On-orbit thermal control coating radiation parameter measuring device

A technology of radiation parameters and thermal control coating, which is applied in the field of on-orbit thermal control coating measurement devices, can solve the problems of complex connection relationship of parts, limited measurement accuracy, uneven internal temperature, etc., to increase the size and improve the measurement accuracy , Improve the effect of temperature regulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

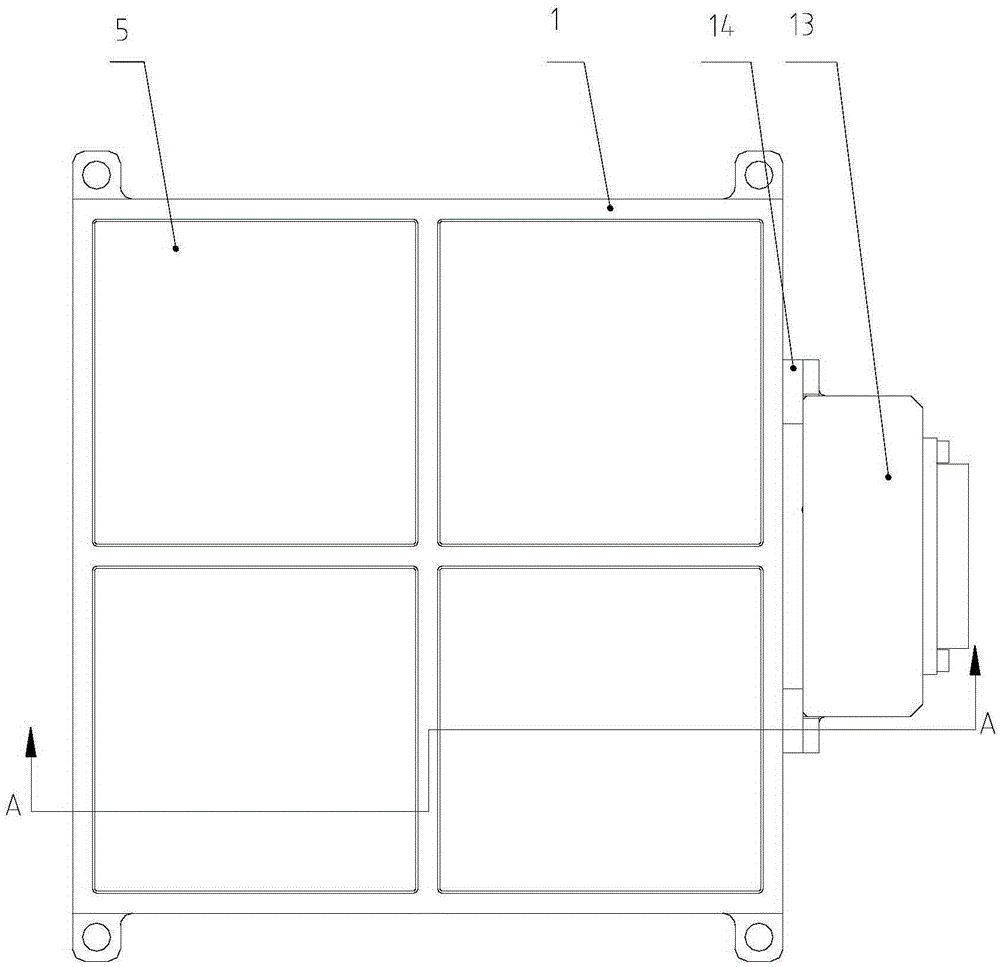

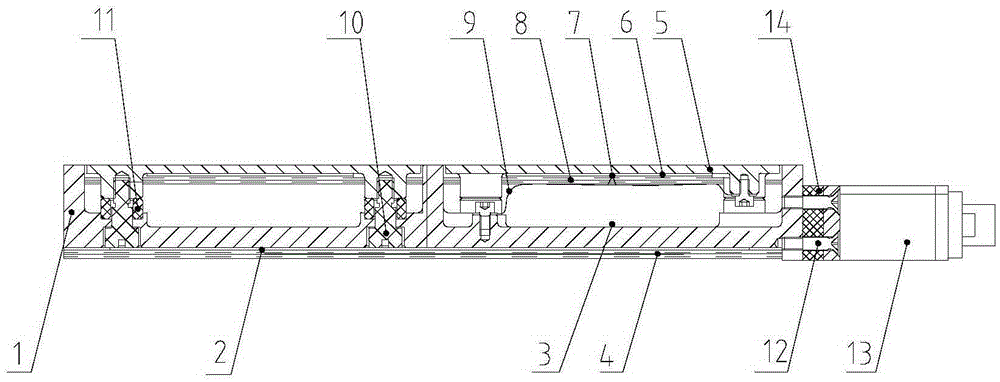

[0018] See attached figure 1 , 2 , the present embodiment provides an on-orbit measurement device for radiation parameters of a thermal control coating, which includes: a cup body 1, a sensitive sheet 5, and an electrical connector 13;

