Controllable heat pipe-based 4K thermal coupling regenerative low-temperature refrigerator and refrigerating method thereof

A low-temperature refrigerator and thermal coupling technology, used in refrigerators, gas cycle refrigerators, refrigeration components, etc., can solve the problems of large heat transfer temperature difference, high copper thermal resistance, lower no-load refrigeration temperature, etc., and achieve low thermal resistance. , High thermal conductivity, the effect of changing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

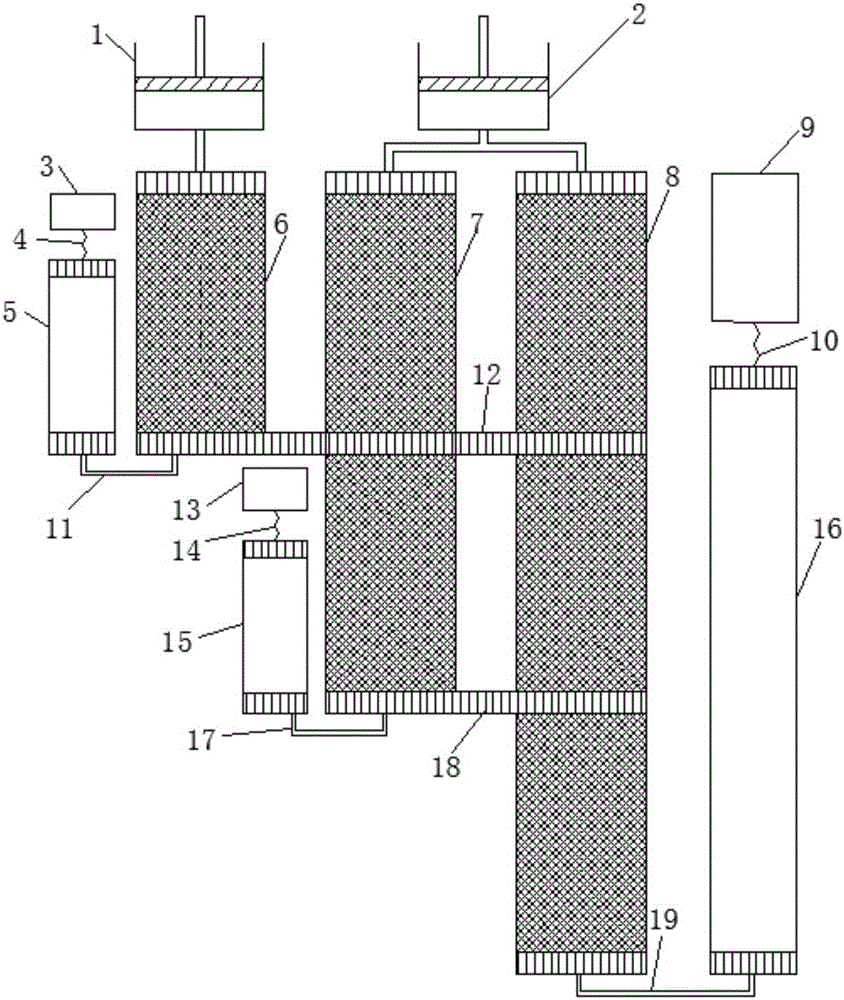

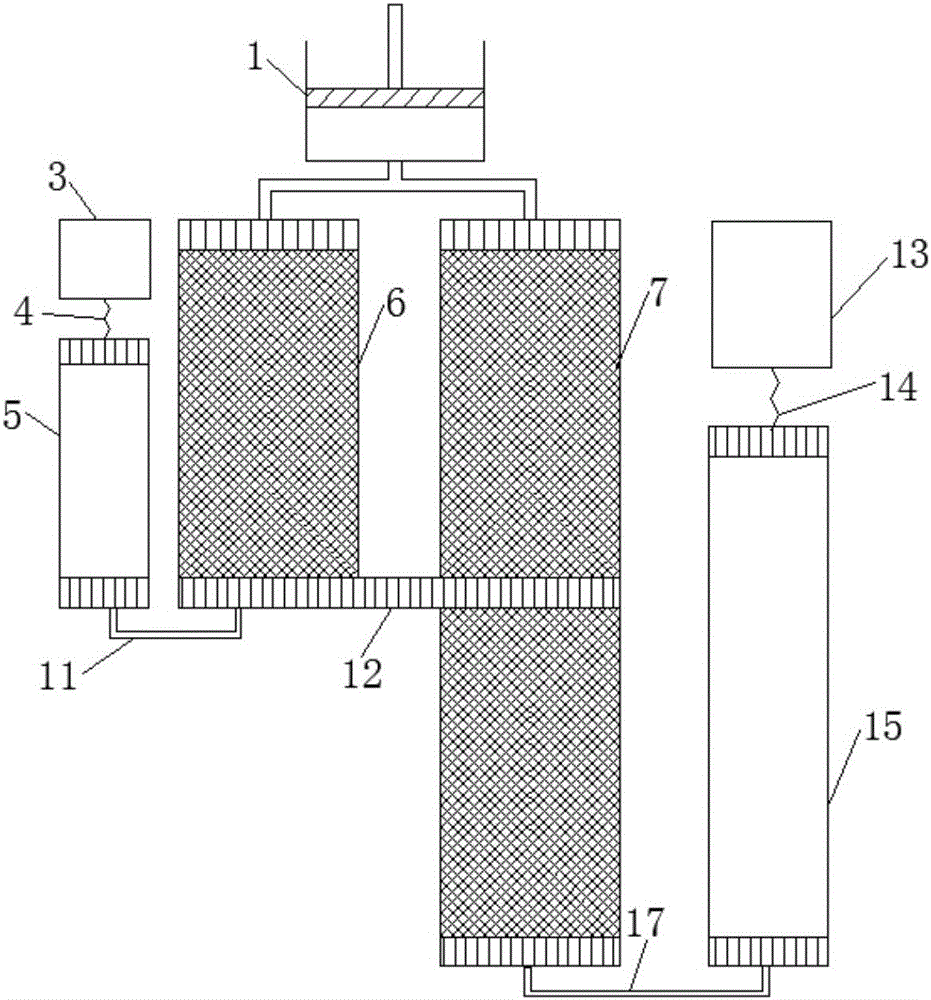

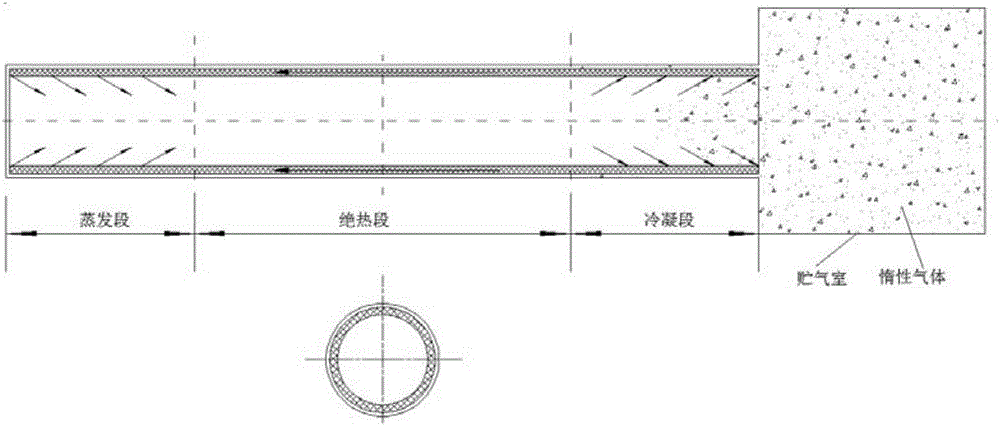

[0033] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0034] Such as figure 1 As shown, the 4K thermally coupled regenerative cryogenic refrigerator based on controllable heat pipes includes a first compressor 1, a second compressor 2, a first-stage gas storage 3, a first-stage inertial tube 4, a first-stage pulse tube 5, a Level 6 regenerator, level 2 heat regenerator 7, level 3 heat regenerator 8, level 3 air storage 9, level 3 inertia tube 10, level 1 diversion tube 11, level 1 heat bridge 12, level 2 gas storage 13 , Secondary inertia tube 14, Secondary vessel 15, Tertiary vessel 16, Secondary diversion tube 17, Secondary thermal bridge 18 and Tertiary diversion tube 19;

[0035] Among them, the first compressor 1, the first-stage regenerator 6, the first-stage guide tube 11, the first-stage pulse tube 5, the first-stage inertia tube 4, and the first-stage gas storage 3 are connected in sequence;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com