Supercritical-carbon-dioxide circulating fluidized bed boiler heating system and heating method

A carbon dioxide and heating system technology, which is applied in the direction of indirect carbon dioxide emission reduction, fluidized bed combustion equipment, combustion methods, etc., can solve the problems of increased difficulty in superheater layout, high exhaust gas temperature, and easy overheating, and achieves compact structure, Uniform heating, saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

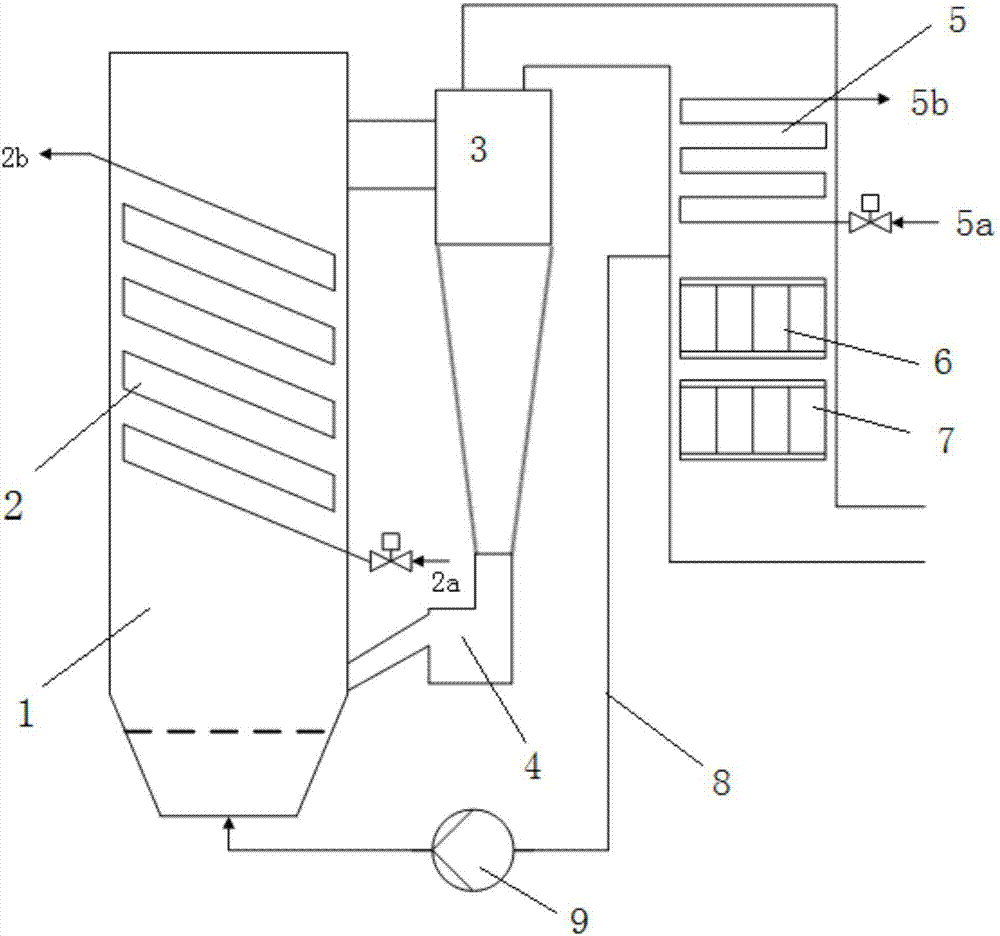

[0043] Such as figure 1 As shown, a small supercritical carbon dioxide circulating fluidized bed boiler device includes a boiler furnace 1, a spiral coil superheater 2, a cyclone separator 3, a return valve 4, a convection superheater 5, and a primary air preheater 6 , secondary air preheater 7, recirculation flue 8, recirculation fan 9 and connecting pipes.

[0044]A semi-buried tube spiral coil superheater 2 is arranged in the furnace wall of the boiler furnace 1, the working medium inlet 2a of the spiral tube superheater is arranged at the lower part of the furnace, the working medium outlet 2b of the spiral tube superheater is arranged at the upper part of the furnace, and the heat exchange coil The number is 1.5-2 circles. The flue gas outlet at the upper part of the boiler furnace 1 is connected to the inlet of the cyclone separator 3, the solid particle outlet at the lower part of the cyclone separator 3 is connected to the inlet of the return valve 4, and the outlet o...

