Multi-solid-waste baking-free steaming-free water permeable brick with double-layer structure and preparation method thereof

A technology of double-layer structure and permeable bricks, which is applied to the pavement paved with prefabricated blocks, pavement details, buildings, etc., to improve strength and wear resistance, realize resource utilization, and reduce site resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

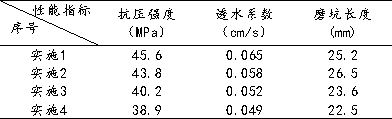

Examples

Embodiment 1

[0024] A multi-solid waste non-burning and non-steaming double-layer structure permeable brick includes a surface layer and a base layer, and the thickness of the surface layer is 5mm. The base layer is 60mm. The raw materials of the surface layer are composed of 100 parts of steel slag powder with a particle size of 10-20 mesh, 20 parts of silica fume, 4 parts of 128 epoxy resin, 2 parts of polyurethane curing agent, and 0.1 part of sulfamic acid water reducer in parts by weight. , 20 parts of water; the base raw materials are composed of 10 parts of P.O42.5 cement, 80 parts of iron ore waste rock with a particle size of 2-5mm, 20 parts of iron tailings powder, and sulfamic acid water-reducing powder in parts by weight. 0.5 parts of agent and 10 parts of water. The main chemical composition of the steel slag powder is 40%-50% of calcium oxide, 5%-20% of ferric oxide, 10%-20% of silicon dioxide, 7%-10% of ferrous oxide, 2%-5% of aluminum oxide %, magnesium oxide 4%-10%. The...

Embodiment 2

[0030] A multi-solid waste non-burning and non-steaming double-layer structure permeable brick includes a surface layer and a base layer, and the thickness of the surface layer is 4mm. The base layer is 61mm. The surface layer raw materials are composed of 85 parts of steel slag powder with a particle size of 10-20 mesh, 30 parts of silica fume, 1 part of 128 epoxy resin, 0.5 parts of polyurethane curing agent, and 0.5 parts of sulfamic acid water reducer in parts by weight. , 10 parts of water; base raw materials are composed of 20 parts of P.O42.5 cement, 90 parts of iron ore waste rock with a particle size of 2-5mm, 30 parts of iron tailings powder, and sulfamic acid water reducing 0.4 parts of agent, 15 parts of water. The main chemical composition of the steel slag powder is 40%-50% of calcium oxide, 5%-20% of ferric oxide, 10%-20% of silicon dioxide, 7%-10% of ferrous oxide, 2%-5% of aluminum oxide %, magnesium oxide 4%-10%. The main chemical components of the iron ta...

Embodiment 3

[0036] A multi-solid waste non-burning and non-steaming double-layer structure permeable brick includes a surface layer and a base layer, and the thickness of the surface layer is 6mm. The base layer is 59mm. The surface layer raw materials are composed of 90 parts of steel slag powder with a particle size of 10-20 mesh, 25 parts of silica fume, 3 parts of 128 epoxy resin, 1 part of polyurethane curing agent, and 0.2 parts of sulfamic acid water reducer in parts by weight. , 15 parts of water; base raw materials are composed of 15 parts of P.O42.5 cement, 85 parts of iron ore waste rock with a particle size of 2-5mm, 25 parts of iron tailings powder, and sulfamic acid water-reducing powder in parts by weight. 0.3 parts of agent and 15 parts of water. The main chemical composition of the steel slag powder is 40%-50% of calcium oxide, 5%-20% of ferric oxide, 10%-20% of silicon dioxide, 7%-10% of ferrous oxide, 2%-5% of aluminum oxide %, magnesium oxide 4%-10%. The main chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com