Patents

Literature

66results about How to "High utilization rate of solid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

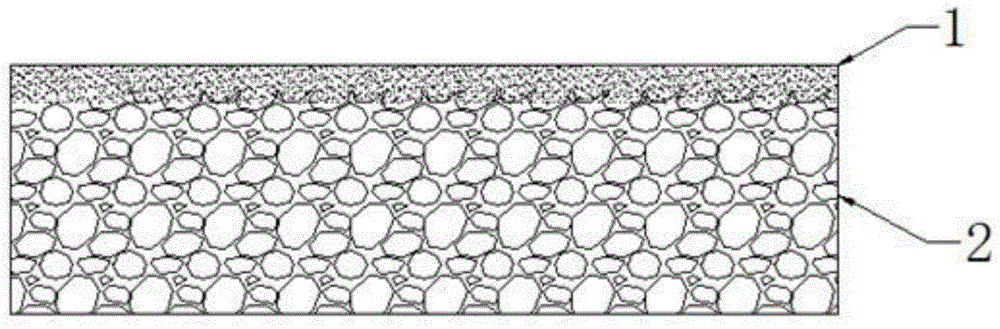

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

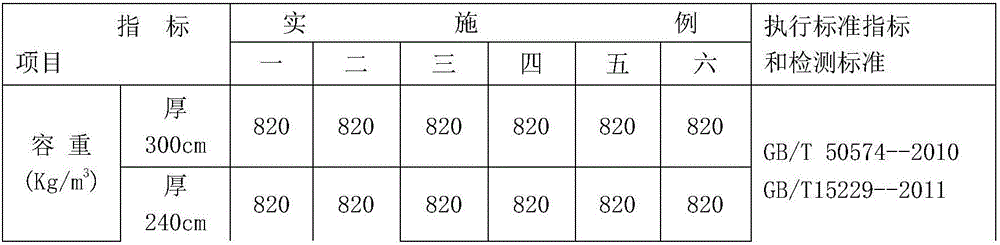

Roll-formed alkali slag and building rubbish plate

InactiveCN106316246AHeat of hydrationImprove impact resistanceConstruction materialSlagCarbonization

The invention discloses a roll-formed alkali slag and building rubbish plate, and belongs to the technical field of building material preparation. The roll-formed alkali slag and building rubbish plate comprises a surface layer and a middle material layer, and a fiberglass mesh is laid between the surface layer and the middle material layer. Industrial waste residues and building rubbish are adopted as raw materials, the advantages of being high in solid waste utilization rate and low in price and cost are achieved, the potential hydration activity of the alkali slag and the the building rubbish is fully utilized, and waste is turned into wealth. The roll-formed alkali slag and building rubbish plate has the advantages of being high in wear resistance, low in heat of hydration, high in impact resistance, low in contractibility rate, good in fatigue resistance, high in carbonization resistance, good in durability and the like, and can be widely applied to the building fields of inner wallboards, outer wallboards and the like. The process has the advantages of being simple, low in price and environmentally friendly, saving energy and the like, and is suitable for volume production.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

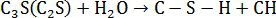

Fly ash and building waste water permeable brick and preparation method thereof

The invention discloses a fly ash and building waste water permeable brick and a preparation method thereof, and belongs to the technical field of building materials. The fly ash and building waste water permeable brick is prepared from, by weight, 100 parts of fly ash, 200-800 parts of building waste, 2-8 parts of silica fume, 1.5-6.5 parts of alkali-activator and 18-36 parts of water. According to the fly ash and building waste water permeable brick and the preparation method thereof, industrial waste residues and building waste are adopted as the raw materials, the solid waste utilization rate is high, and the production cost is low; the molding method adopts compression molding and is simple in technology, free of high-temperature calcination, low in carbon, environmentally friendly and low in energy consumption; a cementing material is an alkali-activator powder coal ash cementing material, and the water permeable brick prepared through the alkali-activator powder coal ash cementing material has the advantages of being high in strength, high in water permeability, low in hydration heat, resistant to carbonization, good in durability and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

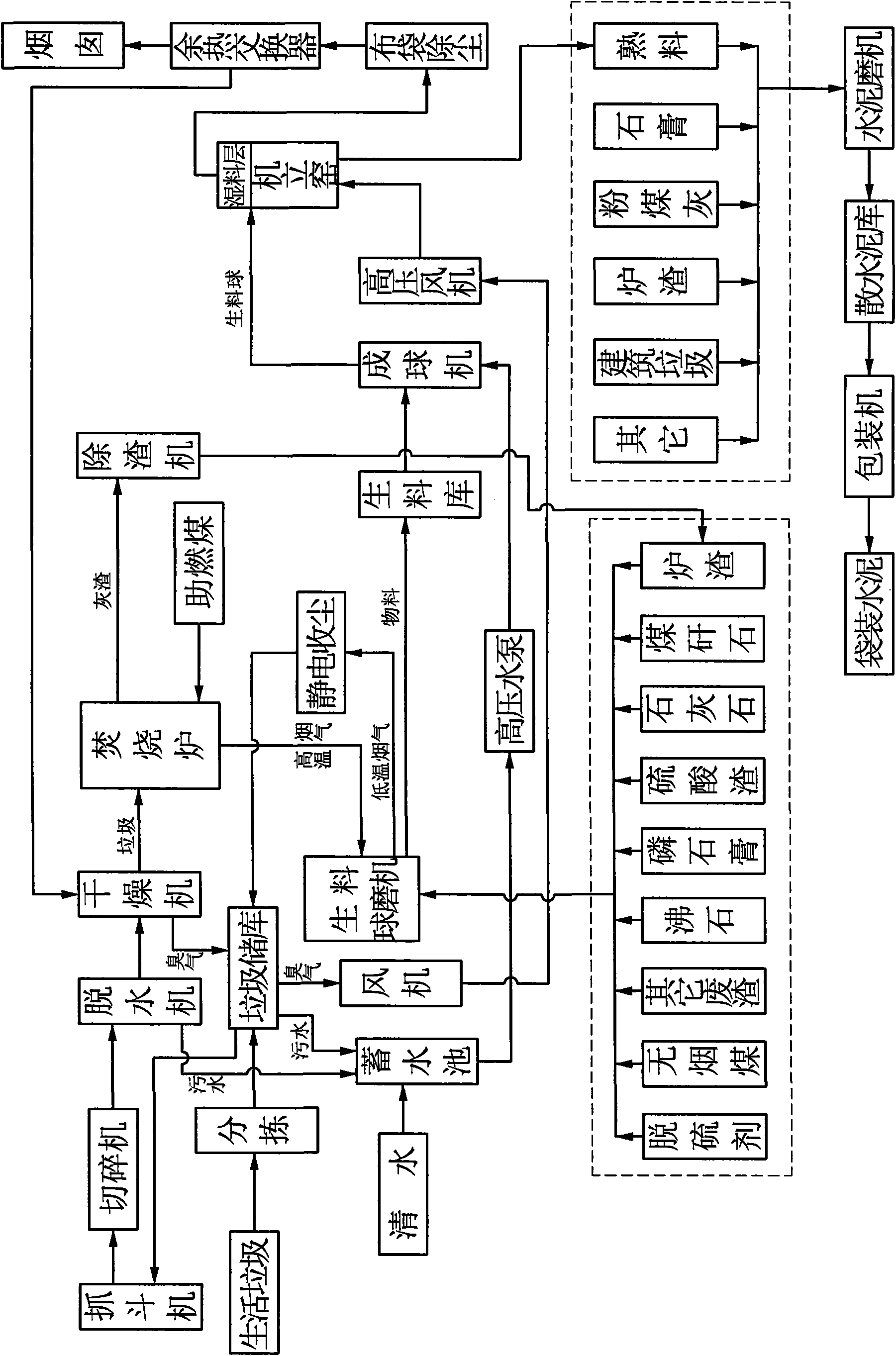

Method for processing municipal solid waste by using shaft kiln cement production line

The invention relates to a method for processing municipal solid waste by using a shaft kiln cement production line. The method comprises the following steps: (1) collecting, separating and warehousing; (2) cutting up, dehydrating and leachate treatment; (3) drying tail gas treatment; (4) burning smoke treatment; (5) slag utilization, raw material ball grinder tail gas treatment; (6) high temperature calcining and tail gas dedusting. The method uses specific conditions of the shaft kiln cement production technology for effectively using heat energy, leachate, slag and the like in the household garbage processing course; simultaneously, all matters generated in the garbage processing course (including taste) are completely dispelled in a high temperature kiln; the method has the advantages of little investment on device reformation, low garbage treatment cost, high waste solid utilization rate, complete garbage treatment and the like, thus truly achieving requirements of minimization, recycling and harmless of the garbage treatment.

