Device for cooling battery mould by using flat heat pipes

A flat heat pipe and module technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve problems such as unbalanced performance of battery modules, shortening the life of power battery systems, and excessive heat accumulation in batteries, achieving excellent performance. Thermally responsive properties, light weight, consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

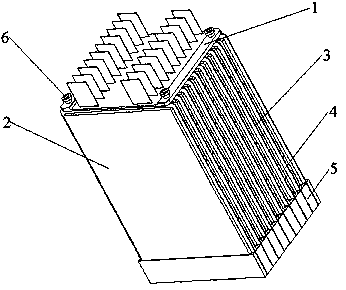

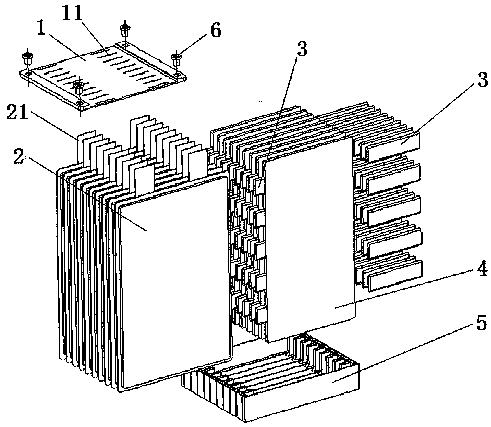

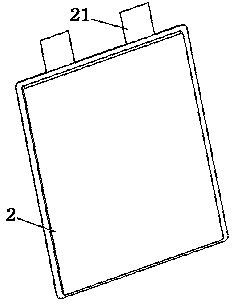

[0020] The present invention will be further described below in conjunction with drawings and embodiments. see Figure 1 to Figure 8 , a flat heat pipe used for heat dissipation of pouch battery modules, including a fixed support 5, a cell unit 2, a heat dissipation aluminum plate 4 and a connecting plate 1, the fixed support 5 is composed of a middle support block 51 and its The two ends of the side support block 52 are formed, the two ends of the middle support block 51 are provided with a T-shaped block 501, and a hollow groove is arranged in the T-shaped block 501; the two ends of the side support block 52 are provided with a protrusion 502, and the protrusion 502 Hollow grooves are also arranged inside, and slots 53 are formed between the middle support blocks 51 and between the side support blocks 52 at both ends; the hollow grooves in the T-shaped block 501 and the hollow grooves in the protrusions 502 are all filled with corresponding change material; the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com