Heat pipe falling film generator for low grade heat drive absorption refrigeration

An absorption refrigeration, heat-driven technology, applied in generators/analyzers, refrigerators, refrigeration components, etc., can solve the problems of ineffective use of low-temperature heat sources, large heat transfer temperature differences, etc., and is conducive to the utilization of large temperature differences, increase Heat transfer and the effect of ensuring effective heat and mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

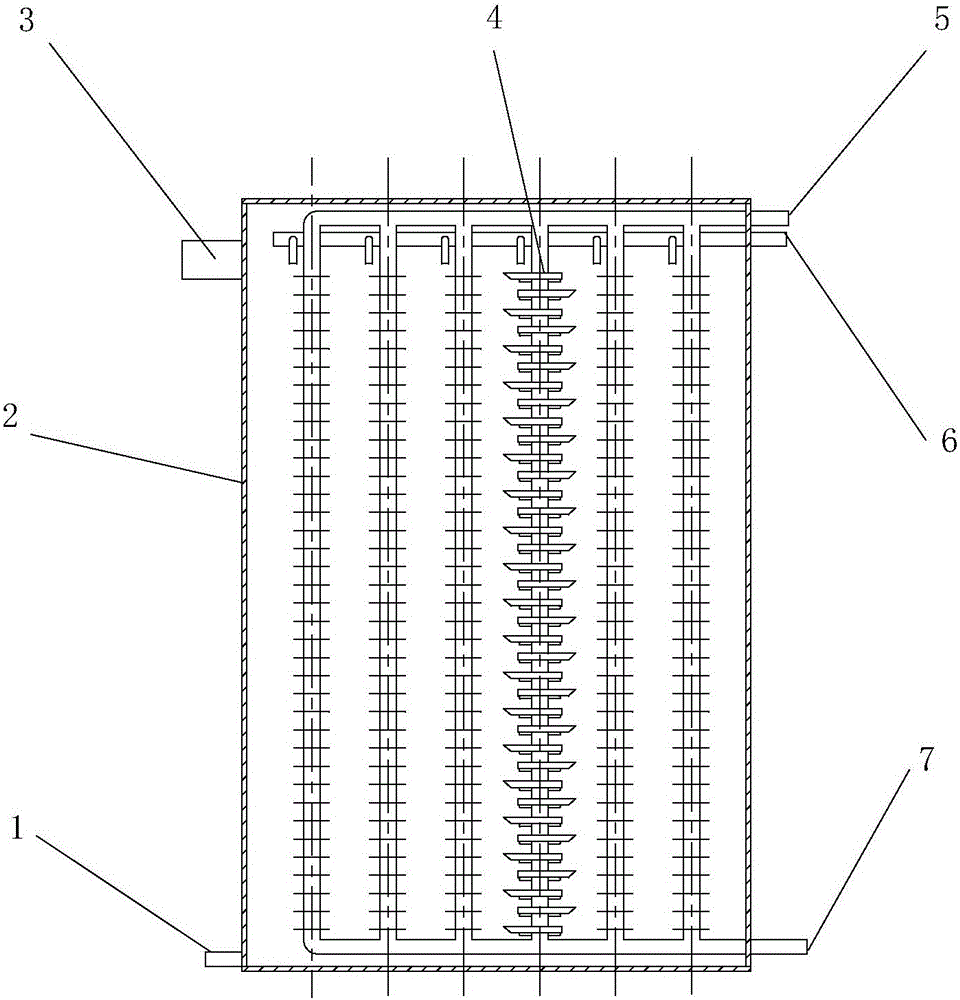

[0032] Such as figure 1 As shown, the present invention mainly includes a solution outlet 1, a generator housing 2, a steam outlet 3, a cascade disk generating tube 4, a hot water outlet 5, a solution inlet 6, and a hot water inlet 7. The cascade disc generating tube 4 is installed vertically in the generator casing 2 . The number of tube rows of the cascade disc tubes 4 and the number of tubes in each row can be changed according to the amount of actual required generation.

