Patents

Literature

69results about How to "No need for high temperature calcination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-additive agent modified high-strength wall self-thermal insulation material and preparing method thereof

InactiveCN101318796ANo need for high temperature calcinationReduce heat transferSolid waste managementCement productionPolymer scienceBrick

The invention discloses a nano additive modified high strength wall self heat preservation brick and a preparation method thereof. The method comprises the following steps: according to mass portion, 1 to 20 portions of bonding agent, 0.1 to 5 portions of admixture and 0.5 to 5 portions of nano additive are evenly mixed and added with admixtures, the weight of which is 0.001 to 0.1 times against the weight of the mixture, and evenly mixed again; and the mixture obtained is added with water and shaped. For the wall self heat preservation brick prepared by the method of the invention, the pressive strength is between 5 and 14MPa, the coefficient of thermal conductivity is between 0.1 and 0.2w / m.k, so that the brick is a highly efficient energy saving building material with superior performance.

Owner:浙江中联建设集团有限公司 +2

Preparation method of supported rare earth doped manganese dioxide (MnO2) used in ozone catalyst

ActiveCN105289585ASimple preparation processNo need for high temperature calcinationWaste water treatment from textile industryMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementMetal nitrate

The invention discloses a preparation method of supported rare earth doped manganese dioxide (MnO2) used in an ozone catalyst. The method comprises the following steps: taking gamma-Al2O3 as a carrier, taking MnO2 as an active constituent of the catalyst, and taking rare earth element as an additive, dissolving manganese sulfate and rare-earth metal nitrate in deionized water, adding isopropyl alcohol, stirring, mixing the carrier in the solution obtained after stirring, continuing stirring uniformly, heating, adding a KMnO4 solution, carrying out an in situ oxidation-reduction reaction on the surface of the carrier to obtain the rare earth doped MnO2 modified gamma-Al2O3. The method has the advantages that the preparation technology is simple; the catalyst is low in cost; the performance is stable; the ozonolysis efficiency is high; the application prospect is broad.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

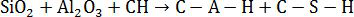

Fly ash and building waste water permeable brick and preparation method thereof

The invention discloses a fly ash and building waste water permeable brick and a preparation method thereof, and belongs to the technical field of building materials. The fly ash and building waste water permeable brick is prepared from, by weight, 100 parts of fly ash, 200-800 parts of building waste, 2-8 parts of silica fume, 1.5-6.5 parts of alkali-activator and 18-36 parts of water. According to the fly ash and building waste water permeable brick and the preparation method thereof, industrial waste residues and building waste are adopted as the raw materials, the solid waste utilization rate is high, and the production cost is low; the molding method adopts compression molding and is simple in technology, free of high-temperature calcination, low in carbon, environmentally friendly and low in energy consumption; a cementing material is an alkali-activator powder coal ash cementing material, and the water permeable brick prepared through the alkali-activator powder coal ash cementing material has the advantages of being high in strength, high in water permeability, low in hydration heat, resistant to carbonization, good in durability and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Anodic electrocatalyst for direct borohydride fuel cell and preparation method thereof

InactiveCN101485982ASimple preparation processNo need for high temperature calcinationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFiberGold particles

The invention relates to an anode electrocatalyst for a direct borohydride fuel cell and a method for preparing the same, in particular to a method for preparing a porous carbon loading nanometer gold catalyst. The preparation method comprises that: by adopting the metal sol loading method, the surface of the porous carbon carrier after purification and surface oxidizing treatment is loaded with a nanometer gold particle, and the size of the gold particle can be controlled by controlling the adding amount of a reducing agent and the gold concentration in the metal sol. The loading capacity of the gold is 5 to 30 percent, and the particle size of the gold is 2 to 6nm. The porous carbon is one of or a mixture of more than one of carbon nanometer pipe, carbon nanometer fiber, active carbon fiber, graphitized carbon black, active carbon and intermediate phase carbon microsphere, and the specific surface area of the carrier is between 100 and 2,000m / g. The method has the advantages of simple preparation process, unnecessary high-temperature calcination, and easy mass production. The prepared gold particle has the advantages of high-degree dispersion on the surface of the carbon carrier and even size distribution. When used as the anode electrocatalyst of the direct borohydride fuel cell, the anode electrocatalyst has good BH4 electric oxidation catalysis activity.

Owner:NO 63971 TROOPS PLA

Preparation and application methods of high-efficiency composite photocatalytic material

InactiveCN104307538ASimple preparation processLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationMethyl orangeCitric acid

The invention relates to preparation and application methods of a high-efficiency composite photocatalytic material MoS2 / SrTiO3. The photocatalytic material is formed by compounding strontium titanate and molybdenum disulfide through a secondary hydrothermal method. The preparation method comprises the following steps: mixing isopropyl carbonate and citric acid, respectively dropwise adding a strontium nitrate solution and a sodium hydroxide solution under ultrasonic stirring conditions to obtain a precursor, heating the obtained precursor in a hydrothermal kettle, and washing and drying a product, thereby obtaining nano strontium titanate; fully mixing strontium titanate with a molybdenum disulfide precursor solution, heating in the hydrothermal kettle, and washing and drying a product, thereby obtaining the photocatalytic material MoS2 / SrTiO3. The photocatalytic material is simple in preparation method, does not need high-temperature calcining, is low in cost and recyclable, is capable of efficiently degrading methyl orange or organic dyestuffs with similar developing groups with the methyl orange, and has wide application prospects in the field of treatment of wastewater containing the organic dyestuffs.

Owner:SOUTHEAST UNIV

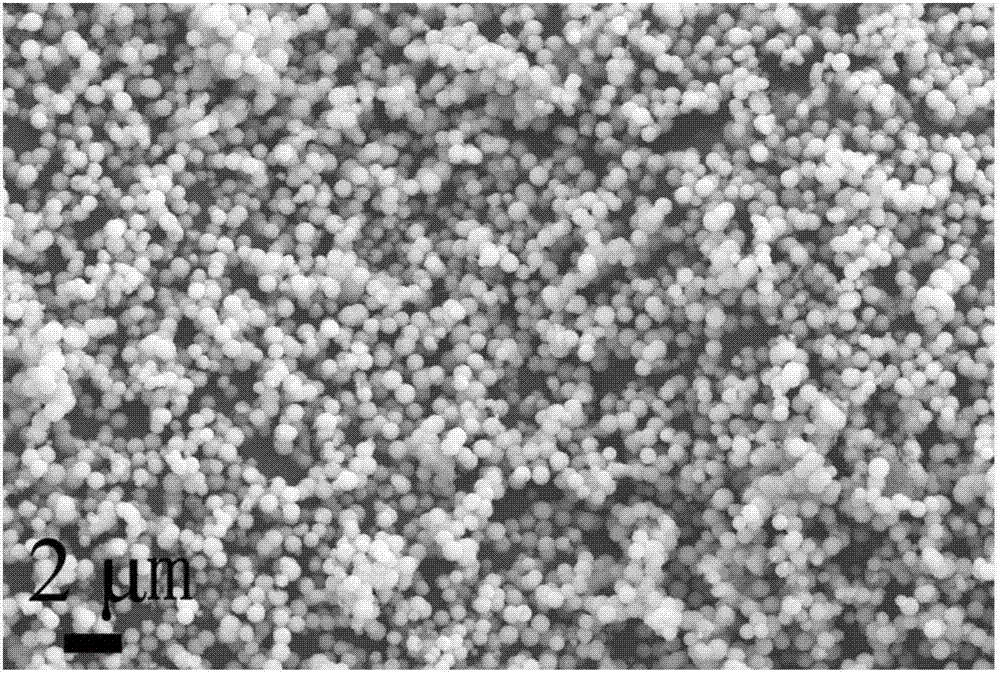

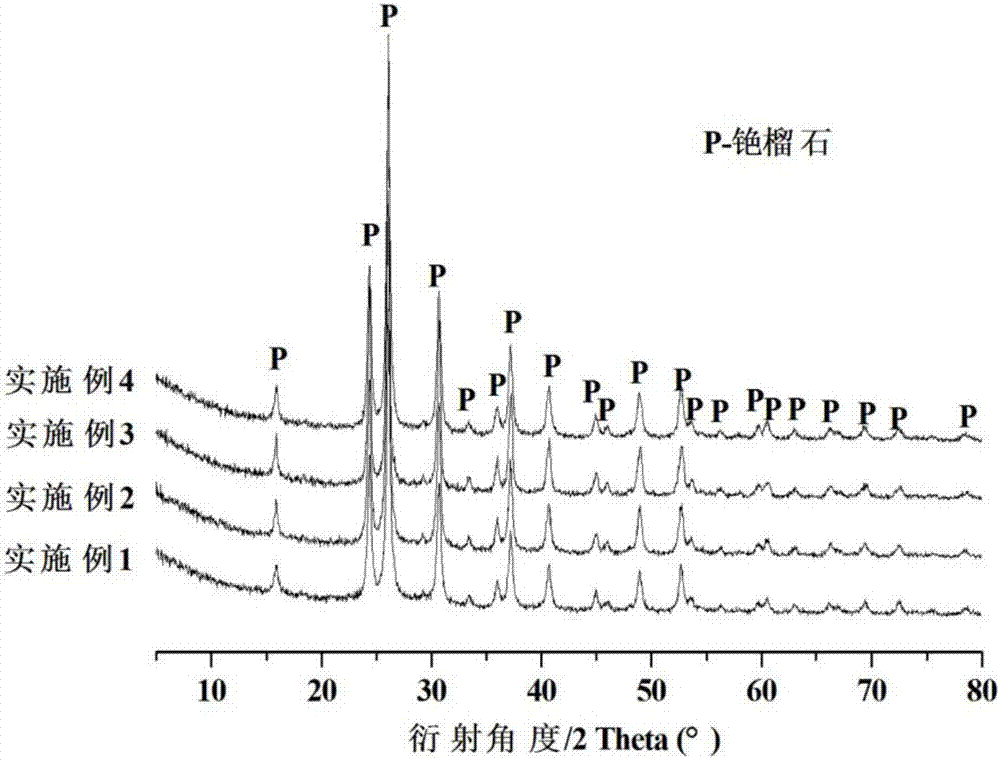

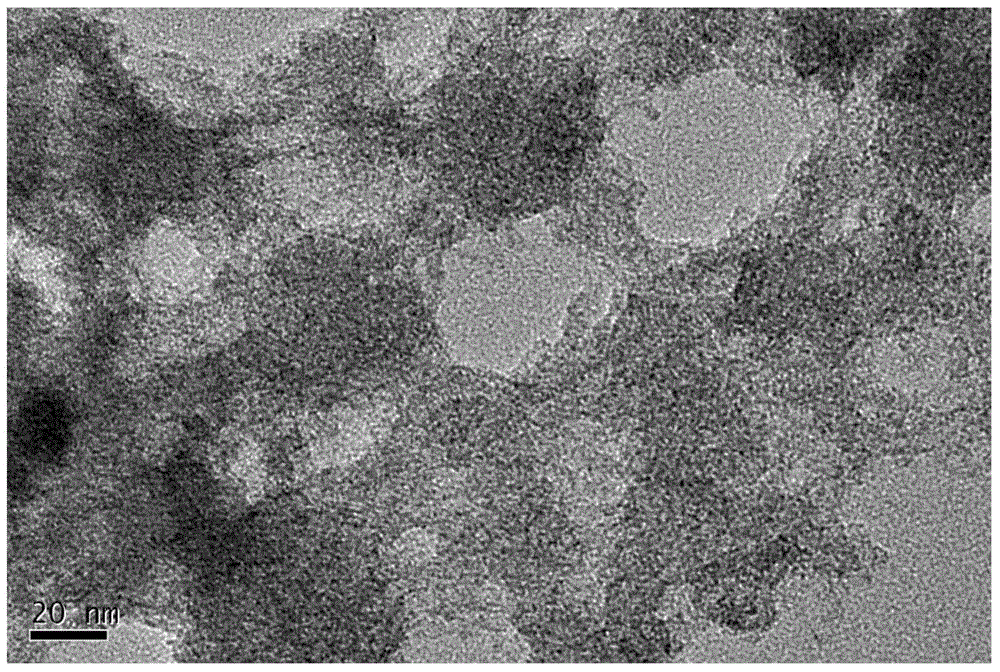

Preparation method of pollucite sub-microspheres with kilogram yield grade

ActiveCN107352550AImprove protectionAvoid high temperature volatilizationAluminium silicatesMicrosphereRadioactive waste

The invention discloses a preparation method of pollucite sub-microspheres with kilogram yield grade. The preparation method is characterized by comprising the following steps: firstly, taking solid raw materials such as amorphous silica, amorphous alumina, metakaolin and cesium hydroxide monohydrate, and adding the solid materials into a autoclaved reaction kettle; secondly, taking deionized water according to the weight ratio of the solid materials to the deionized water being 1 to (15 to 20) and then adding the deionized water into the autoclaved reaction kettle; thirdly, reacting for 4 to 20 hours under the conditions that the temperature is 140 to 200 DEG C, the pressure is 0.3 to 0.8MPa and the stirring speed is 60 to 100r / min, then cooling and filtering; washing solids with water and then drying to obtain the pollucite sub-microspheres. According to the preparation method disclosed by the invention, synthesis and preparation of the pollucite sub-microspheres with the kilogram grade under mild conditions are realized; the preparation method is suitable for industrial scale production. The prepared pollucite sub-microspheres can be used for preparing a ceramic container for storing a cesium radioactive source core material or radioactive wastes, and also can be used for high-temperature-resisting ceramics in the field of aerospace.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Water-permeable bricks prepared from coal gangues and construction waste and preparation method thereof

InactiveCN106277974AHigh strengthGood water permeabilitySolid waste managementCeramicwareBrickCalcination

The invention discloses water-permeable bricks prepared from coal gangues and construction waste and a preparation method thereof and belongs to the technical field of building materials. The water-permeable bricks are prepared from, by weight, 100 parts of coal gangues, 200-800 parts of construction waste, 5-10 parts of silica fume, 1.8-7 parts of alkaline excitant and 18-36 parts of water. The raw materials are industrial waste and construction waste, the solid waste utilization rate is high, and the production cost is low. The water-permeable bricks are formed through pressing and are low in carbon, environmentally friendly and low in energy consumption, the process is simple, and high temperature calcination is not needed. A cementing material is an alkali-activated coal gangue cementing material, so that the water-permeable bricks prepared adopting the cementing material have the advantages of being high in strength, high in water permeability, low in hydration heat, resistant to carbonation, good in durability and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

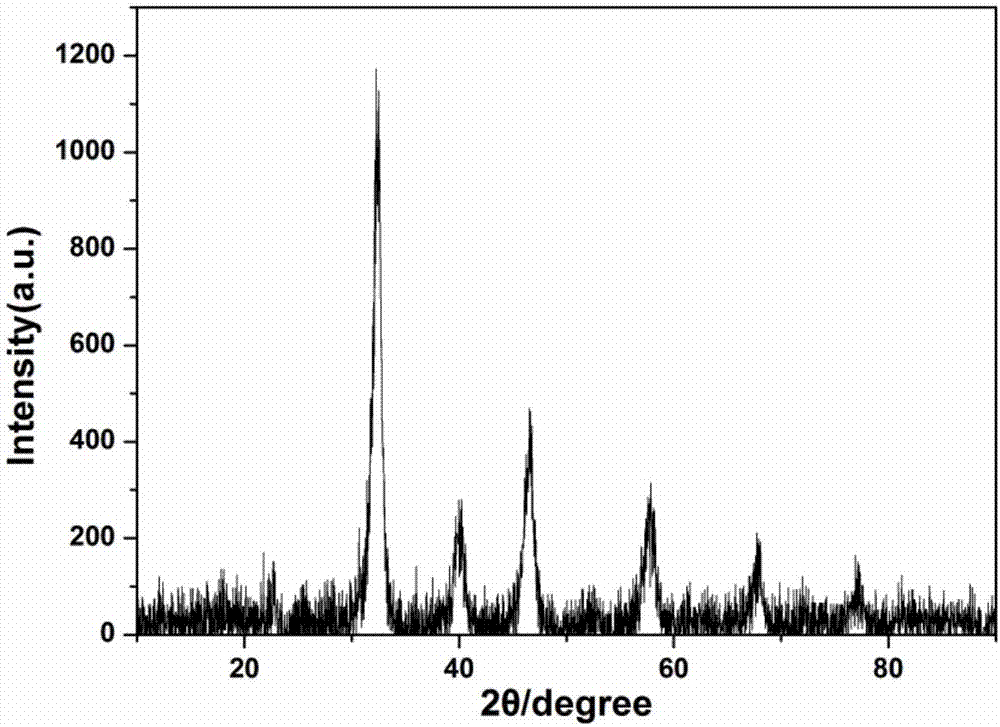

Method for preparing perovskite nano powder

ActiveCN104477978AEffective size controlAvoid toxicityMaterial nanotechnologyZirconium compoundsReaction temperatureIon

The invention provides a method for preparing ABO3 perovskite nano powder. The method comprises the following steps: dropwisely adding a B-site element source alcohol solution into surfactant / acetic acid-dissolved deionized water to obtain a mixed solution, adding ammonia water into the mixed solution, and reacting the reaction system at constant temperature to obtain a B-site element hydrous oxide gel; and preparing a B-site element hydrous oxide gel dispersion solution, adding an A-site element source into the dispersion solution, and carrying out hydrothermal reaction under normal pressure to obtain the ABO3 perovskite nano powder. The aqueous gel-normal pressure hydrothermal process and raw materials with lower cost are adopted, and the aqueous reaction is utilized to avoid the toxicity of the organic solvent. The pH value, surfactant amount, reaction raw material concentration, reaction time, reaction temperature and other conditions of the system are regulated to effectively control the size of the product, thereby obtaining the well-crystallized monodisperse perovskite powder with the particle size of 15-300nm.

