Semiconductor structure and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as hindering chip heat conduction, low heat conduction efficiency, and affecting the reliability of stacked chip packaging structures, etc., to achieve Effect of improving heat dissipation efficiency and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

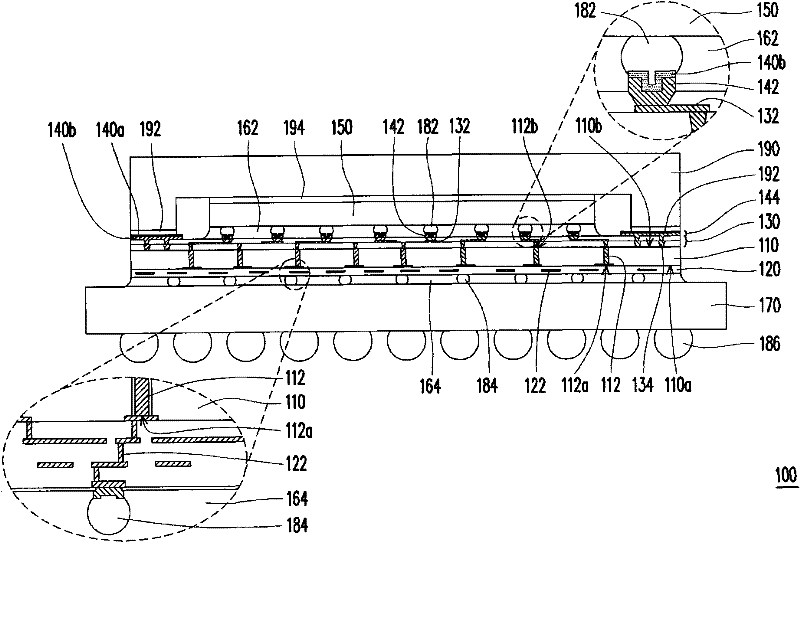

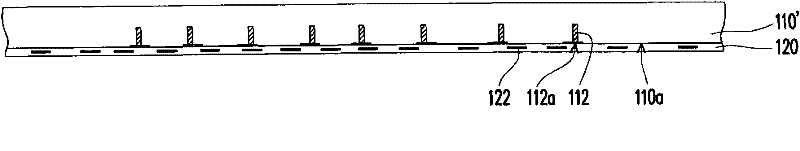

[0058] figure 1 A semiconductor structure according to an embodiment of the invention is shown. Such as figure 1As shown, the semiconductor structure 100 includes a first chip 110 , wherein the first chip 110 has a plurality of TSVs 112 inside. A first wiring layer 120 is disposed on the active surface 110 a of the first chip 110 . Here, the first wiring layer 120 includes a first interconnection 122 , which is, for example, an interconnection formed in a back end of line (BEOL) process in the wafer fabrication process. The first interconnection 122 is, for example, connected between one end 112 a of the TSV 112 and the second conductive bump 184 under the first chip 110 . In addition, there may be other active or passive components (not shown) in the first chip 110 , so the first interconnection 122 may also be connected to these active or passive components.

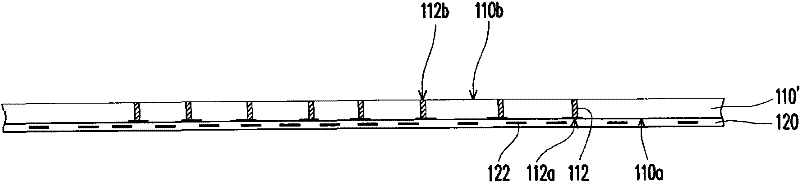

[0059] The second wiring layer 130 is disposed on the back surface 110 b of the first chip 110 . The second wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com