Aerogel composite heat insulation plate and preparation method thereof

An airgel and thermal insulation board technology, applied in the field of airgel composite thermal insulation board and its preparation, can solve the problems of unfavorable high-temperature industrial field energy conservation and emission reduction goals, high production costs, and unfavorable mass production, etc., to achieve Good self-weight support capacity, guaranteed heat insulation effect, and good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

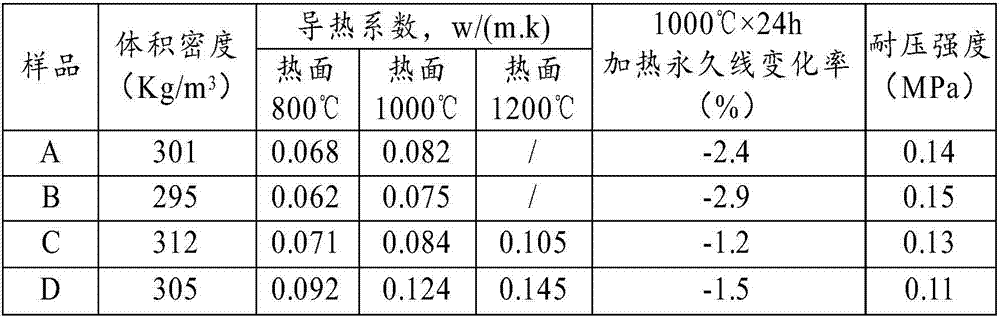

Examples

preparation example Construction

[0037] The raw materials for the preparation of the airgel composite insulation board provided by the present invention include 100 parts by mass of ceramic fibers, wherein the ceramic fibers are preferably aluminum silicate ceramic fibers or magnesium silicate ceramic fibers.

[0038] In the present invention, the ceramic fibers are subjected to beating and deslagging treatment, and the present invention has no special limitation on the methods of beating and deslagging, and the methods known to those skilled in the art will suffice.

[0039] Preferably:

[0040] a) mixing ceramic fibers with water and beating for 20-40 minutes to obtain ceramic fiber cotton pulp;

[0041] b) mixing the ceramic fiber cotton pulp with water, diluting the ceramic fiber cotton pulp to a concentration of 1.0-2.0%, and removing the slag in the ceramic fiber.

[0042] The length of the ceramic fiber after beating is preferably 3-5mm; for every 100 parts by mass of ceramic fiber raw cotton, 20-30 p...

Embodiment 1

[0077] It is made of the following raw materials in parts by weight: 100 parts of aluminum silicate ceramic fiber, 5 parts of organic binder, 10 parts of inorganic binder, 20 parts of silica airgel powder with a moisture content of 10%, infrared shading agent silicon carbide 12 parts of micropowder. Among them, the aluminum silicate ceramic fiber is the standard aluminum silicate fiber produced by Shandong Luyang Energy Saving Materials Co., Ltd., the organic binder is cationic tapioca starch produced by Hebei Hengao Chemical Co., Ltd.; the inorganic binder is produced by Hubei Yulong Chemical Co., Ltd. Silica sol with a concentration of 30%; silica airgel powder was purchased from Zhejiang Shaoxing Shengnuo Energy Saving Technology Co., Ltd., and the infrared sunscreen was purchased from Shandong Jinmeng New Materials Co., Ltd.

[0078] Concrete preparation method comprises the following steps:

[0079] (1) Put the aluminum silicate ceramic fiber into a hydropulper that has ...

Embodiment 2

[0085] It is prepared from the following raw materials in parts by weight: 100 parts of magnesium silicate ceramic fiber, 7 parts of organic binder, 14 parts of inorganic binder, and 30 parts of silicon dioxide airgel powder with a moisture content of 12%. Among them, the magnesium silicate ceramic fiber is alkaline earth silicate soluble ceramic fiber produced by Shandong Luyang Energy Saving Materials Co., Ltd., the organic binder is cationic corn starch produced by Hebei Hengao Chemical Co., Ltd.; the inorganic binder is Hubei Yulong Chemical Co., Ltd. The produced silica sol with a concentration of 30%; the silica airgel powder was purchased from Zhejiang Shaoxing Shengnuo Energy Saving Technology Co., Ltd.

[0086] Concrete preparation method comprises the following steps:

[0087] (1) Put the magnesium silicate ceramic fiber into a hydropulper that has been injected with water in advance, and turn on the beater, and stir for 20 minutes;

[0088] (2) After the fiber is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com