Owner:TSINGHUA UNIV

Method for preparing strontium titanate nano powder through microwave hydrothermal method

InactiveCN102674442ACrystal fineUniform particle sizeNanotechnologyTitanium compoundsSlurryCalcination

The invention discloses a method for preparing strontium titanate nano powder through a microwave hydrothermal method. The method includes: mixing titanate, ethanol and acetic acid, adding water solution containing strontium ions in dropwise mode to form sol, then adding alkali, adjusting potential of hydrogen (pH) value of the sol to 8-14, obtaining precursor slurry, placing the precursor slurry in a reaction kettle, performing microwave hydrothermal reaction, and separating and drying reaction products to obtain the strontium titanate nano powder. Compared with a conventional hydrothermal method, the method is rapid in reaction, easy to control, free of high-temperature calcination, simple in device and low in cost. The obtained strontium titanate nano powder is intact in crystallization, even in particle size and narrow in distribution range.

Owner:无锡隆傲电子有限公司

Water permeable brick prepared from alkali residues and construction waste and preparation method thereof

InactiveCN106278350AHigh utilization rate of solid wasteReduce manufacturing costSolid waste managementCement productionSilica fumeIndustrial waste

The invention discloses a water permeable brick prepared from alkali-residues and construction waste and a preparation method thereof, belonging to the technical field of construction material preparation. The water permeable brick is prepared from the following substances in parts by weight: 100 parts of alkali residues, 200-800 parts of construction waste, 2-8 parts of silica fume, 5-15 parts of cement, 2-7.5 parts of alkali activator and 18-40 parts of water. The water permeable brick is prepared from industrial waste residues and construction waste, and has high solid waste utilization and low production cost; the molding method adopts press molding, is simple in process, does not need high-temperature calcining, and has the advantages of low carbon, environmental friendliness and low energy consumption; and the gel material is alkali-activated alkali residue gel material to prepare the water permeable brick having the advantages of high strength, high water permeability, low hydration heat, carbonization resistance, good durability and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

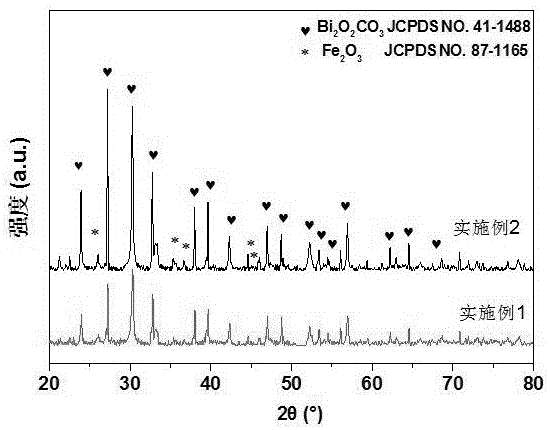

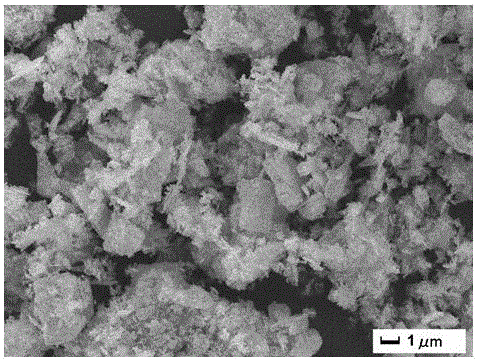

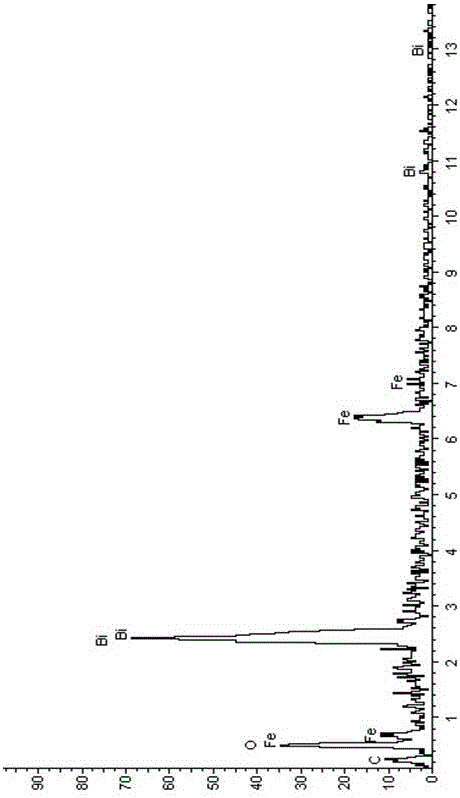

Preparation method of iron sesquioxide-bismuthylcarbonate composite light catalyst

InactiveCN106268895ANo need for high temperature calcinationEvenly distributedPhysical/chemical process catalystsWater/sewage treatment by irradiationMaterials preparationNanoparticle

The invention discloses a preparation method of an iron sesquioxide-bismuthylcarbonate composite light catalyst, and belongs to the technical field of novel material preparation. A low-temperature hydrothermal method is adopted, iron-based gel is adopted as a precursor, Fe2O3 is introduced on the surface of bismuthylcarbonate in one step, and the composite light catalyst is formed. The problem that the composite light catalyst is hard to synthesize is solved, and the iron sesquioxide-bismuthylcarbonate composite light catalyst is successfully prepared. On the basis of the simple sol-gel soaking method, no surface active agent or template agent is added, high temperature calcination is not needed, the technology is simple, the preparation process is easy to control, water is adopted as the reaction solvent, and obtained nanoparticles are uniform in distribution.

