Recycled concrete mine filling material prepared from corncobs and preparation method of recycled concrete mine filling material

A technology for recycled concrete and mine filling, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as shrinkage and shrinkage of filling materials, achieve high moisture content, reduce land occupation, and good water absorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

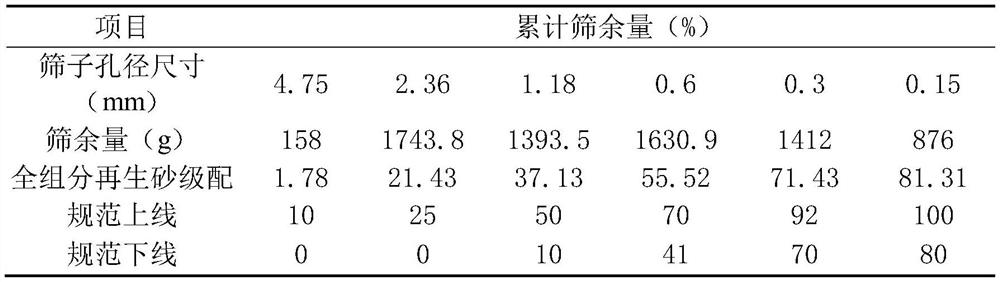

Method used

Image

Examples

preparation example Construction

[0046] A preparation method of corncob-made recycled concrete mine filling material, characterized in that, comprising:

[0047] (1) Mix the cement and the reclaimed sand evenly;

[0048] (2) adding water again and stirring to form mortar;

[0049] (3) Finally, pour in the corncob particles while compacting and stirring. After the corncob is completely wrapped by the mortar, the mixture that is segregated and precipitated at the bottom is turned over with the corncob particles, and stirred again for 1-2 minutes to obtain a recycled concrete mine. Filling material; wherein, the recycled concrete mine filling material is composed of the following raw materials by weight: 25 parts of cement, 30-50 parts of water, 55-85 parts of recycled sand, and 5.5-8 parts of corncob particles; The volume ratio of concrete mine filling materials is 44.4%-54.6%.

[0050] In some embodiments, the stirring in step (1)-step (3) is to use a horizontal mixer to stir, and when a horizontal mixer is ...

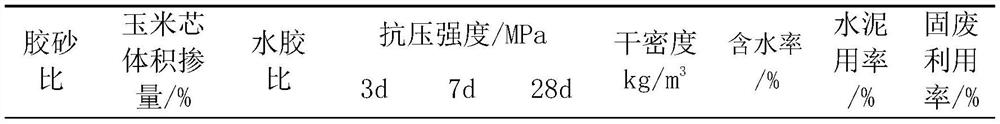

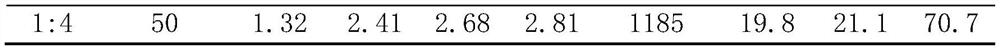

Embodiment 1

[0059] The recycled concrete mine filling material of the present embodiment is composed of the following raw materials by weight: 25 parts of cement, 30 parts of water, 55 parts of recycled sand, and 5.5 parts of corncob particles.

Embodiment 2

[0061] The recycled concrete mine filling material of the present embodiment is composed of the following raw materials by weight: 25 parts of cement, 50 parts of water, 85 parts of recycled sand, and 8 parts of corncob particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com