Treatment device for dioxin atmospheric pollutants in scrap copper smelting flue gas

An air pollutant and dioxin-like technology is applied in the field of treatment devices for dioxin-like air pollutants in waste copper smelting flue gas. High temperature burning time, effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Example 1 A treatment device for dioxin-like air pollutants in waste miscellaneous copper smelting flue gas

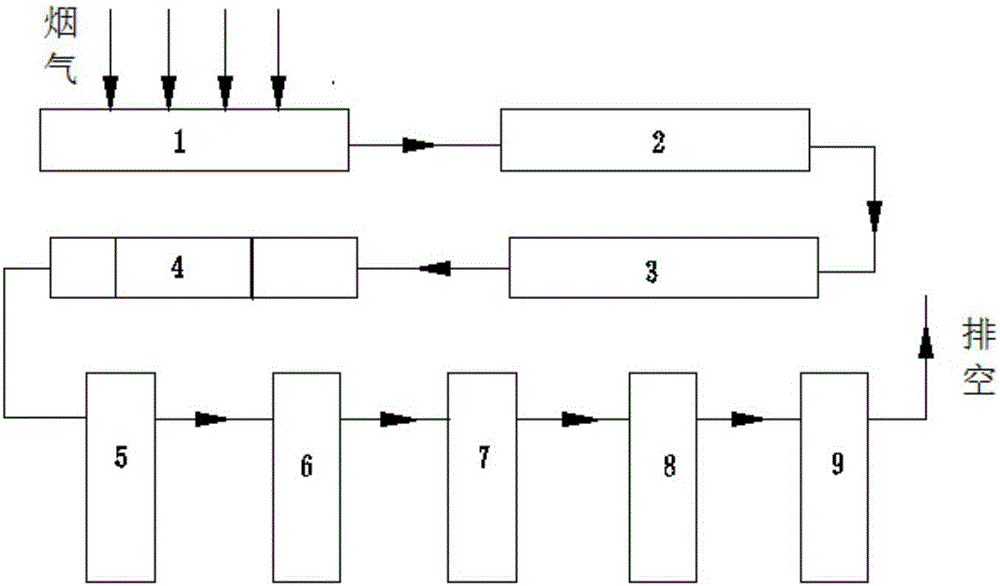

[0102] The processing device is composed of equipment connected in the following order: primary enhanced combustion furnace 1, secondary enhanced combustion furnace 2, silicon nitride porous ceramic filter 3, countercurrent heat exchange waste heat boiler 4, combined heat pipe heat exchanger 5, filter bag Dust collector 6, desulfurization system 7, activated carbon adsorption tower 8 and induced draft fan 9;

[0103] The operating method of the processing device comprises the following steps:

[0104] ①. Flue gas enhanced combustion

[0105] The flue gas from the scrap copper smelting furnace first enters the primary intensified combustion furnace 1, and then enters the secondary intensified combustion furnace 2 for intensified combustion; so that the organic combustibles carried in the flue gas continue to fully burn; at the same time, during the smelting proc...

Embodiment 2

[0126] Example 2 A treatment device for dioxin-like air pollutants in waste miscellaneous copper smelting flue gas

[0127] The processing device is composed of equipment connected in the following order: primary enhanced combustion furnace 1, secondary enhanced combustion furnace 2, silicon nitride porous ceramic filter 3, countercurrent heat exchange waste heat boiler 4, combined heat pipe heat exchanger 5, filter bag Dust collector 6, desulfurization system 7, activated carbon adsorption tower 8 and induced draft fan 9;

[0128] The operating method of the processing device comprises the following steps:

[0129] ①. Flue gas enhanced combustion

[0130] The flue gas from the scrap copper smelting furnace first enters the primary intensified combustion furnace 1, and then enters the secondary intensified combustion furnace 2 for intensified combustion; so that the organic combustibles carried in the flue gas continue to fully burn; at the same time, during the smelting proc...

Embodiment 3

[0151] Example 3 A treatment device for dioxin-like air pollutants in waste miscellaneous copper smelting flue gas

[0152] The processing device is composed of equipment connected in the following order: primary enhanced combustion furnace 1, secondary enhanced combustion furnace 2, silicon nitride porous ceramic filter 3, countercurrent heat exchange waste heat boiler 4, combined heat pipe heat exchanger 5, filter bag Dust collector 6, desulfurization system 7, activated carbon adsorption tower 8 and induced draft fan 9;

[0153] The operating method of the processing device comprises the following steps:

[0154] ①. Flue gas enhanced combustion

[0155] The flue gas from the scrap copper smelting furnace first enters the primary intensified combustion furnace 1, and then enters the secondary intensified combustion furnace 2 for intensified combustion; so that the organic combustibles carried in the flue gas continue to fully burn; at the same time, during the smelting proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com