Owner:YANGZHOU TIANCHEN FINE CHEM +2

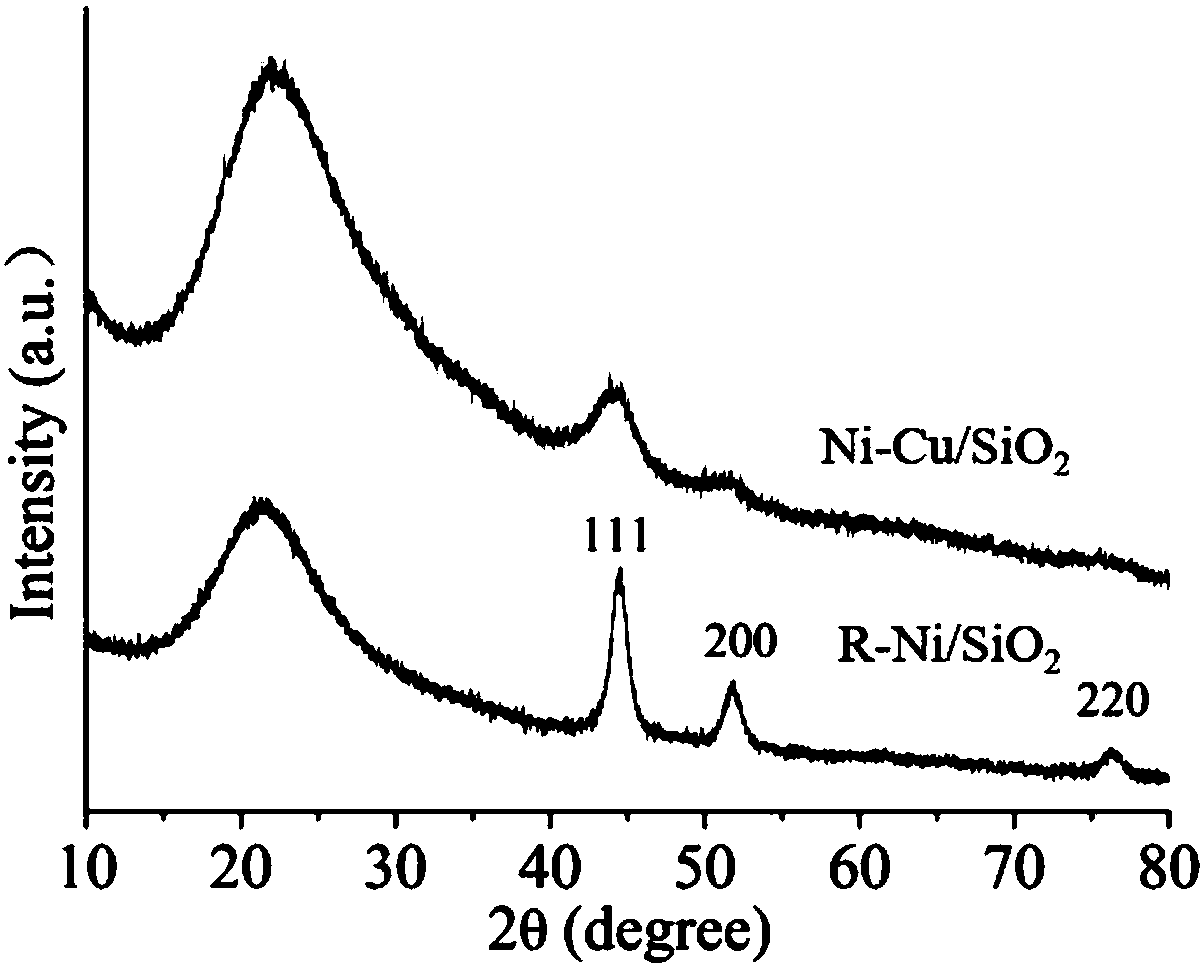

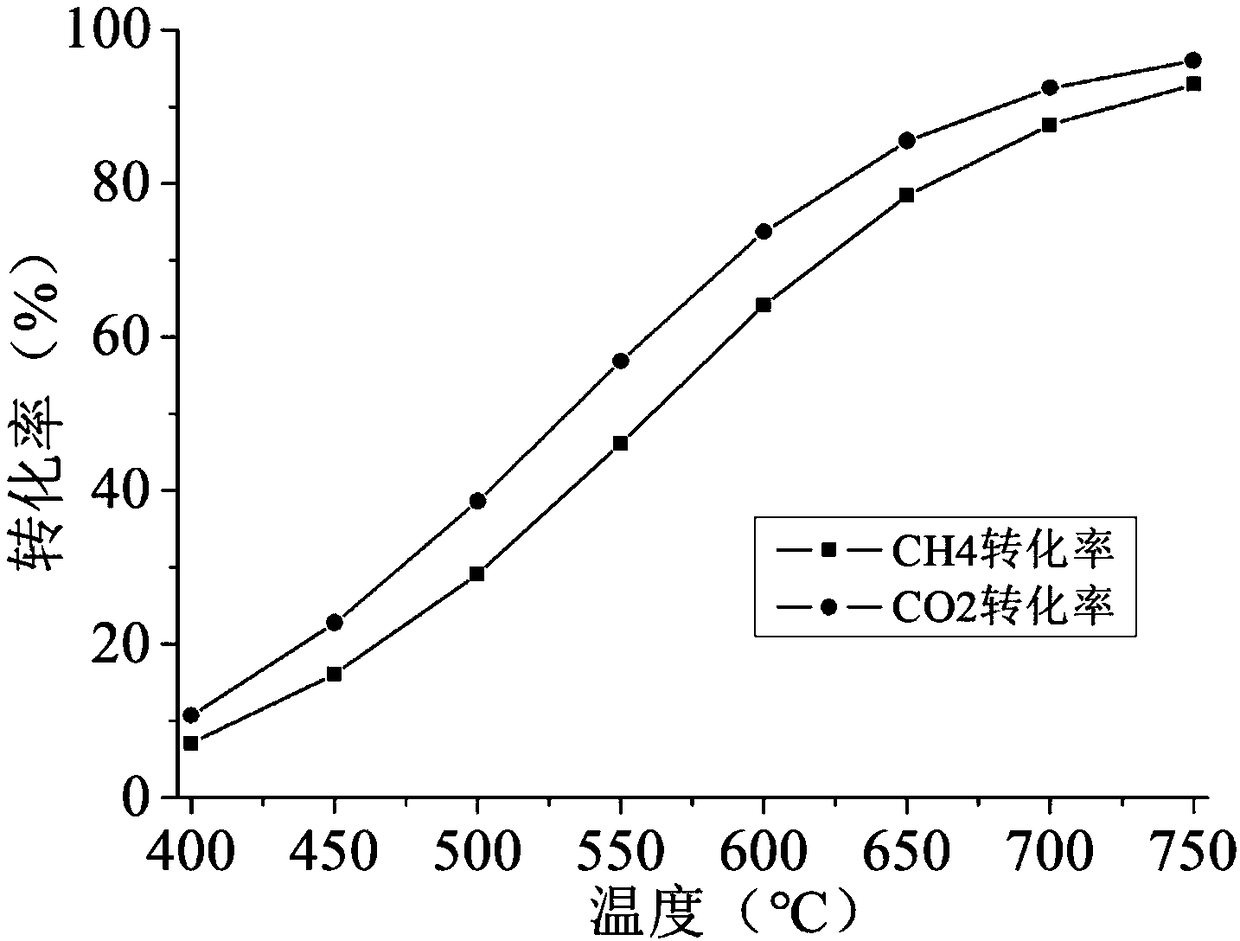

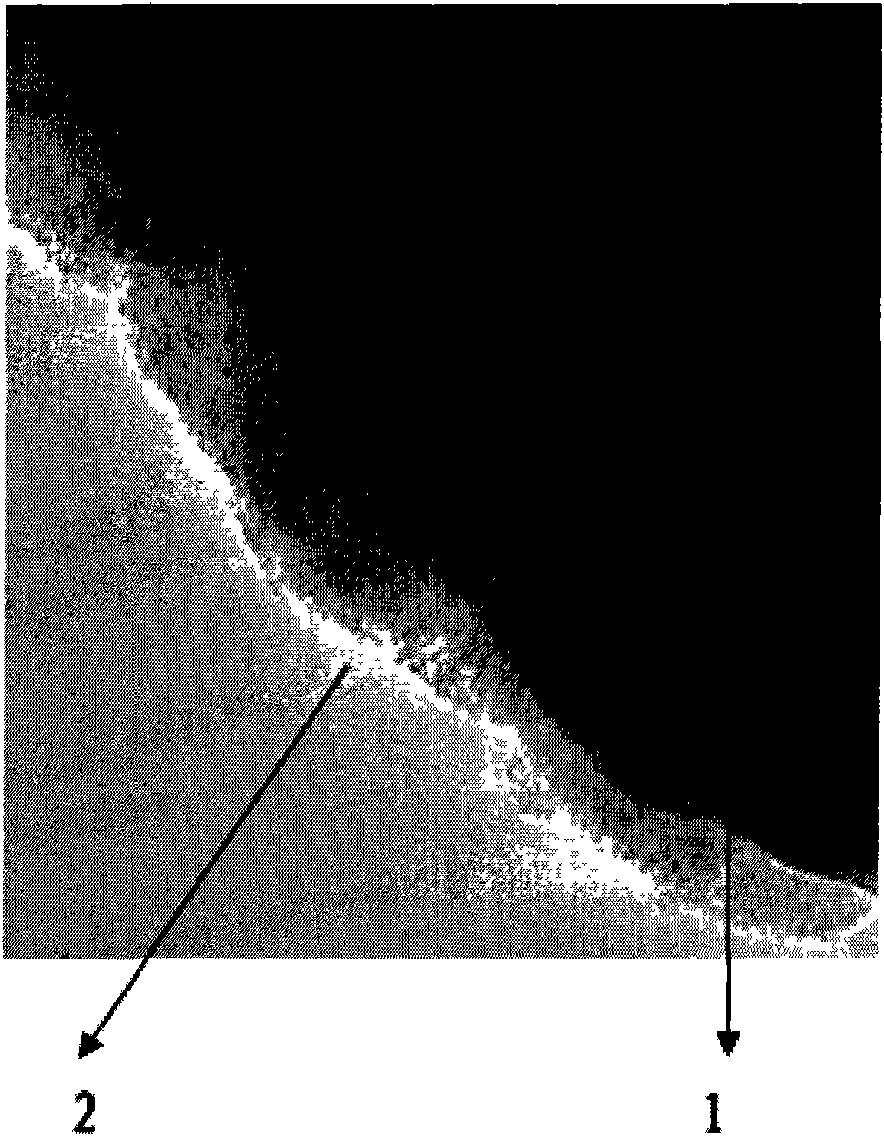

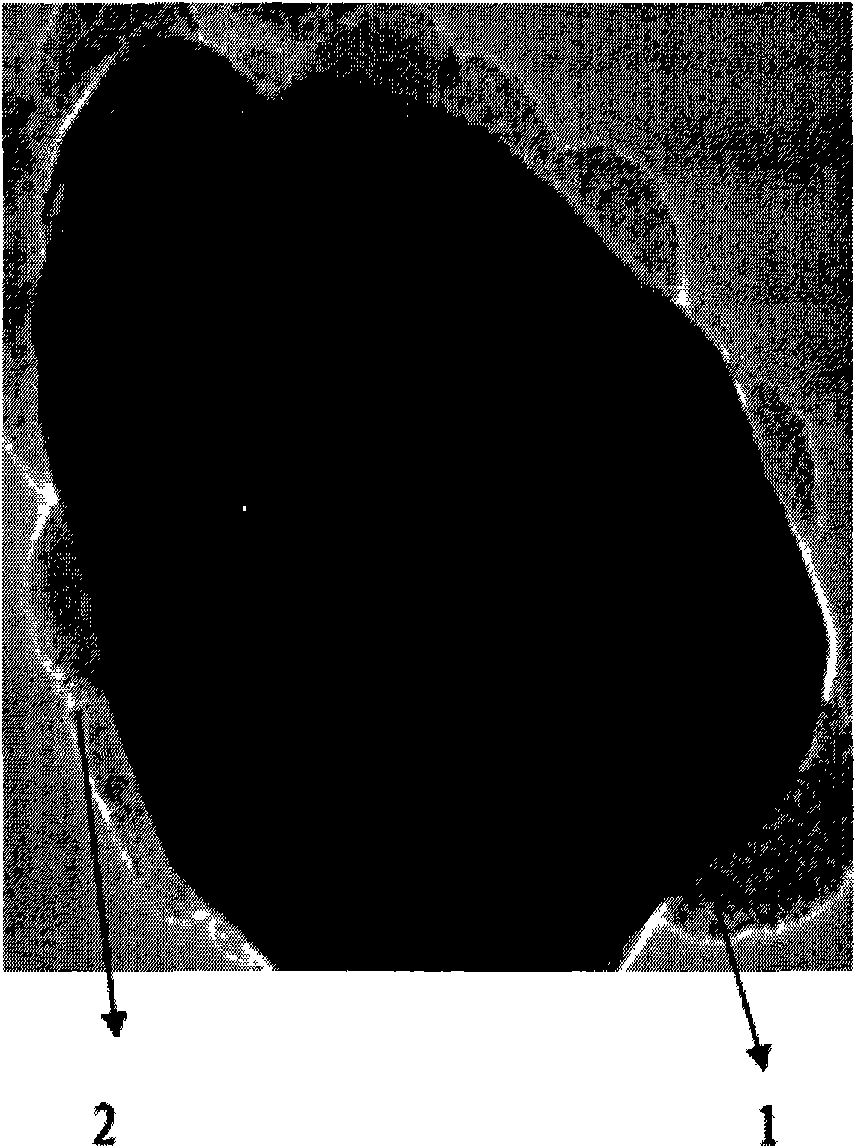

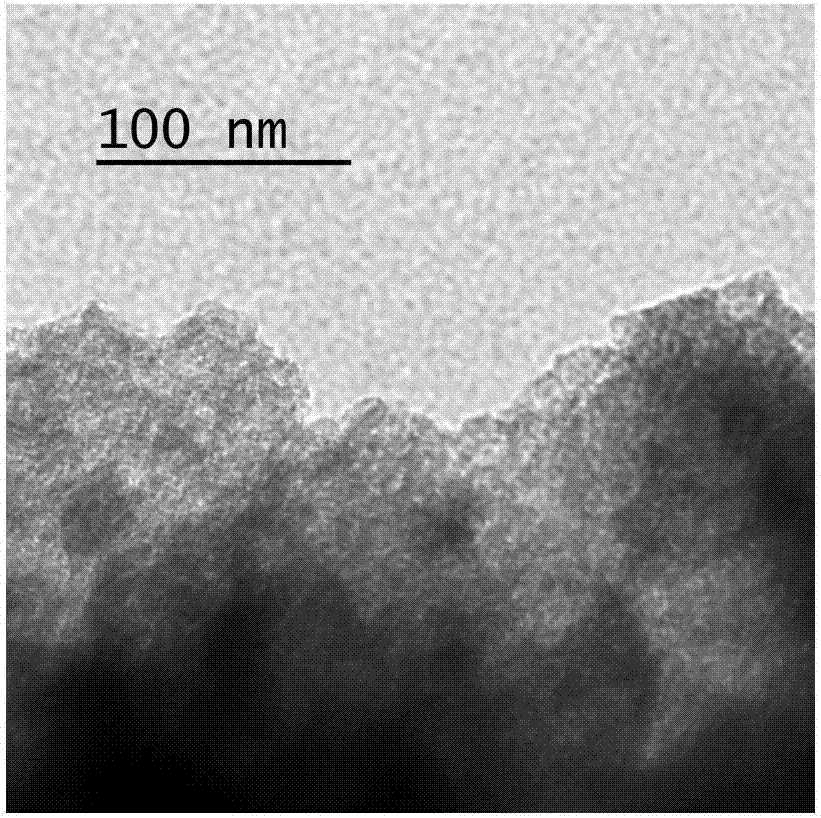

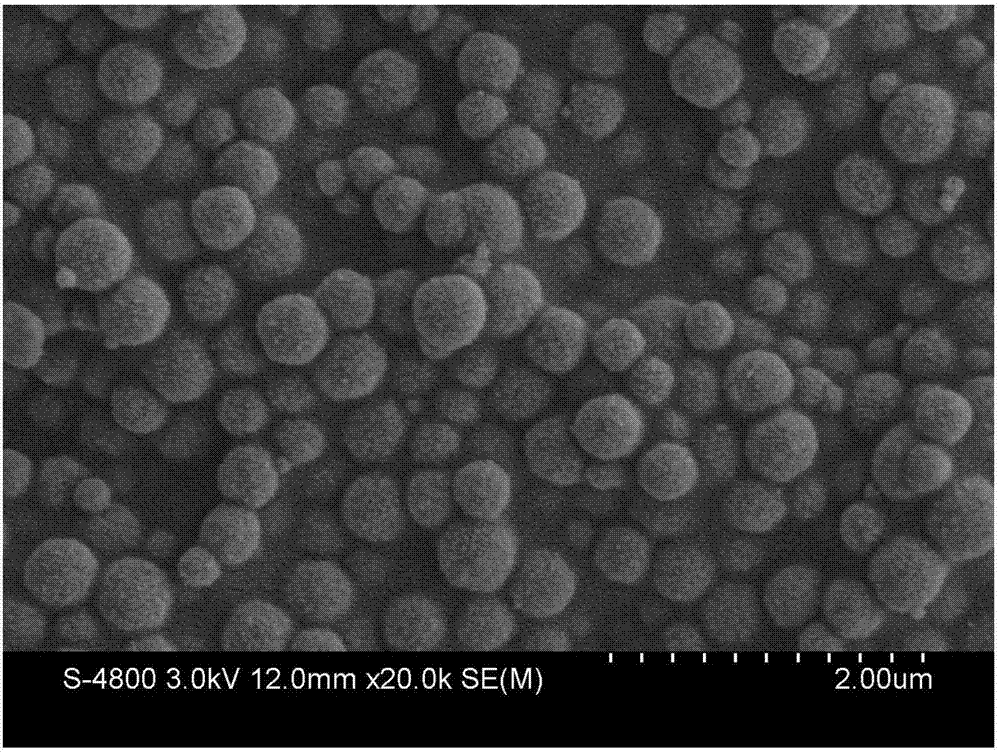

Copper doped Ni/SiO2 nanocomposite catalyst and preparation method thereof

InactiveCN108579750AImprove stabilityImprove anti-coking performanceHydrogenCatalyst activation/preparationMesoporous silicaSilicon dioxide

The invention relates to a method for improving the stability of an Ni-Cu / SiO2 nanocomposite catalyst in methane dry reforming by using mesoporous silica as a carrier and nickel nanocrystal as a mainactive component through copper doping, belonging to the technical field of catalyst preparation. The nanocomposite catalyst is prepared from raw materials like nickel nitrate, sodium silicate and diluted nitric acid by a simple precipitation method through steps of aging, filtering and washing, drying, grinding and reducing; the method provided by the invention has simple preparation process, noneed of high-temperature calcination, cheap and easily available raw materials and low cost; and the catalyst prepared by using the method provided by the invention has the advantages of high catalytic activity, good stability, no significant decrease in activity after reacted under the condition of 700 DEG C for 140 hours, strong capability of resisting sintering and carbon deposition, etc. The catalyst provided by the invention is applied to a methane dry reforming reaction, and provides an effective solution channel for effective utilization of natural gas and emission reduction of CO2.

Owner:WUHAN UNIV OF TECH

Method for preparing photocatalyst with core-shell structure

InactiveCN101676030AReduce energy consumptionSimple preparation processCatalyst activation/preparationInorganic compoundTitanium tetrachloride

The invention relates to a method for preparing a photocatalyst with a core-shell structure, which comprises the following steps: (A) activating an acid-resisting non-metallic ore or a non-metallic synthetic compound, and removing acid-soluble impurities; (B) under the synergistic action of hydrochloric acid and a macromolecular compound, moderately hydrolyzing titanium tetrachloride, and preparing the hydrolyzate required for coating a core; and (C) depositing and coating the core and a shell. The invention has the advantage that under the conditions of normal pressure, low temperature and no need of high temperature calcination, 2-8 nanometers of titanium dioxide particles are deposited and coated on the surface of an acid-resisting non-metallic inorganic mineral or a synthetic inorganic compound. The preparation technology not only keeps the high catalytic activity of 2-8 nanometers of titanium dioxide but also eliminates the defect of agglomeration or coating of photocatalytic materials in application systems, such as plastics, paint and the like. Compared with the prior method, the anatase type nano titanium dioxide coated on the surface can form a complete crystal at the temperature lower than 100 DEG C without calcination, thus the invention has simple preparation technology and low energy consumption and is suitable for industrial production.