Owner:郭涵

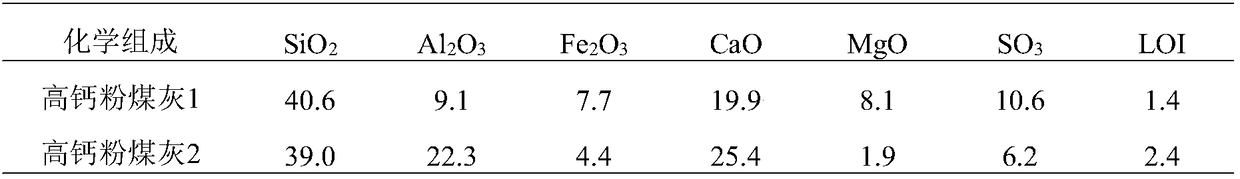

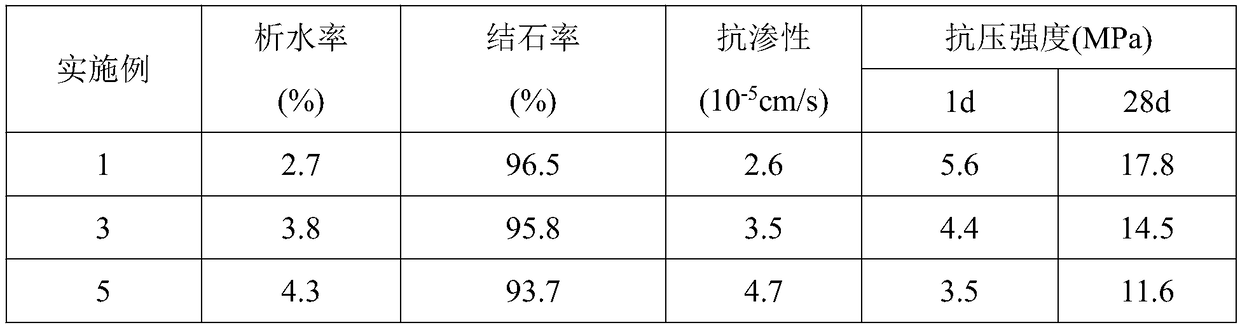

Micro-expansion grouting material and preparation method thereof

The invention discloses a micro-expansion grouting material. The micro-expansion grouting material is characterized by being prepared from the following materials in parts by mass: 30-50 parts of high-calcium flyash, 15-30 parts of calcined shale, 5-20 parts of phosphorus gypsum, 10-20 parts of ordinary silicate cement and 5-15 parts of rapidly-hardened sulphate aluminum cement. Further, additivematerials and water are added according to the times of the total parts by mass of the above materials on the basis that the total parts by mass of the materials are prepared to 100 parts. The additive materials comprise 0.5-1 part of a polycarboxylic acid water reducer, 0.1-1 part of redispersible latex powder, 0.05-0.15 part of hydroxypropyl methyl cellulose ether, 0.2-0.4 part of calcium lignosulphonate and 0.1-0.5 part of a cationic organic polymer; the water accounts for 8-10 parts. The micro-expansion grouting material has the characteristics of excellent mechanical property, micro expansion, low preparation cost, high solid waste utilization rate, green and environmental protection and high compatibility with soil.

Owner:重庆建工第七建筑工程有限责任公司 +1

Cementing material based on multiple solid wastes and preparation method thereof

The invention discloses a cementing material based on multiple solid wastes, which comprises the following components in percentage by mass: 15-40% of shale vanadium extraction tailings, 10-25% of Bayer process red mud, 25-40% of fly ash, 1-4% of sodium hydroxide, 6-10% of water glass and 10-16% of water. The cementing material is obtained by taking the shale vanadium extraction tailings, the Bayer process red mud and the coal ash as main raw materials, the technological process is simple, the production cost is low, the solid waste utilization rate is high, and the obtained cementing materialhas good strength and can be used as a roadbed material, a curing material and a building material.

Owner:WUHAN UNIV OF TECH

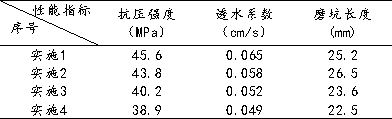

Fabricated light heat insulation wallboard for buildings and preparing technology

InactiveCN106320597AHigh utilization rate of solid wasteReduce manufacturing costConstruction materialGypsumConstruction aggregate

The invention discloses a fabricated light heat insulation wallboard for buildings. Water is added into a light heat insulation wallboard material to form liquid slurry through mixing, and then pouring forming is carried out in a disassembly-free mould. The light heat insulation wallboard material is prepared from, by weight, 80-85% of a cementing material, 10-17% of light heat insulation aggregate and 3-5% of a composite additive, wherein the sum of the weight percentages of the components is 100%, and the weight ratio of the added water to the cementing material is (0.50-0.60):1. The preparing technology of the fabricated light heat insulation wallboard for buildings includes the following steps that firstly, calcium silicate boards are prepared; secondly, the mould is prepared; thirdly, the composite additive and the cementing material are mixed and then doped with the light heat insulation aggregate, water is added, the mixture is stirred to be uniform and then poured into the mould, and after initial setting, final setting, carrying, stacking and curing, the finished product is obtained. By utilizing chemical gypsum, the fabricated light heat insulation wallboard for buildings is prepared and is light, good in fireproofness, waterproofness, heat insulation, sound insulation, compression resistance and fracture resistance and convenient to prepare and construct.

Owner:李宁

Operation method of industrial solid waste and sludge rotary kiln co-processing integrated device

InactiveCN110734209AThe treatment process is thoroughFast and economical processingCombination devicesSludge treatment by de-watering/drying/thickeningSludgeFlue gas

The invention relates to a co-processing integrated device, in particular to an operation method of an industrial solid waste and sludge rotary kiln co-processing integrated device. The sludge spray drying (direct drying) + disc drying (indirect drying), rotary kiln and industrial leftover material (solid waste) collaborative incineration and flue gas purification system integrated device integrates sludge drying, sludge drying and industrial leftover material (solid waste) collaborative incineration and flue gas purification, achieves waste reutilization and reduces environmental pollution.

Owner:ZHEJIANG HUANXING MACHINERY

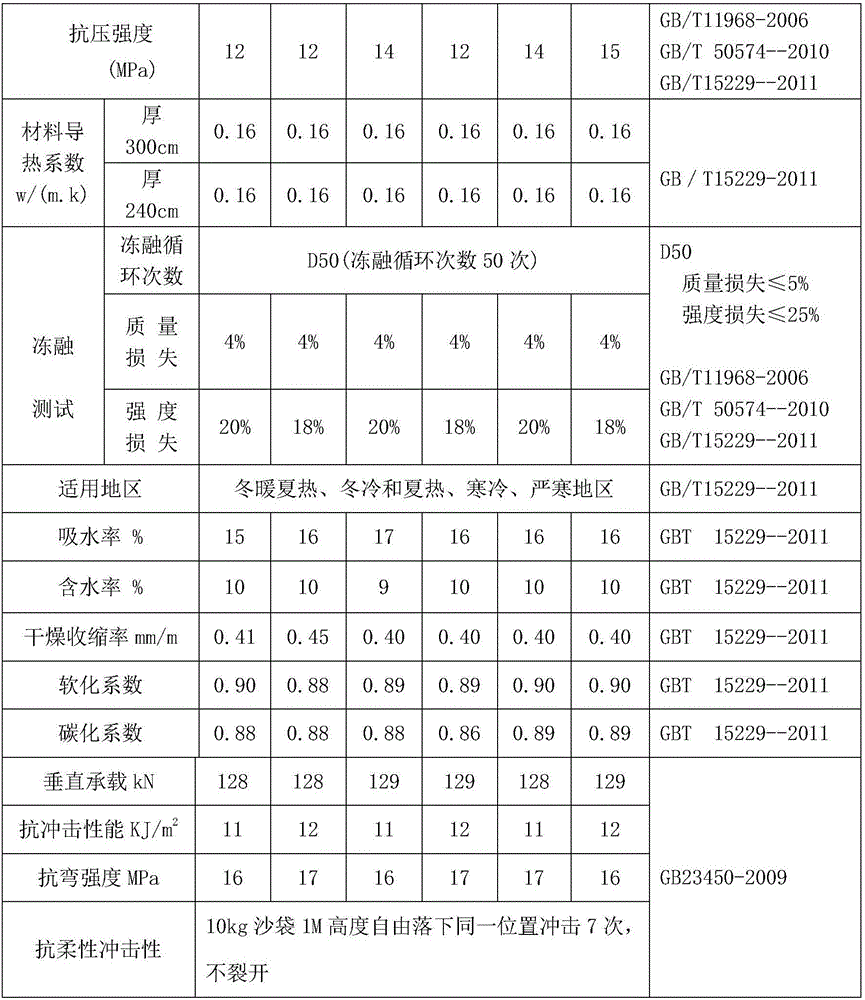

High-strength nickel slag-based solid waste cementing material and preparation method thereof

