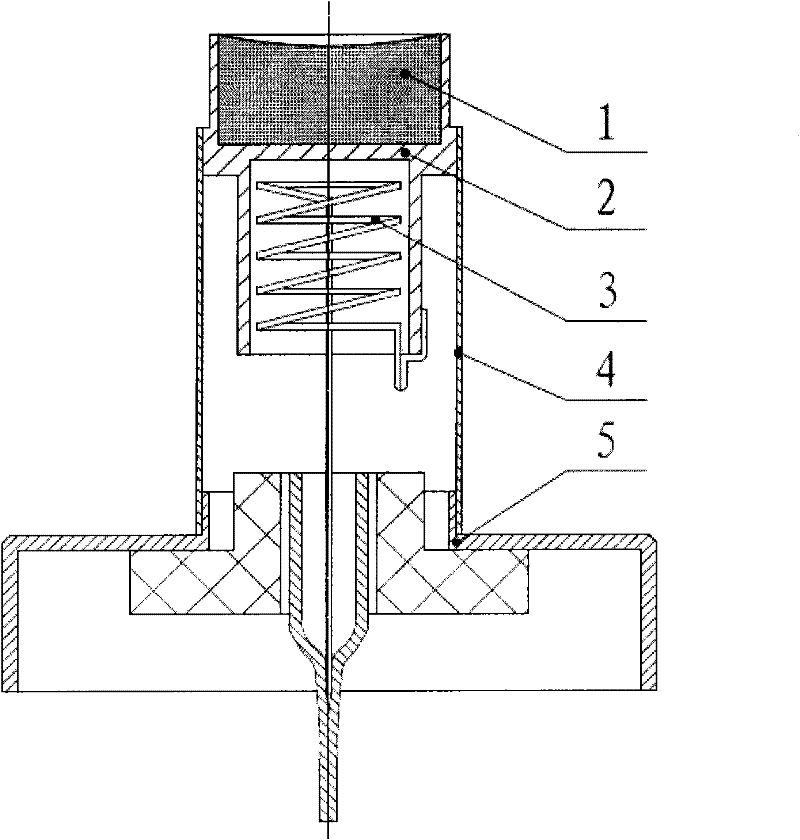

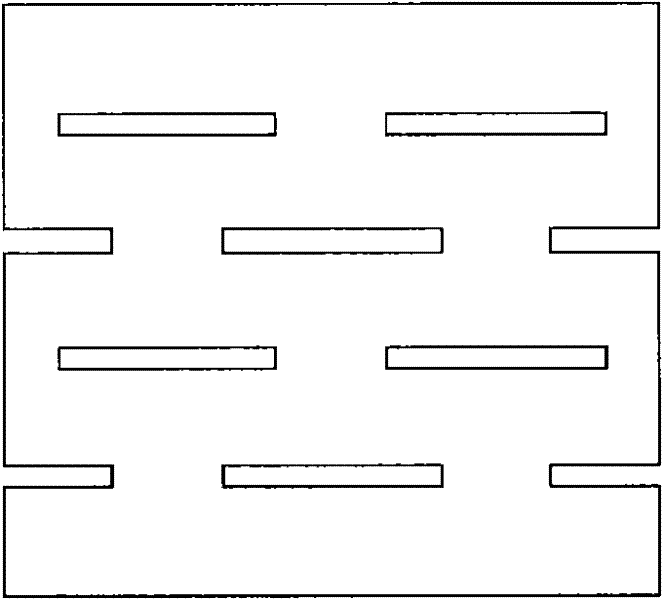

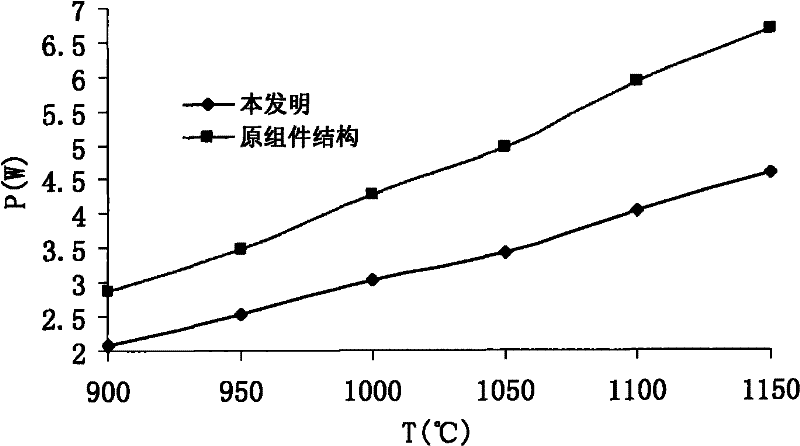

[0024] A structure and preparation method for improving the heating efficiency of the cathode thermal subassembly of the present invention, under the premise of meeting the harsh environmental test conditions of the space traveling wave tube, adopt the structure of heat insulation grooves on the surface of the heat shield tube, and select the mechanical strength High refractory metal alloy materials and other methods overcome the contradiction between the thickness of the heat shield tube and the heating efficiency in the prior art. The cathode thermal subassembly of this structure is applied to the development of various space traveling wave tubes such as X, Ku, and Ka bands, and obtains high heating efficiency. Under the same cathode temperature condition, the heating efficiency of the cathode heating subassembly is increased by more than 30% compared with the original structure, thereby reducing the heat load of the cathode heating subassembly during operation and greatly im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com