Structure gradient type cement-based water-permeable pavement bricks and preparation method thereof

A technology of permeable pavement bricks and structural gradients, applied in the directions of roads, roads, pavement details, etc., can solve the problems of high production cost, poor wear resistance, shrinkage of compressive strength of permeable bricks, etc., to achieve low production costs and improve water permeability. , The effect of good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

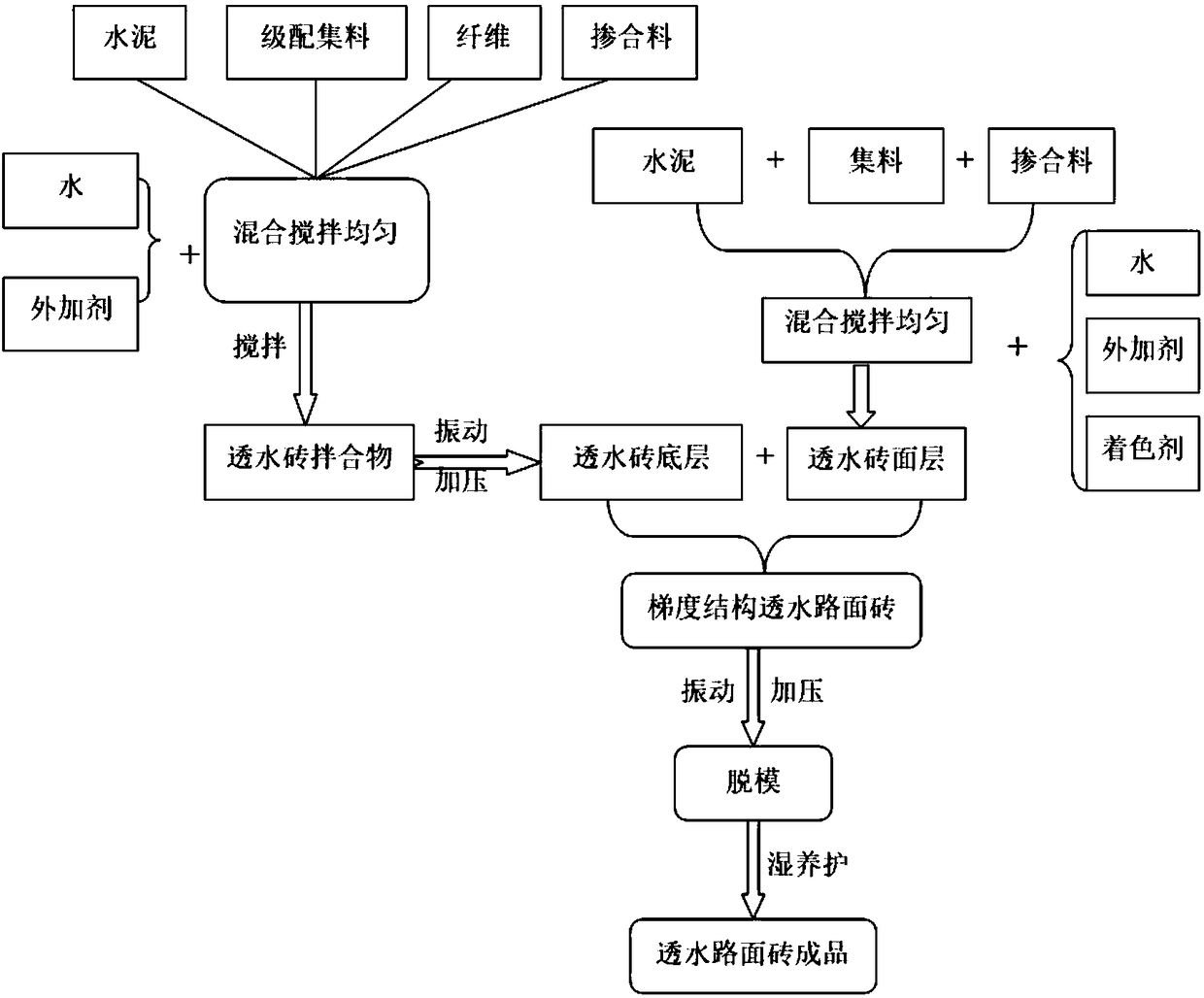

Method used

Image

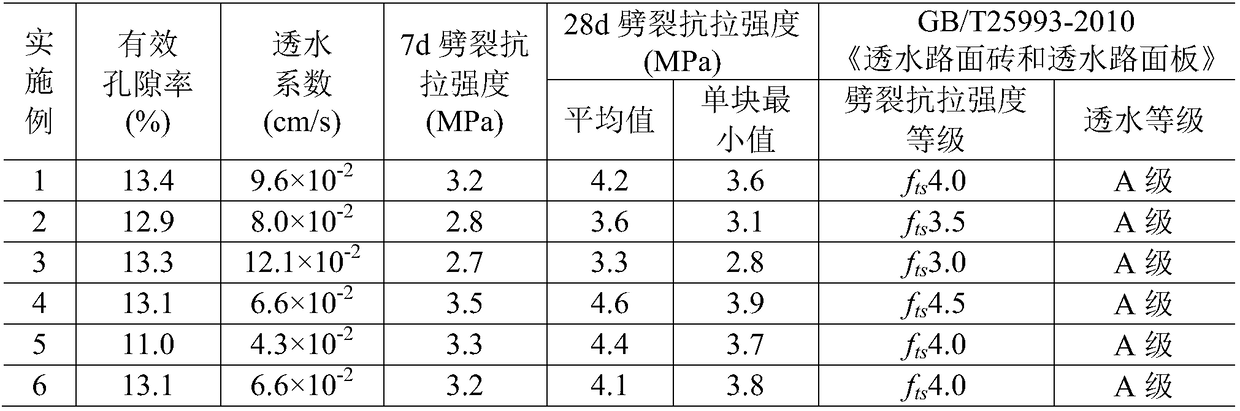

Examples

Embodiment 1

[0023] The structural gradient cement-based permeable pavement brick of this embodiment is composed of a bottom layer and a surface layer, and the thickness of the surface layer is 5% of the total thickness of the permeable pavement brick; the bottom layer includes the following components by weight: 400 parts of cementitious material, aggregate 1500 parts of material, 90 parts of water, 5 parts of admixture, and 1.8 parts of fiber; the surface layer includes the following components in parts by weight: 400 parts of gelling material, 1500 parts of aggregate, 96 parts of water, and 5 parts of admixture.

[0024] The cementitious materials in the bottom layer and the surface layer are composed of the following components by weight: 50% cement, 50% admixture; the admixture is compounded by the following components by weight: 70% slag powder, Steel slag powder 30%.

[0025] The aggregate in the bottom layer is limestone with a maximum particle size of 16mm. The aggregate gradation...

Embodiment 2

