COB (Chip On Board) packaged LED (Light Emitting Diode) light source and manufacturing method

A technology of LED light source and manufacturing method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as limitation of luminous angle, product application limitation, small luminous angle and range, etc., so as to improve the luminous angle and luminous range, improve light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] As mentioned in the background technology section, COB packaged LED light sources in the prior art all have the problem of small lighting angle and range of the product. Generally, the lighting angle is limited to 120 degrees or less, and the product application is greatly restricted.

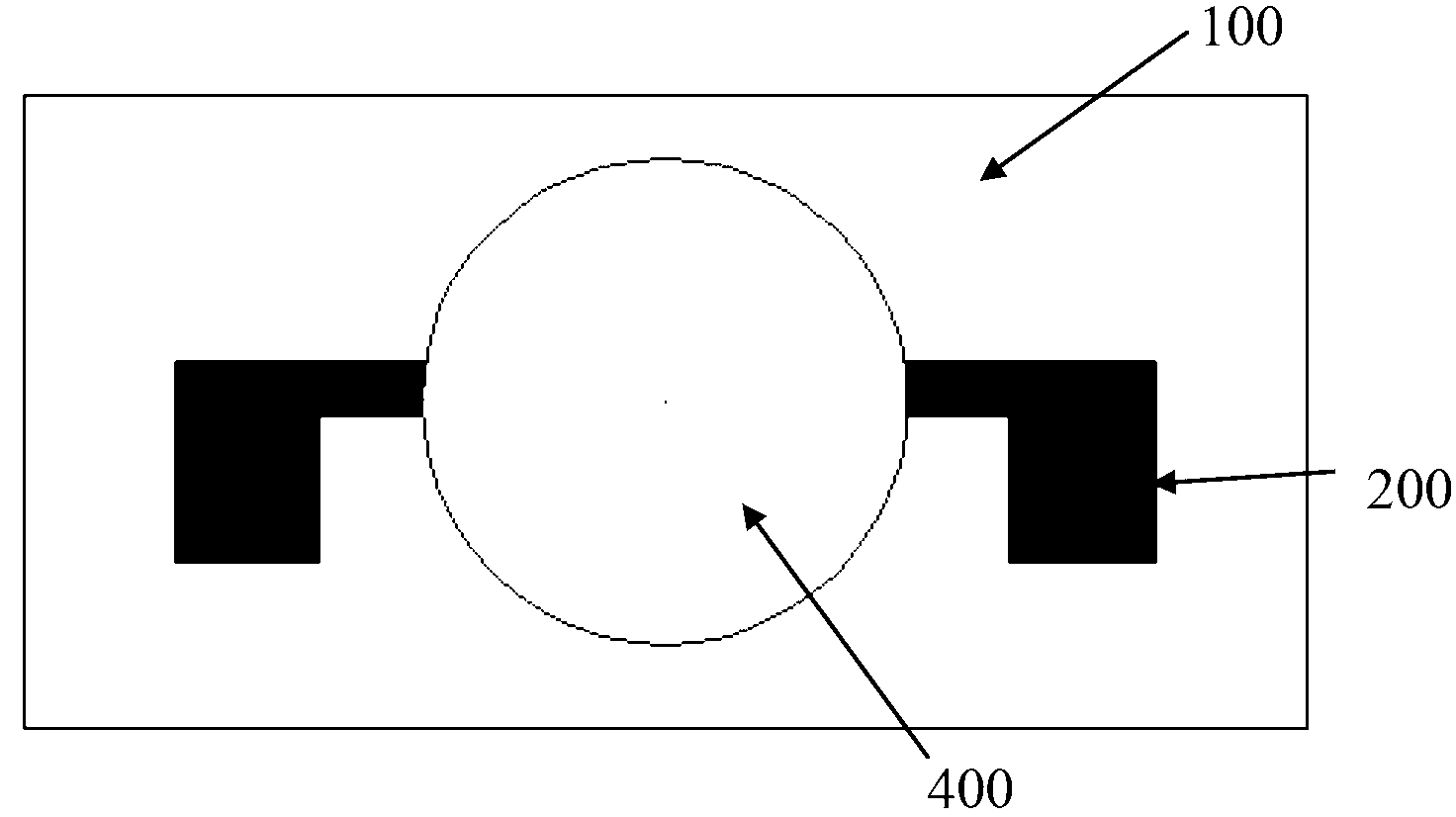

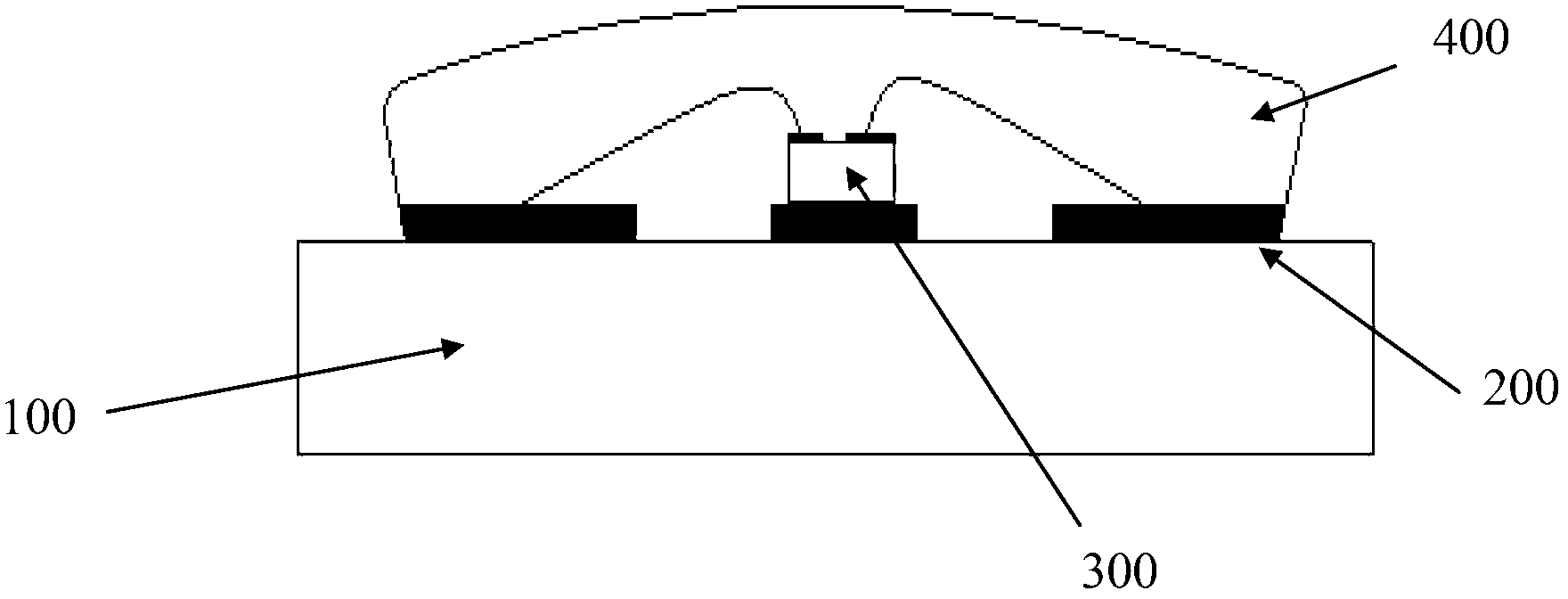

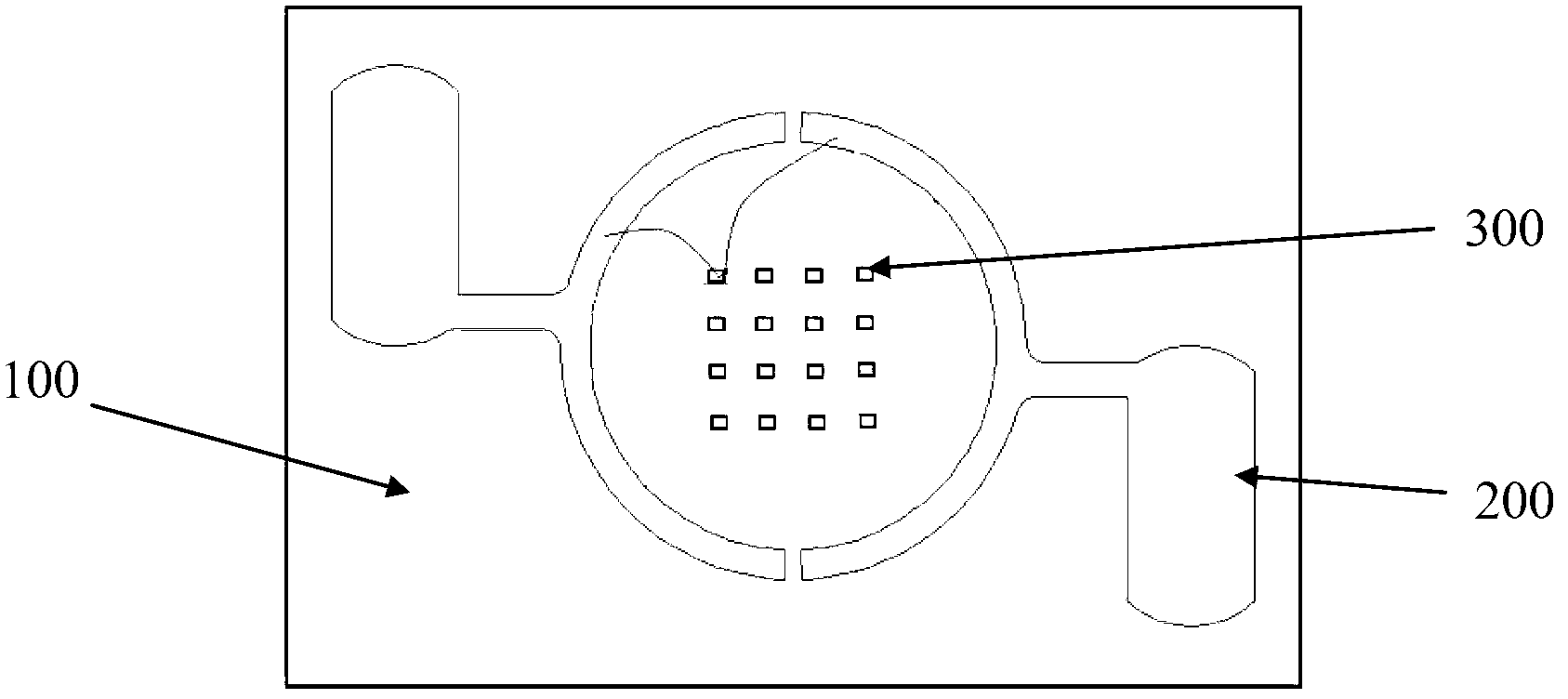

[0043] Based on the above reasons, this embodiment discloses a COB packaged LED light source, the structure of which is as follows Figure 1-Figure 3 as shown, figure 1 For its schematic diagram, figure 2 for its profile, image 3 It is a schematic diagram of the connection between the LED chip and the electrodes. The LED light source includes:

