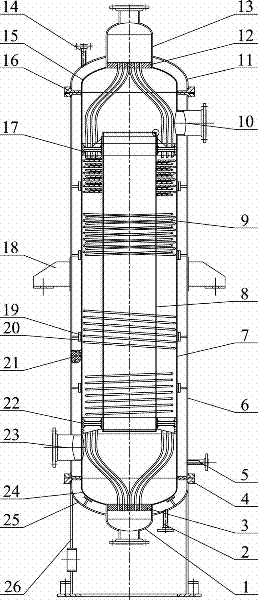

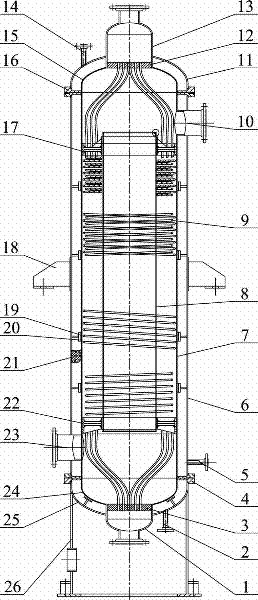

Single-flow low-temperature spiral winding tube type heat exchanger with vacuum heat-insulation effect

A tubular heat exchanger, spiral winding technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve safety problems, no design standards, large volume and other problems, achieve performance improvement, Eliminate the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] According to the established mathematical model of tube bundle winding, the present invention applies the heat transfer numerical simulation method to firstly determine the theoretical winding method of the tube bundle in the spirally wound tube heat exchanger, and the relevant parameters such as the tube spacing and layer spacing during the tube bundle winding process, Apply heat transfer and flow field numerical simulation methods to determine the best internal arrangement structure of the wound tube heat exchanger, and then determine important parameters such as helix angle, tube spacing, layer spacing, etc., and finally, determine the complete arrangement method according to the existing parameters. Obtain the determined tube bundle design scheme, and carry out the processing and manufacturing process of related products. Wrap the processed spiral tube bundle on the central cylinder according to the mathematical model described in the present invention, and install a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com