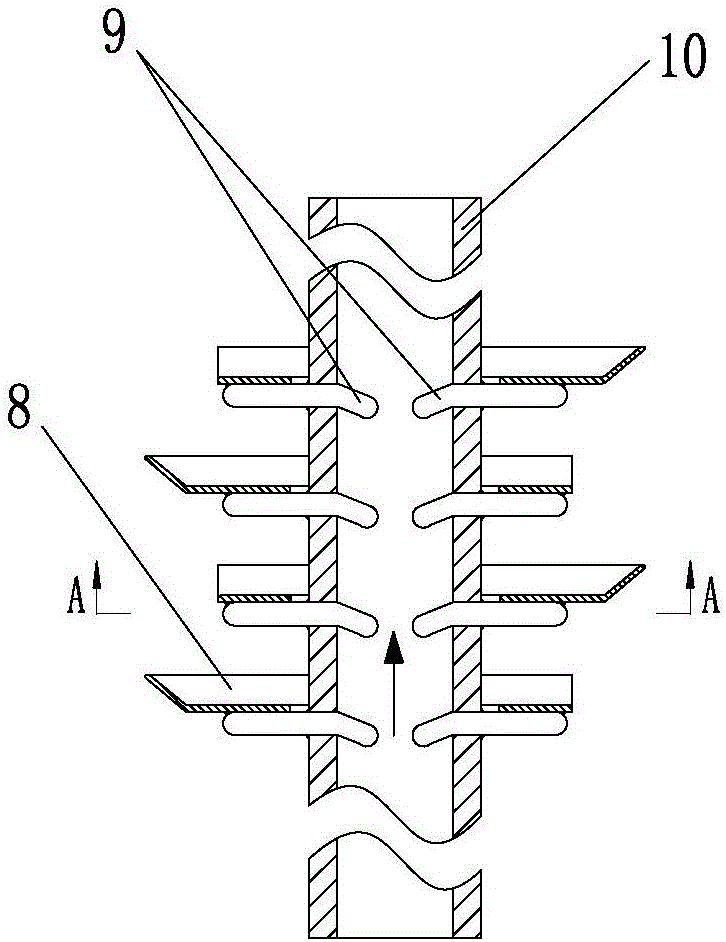

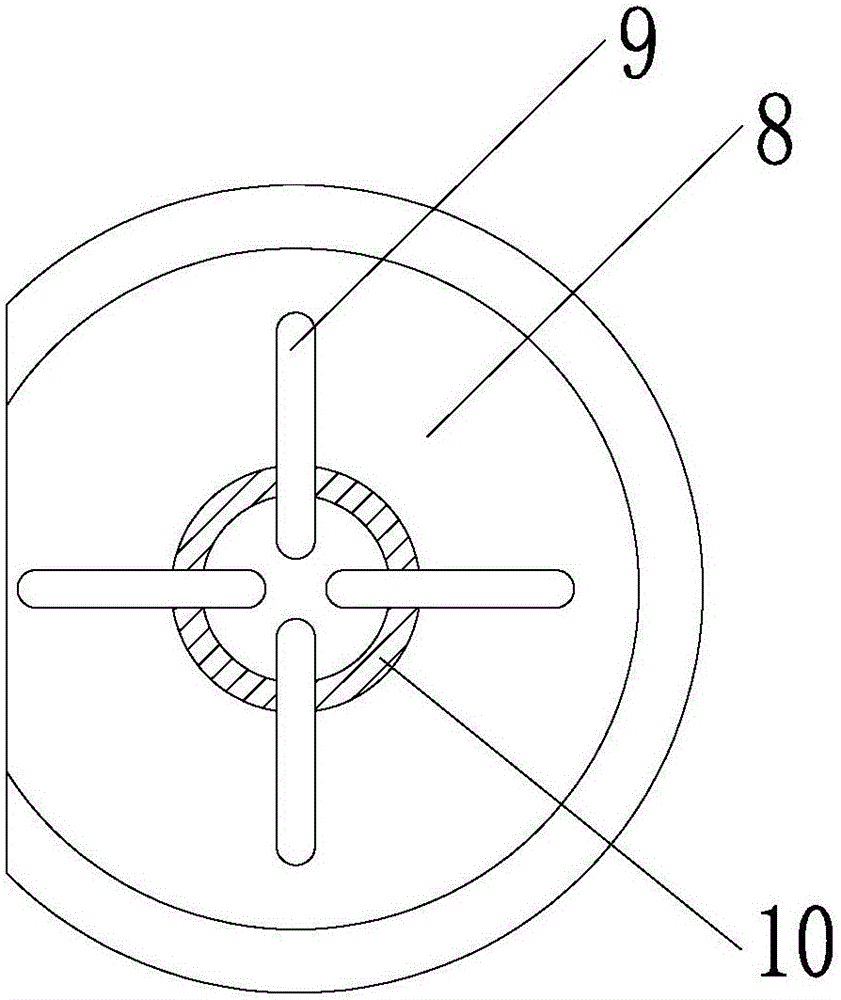

[0033] The core component of the present invention is the cascade disc tube 4, and its structure is as follows: figure 2 with image 3 shown. Evenly punch four circular holes with diameter slightly larger than the outer diameter of the heat pipe at the suitable circumferential position of the stainless steel pipe 10, and then extend the hot end of the folded heat pipe 9 into the stainless steel pipe 10 inside, and the cold end then stays outside the stainless steel pipe 10. Weld and fix the hot end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com