[0044] Substrate 100 , electrodes 200 , LED chips 300 and fluorescent glue 400 ; the front area of the substrate 100 is a device placement area, and the electrodes 200 are arranged on the substrate 100 . The LED chip 300 is arranged on the front of the substrate 100 ; the fluorescent glue 400 covers the surface of the LED chip 300 . Wher...

Embodiment 2

[0061] The difference between this embodiment and the previous embodiment is that in this embodiment, a sapphire substrate is used to make the LED light source. Since the light transmittance of the sapphire material is much higher than 80%, the light efficiency of the light source is as high as 130lm / W or more. Moreover, since the thermal conductivity of the sapphire material reaches 25W / mk, the LED light source made of it dissipates heat quickly during operation, so that the service life of the light source can reach 50,000 hours, and it has higher temperature resistance than traditional aluminum substrates.

Embodiment 3

[0063] The difference between this embodiment and the above-mentioned embodiments is that in this embodiment, a flip-chip connection method is adopted. In this flip-chip connection method, it is necessary to set a part of the electrodes inside the substrate, and this part of the electrodes also includes the positive part and the negative part respectively. The connection method is shown in Figure 5 (B), specifically:

[0064] The two electrodes of the LED chip are directly electrically connected to the corresponding parts of the electrode 200 after reflow soldering with the solder paste. Specifically, the positive part of the LED chip is welded to the positive part of the electrode, and the negative part of the LED chip is welded to the negative part of the electrode.

[0065] This method saves the step of connecting the electrodes through conductive leads. At the same time, most of the light-emitting surface of the flip-chip chip is on the fluorescent glue surface of the ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Light effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com