ActiveCN112608043AGive full play to the micro-aggregate effectIncrease alkalinityCement productionCompressive resistanceSlag

The invention discloses a high-strength nickel slag-based solid waste cementing material and a preparation method thereof, and belongs to the field of building materials. The cementing material is prepared from blast furnace nickel slag and ardealite and is prepared from the following raw materials in parts by mass: 100-200 parts of steel slag, 400-500 parts of blast furnace nickel slag, 300-400 parts of ardealite, 100 parts of cement clinker, 300-320 parts of water and 1-3 parts of water reducing agent. The cementing material is applied to road engineering, the initial fluidity of a roadbed material can reach 190mm or above, the compressive strength of a cement test block in one day reaches 25Mpa or above, the compressive strength of the cement test block in 28 days reaches 45Mpa or above, and the cementing material has high working and durability. The method is simple to operate, high in solid waste utilization rate, energy-saving, environment-friendly and good in economy.

Owner:HUBEI UNIV OF TECH

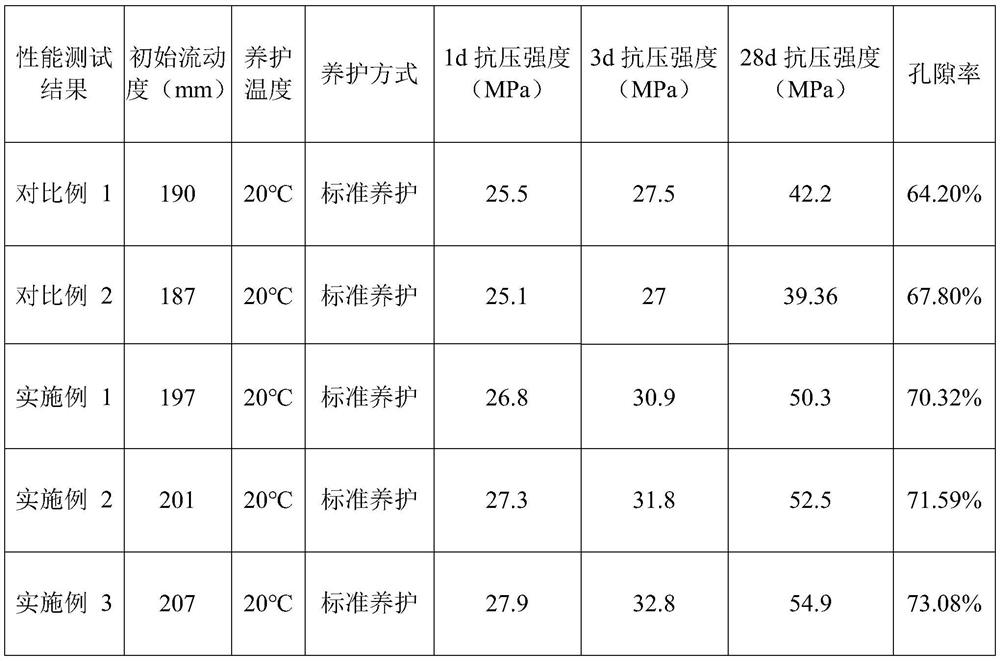

Method for preparing aggregates with high apparent density through industrial waste residues

ActiveCN105712643AHigh apparent densityHigh utilization rate of solid wasteApparent densityResource utilization

The invention discloses a method for preparing aggregates with the high apparent density through industrial waste residues. The method comprises the steps that 10-50% of waste incineration ash, 1-40% of chromium slag, 1-40% of nickel slag, 1-50% of lead slag, 10-60% of clay and other industrial waste residue soil are uniformly mixed and ground into powder, water is added for stirring to be uniform, and the aggregates with the high apparent density are obtained through burning by means of the technologies such as extrusion pelletization, drying, calcination and cooling; resource utilization of industrial waste residues is achieved, the scientific and effective way is provided, and the obtained aggregates with the high apparent density can be used for preparing concrete.

Owner:天津朝阳环保科技集团有限公司

Water-permeable bricks prepared from coal gangues and construction waste and preparation method thereof

InactiveCN106277974AHigh strengthGood water permeabilitySolid waste managementCeramicwareBrickCalcination

The invention discloses water-permeable bricks prepared from coal gangues and construction waste and a preparation method thereof and belongs to the technical field of building materials. The water-permeable bricks are prepared from, by weight, 100 parts of coal gangues, 200-800 parts of construction waste, 5-10 parts of silica fume, 1.8-7 parts of alkaline excitant and 18-36 parts of water. The raw materials are industrial waste and construction waste, the solid waste utilization rate is high, and the production cost is low. The water-permeable bricks are formed through pressing and are low in carbon, environmentally friendly and low in energy consumption, the process is simple, and high temperature calcination is not needed. A cementing material is an alkali-activated coal gangue cementing material, so that the water-permeable bricks prepared adopting the cementing material have the advantages of being high in strength, high in water permeability, low in hydration heat, resistant to carbonation, good in durability and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Rolling-formed fly ash-construction waste slab material

InactiveCN106431122AHeat of hydrationImprove impact resistanceSolid waste managementGlass/slag layered productsCarbonizationShock resistance

The invention discloses a rolling-formed fly ash-construction waste slab material and belongs to the technical field of preparation of building materials. The slab material comprises a surface layer and a middle material layer, wherein glass fiber grid cloth is laid between the surface layer and the middle material layer. According to the rolling-formed fly ash-construction waste slab material, industrial waste residues and construction wastes serve as raw materials, so that the slab material has the characteristics of high solid waste utilization ratio, low price and low cost; and the potential hydration activity of fly ash and the construction wastes is fully used, so that the waste is changed into the valuable. The rolling-formed fly ash-construction waste slab material has the characteristics of light weight, high strength, low hydration heat, high shock resistance, low shrinkage, good fatigue resistance, high carbonization resistance, good durability and the like, thereby being capable of being extensively applied to the construction fields of interior wall slabs, exterior wall slabs and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Water permeable brick prepared from alkali residues and construction waste and preparation method thereof

InactiveCN106278350AHigh utilization rate of solid wasteReduce manufacturing costSolid waste managementCement productionSilica fumeIndustrial waste

The invention discloses a water permeable brick prepared from alkali-residues and construction waste and a preparation method thereof, belonging to the technical field of construction material preparation. The water permeable brick is prepared from the following substances in parts by weight: 100 parts of alkali residues, 200-800 parts of construction waste, 2-8 parts of silica fume, 5-15 parts of cement, 2-7.5 parts of alkali activator and 18-40 parts of water. The water permeable brick is prepared from industrial waste residues and construction waste, and has high solid waste utilization and low production cost; the molding method adopts press molding, is simple in process, does not need high-temperature calcining, and has the advantages of low carbon, environmental friendliness and low energy consumption; and the gel material is alkali-activated alkali residue gel material to prepare the water permeable brick having the advantages of high strength, high water permeability, low hydration heat, carbonization resistance, good durability and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Multi-solid-waste large-mixing-amount non-fired water permeable brick and preparation method thereof

InactiveCN112142420AIncrease added valueRealize resource utilizationSolid waste managementCeramic shaping apparatusMaterials preparationBrick

The invention relates to a multi-solid-waste large-mixing-amount non-fired water permeable brick and a preparation method thereof, and belongs to the field of building material preparation, the multi-solid-waste large-mixing-amount non-fired water permeable brick comprises the following components in proportion: 45%-50% of steel slag, 10%-20% of coal gangue, 8%-15% of desulfurized gypsum, 10-20% of aggregate, 8%-10% of water and 1%-3% of water reducing agent, wherein the aggregate is composed of iron mine waste rock and building waste at 1:1. A large amount of solid waste is adopted as the rawmaterial, the ecological pressure can be reduced while the cost is saved, the solid waste utilization rate is increased, energy is greatly saved in an unfired mode, the activity of the raw material is improved through mechanical grinding, the activity of steel slag can be stimulated through addition of coal gangue and desulfurized gypsum, and the permeable strength and wear resistance are improved.

