Preparation method of pollucite sub-microspheres with kilogram yield grade

A cesium garnet, sub-micron technology, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of quartz with many impurities and not suitable for preparation, and achieve the effects of simple preparation process, environmental protection and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

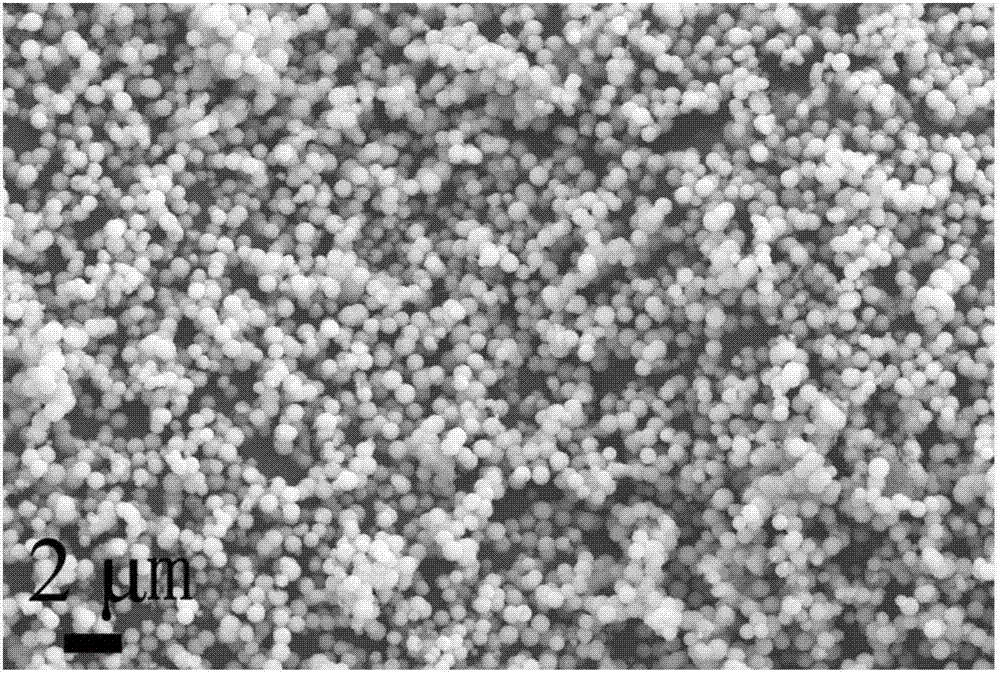

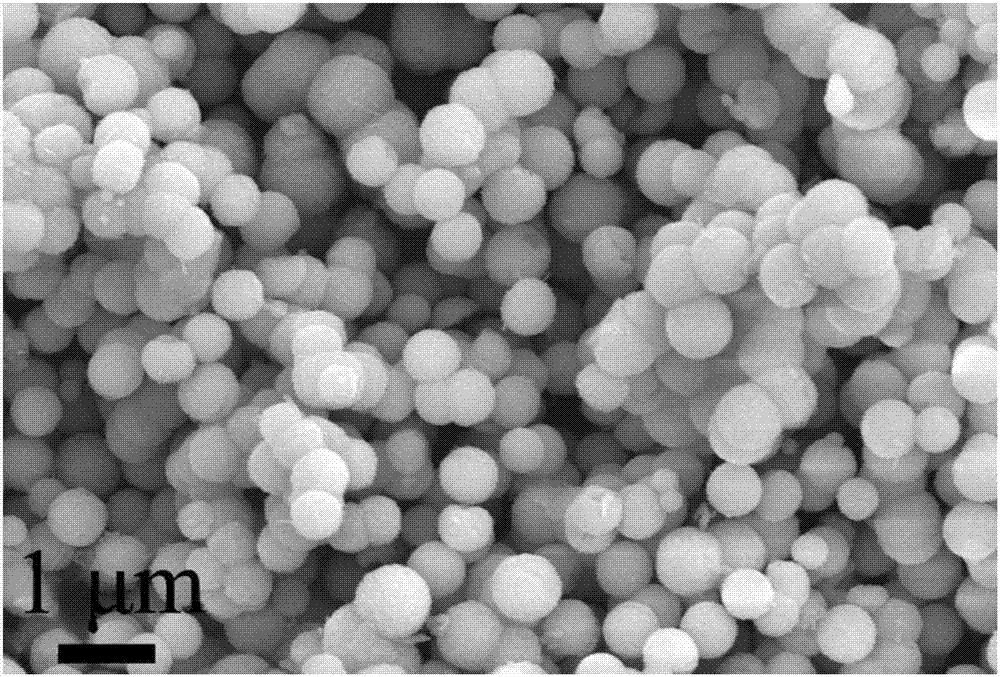

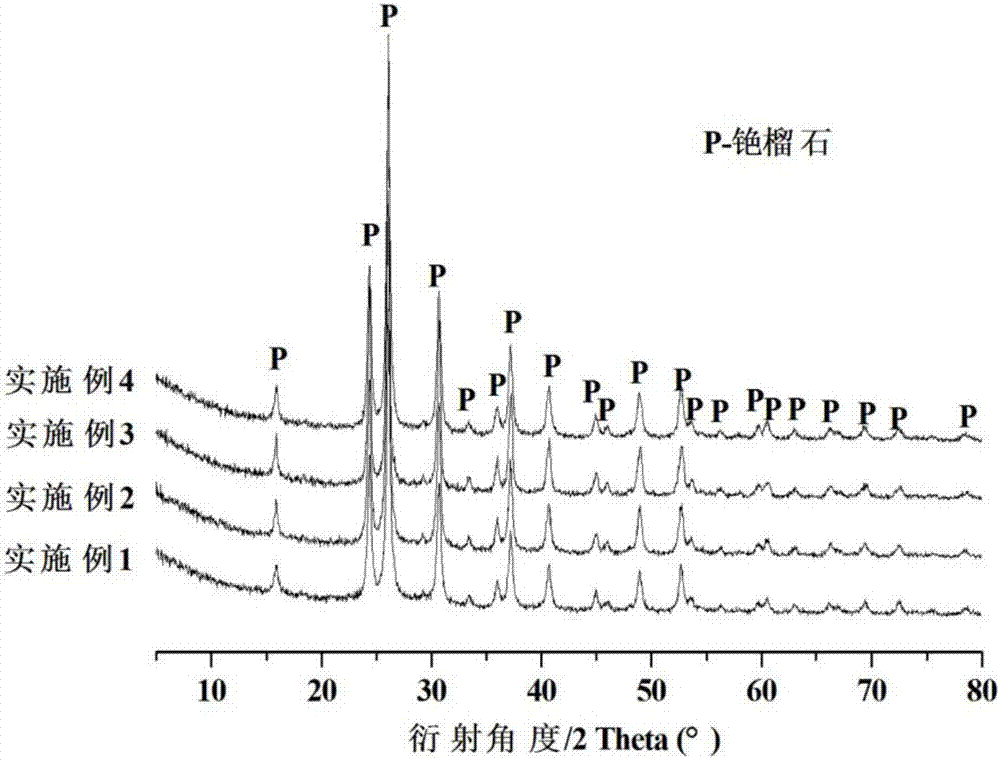

[0027] A preparation method of kilogram output level cesium garnet submicron spheres, the steps are: according to the molar ratio Cs:Al:Si=1:1:2, carry out batching, weigh amorphous silica, amorphous alumina, metakaolin , cesium hydroxide monohydrate, and added to (can be 20L, the same below) in the autoclaved reaction kettle with a built-in stirrer (or stirring blade, the same below); according to the solid raw material amorphous silica, amorphous oxidation The total weight of aluminum, metakaolin and cesium hydroxide monohydrate: deionized water is the weight ratio of 1:18 to take deionized water, join in the autoclave reactor and become liquid-solid mixture (the liquid level after adding deionized water reaches About 2 / 3 of the volume of the autoclaved reactor), close the autoclaved reactor; set the stirring speed at 60-100 rpm; crystallize in a hydrothermal environment with a temperature of 140 ° C and a pressure of 0.3-0.8 MPa for 10 hours and then cool Take it out, wash ...

Embodiment 2