Owner:SHANGHAI WORLD PROSPECT INT TRADE +1

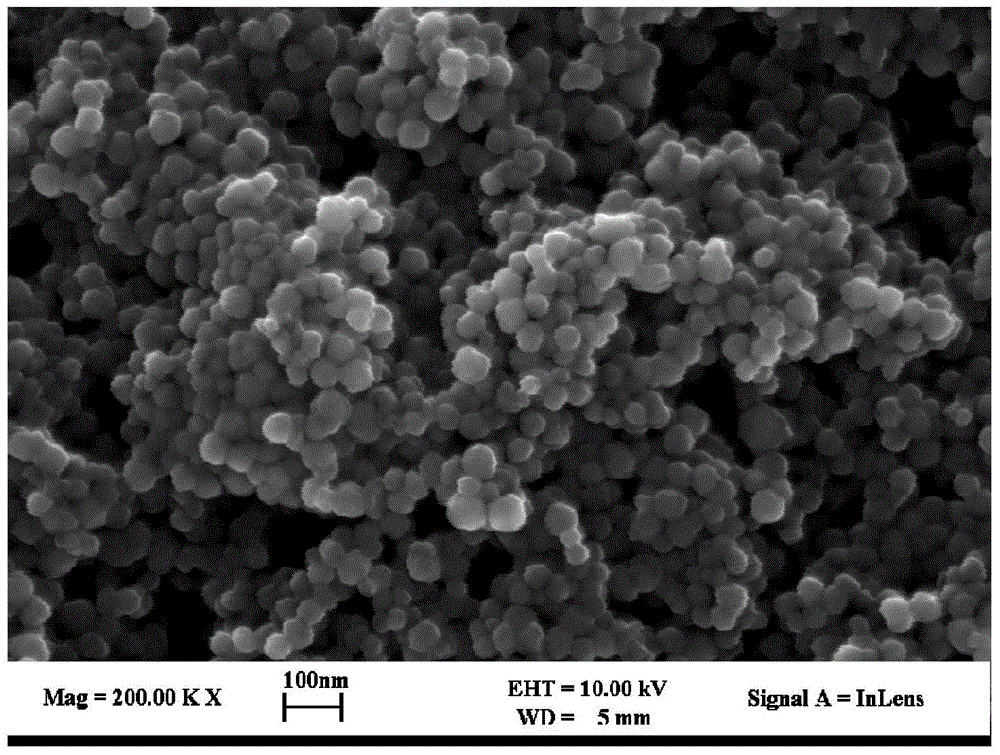

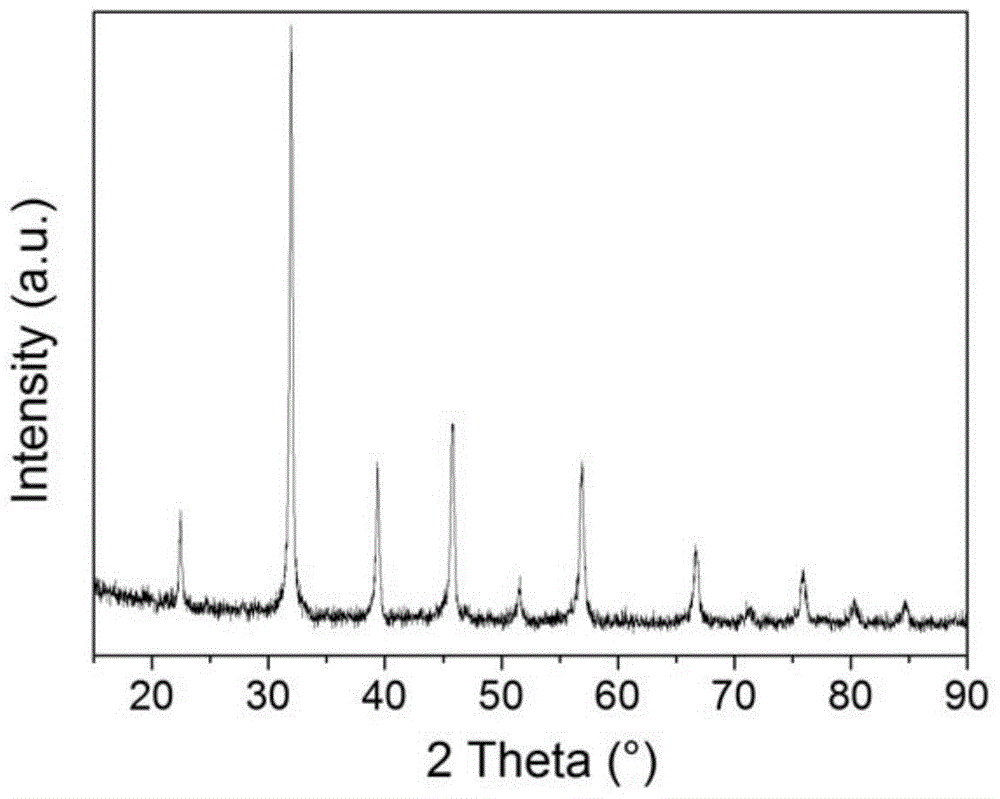

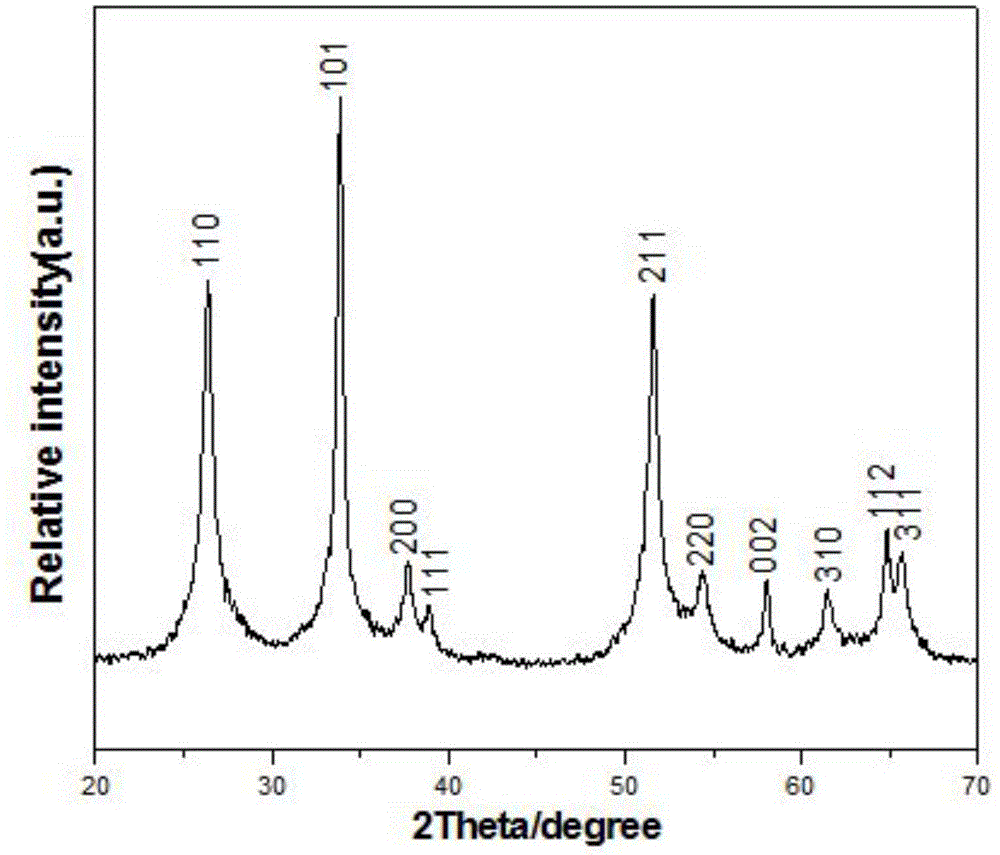

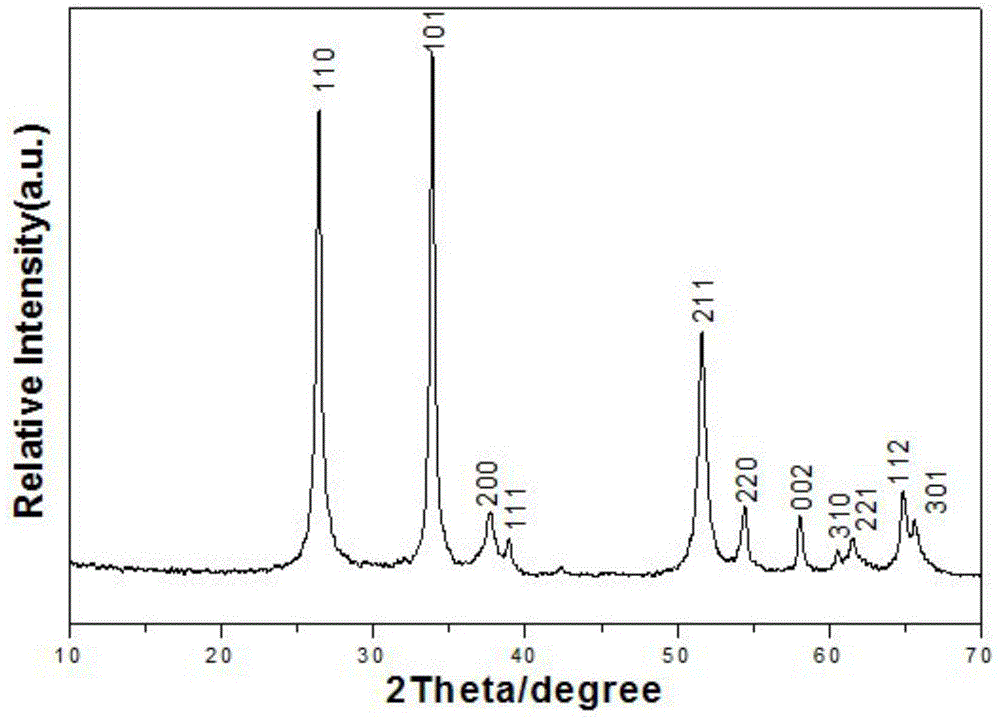

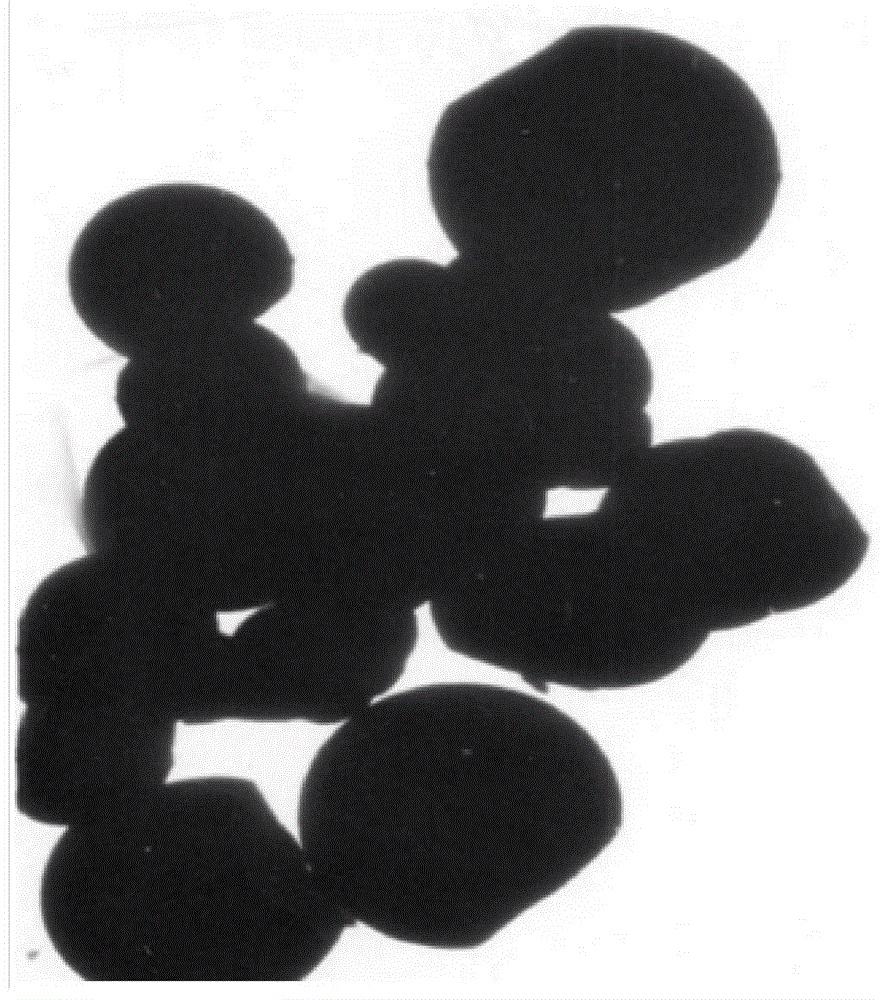

Method for direct synthesis of Mn<+>-doped SnO2 nanocrystals with one-step hydrothermal method

The invention discloses a method for direct synthesis of Mn<+>-doped SnO2 nanocrystals with a one-step hydrothermal method, wherein the method comprises the following steps: under stirring, slowly dropwise adding an Sn<4+> salt solution into an NaOH solution, and forming a transparent solution; then dropwise adding an Mn<+> salt solution into the above solution, and forming a suspension; transferring the suspension into a high-pressure reaction kettle, adding distilled water, then sealing, putting into an electric heating drying oven, and at the temperature of 140-200 DEG C, carrying out a reaction for 12-36 h; after the reaction is finished and after the high-pressure reaction kettle is naturally cooled, opening the reaction kettle, taking out a precipitate in a polytetrafluoroethylene container, separating, and respectively washing with distilled water and absolute ethyl alcohol, putting the precipitate in a 60 DEG C vacuum drying oven, drying for 4-6 h, and thus obtaining the product. The Mn<+>-doped SnO2 nanocrystals have the advantages of good morphology and regular dimension; and the method has the advantages of simple instrument and equipment, simple process, easily controlled conditions, and green environmental protection.

Owner:ANHUI SCI & TECH UNIV

Multi-solid-waste large-mixing-amount non-fired water permeable brick and preparation method thereof

InactiveCN112142420AIncrease added valueRealize resource utilizationSolid waste managementCeramic shaping apparatusMaterials preparationBrick

The invention relates to a multi-solid-waste large-mixing-amount non-fired water permeable brick and a preparation method thereof, and belongs to the field of building material preparation, the multi-solid-waste large-mixing-amount non-fired water permeable brick comprises the following components in proportion: 45%-50% of steel slag, 10%-20% of coal gangue, 8%-15% of desulfurized gypsum, 10-20% of aggregate, 8%-10% of water and 1%-3% of water reducing agent, wherein the aggregate is composed of iron mine waste rock and building waste at 1:1. A large amount of solid waste is adopted as the rawmaterial, the ecological pressure can be reduced while the cost is saved, the solid waste utilization rate is increased, energy is greatly saved in an unfired mode, the activity of the raw material is improved through mechanical grinding, the activity of steel slag can be stimulated through addition of coal gangue and desulfurized gypsum, and the permeable strength and wear resistance are improved.

Owner:张延年

Multi-solid-waste baking-free steaming-free water permeable brick with double-layer structure and preparation method thereof

The invention discloses a multi-solid-waste baking-free steaming-free water permeable brick with a double-layer structure and a preparation method thereof, and belongs to the field of preparation of building materials; the water permeable brick comprises a surface layer and a base layer, and the surface layer is composed of the raw materials in parts by weight: 80-100 parts of steel slag micro powder, 20-30 parts of silica fume, 1-4 parts of epoxy resin, 0.5-2 parts of a curing agent, 0.1-0.5 part of a water reducing agent and 10-20 parts of water; the base layer is composed of the raw materials in parts by weight: 10-20 parts of cement, 80-100 parts of iron ore waste rock, 20-30 parts of iron tailing powder, 0.1-0.5 part of a water reducing agent and 10-20 parts of water; the water permeable brick has the beneficial effects that the solid waste utilization rate is high, resource utilization of solid waste is achieved, the process is simple, high-temperature calcination is not needed,energy consumption is low, the surface layer adopts extremely fine particles, and the situation that the interior of the water permeable brick is blocked due to overlong use time is avoided; and silica fume is added into the surface layer as an excitant, so that the strength and the wear resistance of the water permeable brick are improved.

Owner:张延年

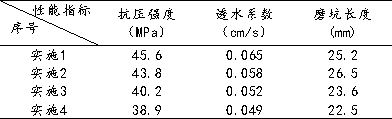

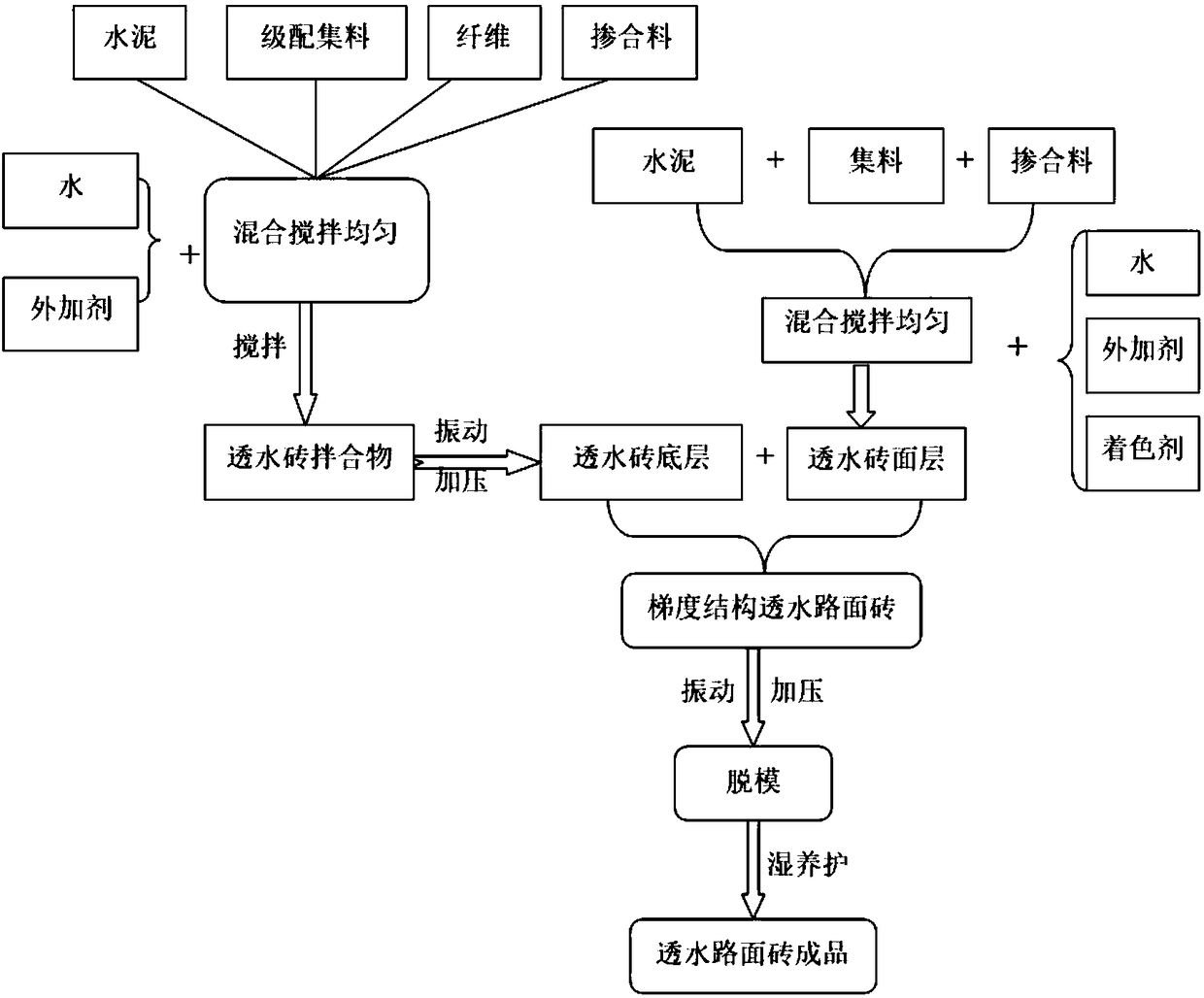

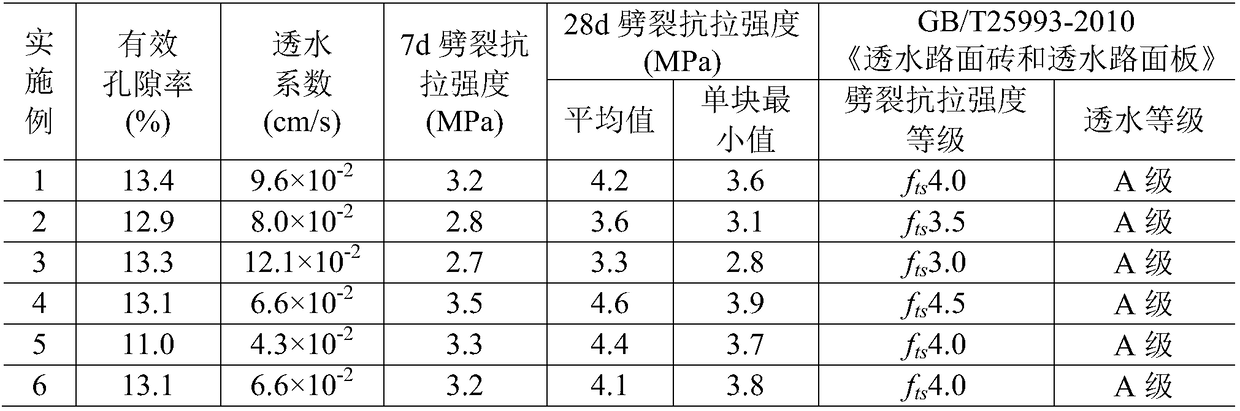

Structure gradient type cement-based water-permeable pavement bricks and preparation method thereof

The invention relates to structure gradient type cement-based water-permeable pavement bricks and a preparation method thereof. Each water-permeable pavement brick is composed of a bottom layer and asurface layer; the thickness of the surface layer is 2 to 15 percent of the total thickness of the water-permeable pavement brick; the bottom layer is prepared from the following components in parts by weight: 300 to 500 parts of a gel material, 1200 to 1800 parts of aggregate, 85 to 120 parts of water, 5 to 15 parts of an additive and 1 to 3 parts of fiber; the surface layer is prepared from thefollowing components in parts by weight: 300 to 500 parts of a gel material, 1200 to 1800 parts of aggregate, 85 to 120 parts of water, 5 to 15 parts of an additive and 0 to 5 parts of a coloring agent. The structure gradient type cement-based water-permeable pavement bricks provided by the invention have the advantages of high strength, good water-permeable performance, simple preparation technology and low cost.