Owner:张延年

Multi-solid-waste baking-free steaming-free water permeable brick with double-layer structure and preparation method thereof

The invention discloses a multi-solid-waste baking-free steaming-free water permeable brick with a double-layer structure and a preparation method thereof, and belongs to the field of preparation of building materials; the water permeable brick comprises a surface layer and a base layer, and the surface layer is composed of the raw materials in parts by weight: 80-100 parts of steel slag micro powder, 20-30 parts of silica fume, 1-4 parts of epoxy resin, 0.5-2 parts of a curing agent, 0.1-0.5 part of a water reducing agent and 10-20 parts of water; the base layer is composed of the raw materials in parts by weight: 10-20 parts of cement, 80-100 parts of iron ore waste rock, 20-30 parts of iron tailing powder, 0.1-0.5 part of a water reducing agent and 10-20 parts of water; the water permeable brick has the beneficial effects that the solid waste utilization rate is high, resource utilization of solid waste is achieved, the process is simple, high-temperature calcination is not needed,energy consumption is low, the surface layer adopts extremely fine particles, and the situation that the interior of the water permeable brick is blocked due to overlong use time is avoided; and silica fume is added into the surface layer as an excitant, so that the strength and the wear resistance of the water permeable brick are improved.

Owner:张延年

Lepidolite tailing one-step sintered microcrystalline foam heat preservation and decoration integrated plate

ActiveCN111499205AImprove toughnessLow thermal conductivityGlass shaping apparatusCeramic materials productionIndustrial wasteHeat conservation

The invention discloses a Lepidolite tailing one-step sintered microcrystal foam heat preservation and decoration integrated plate and a preparation method thereof. The heat preservation and decoration integrated plate is of a two-layer structure. The microcrystalline foaming light layer is prepared from the following raw materials: lepidolite tailings, clay, industrial waste residue phosphogypsum, red mud, construction waste, kaolin, graphene, cement mortar, wood fiber, cellulose ether and the like; the microcrystalline wear-resistant decorative surface layer is prepared from kaolin, silica,red clay, purple shale, graphene, water glass and the like. The prepared integrated plate is high in mechanical performance, low in heat conductivity coefficient, high in double-layer cohesiveness, good in heat preservation effect, resistant to high temperature, not prone to cracking and stable in color development.

Owner:江西鼎盛新材料科技有限公司 +1

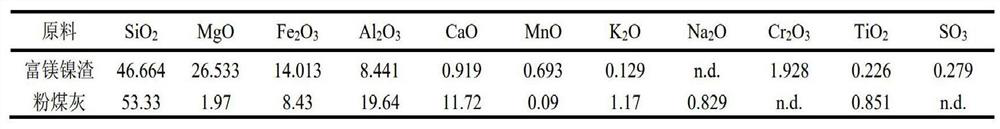

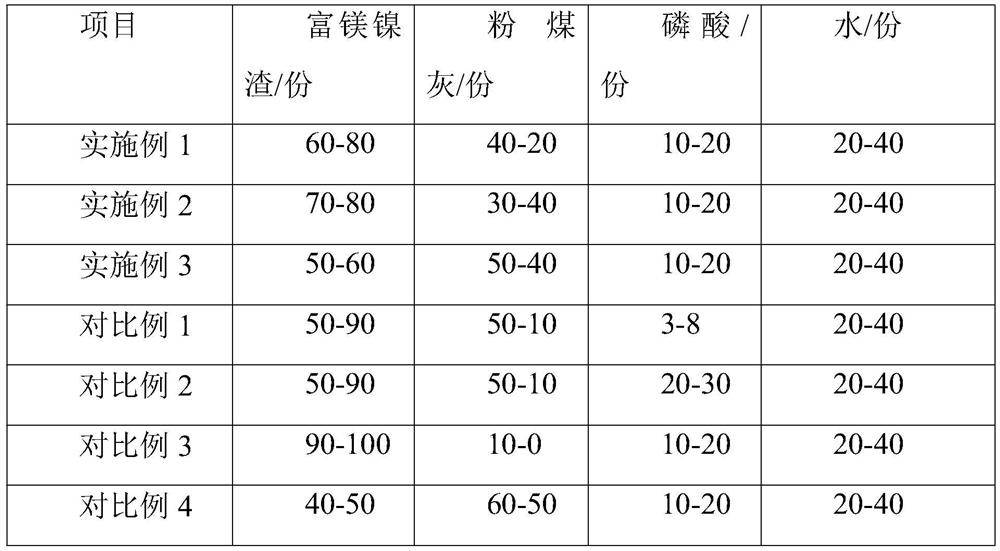

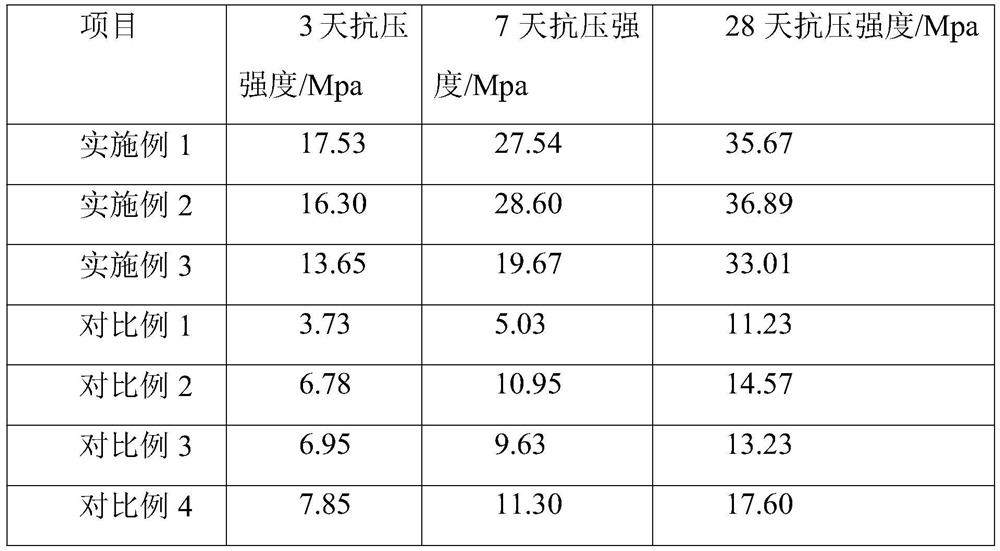

Phosphoric acid excited magnesium-rich nickel slag geopolymer cementing material and preparation method thereof

PendingCN113880506ASimple compositionLow costCement productionCompressive resistanceO-Phosphoric Acid

The invention discloses a phosphoric acid excited magnesium-rich nickel slag geopolymer cementing material and a preparation method thereof. The cementing material is composed of magnesium-rich nickel slag and fly ash, and the cementing material is mainly composed of, by weight, 50-90 parts of magnesium-rich nickel slag, 50-10 parts of fly ash, 10-20 parts of phosphoric acid, and 20-40 parts of water. The magnesium-rich nickel slag with complex components and the fly ash can be directly used for preparing the cementing material, the cementing material with excellent comprehensive performances such as compressive strength is finally obtained by controlling the ratio of the raw materials, and the cementing material can be used as an admixture of cement and can also be used as a cementing material of concrete. According to the invention, the solid waste cementing material excited by acid is utilized, and the method has the advantages of simple processing technology, environmental protection, low energy consumption and low cost, and can show better compressive strength.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Alkaline residue-building waste ceramsite and preparing method thereof