[0033] The structural gradient cement-based permeable pavement brick of this embodiment is composed of a bottom layer and a surface layer, and the thickness of the surface layer is 5% of the total thickness of the permeable pavement brick; the bottom layer includes the following components by weight: 400 parts of cementitious material, aggregate 1500 parts of material, 90 parts of water, 5 parts of admixture, and 1.8 parts of fiber; the surface layer includes the following components in parts by weight: 400 parts of gelling material, 1500 parts of aggregate, 96 parts of water, and 5 parts of admixture.

[0034] The cementitious materials in the bottom layer and the surface layer are composed of the following components by weight: 50% cement, 50% admixture; the admixture is compounded by the following components by weight: 70% slag powder, Steel slag powder 30%.

[0035]The aggregate in the bottom layer is limestone with a maximum particle size of 16mm. The aggregate gradation ...

Embodiment 3

[0043] The structural gradient cement-based permeable pavement brick of this embodiment is composed of a bottom layer and a surface layer, and the thickness of the surface layer is 5% of the total thickness of the permeable pavement brick; the bottom layer includes the following components by weight: 400 parts of cementitious material, aggregate 1500 parts of material, 90 parts of water, 5 parts of admixture, and 1.8 parts of fiber; the surface layer includes the following components in parts by weight: 400 parts of gelling material, 1500 parts of aggregate, 96 parts of water, and 5 parts of admixture.

[0044] The cementitious material in the bottom layer and the surface layer is composed of the following components by weight: 50% cement, 50% admixture; the admixture is compounded by the following components by weight: 50% slag powder, Steel slag powder 30%, fly ash powder 20%.

[0045] The aggregate in the bottom layer is limestone with a maximum particle size of 16mm. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com