Owner:SHAOGUAN COLLEGE

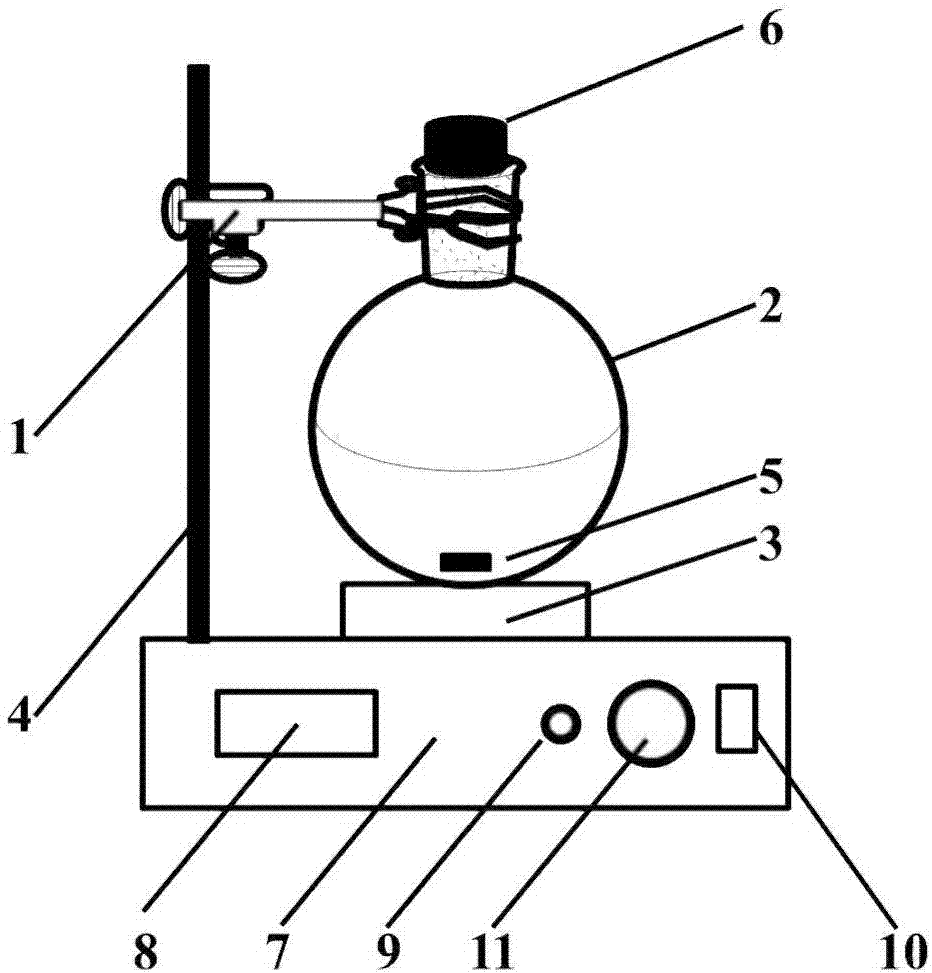

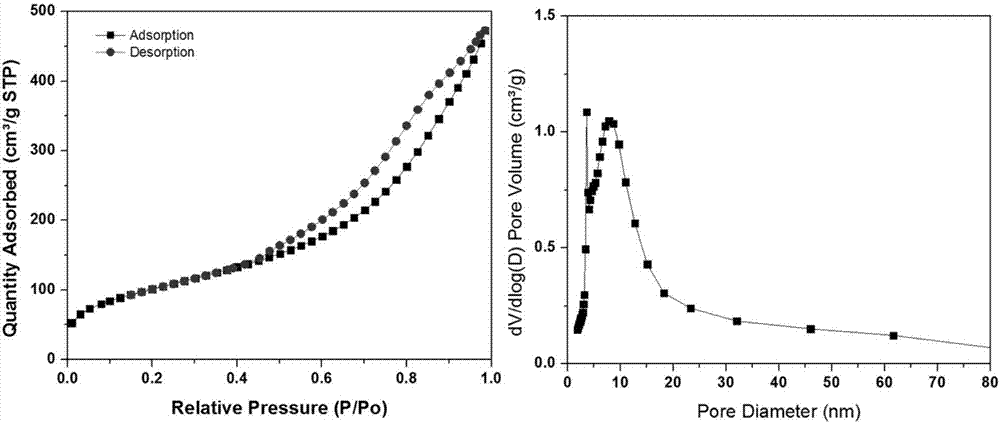

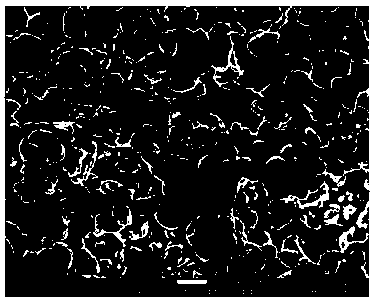

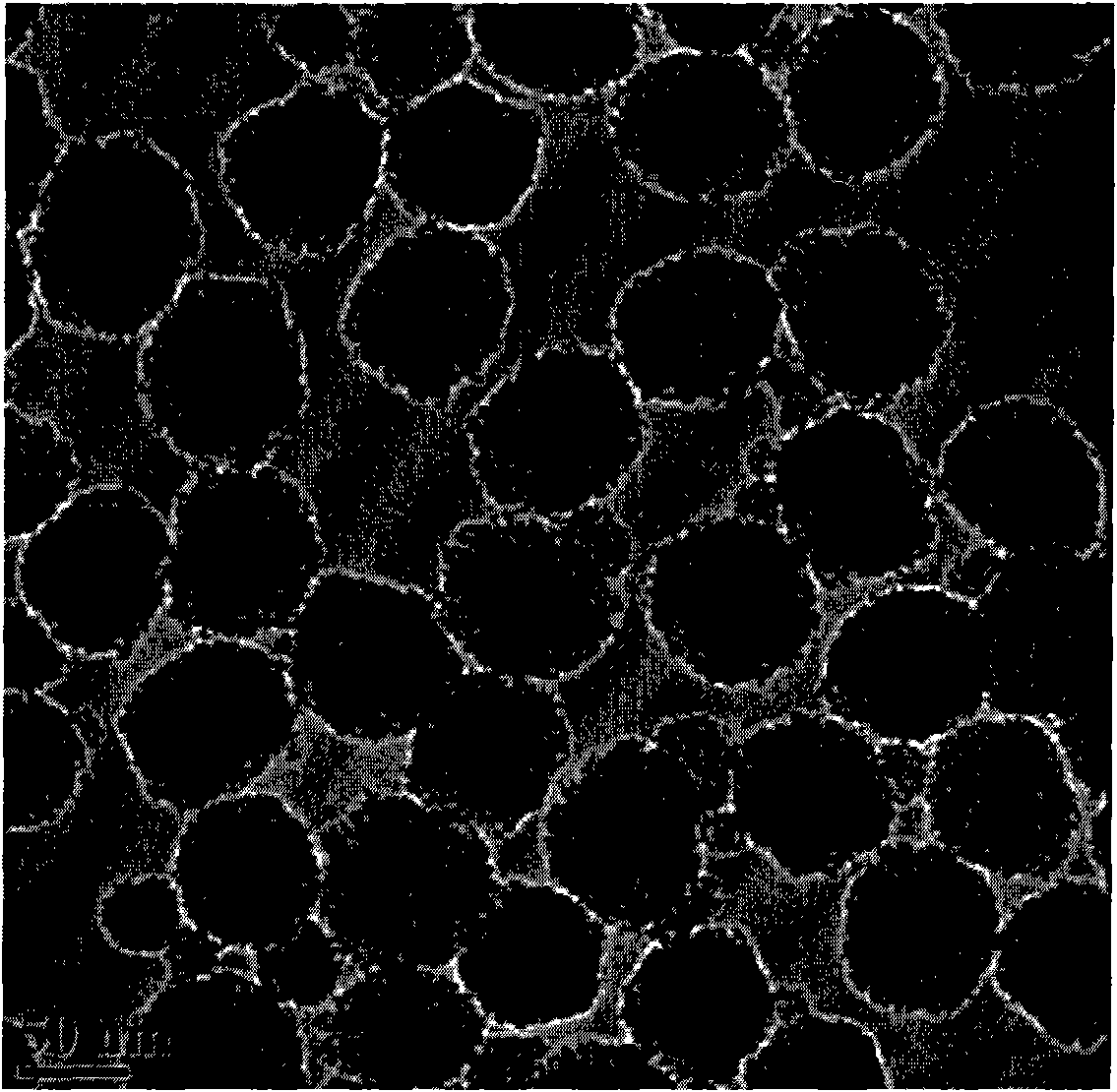

Mesoporous carbon material preparation method

The invention relates to a mesoporous carbon material preparation method, and belongs to the technical field of preparation and applications of a carbon material. Compared with the background art, the mesoporous carbon material preparation method has obvious progresses, a small organic molecule is taken as a carbon source, a Na-K alloy is taken as a reducing agent, methylbenzene is taken as a solvent, the materials are stirred at the room temperature to prepare a reaction solution, the reaction solution is subjected to suction filtration, washing and vacuum drying to prepare a mesoporous carbon material, the process of the preparation method is advanced, the data are full and accurate, the preparation is fast, high-temperature calcination is not needed, the product is a black powder, the black powder has a mesoporous porous structure, the yield of the product is as high as 75.6%, the mesoporous carbon material can be matched with various chemical substances, and the preparation method is a quite ideal method for preparing the mesoporous carbon material.

Owner:SHENYANG NORMAL UNIV

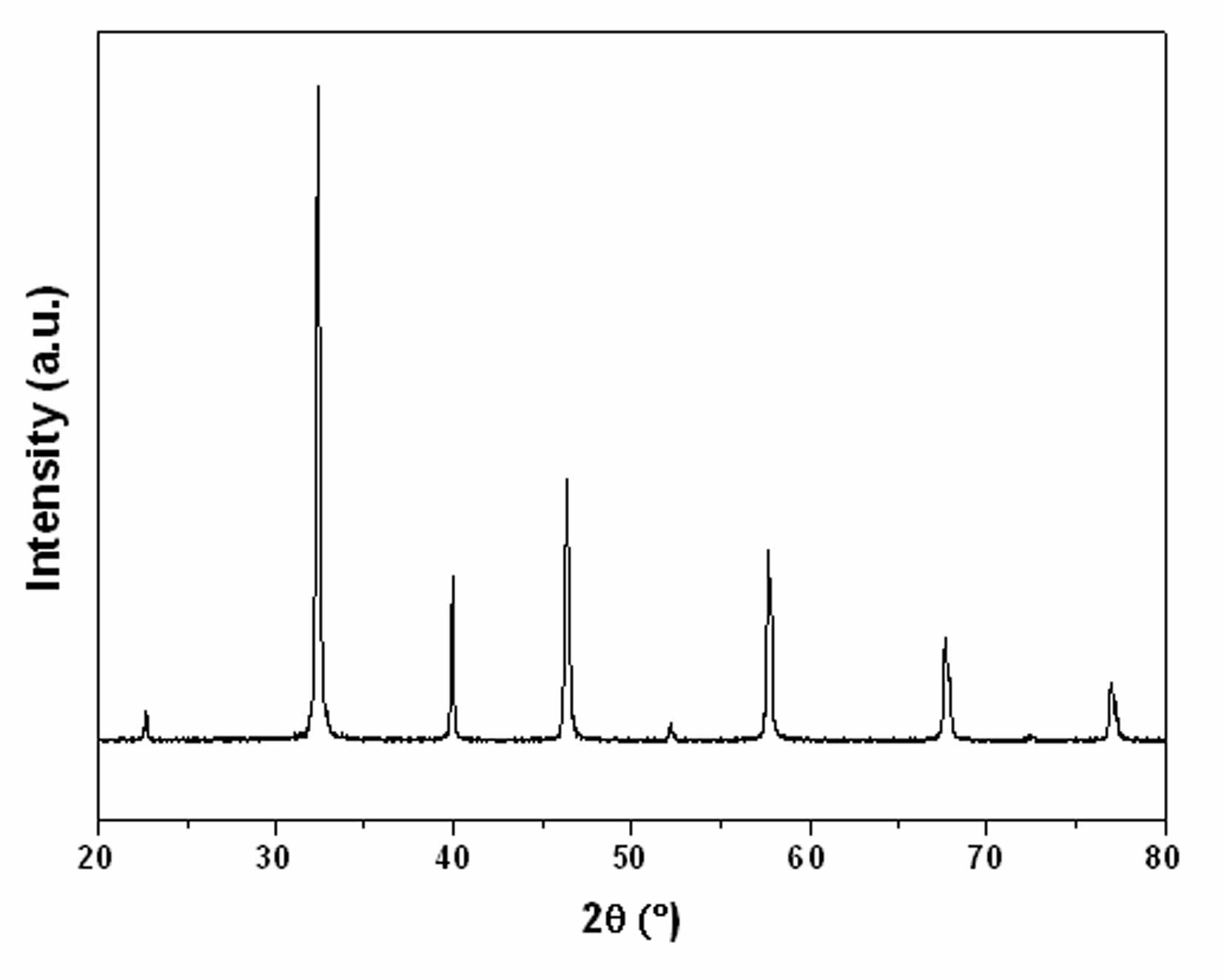

Method for preparation of lithium tantalate nano-powder by hydrothermal process

InactiveCN103833079AThe grains are fine, complete and uniformHigh purityMaterial nanotechnologyTantalum compoundsLithiumPhysical chemistry

The invention discloses a method for preparation of lithium tantalate nano-powder by a hydrothermal process. The method includes: using deionized water as a reaction solvent, adding a lithium source and a tantalum source, ensuring the mole ratio of tantalum ions to lithium ions at 1:(1-8), carrying out reaction for 8-24h in an autoclave, keeping the reaction temperature at 200-260DEG C, and at the end of the reaction, firstly conducting washing by deionized water, and then performing washing by an alcohol solvent, thus obtaining the lithium tantalate nano-powder. The lithium source is LiOH or Li2CO3, and the tantalum source is Ta(OH)5 or Ta2O5. The method provided by the invention adopts different lithium sources and different tantalum sources as the raw materials, and takes deionized water as a reaction solvent to synthesize the LiTaO3 nano-powder. The prepared LiTaO3 powder has a regular shape, fine, complete and uniform grains, high purity, no aggregation or less agglomeration, and has no need for high-temperature calcination treatment. The method provided by the invention has the advantages of fewer steps, simple preparation, short reaction time, low reaction temperature, and is suitable for mass production.

Owner:SHANGHAI MARITIME UNIVERSITY

Titanium dioxide nanosphere and applications thereof

InactiveCN101676214AImprove photocatalytic activityLarge specific surface areaTitanium dioxidePlastic materialsPhosphoric acid

The invention relates to a titanium dioxide nanosphere which can be prepared by the following method comprising the following steps: (A) dissolving water-soluble organic macromolecules in a 5%-25% hydrochloric acid solution; (B) dripping the mixed solution which is prepared in step A and has the volume which is 1-5 times of the volume of titanium tetrachloride into a titanium tetrachloride solution to obtain brownish-black hydrolyzate; (C) adding a surfactant into the hydrolyzate obtained in step B; and (D) maintaining the temperature of the mixed solution obtained in step C at 50 DEG C-100 DEG C, continuously adding a 15%-20% hydrochloric acid solution according to the volume ratio, and simultaneously adding phosphoric acid, the adding amount of which is 0.1%-3% of the adding amount of the titanium tetrachloride. The invention also provides applications of the titanium dioxide nanosphere in building decoration materials and plastic materials. The invention has the advantage that the antibacterial test and the formaldehyde degrading test prove that the titanium dioxide nanosphere has stronger photocatalytic activity in the ranges of ultraviolet light and visible light.

