Microbial coal gangue/coal slime building material and manufacturing method thereof

A coal gangue and microbial technology, applied in the field of microbial coal gangue/coal slime building materials and its manufacturing, achieves high solid waste utilization rate, significant environmental and social benefits, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

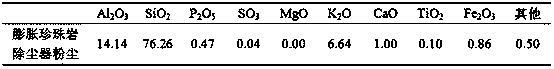

[0025] Microbial gangue concrete can be made from raw materials in the following weight fraction ranges: 50-80 parts of coal gangue, 5-30 parts of steel slag, 5-50 parts of waste incineration fly ash, 2-10 parts of silicon micropowder, 10-20 parts of slaked lime, Expanded perlite dust collector dust 5~50 parts, bacteria liquid 10~40 parts, EVA emulsion 2~4 parts, silane coupling agent 0.1~0.5 parts, water reducer 0.2~0.5 parts.

[0026] The microbial coal gangue concrete described in the present embodiment is prepared according to the following raw material parts by weight:

[0027] 80 parts of coal gangue, 5 parts of steel slag, 5 parts of waste incineration fly ash, 2 parts of silicon micropowder, 20 parts of slaked lime, 5 parts of expanded perlite dust collector dust, 30 parts of bacterial liquid, 2 parts of EVA emulsion, silane coupling agent KH560 0.1 part, 0.5 part of superplasticizer.

[0028] The bacterial liquid adopts the bacterial liquid obtained by screening, act...

Embodiment 2

[0032] The microbial gangue coal slime concrete described in the present embodiment is prepared according to the following raw material parts by weight:

[0033] 50 parts of coal gangue, 30 parts of coal slime, 10 parts of steel slag, 15 parts of waste incineration fly ash, 10 parts of silicon micropowder, 20 parts of slaked lime, 20 parts of expanded perlite dust collector, 40 parts of bacterial liquid, 4 parts of EVA emulsion, silane 0.1 parts of coupling agent KH560, 0.5 parts of water reducer.

[0034] The bacterial liquid adopts the bacterial liquid obtained by screening, activating and culturing the microbial KJ01 strain.

[0035] The preparation method of microbial coal gangue slime concrete: (1), crush the coal gangue to coal gangue particles with a particle size of 0.15 mm to 1 mm for later use; (2), dry the coal slime and pass it through a 100-mesh sieve for later use; (3 ), mix coal gangue, coal slime, steel slag, waste incineration fly ash, silicon micropowder, sl...

Embodiment 3

[0039] Microbial gangue blocks can be made from the following raw materials in weight fractions: 50-80 parts of coal gangue, 5-30 parts of steel slag, 5-50 parts of waste incineration fly ash, 2-10 parts of silicon micropowder, 10-20 parts of slaked lime, 5~50 parts of expanded perlite dust collector dust, 10~40 parts of bacterial liquid, 2~4 parts of EVA emulsion, 0.1~0.5 parts of silane coupling agent.

[0040] The microbial coal gangue block described in the present embodiment is prepared by the following raw material parts by weight:

[0041] 80 parts of coal gangue, 30 parts of steel slag, 5 parts of waste incineration fly ash, 10 parts of silicon micropowder, 20 parts of slaked lime, 5 parts of expanded perlite dust collector dust, 20 parts of bacterial liquid, 4 parts of EVA emulsion, silane coupling agent KH560 0.1 share.

[0042] The bacterial liquid adopts the bacterial liquid obtained by screening, activating and culturing the microbial KJ01 strain.

[0043] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com