Titanium dioxide nanosphere and applications thereof

A technology of titanium dioxide and nanospheres, which is applied in the field of nanospheres to achieve the effects of strong adsorption capacity, solution and easy loss, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] One, 15 grams of polyethylene glycol 2000 is dissolved in the 20% hydrochloric acid solution of 1200 milliliters;

[0029] Two, the mixed solution of step one configuration is added dropwise in the titanium tetrachloride solution of 700 milliliters and obtains brown black hydrolyzate;

[0030] 3. Add 2 grams of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 85°C, maintain the stirring speed at 300 rpm, and stir and heat for 4 hours;

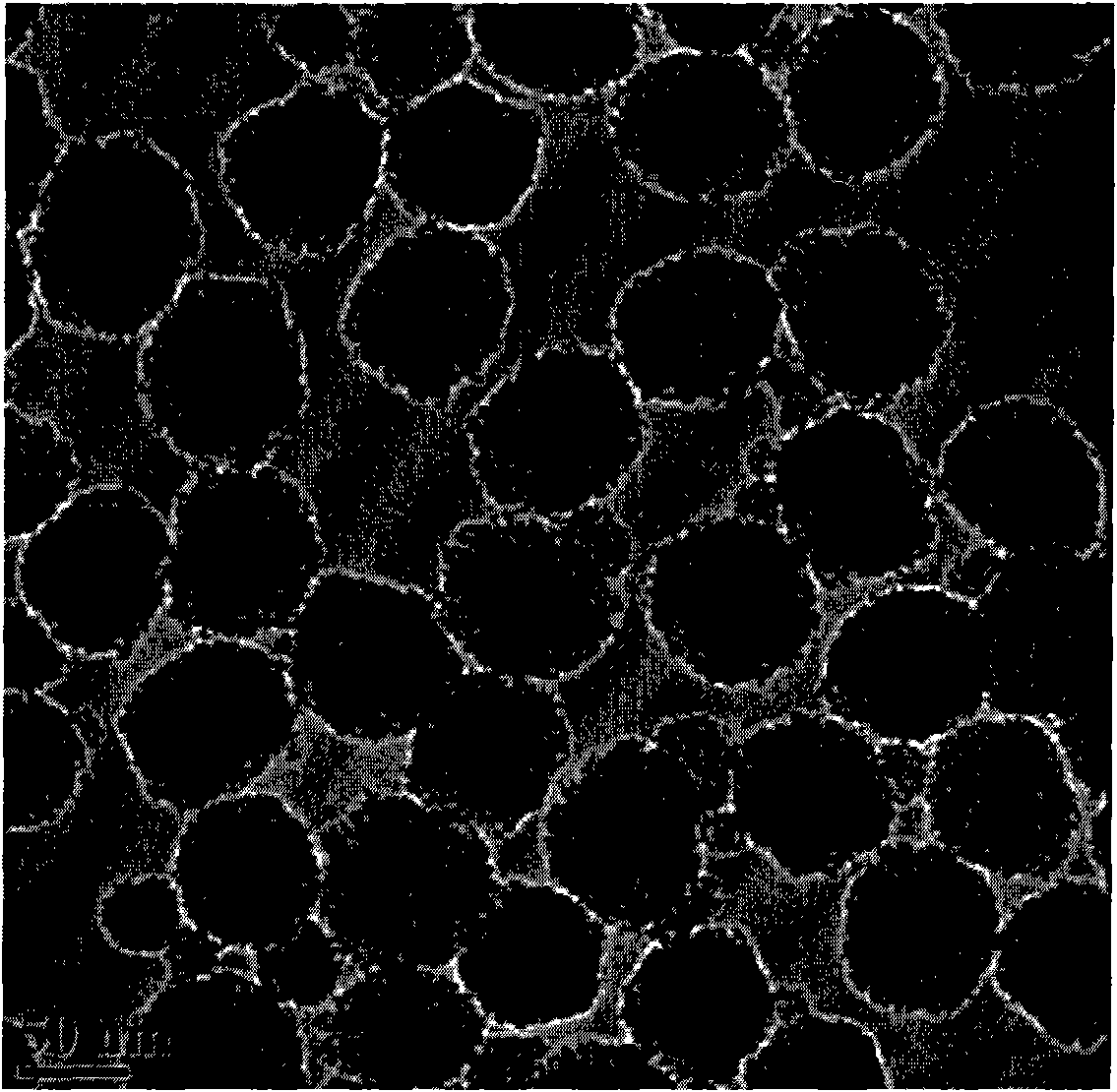

[0031] 4. Heat the mixed solution in step 3 to 95°C and maintain this temperature, continue to add 800 ml of 20% hydrochloric acid solution, and add 12 ml of phosphoric acid at the same time, stir for 1 hour, cool, filter, wash with water, and get the finished product after drying. figure 1 . figure 1 It is a transmission electron micrograph of titanium dioxide nanospheres of 60-80 nanometers formed by combining titanium dioxide with a particle size of 2-8 nanometers prepared in this embodiment.

Embodiment 2

[0033] One, 15 grams of sodium polyacrylate are dissolved in the 10% hydrochloric acid solution of 3000 milliliters;

[0034] Two, the mixed solution of step one configuration is added dropwise in the titanium tetrachloride solution of 600 milliliters and obtains brown black hydrolyzate;

[0035] 3. Add 2 grams of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 95°C, maintain the stirring speed at 350 rpm, and stir and heat for 8 hours;

[0036] 4. Heat the mixed solution in step 3 to 100°C and maintain this temperature, continue to add 900 milliliters of 10% hydrochloric acid solution, and simultaneously add 18 milliliters of phosphoric acid, stir for 3 hours, cool, filter, wash with water, and dry to obtain the finished product.

Embodiment 3

[0038] One, 15 grams of polyethylene glycol 2000 and sodium polyacrylate are dissolved in 428 milliliters of 25% hydrochloric acid solution;

[0039] Two, the mixed solution that step one configures is added dropwise in the titanium tetrachloride solution of 428 milliliters and obtains brown black hydrolyzate;

[0040] 3. Add 2 grams of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 10°C, maintain the stirring speed at 180 rpm, and stir and heat for 2 hours;

[0041] 4. Heat the mixed solution of step 3 to 50°C and maintain this temperature, continue to add 214 milliliters of 25% hydrochloric acid solution, and simultaneously add 5 milliliters of phosphoric acid, stir for 0.5 hours, cool, filter, wash with water, and dry to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com