Owner:SHANGHAI WORLD PROSPECT INT TRADE +1

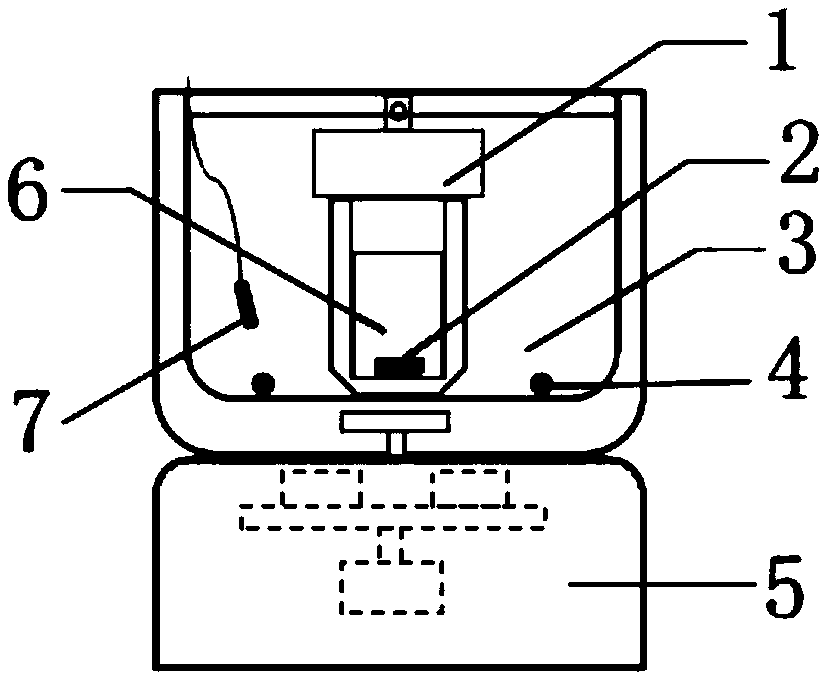

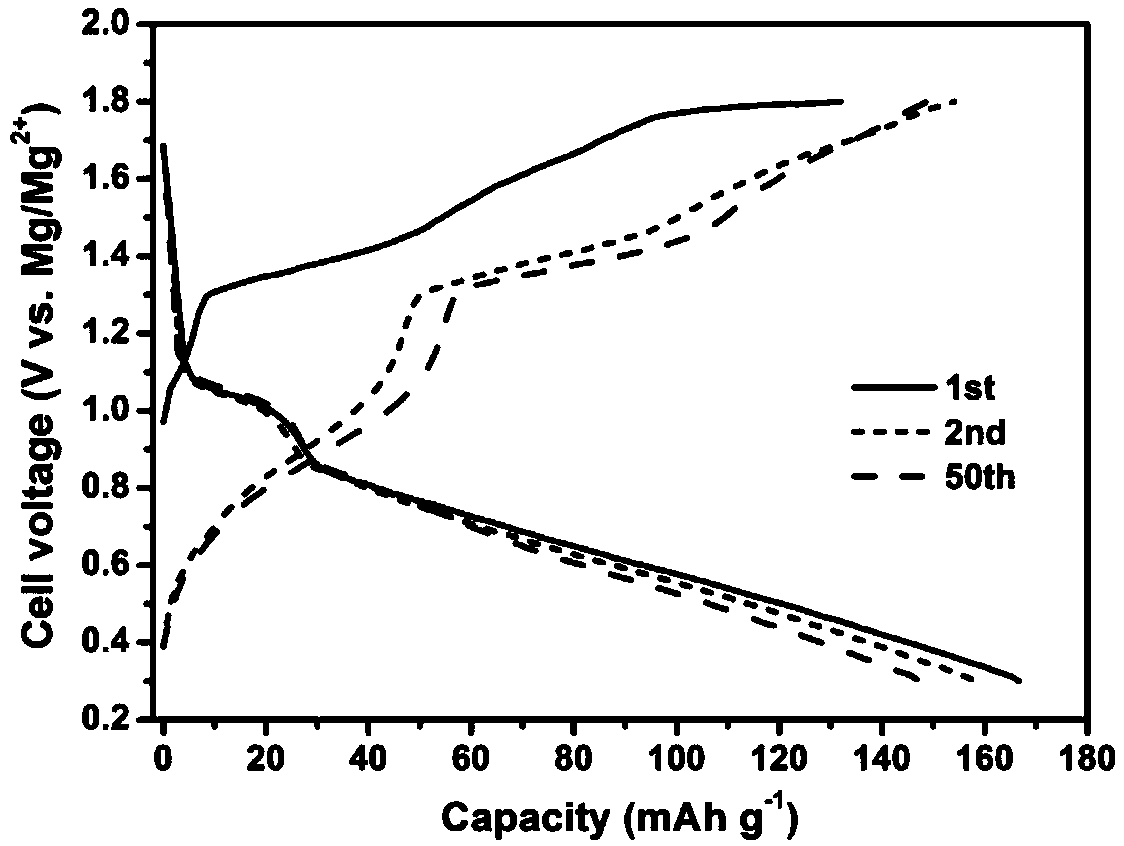

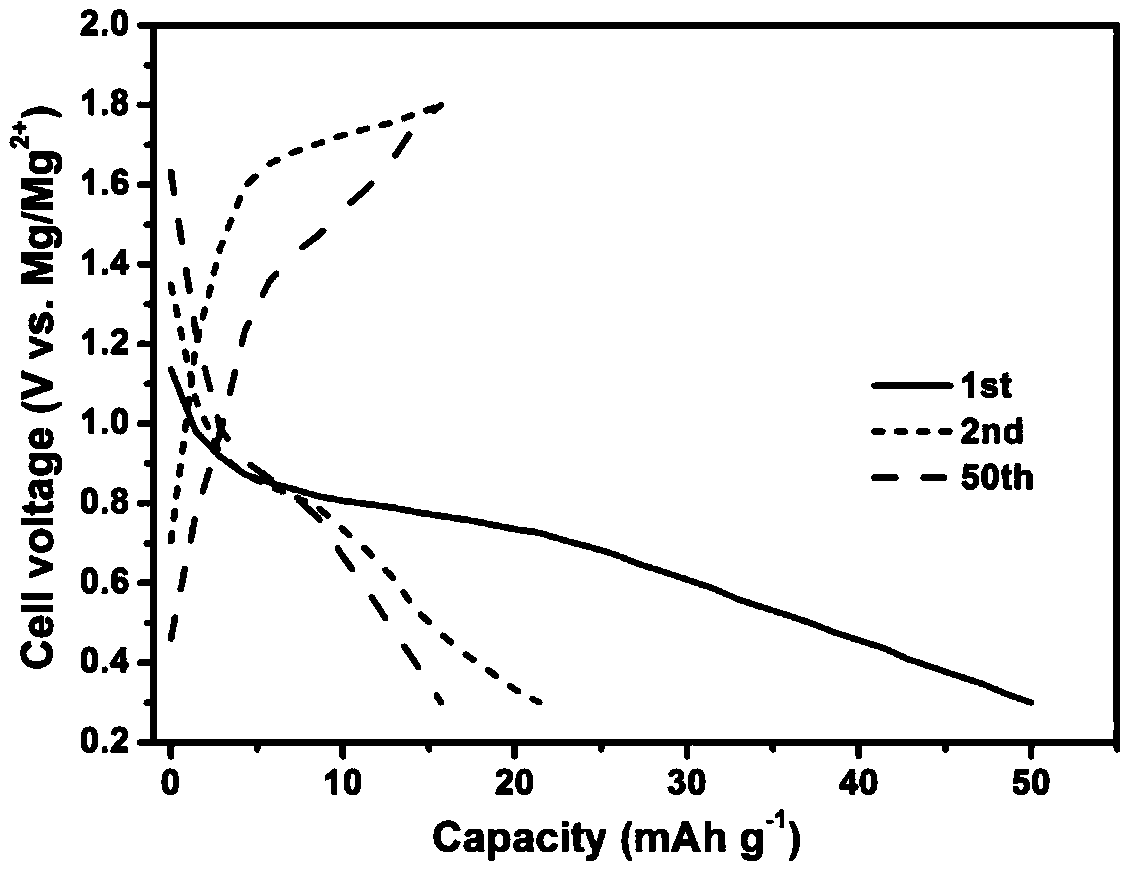

A positive electrode material of a magnesium secondary battery and a preparation method thereof

ActiveCN109037623AHigh charge and discharge capacityPromote circulationMaterial nanotechnologyCell electrodesCarbon compositesCharge discharge

A positive electrode material of a magnesium secondary battery, the positive electrode material is a ferrous disulfide / nanometer carbon composite material formed by in-situ cladding of ferrous disulfide with a carbon nanometer material, and the weight percentage of the carbon material and the ferrous disulfide in the ferrous disulfide / nano carbon composite material is 2 to 5 percent of carbon material and 98 to 95 percent of ferrous disulfide. The invention adopts ferrous disulfide as a basic material, adopts doped nanometer carbon material to carry out in-situ carbon cladding, and obtains thefinal composite material by ''one-step hydrothermal method''. The material can provide more channels for the reversible diffusion of magnesium ions when used for a positive electrode material of a magnesium secondary battery, so that the battery has higher charge-discharge specific capacity and excellent cycle performance. The synthesis of the base material of the invention only needs two elements, the step method is simple and convenient, does not need high-temperature calcination, can be directly applied after preparation, the prepared raw material is rich, the cost is low, and method is easy to produce on a large scale.

Owner:UNIV OF SCI & TECH LIAONING

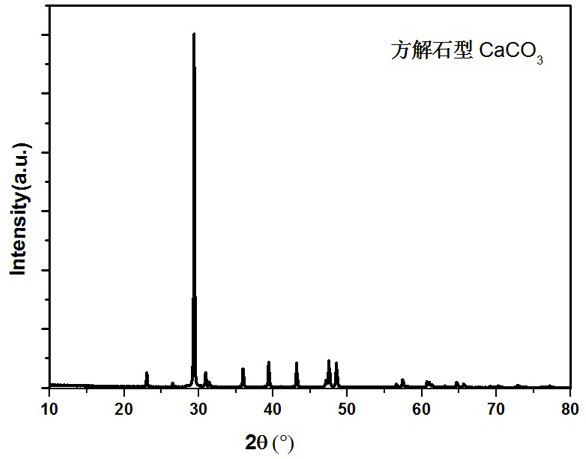

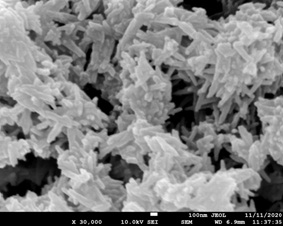

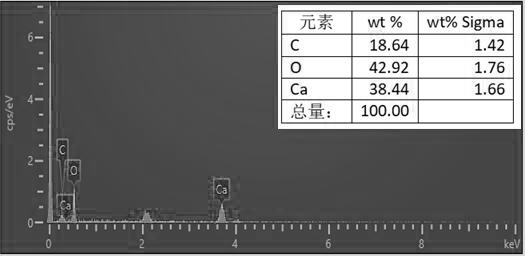

Rare earth ion doped nano calcium carbonate luminescent material with different morphologies and preparation method and application thereof

ActiveCN112322286AHigh luminous intensityImprove thermal stabilityCalcium/strontium/barium carbonatesMaterial nanotechnologyCarbonizationEngineering

The invention relates to a rare earth ion doped nano calcium carbonate luminescent material with different morphologies and a preparation method and application thereof, and the luminescent material is prepared by taking natural limestone which is not subjected to any modification treatment as a calcium source and introducing rare earth ions into crystal lattices of synthesized nano calcium carbonate in a carbonization reaction process. The mass ratio of rare earth ions to Ca < 2 + > in the luminescent material is (0.001-0.06): 1; according to the invention, natural limestone is used as a calcium source, the reserves are rich, the cost is reduced, and the additional value of natural minerals is improved; the preparation method is simple in process, low in energy consumption and suitable for industrial production and application; by doping different rare earth ions in the carbonization crystallization process, the morphology of nano calcium carbonate can be changed, luminescent materials with different colors can be obtained at the same time, and the material is a light conversion material with good luminescent characteristics and stability, is applied to the field of optics, and ismainly combined with a near ultraviolet LED chip to prepare a white light LED with high luminescent performance.

