Method for processing municipal solid waste by using shaft kiln cement production line

A technology of municipal solid waste and solid waste, which is applied in the field of municipal solid waste treatment by shaft kiln cement production line, can solve the problems of ineffective utilization, long transportation distance, large investment, etc., and achieve low cost of waste treatment and investment in equipment transformation The effect of less and thorough garbage disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

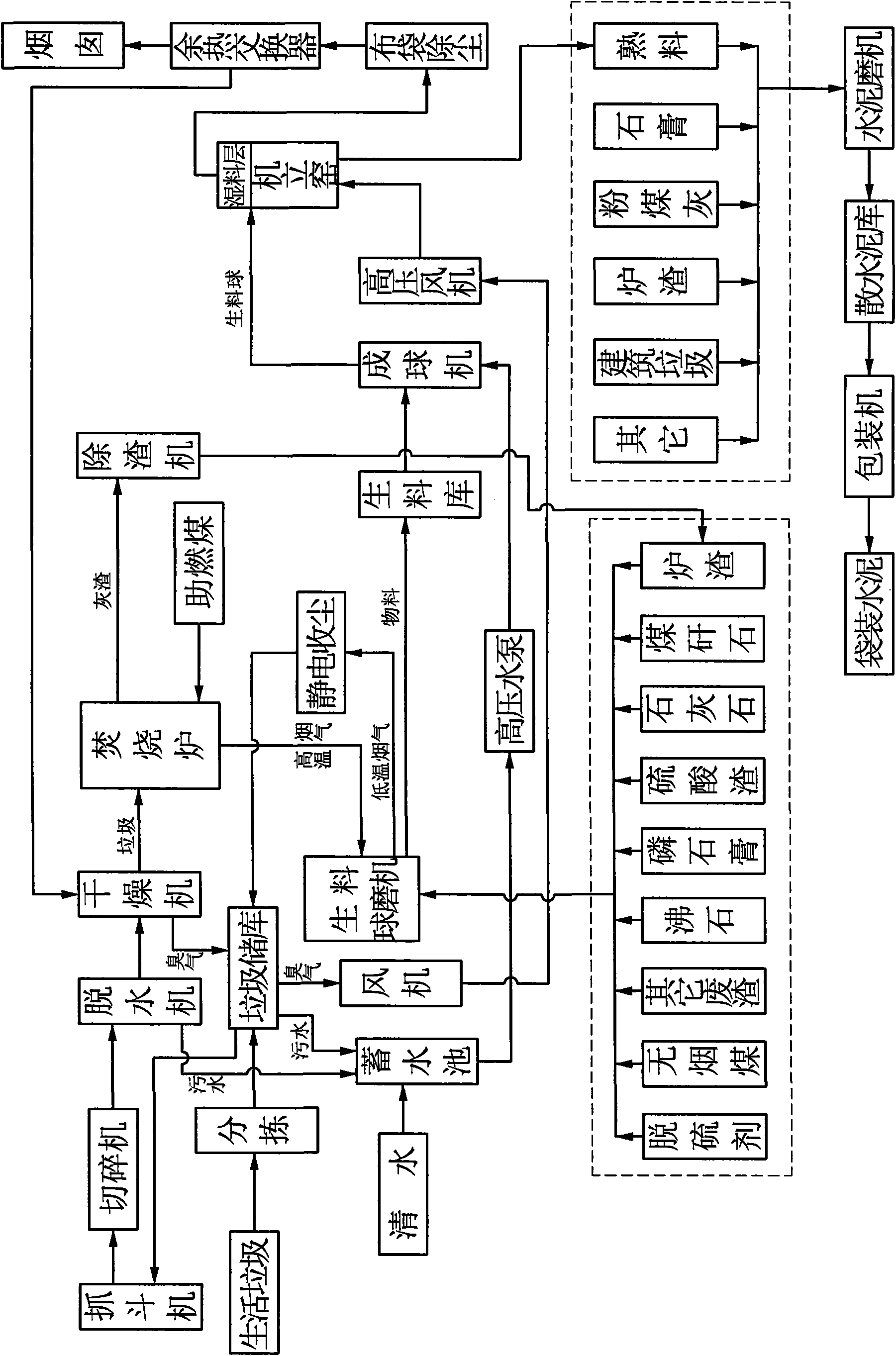

[0008] As shown in the accompanying drawing, the method for utilizing the vertical kiln cement production line of the present embodiment to process municipal solid waste is to carry out according to the following steps: (1), after the domestic solid waste is sorted by the staff of the property community, the rubbish without recycling value is collected by Garbage extrusion trucks collect and transfer to the garbage storage in the cement plant in a unified manner; (2) After the domestic garbage in the garbage storage is chopped, it is sent to the extrusion dehydrator for dehydration, and the discharged garbage leach is mixed with clean water and sent to The raw material ball machine and the raw material are mixed into balls and then enter the kiln for calcination; (3) The dehydrated domestic garbage is sent to the drum dryer for hot air drying, and the dried tail gas is sent to the garbage storage, and then sent to the High-temperature calcination in the kiln eliminates odor and...

Embodiment approach 2

[0014] The difference between this embodiment and the first embodiment is that the clear water mixed with the garbage leach in step (2) is 200 times of the garbage leach.

Embodiment approach 3

[0016] The difference between this embodiment and the first embodiment is that the clear water mixed with the garbage leach in step (2) is 300 times of the garbage leach.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com