The invention discloses alkali slag construction waste ceramsite and a preparation method thereof, which belong to the technical field of building material preparation. It consists of the following parts by weight: 100 parts of alkali slag, 150-600 parts of construction waste, 2-8 parts of silica fume, 10-25 parts of cement, 2.5-8.5 parts of alkaline activator, 0.06-1.5 parts of additive, water 13‑35 servings. The alkali slag construction waste ceramsite of the present invention has a simple molding process, does not need high-temperature calcination, is low-carbon, environmentally friendly, and low in energy consumption. Alkali slag construction waste ceramsite is spherical in shape, rough and hard on the surface, with fine pores inside. It has a wide range of raw material sources, light weight, low apparent density, high strength, low shrinkage, carbonization resistance, good durability, high temperature resistance, and heat preservation. Good performance, good waterproof performance and so on.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Ceramsite with slag and building waste and method for preparing ceramsite

InactiveCN106348662ASimple molding processReduce energy consumptionCeramic shaping apparatusCeramicwareSlagCarbonization

The invention belongs to the field of technologies for preparing building materials, and discloses ceramsite with slag and building waste and a method for preparing the ceramsite. The ceramsite comprises, by weight, 100 parts of the slag, 150-170 parts of the building waste, 2-8 parts of silica fume, 1.0-5.0 parts of alkali activators, 0.05-0.8 part of additives and 10-25 parts of water. The ceramsite with the slag and the building waste and the method have the advantages that processes for forming the ceramsite are simple, high-temperature calcination can be omitted, and the ceramsite is low-carbon, is environmentally friendly, is low in energy consumption, is mostly filled with zeolite-like hydration products, is light and porous and is high in strength; the ceramsite with the slag and the building waste is in the shape of a round sphere and has rough and hard surfaces, tiny air holes are formed in the ceramsite, raw materials for the ceramsite can come from wide sources, the ceramsite is light, carbonization-resistant and high-temperature-resistant and is low in apparent density and shrinkage, high in strength and good in durability, heat-insulation property and waterproof property, and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

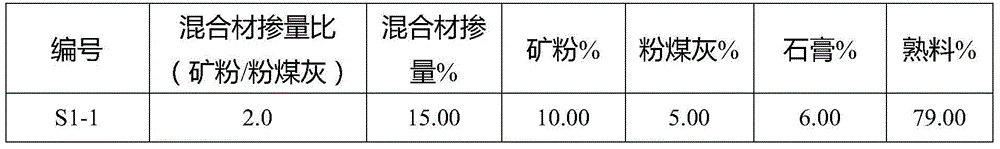

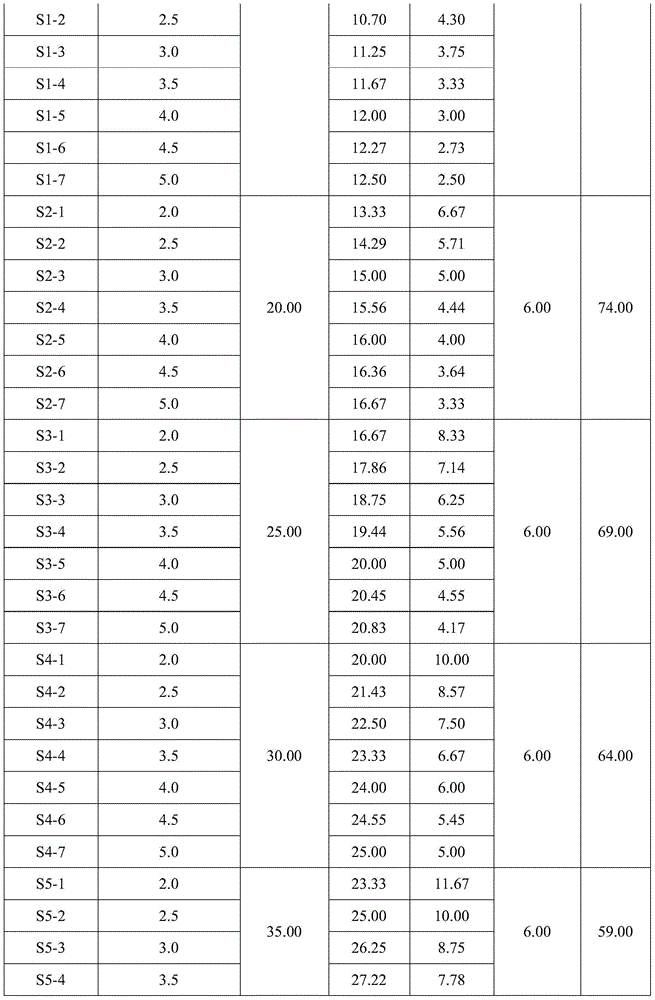

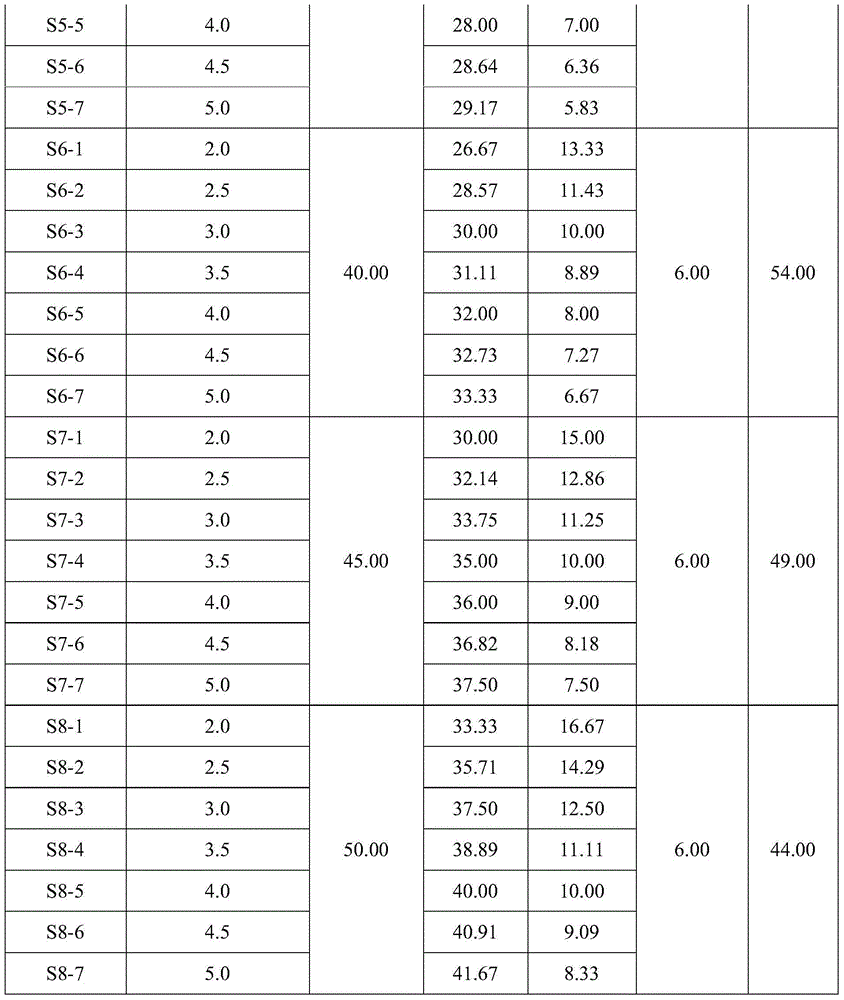

High-performance cement with large mixed material mixing amount and preparation method therefor

InactiveCN104860555AIncrease dosageHigh utilization rate of solid wasteCement productionCoalEnvironmental resistance