Owner:湖北丰源钙业科技有限公司

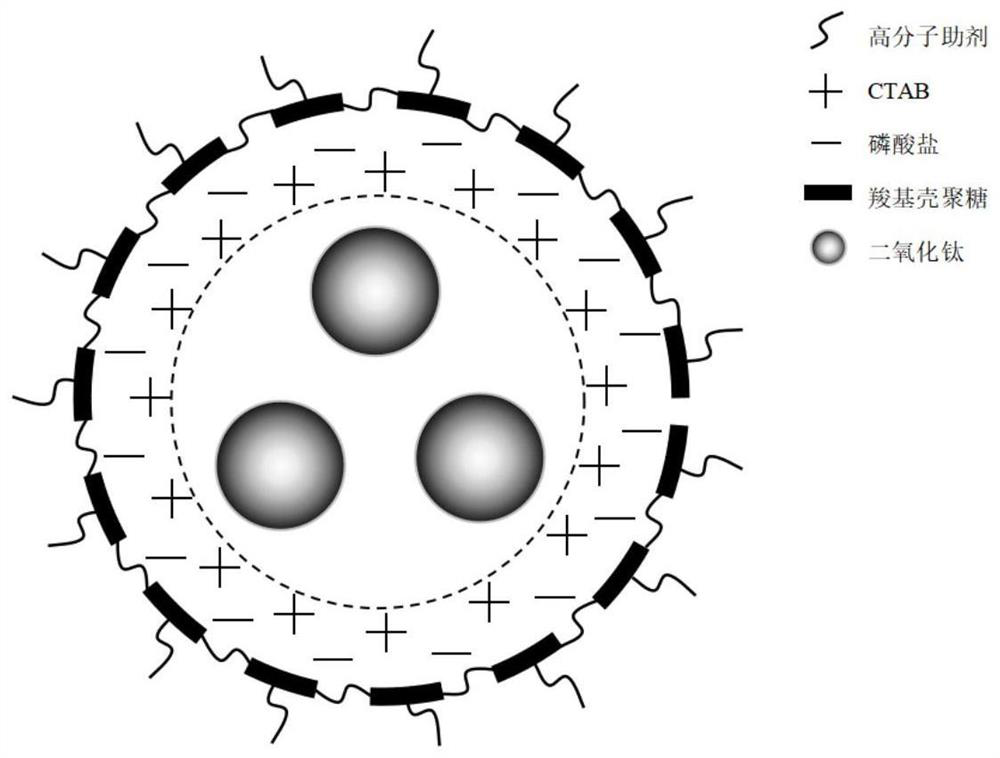

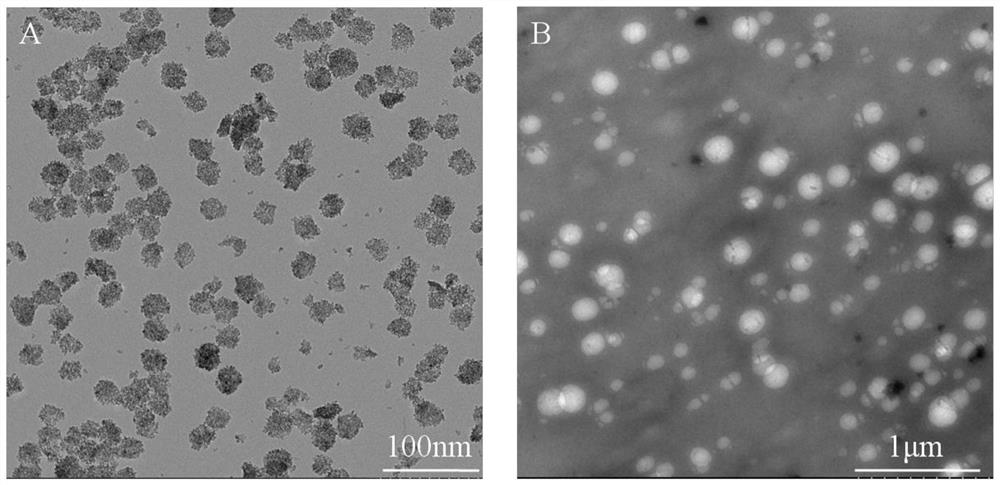

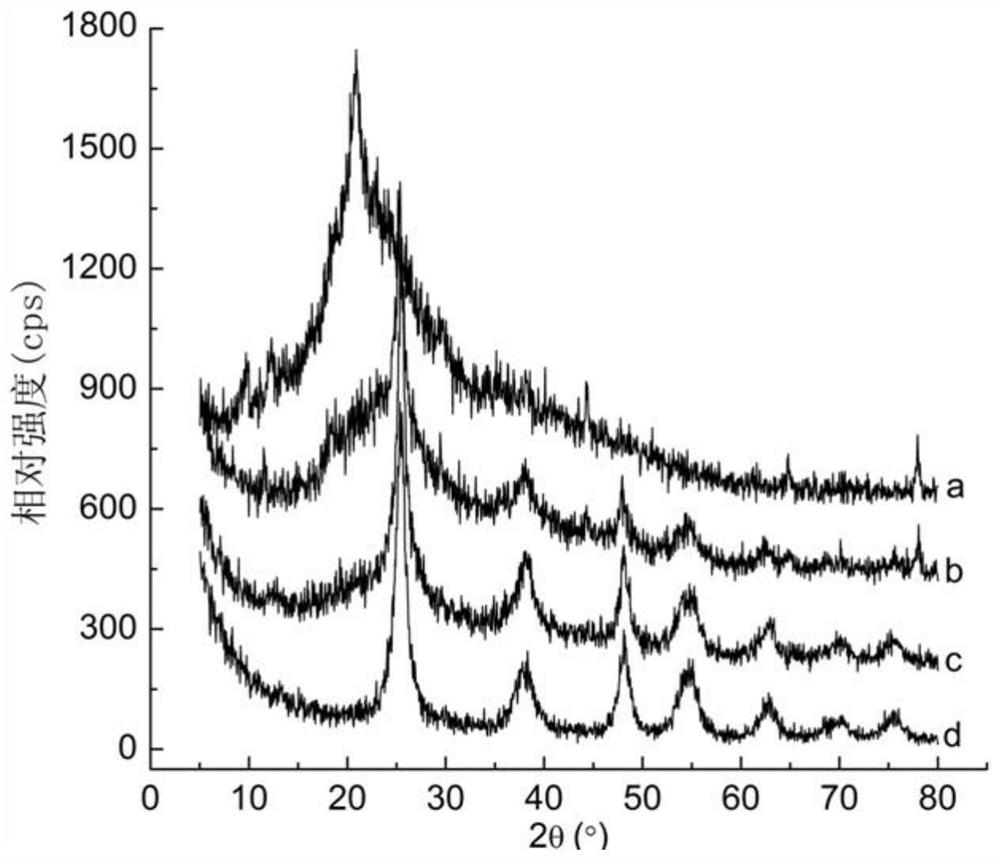

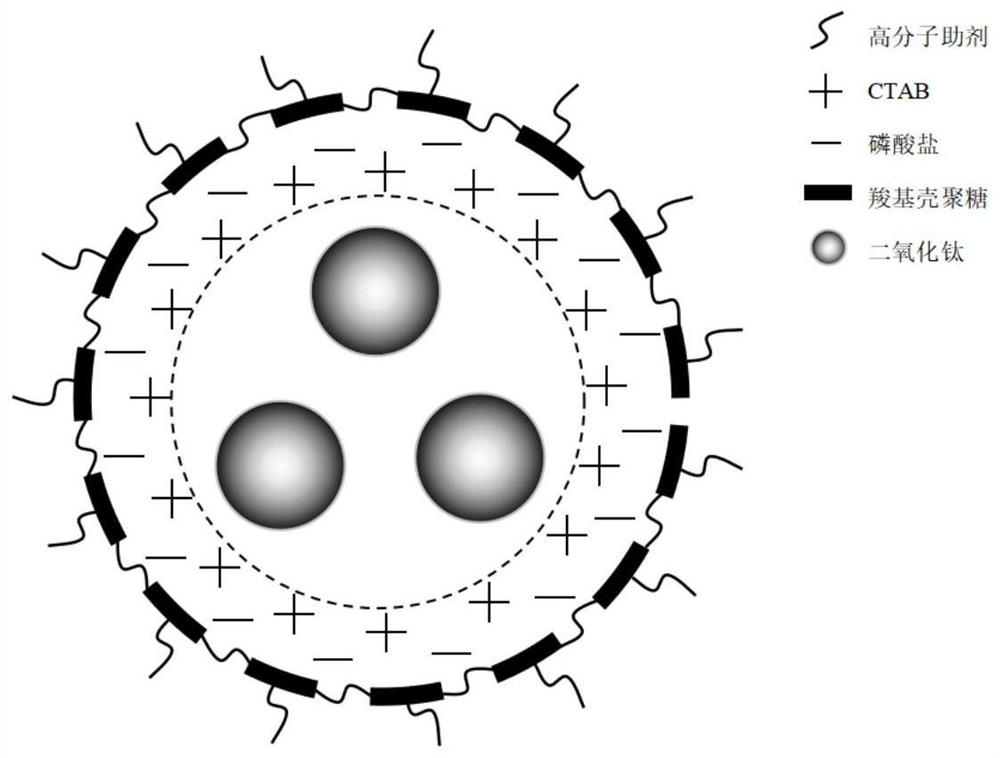

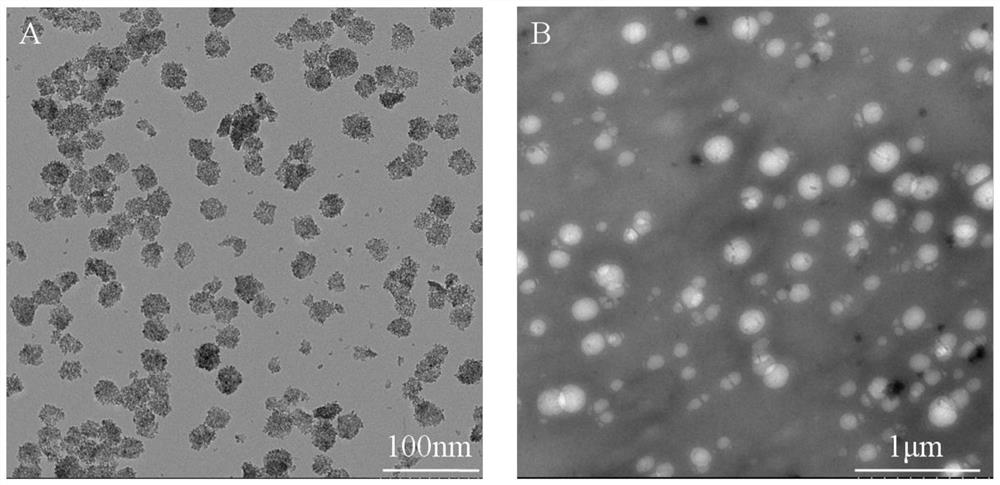

Preparation method of core-shell type titanium dioxide-coated carboxyl chitosan nanoparticles

ActiveCN113441182AShort cycleImprove efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsChitosan nanoparticlesIonic liquid

The invention discloses a preparation method of core-shell type titanium dioxide and carboxyl chitosan nanoparticles. Anatase type nano titanium dioxide prepared by ionic liquid reaction and carboxyl chitosan are used as raw materials, and the core-shell type titanium dioxide-coated carboxyl chitosan nanoparticles are prepared through the ionic gelation effect of CTAB cation modified titanium dioxide and phosphate and the cross-linking assembly of a polymer assistant. The method disclosed by the invention is simple and convenient to operate, green and environment-friendly, the prepared core-shell nanoparticles can effectively avoid photo-corrosion of nano titanium dioxide to a carrier, and as amino and carboxyl of carboxyl chitosan can be respectively combined with photo-induced electrons and holes of nano titanium dioxide, the photocatalytic performance of titanium dioxide is remarkably enhanced, and electrostatic repulsion exists on the surfaces of the core-shell nanoparticles, so that the defect that the nanoparticles are easy to agglomerate is overcome, and the application prospect is wide.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Environmental-protection acoustical building panel and production method thereof

InactiveCN106892607AStrong double layer structureGood sound absorptionSound proofingCoal gangueBuilding material

Disclosed is an environment-friendly acoustical building panel which is of a double-layer porous structure formed by a surface material layer and a substrate layer. The surface material layer is made from construction waste regeneration fine aggregate, coal gangue, cement, lime and slurry; the substrate layer is made from the construction waste regeneration fine aggregate, the cement and the slurry. The environment-friendly acoustical building panel with solid waste of the slurry, the coal gangue and the like as main materials is of the porous structure, even pores are arranged in the surface and the interior of the material, and the acoustical effect of the material is higher when porosity is higher.

Owner:河南永泽环境科技有限公司

A preparation method of core-shell titanium dioxide@carboxychitosan nanoparticles

ActiveCN113441182BShort cycleImprove efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsChitosan nanoparticlesO-Phosphoric Acid

The invention discloses a method for preparing core-shell titanium dioxide@carboxychitosan nanoparticles, which uses anatase nanometer titanium dioxide and carboxychitosan prepared by ionic liquid reaction as raw materials, and uses CTAB cations to modify titanium dioxide and phosphoric acid. It is prepared by the ionic gelation of salt and the cross-linking assembly of polymer additives. The method of the present invention is easy to operate and environmentally friendly, and the prepared core-shell nanoparticles can effectively avoid the photocorrosion of nano-titanium dioxide to the carrier. Since the amino group and carboxyl group of carboxychitosan can respectively combine with the photogenerated electrons and holes of nano-titanium dioxide, significantly The photocatalytic performance of titanium dioxide is enhanced, and there is electrostatic repulsion on the surface of core-shell nanoparticles, which overcomes the defect that nanoparticles are easy to agglomerate, and has broad application prospects.

Owner:ANHUI AGRICULTURAL UNIVERSITY

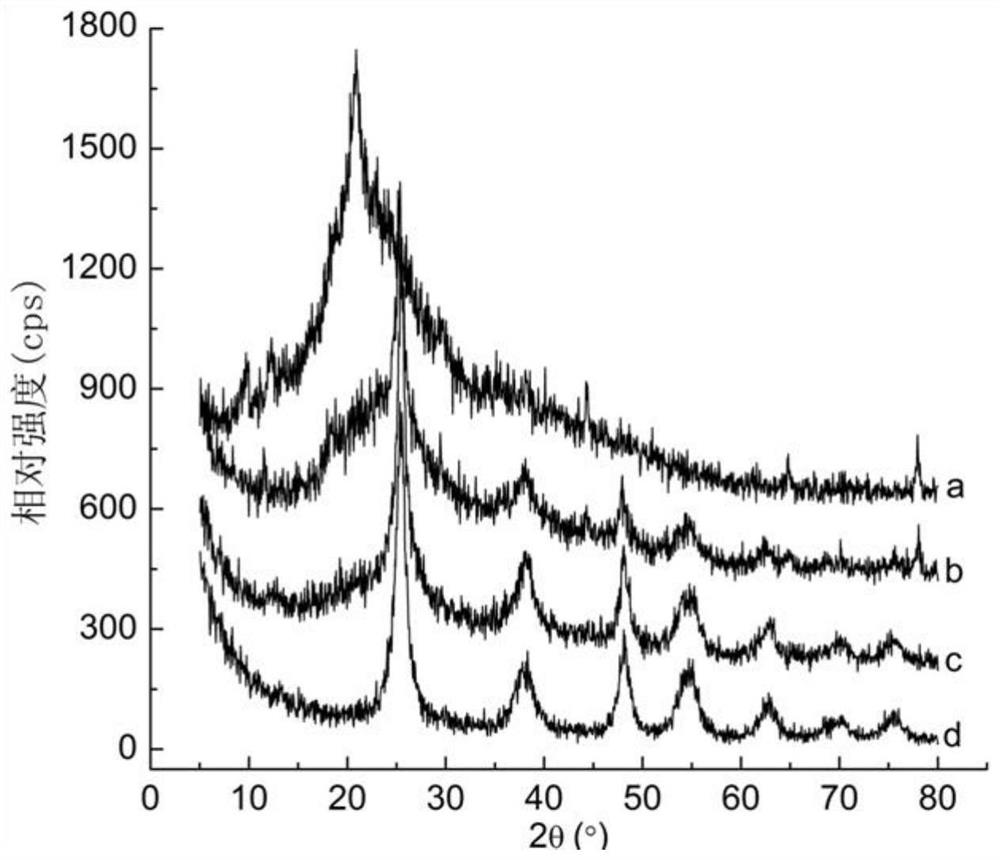

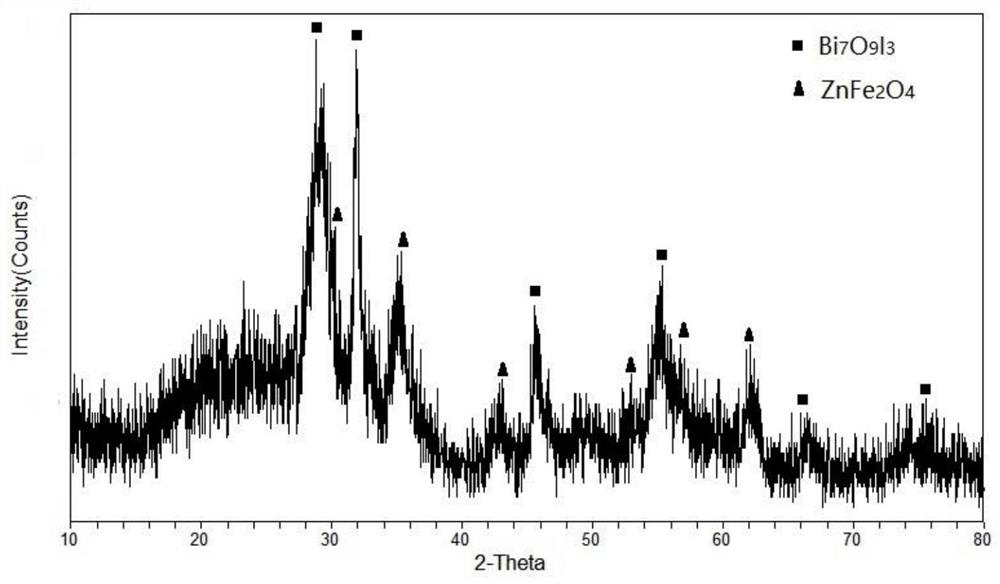

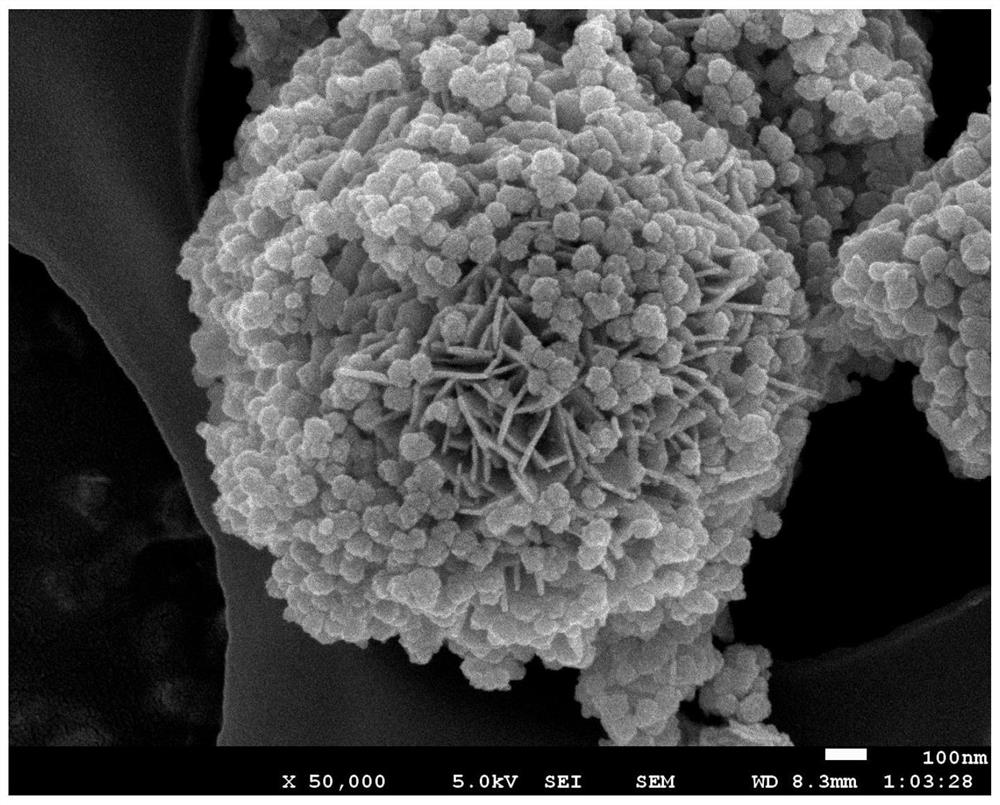

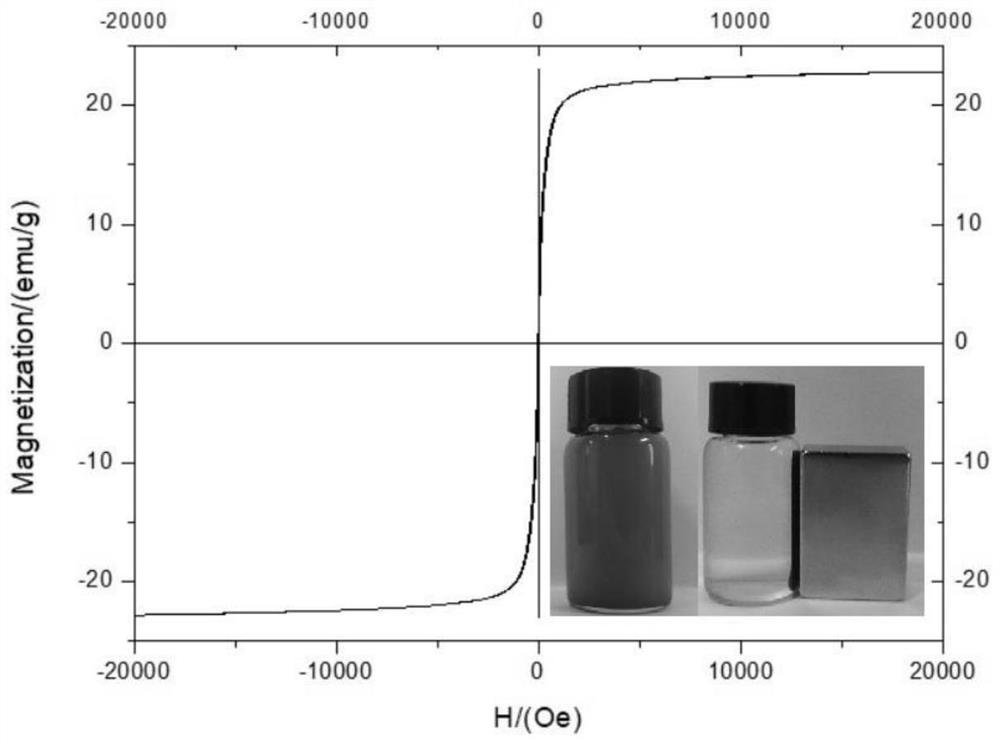

ZnFe2O4/Bi7O9I3 magnetic composite photocatalytic material and preparation method thereof

