Multi-solid-waste large-mixing-amount non-fired water permeable brick and preparation method thereof

A technology of permeable bricks and large dosage is applied in the field of building materials to achieve the effect of high utilization rate of solid waste, simple process and reduction of site resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

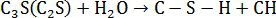

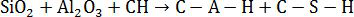

Method used

Image

Examples

Embodiment 1

[0039] A non-burning permeable brick with a large amount of solid waste and a preparation method thereof. The permeable brick is prepared by using 46% of steel slag, 20% of coal gangue, 14% of desulfurized gypsum, 10% of aggregate, 8% of water, and 2% of water reducing agent. The preparation process is as follows:

[0040] 1) The steel slag and coal gangue are respectively crushed and ground until the specific surface area is 580㎡ / kg, and the

[0041] 2) Mix and crush iron ore waste rock and construction waste at a ratio of 1:1 to a particle size of 1-2mm, and set aside

[0042] 3) Dry the desulfurized gypsum at 60°C and grind it to a specific surface area of 600㎡ / kg for later use

[0043] 4) Add the materials into the mixer according to the ratio and stir for 3-5 minutes, then add water and water reducer and stir for 10 minutes to make the materials fully mixed and even

[0044] 5) Put it into the permeable brick mould, press and form it on the hydraulic device, the formi...

Embodiment 2

[0056] A non-burning permeable brick with a large amount of solid waste and a preparation method thereof. The permeable brick is prepared by using 48% of steel slag, 16% of coal gangue, 12% of desulfurized gypsum, 13% of aggregate, 8% of water, and 3% of water reducing agent. The preparation process is as follows:

[0057] 1) The steel slag and coal gangue are respectively crushed and ground until the specific surface area is 580㎡ / kg, and the

[0058] 2) Mix and crush iron ore waste rock and construction waste at a ratio of 1:1 to a particle size of 1-2mm, and set aside

[0059] 3) Dry the desulfurized gypsum at 60°C and grind it to a specific surface area of 600㎡ / kg for later use

[0060] 4) Add the materials into the mixer according to the ratio and stir for 3-5 minutes, then add water and water reducer and stir for 10 minutes to make the materials fully mixed and even

[0061] 5) Put it into the permeable brick mould, press and form it on the hydraulic device, the formi...

Embodiment 3

[0073] A non-burning permeable brick with a large amount of solid waste and a preparation method thereof. The permeable brick is prepared by using 45% of steel slag, 20% of coal gangue, 10% of desulfurized gypsum, 15% of aggregate, 9% of water, and 1% of water reducing agent. The preparation process is as follows:

[0074] 1) The steel slag and coal gangue are respectively crushed and ground until the specific surface area is 580㎡ / kg, and the

[0075] 2) Mix and crush iron ore waste rock and construction waste at a ratio of 1:1 to a particle size of 1-2mm, and set aside

[0076] 3) Dry the desulfurized gypsum at 60°C and grind it to a specific surface area of 600㎡ / kg for later use

[0077] 4) Add the materials into the mixer according to the ratio and stir for 3-5 minutes, then add water and water reducer and stir for 10 minutes to make the materials fully mixed and even

[0078] 5) Put it into the permeable brick mould, press and form it on the hydraulic device, the formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com