Owner:CHINA RESOURCES CEMENT TECH RES DEV

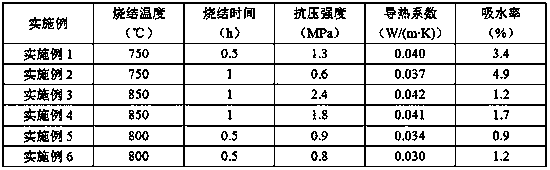

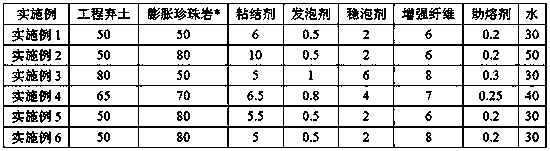

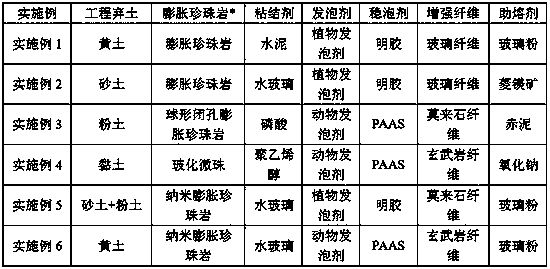

Sintering project abandoned soil expanded perlite heat insulation and decoration integral board and preparation method thereof

ActiveCN108129135AHigh utilization rate of solid wasteTake advantage ofCeramic materials productionCeramicwareLithium oxideFiber

The invention discloses a sintering project abandoned soil expanded perlite heat insulation and decoration integral board, which consists of a heat insulation base layer and a decoration surface layer, wherein the heat insulation base layer is prepared from 50 to 80 parts of engineering waste soil, 50 to 80 parts of expanded perlite, 5 to 10 parts of bonding agents, 0.5 to 1 part of foaming agents, 2 to 6 parts of foam stabilizing agents, 6 to 8 parts of reinforced fiber, 0.2 to 0.3 part of cosolvents and 30 to 50 parts of water through sintering; the decoration surface layer is prepared from20 to 70 parts of silicon dioxide, 30 to 80 parts of zinc oxide, 5 to 8 parts of boric oxide, 2 to 4 parts of aluminum oxide, 0.5 to 2 parts of lithium oxide, 0.5 to 3 parts of coloring agents, 0.2 to0.3 part of dispersing agents, 0.1 to 0.4 part of anti-foaming agents and 20 to 40 parts of water through sintering. The solid wastes are efficiently utilized; meanwhile, the prepared sintering project abandoned soil expanded perlite heat insulation board has the integral functions of fire prevention, heat insulation and decoration.

Owner:山西晟科微生物建材科技有限公司

Coal gangue construction waste ceramsite and preparation method thereof

InactiveCN106277878ASimple molding processExtensive molding processSolid waste managementMaterials preparationApparent density

The invention discloses coal gangue construction waste ceramsite and a preparation method thereof, and belongs to the technical field of building material preparation. The coal gangue construction waste ceramsite is prepared from, by weight, 100 parts of coal gangue, 150-600 parts of construction waste, 5-10 parts of silica fume, 1.5-8.0 parts of alkali-activator, 0.05-1.0 part of additive and 10-25 parts of water. According to the coal gangue construction waste ceramsite, the forming process is simple, high-temperature calcination is not needed, low carbon, environmental protection and low energy consumption are achieved, and the ceramsite mainly contains zeotype-shaped hydration products and is low in mass, porous and high in strength. The coal gangue construction waste ceramsite is shaped like a sphere, the surface is rough and hard, the ceramsite is internally provided with tiny pores, and the ceramsite has the advantages of being wide in raw materials source, low in mass, low in apparent density, high in strength, low in contraction, resistant to carbonization, good in durability, resistant to high temperature, good in thermal insulation property, good in waterproof property and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

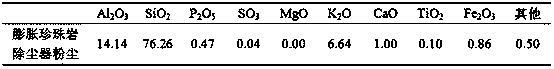

Microbial coal gangue/coal slime building material and manufacturing method thereof

The invention discloses a microbial coal gangue / coal slime building material and a preparation method thereof. The specific formula comprises: 0-80 parts of coal gangue, 0-30 parts of coal slime, 5-30parts of steel slag, 5-50 parts of waste incineration fly ash, 2-10 parts of silica powder, 10-20 parts of slaked lime, 5-50 parts of expanded perlite dust remover dust, 10-40 parts of bacterial liquid, 2-4 parts of an EVA emulsion, 0.1-0.5 part of a silane coupling agent and 0-0.5 part of a water reducer. According to the invention, various microbial coal gangue coal slime building material products including coal gangue coal slime concrete, coal gangue coal slime building blocks and coal gangue coal slime water permeable bricks can be prepared, and the preparation method is green and pollution-free, has high solid waste utilization rate, and has good environmental benefits.

Owner:山西晟科微生物建材科技有限公司

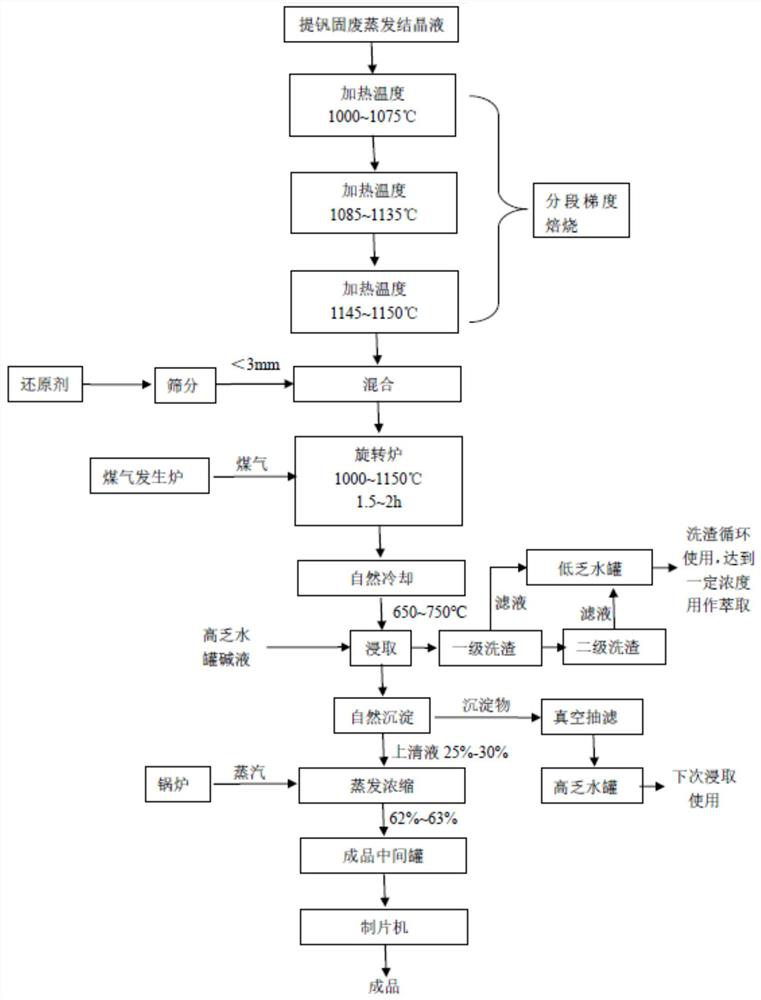

Drying method for evaporative crystallization liquid of vanadium precipitation wastewater and method for recovering sodium sulfide

ActiveCN111704303AShorten drying timeHigh yieldWater contaminantsTreatment involving filtrationWastewaterVanadium atom

The invention relates to a drying method for evaporative crystallization liquid of vanadium precipitation wastewater and a method for recycling sodium sulfide, belonging to the field of recycling of vanadium extraction waste liquid. According to the drying method for the evaporative crystallization liquid of the vanadium precipitation wastewater, the for evaporative crystallization liquid of the vanadium precipitation wastewater is dried in a sectional heating mode. A sectional heating method comprises the following steps: firstly, carrying out heating for 0.25 to 0.5 hour at 1000 to 1075 DEGC; then, performing heating for 0.25 to 0.5 h at a temperature of 1085 to 1135 DEG C; and finally, conducting heating for 0.5-1 hour at a temperature of 1145-1175 DEG C. The evaporative crystallization liquid of the vanadium precipitation wastewater is treated in the sectional heating mode, so drying time is shortened by 75% or above, efficiency is improved, and cost is saved.