ActiveCN111822010AIncrease the areaIncrease contact pointsPhysical/chemical process catalystsWater/sewage treatment by irradiationMagnetite NanoparticlesSuperparamagnetism

The invention belongs to the field of magnetic composite photocatalytic materials, and in particular relates to a ZnFe2O4 / Bi7O9I3 magnetic composite photocatalytic material and a preparation method thereof. The preparation method comprises the following steps of: firstly, inserting ZnFe2O4 magnetic nanoparticles into a micron-sized flower-like structure formed by Bi7O9I3 nanosheets to form a composite structure in which particles are inserted into micron flowers; wherein the size of the ZnFe2O4 nanoparticles is 20-80nm, the thickness of the Bi7O9I3 nanosheet forming the Bi7O9I3 micron flowersis 5-10nm; ZnFe2O4 and Bi7O9I3 are compounded according to a mass ratio of 1:(2-6), the formed magnetic composite photocatalytic material shows superparamagnetism, is high in saturation magnetizationintensity, strong in photocatalytic activity and strong in magnetic separability, has good visible light degradation capability on a target pollutant bisphenol A, and can be quickly recycled through an external magnetic field to achieve the purpose of recycling for multiple times; and the preparation method of the magnetic composite photocatalytic material is reliable in principle, simple, easy tocontrol, green, safe, free of high-temperature calcination, conventional in equipment and low in cost, and has the industrial prospect of large-scale production.

Owner:QINGDAO UNIV OF SCI & TECH

Unfired water permeable brick based on granite waste and fire coal slag and preparation method of unfired water permeable brick

The invention discloses an unfired water permeable brick based on granite waste and fire coal slag and a preparation method of the unfired water permeable brick. The unfired water permeable brick is prepared from the following raw materials in parts by weight: 160 to 250 parts of granite particles, 5 to 15 parts of granite powder, 15 to 25 parts of active fire coal slag, 2 to 10 parts of modified desulfurized gypsum, 2 to 8 parts of quick lime, 10 to 20 parts of cement, 1 to 5 parts of additive and water. The water permeable brick is prepared by taking the granite waste and the fire coal slag as main raw materials, a large amount of solid waste is consumed, waste is turned into wealth, low-cost preparation of the water permeable brick is realized, the water permeable brick has the characteristics of stable ecology, energy conservation, environmental protection and resource circulation, and meanwhile, the problems of land resource waste and environmental pollution caused by solid waste accumulation are solved.

Owner:WUHAN UNIV OF TECH

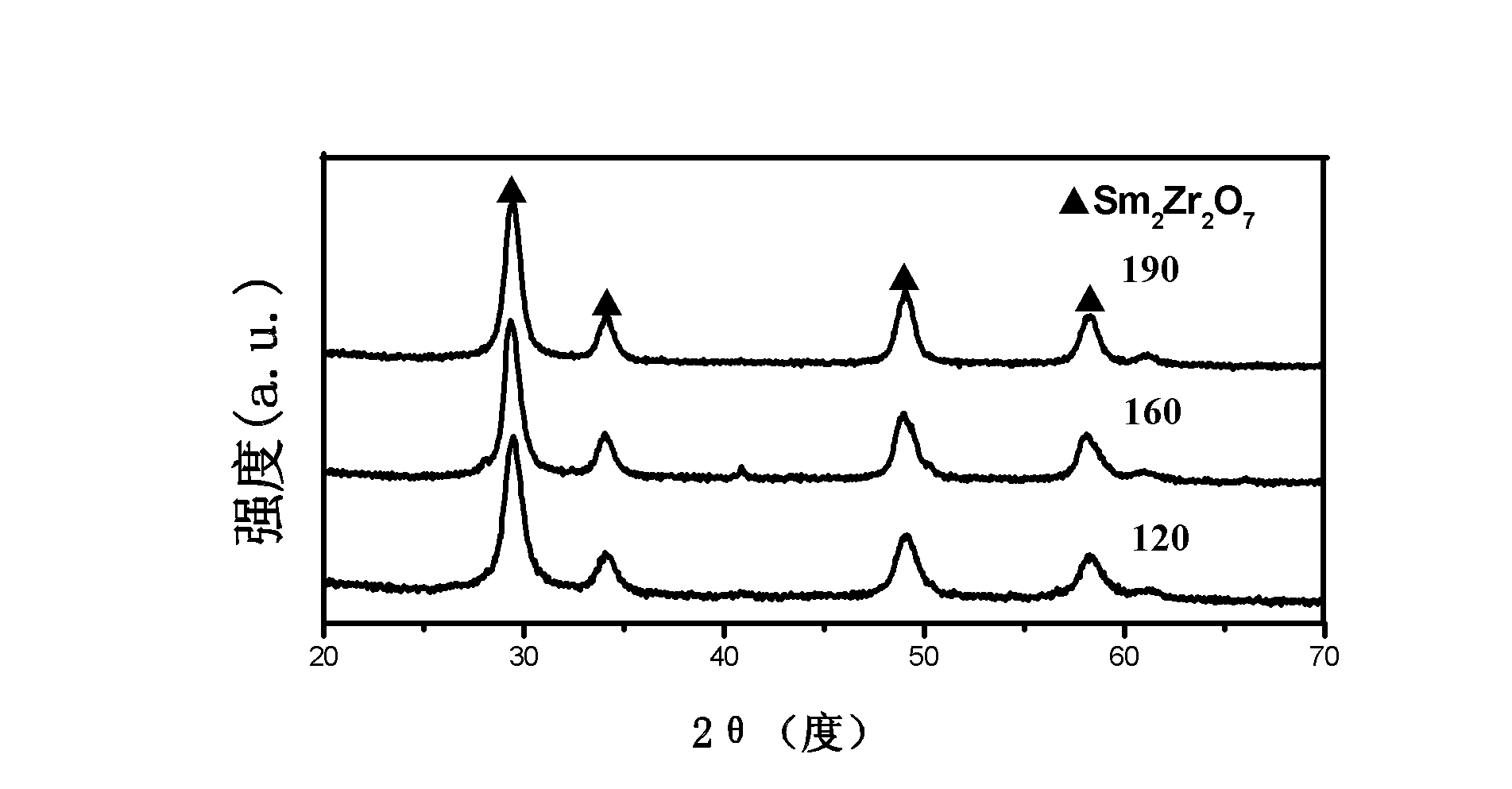

Rare earth samarium zirconate nano material and hydrothermal preparation method thereof

InactiveCN102674455AIncrease scatteringMean Free Path DecreaseZirconium compoundsNanotechnologySemiconductor materialsZirconate

The invention discloses rare earth samarium zirconate nano material and a hydrothermal preparation method of the rare earth samarium zirconate nano material. The rare earth samarium zirconate nano material adopts nanoscale rare earth samarium zirconate powder formed by directly performing hydro-thermal synthesis on coprecipitated precursors. The rare earth samarium zirconate powder prepared through the method has a low thermal coefficient and a good thermal barrier effect, and belongs to potential photocatalytic semiconductor material. The method comprises the following steps: firstly, dissolving a zirconium source in deionized water, and then mixing the zirconium source with samarium source solution, secondly, adding prepared strong alkali solution in the mixed solution of the step one, sufficiently stirring to obtain precursor products, and performing centrifugalization to obtain solid precipitate, thirdly, dispersing the solid precipitate of the step two in deionized water, adjusting the PH value of solution, and adding slurry in a high-pressure reaction kettle to be reacted; and fourthly, taking out powder after the reaction, and washing the powder obtain pour phase samarium zirconate nano powder.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

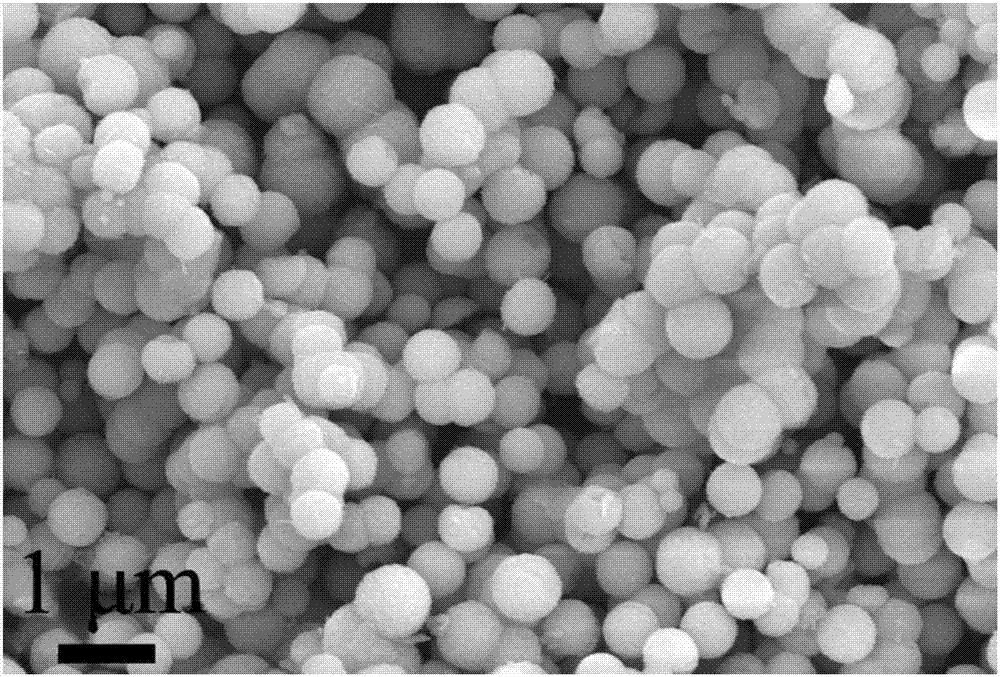

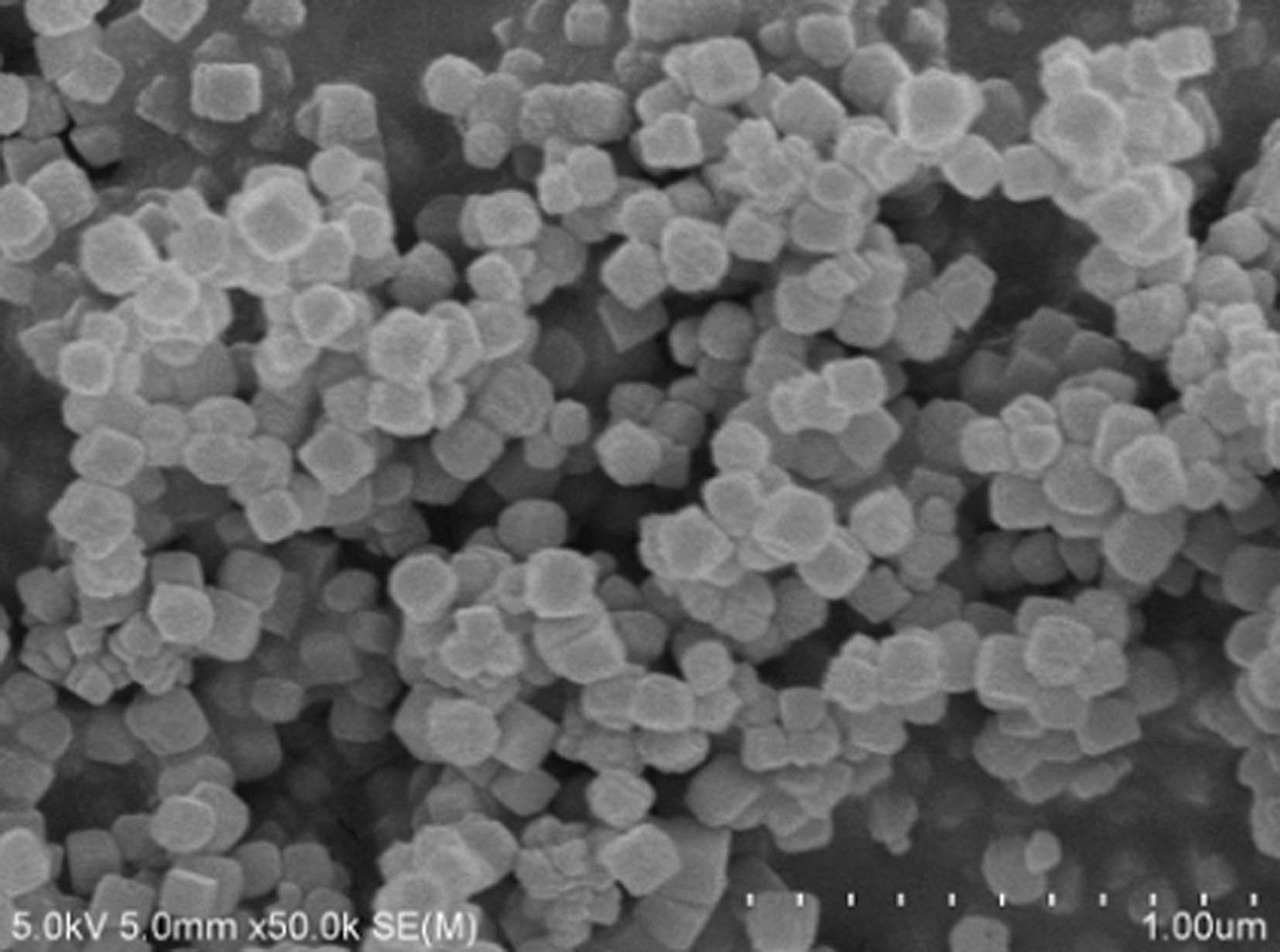

Preparation method of particle spherical lanthanum titanate

ActiveCN107226481AUniform sizeRaw materials are cheap and easy to getTitanatesLanthanum titanateSource water

The invention provides a preparation method of particle spherical lanthanum titanate. The method comprises the following steps: under a stirring condition, adding 10 to 20 parts of a lanthanum source-water mixed solution into 40 to 50 parts of a titanium source-alcohol mixed solution; adding sodium hydroxide into the solution and magnetically stirring for 20min to 30min; then transferring a mixture into a reaction kettle and raising the temperature to 180 DEG C to 220 DEG C; reacting for 3h to 48h; standing to room temperature; after removing supernatant, adding a sediment part into a reactor containing 100 parts of a hydrochloric acid solution; after stirring for 20min to 30min, washing with water; centrifugally separating; drying at 60 DEG C to 100 DEG C to obtain white powder, namely the particle spherical lanthanum titanate. The method provided by the invention has the advantages of simple process, low cost, uniform components and a novel shape.

Owner:HEBEI UNIV OF TECH

A preparation method of supported rare earth doped manganese oxide for ozone catalyst

ActiveCN105289585BSimple preparation processNo need for high temperature calcinationWaste water treatment from textile industryMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementNitrate

The invention discloses a preparation method of a supported rare earth-doped manganese oxide for ozone catalyst. The method uses γ-Al2O3 as a carrier, manganese oxide as an active component of the catalyst, rare earth element as an auxiliary, and sulfuric acid is used as an auxiliary agent. Manganese and rare earth metal nitrate are dissolved in deionized water, isopropanol is added, stirred, the carrier is mixed in the above solution, stirred evenly, heated, and then added with KMnO4 solution, the surface of the carrier is in situ redox reaction to obtain rare earth doped MnO2 modification γ‑Al2O3. The advantages of the method are that the preparation process is simple, the catalyst cost is low, the performance is stable, the ozone decomposition efficiency is high, and the method has broad application prospects.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com