Embodiment 2

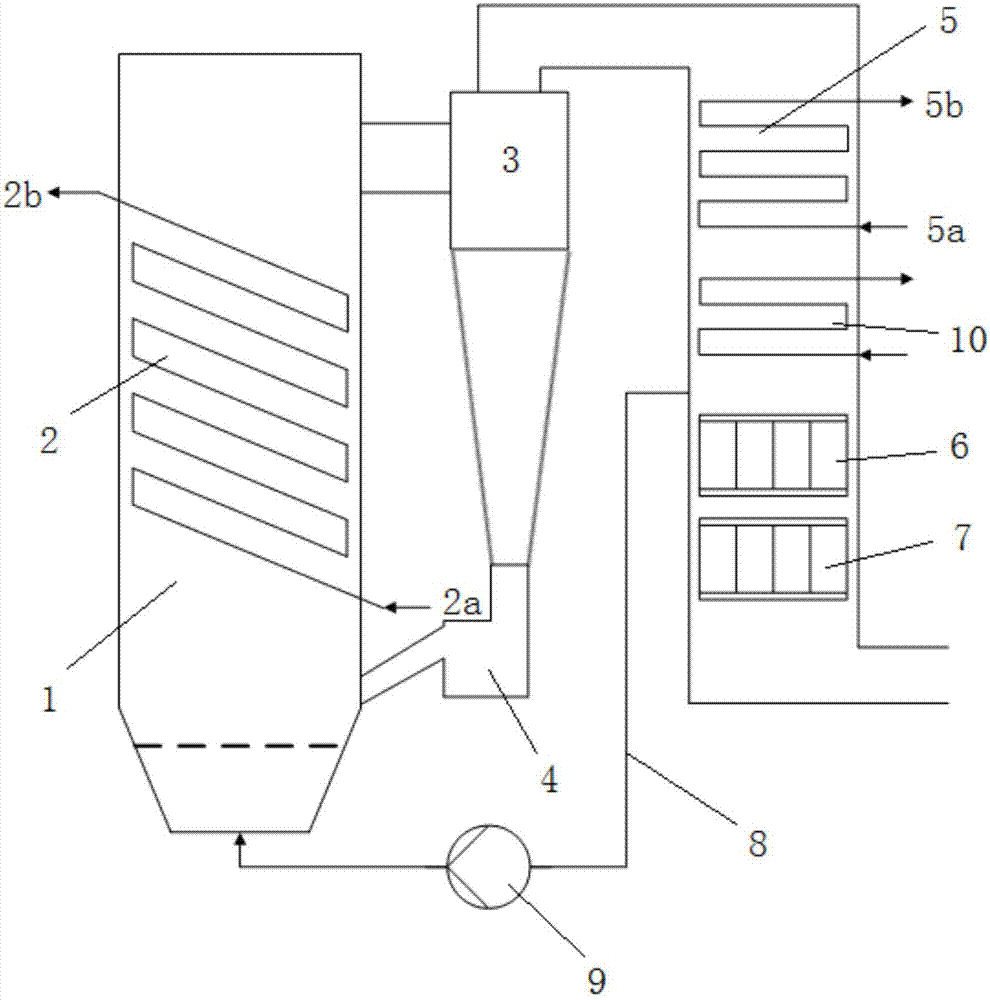

[0048] Such as figure 2 As shown, a small supercritical carbon dioxide circulating fluidized bed boiler device includes a boiler furnace 1, a spiral coil superheater 2, a cyclone separator 3, a return valve 4, a convection superheater 5, and a secondary air preheater 6 , Primary air preheater 7, recirculation flue 8, recirculation fan 9, split economizer 10 and connecting pipes.

[0049] The difference between this embodiment and embodiment 1 is:

[0050] The spiral coil superheater and the convective superheater are connected in series, the working medium outlet 2b of the spiral coil superheater is connected with the working medium 5a of the convective superheater, and the supercritical carbon dioxide working fluid entering the boiler passes through the spiral coil superheater 2 and the convective superheater successively. device 5. In the tail flue, a split economizer 10 is arranged between the convection superheater 5 and the secondary flue gas preheater 6, and the recir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com