Preparation method of particle spherical lanthanum titanate

A lanthanum titanate, spherical technology, applied in the field of titanate, can solve the problems of harsh conditions, complex process, high temperature calcination, etc., and achieves the effect of simple method, cheap and easy-to-obtain raw materials, and favorable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

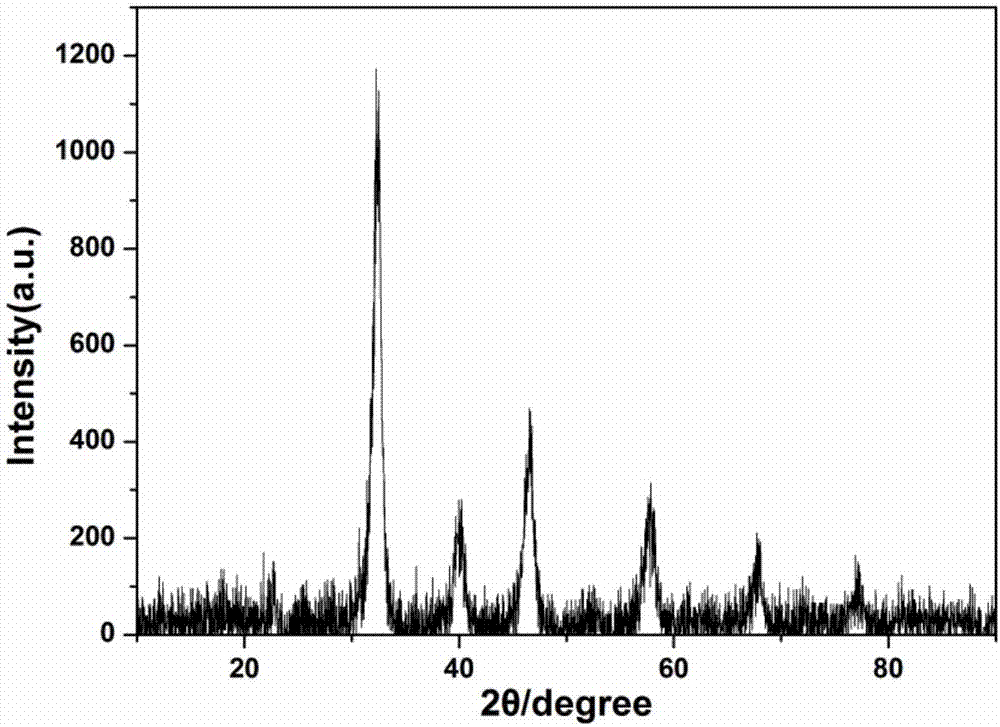

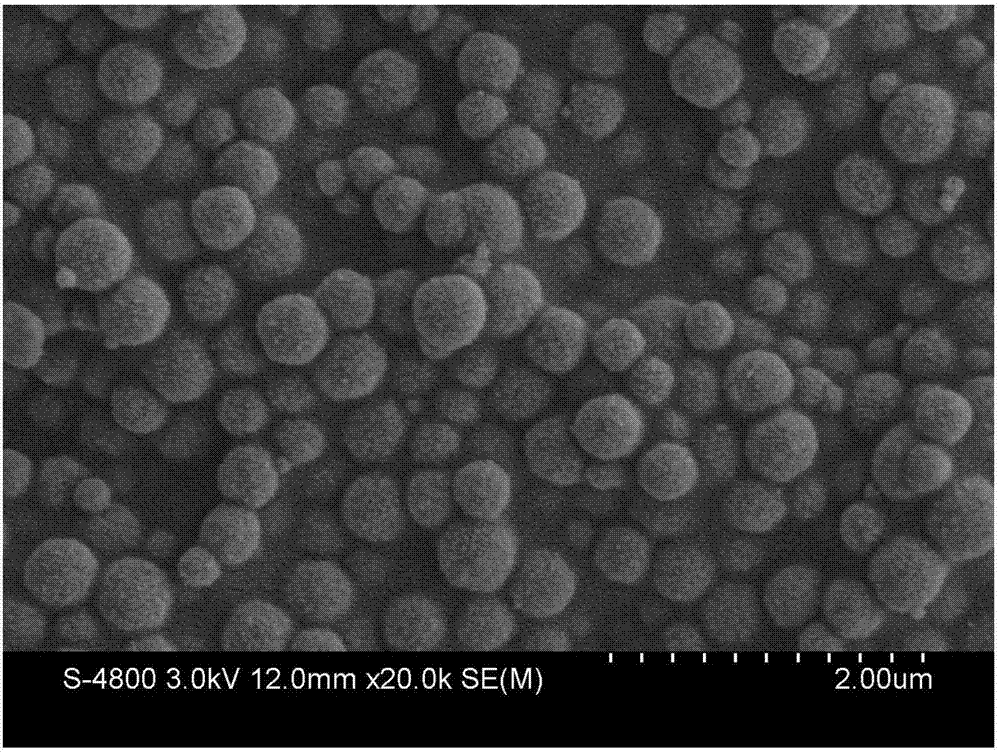

Image

Examples

Embodiment 1

[0025] (1) Dissolve 0.8ml butyl titanate (about 0.0023mol) in 40ml ethylene glycol solution, stir well, and set aside;

[0026] (2) Dissolve 1 g (about 0.0023 mol) of lanthanum nitrate hexahydrate in 20 ml of deionized water, stir until completely dissolved, and set aside;

[0027] (3) Under stirring conditions, add the liquid prepared in step (2) into the reactor in step (1) for 50 to 60 seconds, and after the solution is evenly mixed, add 2.4 g of sodium hydroxide and stir magnetically 30 minutes;

[0028] (4) Then move the mixture obtained in step (3) to the reactor, heat up to 220°C after airtight, and react for 24 hours;

[0029] (5) Leave the stock solution at room temperature, remove the supernatant, add the remaining precipitated part into a reactor containing 100ml, 0.2mol / L hydrochloric acid solution, stir for 30 minutes, wash with water, and then centrifuge for 80 ℃ drying, the obtained white powder is about 1.1 g of granular spherical lanthanum titanate.

[0030...

Embodiment 2

[0032] The reaction temperature in the step (4) in the embodiment 1 is set as 180 ℃, and other steps are the same as the embodiment 1. Obtain product with embodiment 1.

Embodiment 3

[0034] The reaction temperature in step (4) in embodiment 1 is set as 200 ℃, and other steps are the same as embodiment 1. Obtain product with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com