Owner:PANZHIHUA UNIV

Foamed lightweight aggregate prepared from iron tailings and preparation method thereof

InactiveCN111087185AHigh utilization rate of solid wasteHigh strengthSolid waste managementFoaming agentRaw material

The invention discloses a preparation method of foamed lightweight aggregate prepared from iron tailings. The preparation method comprises the following steps: detecting the content of each componentin the iron tailings, and regulating the mass part addition ratio of raw materials; carrying out ball milling until a particle size is 150 microns or below to obtain raw material powder; adding a fluxing agent, a binder, a foaming agent and an aluminum content regulator into the raw material powder to obtain a mixture; conducting granulating to obtain an semi-finished aggregate product; subjectingthe semi-finished aggregate product to drying, sintering at high temperature, and cooling to obtain the foamed lightweight aggregate. The invention further discloses the foamed lightweight aggregateprepared from the iron tailings. According to the invention, the content of each component in different iron tailings is determined, and the ratio of the iron tailings, the fluxing agent, the binder,the foaming agent and the aluminum content regulator is reasonably controlled, so the iron tailings are ensured to have high solid waste utilization rate, the goals of high strength, low stacking density and low water absorption rate are effectively achieved, and the iron tailings in different reservoir areas are fully recycled; and the preparation method is simple in process, friendly to environment, and convenient for industrial production.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD +1

Method for extruding and compounding calcium carbide smelting material through calcium carbide furnace tail gas and dust

InactiveCN103274413AHigh utilization rate of solid wasteLow costChemical industryCalcium carbideEconomic benefitsCoal tar

The invention relates to a method for extruding and compounding calcium carbide smelting material through calcium carbide furnace tail gas and dust. The method comprises the steps of mixing calcium carbide furnace tail gas and dust and coal tar according to weight ratio of 80 to 85 percent : 20 to 15 percent, sufficiently stirring the calcium carbide furnace tail gas and dust and the coal tar, and performing extrusion forming. The method directly utilizes the calcium carbide furnace tail gas and dust to extrude and compound the calcium carbide smelting material, ensures that the calcium carbide furnace tail gas and dust can be sufficiently utilized in the calcium carbide furnace smelting, achieves the purposes of high solid waste use ratio, cost reducing, energy saving and environment protection, and simultaneously is simple in production process, low in technical requirements, small in energy consumption, low in cost, and obvious in economic benefit.

Owner:宁夏兴平精细化工股份有限公司

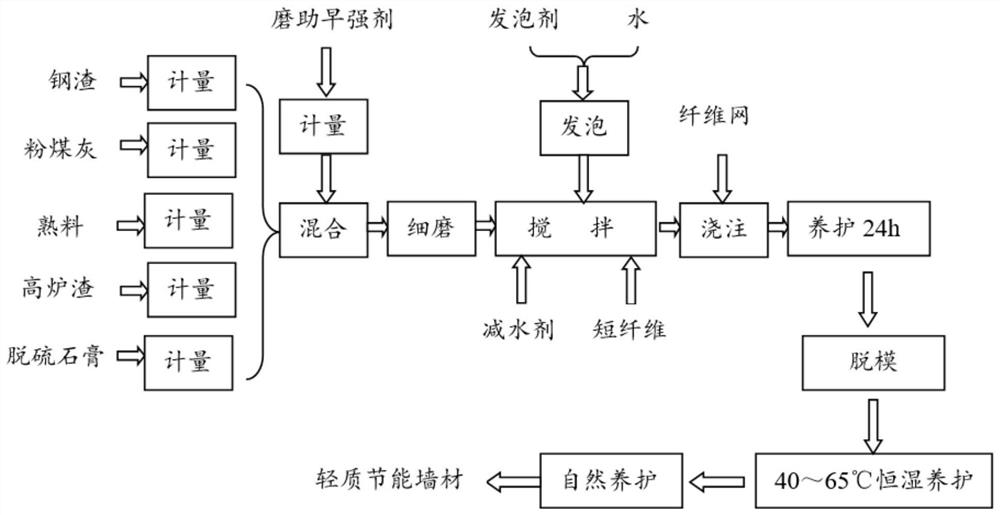

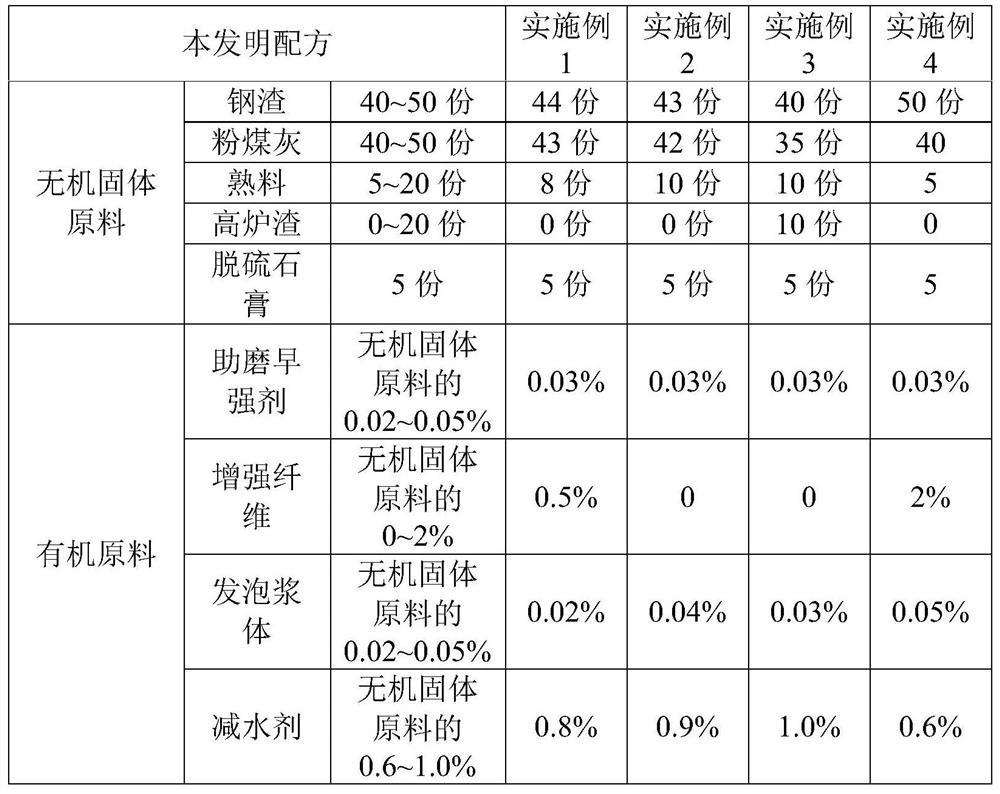

Method for preparing lightweight energy-saving building wall material from high-content steel slag

InactiveCN112919877AEliminate negative effectsImprove mechanical excitation effectSolid waste managementCeramicwareFiberSlag

The invention discloses a method for preparing a lightweight energy-saving building wall material by using high-content steel slag, and solves the problems of low utilization rate, low additional value and low consumption of the existing steel slag. The preparation method comprises the following steps: mixing 40-50 parts of steel slag, 10-20 parts of clinker, 0-20 parts of blast furnace slag, 40-50 parts of fly ash and 5 parts of desulfurized gypsum powder; performing mixing, adding 0.02-0.05% of a grinding-aid early strength agent, and performing fine grinding; adding 0-2% of reinforcing fibers into the mixture after fine grinding; mixing with foaming slurry, and adding a water reducing agent; after uniform stirring, pouring the mixture into a mold; curing the test piece for 1 day under the condition of constant humidity of 30 DEG C, performing demolding, performing curing for 3-6 days under the condition of constant humidity of 35-65 DEG C, and performing natural curing for 28 days to prepare the qualified light energy-saving wall material. The solid waste utilization rate can reach 90%, and the steel slag utilization rate can reach 42.5% or above.