[0029]A preparation method of kilogram output level cesium garnet submicron spheres, the steps are: according to the molar ratio Cs:Al:Si=1:1:2, carry out batching, weigh amorphous silica, amorphous alumina, metakaolin , cesium hydroxide monohydrate, and added to (20L) built-in autoclaved reactor with stirring blade; according to the total weight of solid raw material amorphous silica, amorphous alumina, metakaolin and cesium hydroxide monohydrate: The weight ratio of deionized water is 1:18. Take deionized water and add it to the autoclaved reactor to form a liquid-solid mixture (the liquid level after adding deionized water reaches about 2 / 3 of the volume of the autoclaved reactor), close Autoclave reaction kettle; set the stirring speed at 60-100 rpm; crystallize in a hydrothermal environment with a temperature of 160°C and a pressure of 0.3-0.8 MPa for 11 hours, then take it out after cooling, wash and dry to obtain cesium garnet submicron spheres.

Embodiment 3

[0031] A preparation method of kilogram output level cesium garnet submicron spheres, the steps are: according to the molar ratio Cs:Al:Si=1:1:2, carry out batching, weigh amorphous silica, amorphous alumina, metakaolin , cesium hydroxide monohydrate, and added to (20L) autoclaved reaction kettle with built-in stirring blade; according to the total weight of solid raw material amorphous silica, amorphous alumina, metakaolin and cesium hydroxide monohydrate: to The weight ratio of ionized water is 1:18. Take deionized water and add it to the autoclaved reactor to form a liquid-solid mixture (the liquid level after adding deionized water reaches about 2 / 3 of the volume of the autoclaved reactor), close the steamer Press the reaction kettle; set the stirring speed at 60-100 rpm; crystallize in a hydrothermal environment with a temperature of 180°C and a pressure of 0.3-0.8 MPa for 13 hours, then take it out after cooling, wash with water, and dry to obtain cesium garnet submicron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com