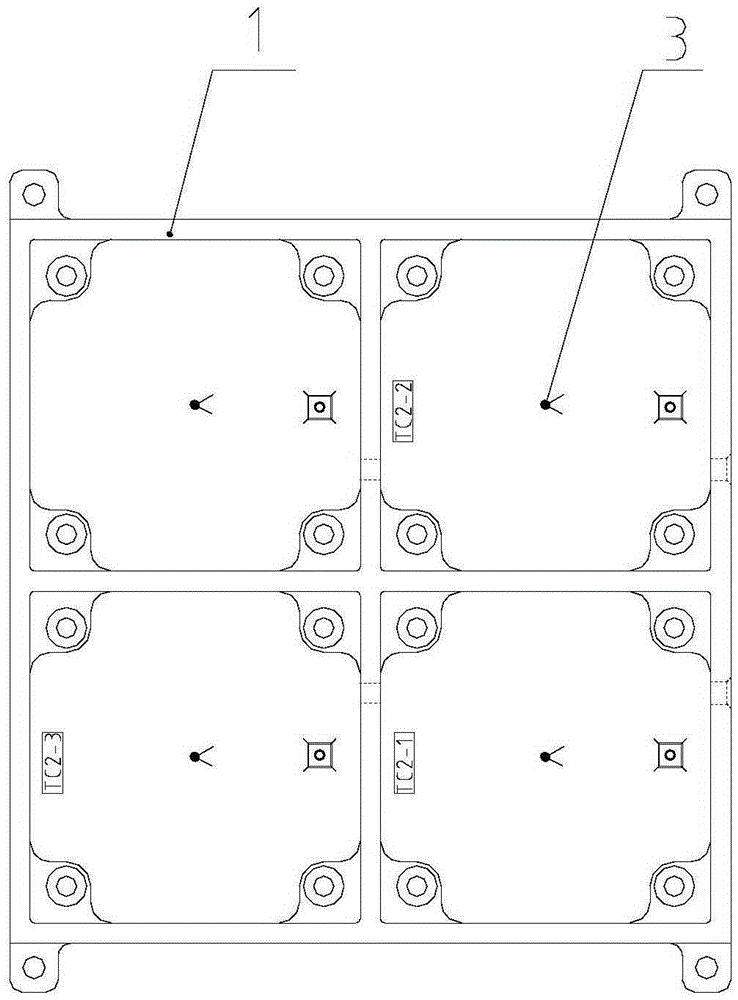

[0019] See attached image 3 , 4 , the cup body 1 is an overall aluminum alloy flat structure, which is divided into 4 chambers, the surface of each chamber is black anodized, and the middle part of the bottom surface of the chamber is pasted with a cup body thermistor 3; the outer wall of the cup body 1 is pasted with F46 film, Paste the cup body heating sheet 2 on the bottom surface and cover the cup body multi-layer heat insulation component 4;

[0020] See attached Figure 5 Each cavity opening of the cup body 1 is provided with a sensitive sheet 5 to close it. The sensitive sheet 5 is a square sheet structure wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com