Owner:安徽马钢嘉华新型建材有限公司 +1

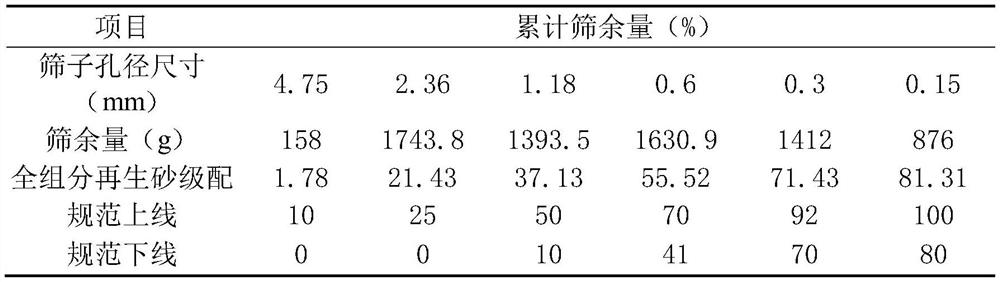

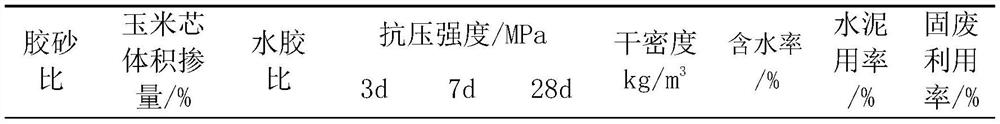

Recycled concrete mine filling material prepared from corncobs and preparation method of recycled concrete mine filling material

PendingCN114538838AEasy to manufactureReduce occupancySolid waste managementMining engineeringWaste management

The invention belongs to the technical field of mine backfilling, discloses a recycled concrete mine filling material prepared from corncobs and a preparation method of the recycled concrete mine filling material, and aims to solve the problems that the cost is high, the filling material is easy to shrink and a filling body shrinks when cement is adopted for mine filling. The recycled concrete mine filling material is prepared from the following raw materials in parts by weight: 25 parts of cement, 30-50 parts of water, 55-85 parts of recycled sand and 5.5-8 parts of corncob particles. According to the invention, a large amount of solid wastes (corncob and reclaimed sand) existing in China are fully utilized and reasonably proportioned, so that the filling material specially used for mine filling can be conveniently and quickly manufactured, and the problems of settlement, collapse and the like caused by shrinkage and shrinkage after solidification of the existing mine filling material can be solved; and meanwhile, the cost of the mine filling material is reduced.

Owner:GUIZHOU UNIV

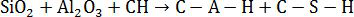

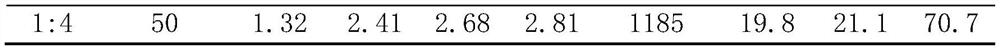

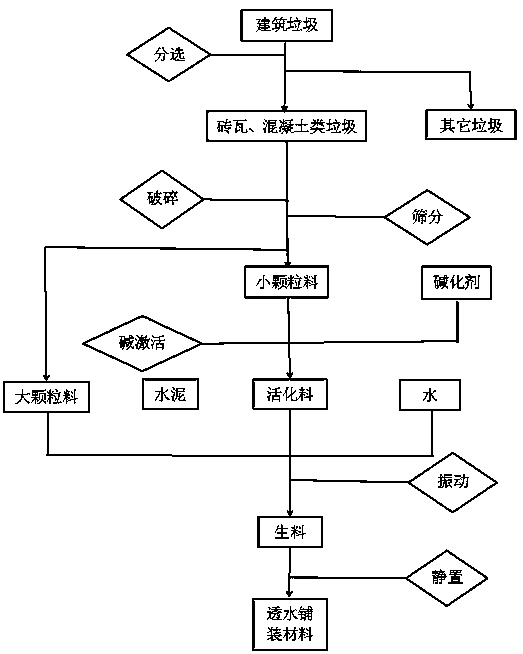

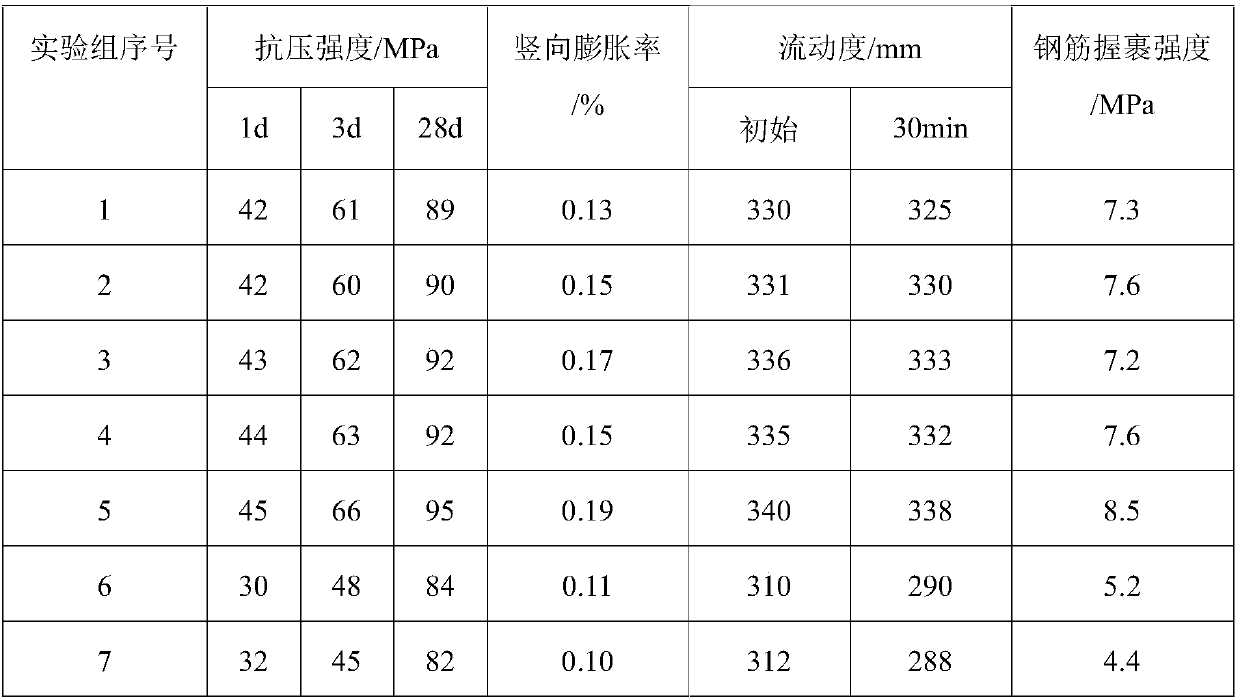

Method for preparing water-permeable pavement material from construction waste

The invention relates to the technical field of solid waste comprehensive utilization and discloses a method for preparing a water-permeable pavement material from construction waste. The method includes: step one, sorting the construction waste to remove plastic, metal, wood and the like from the construction waste, and only keeping solid waste such as bricks, tiles and concrete; step two, crushing the solid waste by a crushing machine, screening to obtain large particles in particle size of 1-5mm and small particles in particle size smaller than 1mm; step three, mixing the small particles and an alkalizer according to a ratio of 100:(5-10), adopting a ball mill for ball milling for 6-12h to obtain an activated material. By making full use of the bricks, the tiles and the concrete in theconstruction waste, the method has the advantage of high solid waste utilization rate. The water-permeable pavement material produced according to the method is high in strength, water permeability and solid waste content, low in cost, high in additional value, promising in market prospect and beneficial to further increase of the comprehensive utilization rate of the construction waste.

Owner:柳州紫荆生态工程科技有限公司

Grouting material for sound barrier backboard

InactiveCN107602006AHas fast hardeningGood adhesionNoise reduction constructionPre stressingHeat stability

The invention relates to the technical field of building materials and provides a grouting material for a sound barrier backboard. The grouting material comprises the following raw materials (by weight): 15-25 parts of Portland cement, 30-40 parts of fly ash, 50-70 parts of building rubbish, 10-15 parts of water and 0.61-1.08 parts of additives. The grouting material has advantages of wide sourcesof raw materials, high utilization rate of solid wastes, low cost, rapid hardening, early strength, slight expansion, strong bonding force, good heat stability and the like, and can be used as a binder for bonding or reinforcement of engineering equipment. The sound barrier backboard is provided with multiple reinforcing holes. after the backboard is maintained to design strength, the backboard is tensioned with pre-stress steel bars or steel strands, and then the grouting material is injected to glue the pre-stress steel bars or steel strands with the sound barrier backboard as a whole. Thus, the sound barrier backboard is safe and stable and durable.

Owner:SICHUAN SHUANGTIE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com