Beneficiation method for producing blast furnace lump ore by hematite at medium-high grade

A beneficiation method and iron ore technology, which is applied in the beneficiation of medium and high-grade hematite ore, and in the field of blast furnace lump ore, can solve the problems of inability to obtain high-grade hematite ore, and achieve the effect of comprehensive utilization of large quantities and significant emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

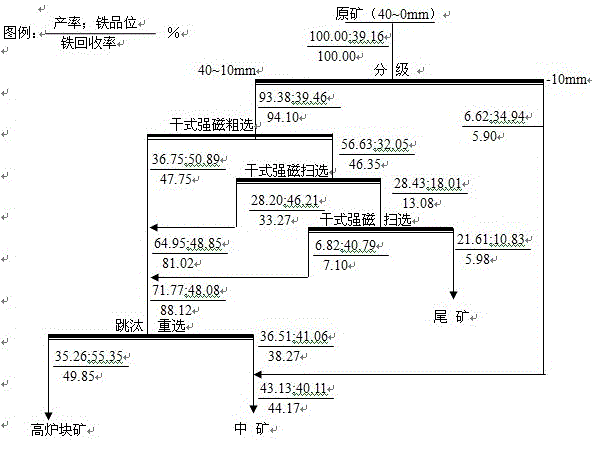

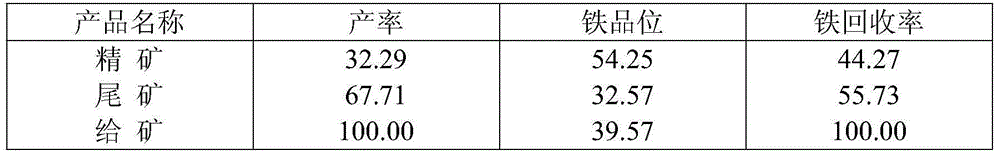

[0015] In order to further describe the present invention, a kind of beneficiation method of utilizing middle and high-grade hematite ore to produce blast furnace lump ore of the present invention will be further described below in conjunction with accompanying drawings and examples.

[0016] The ore processed in this embodiment is the actual ore produced in the stope of Hainan Mining Co., Ltd., and the iron grade of the raw ore is 39.16%.

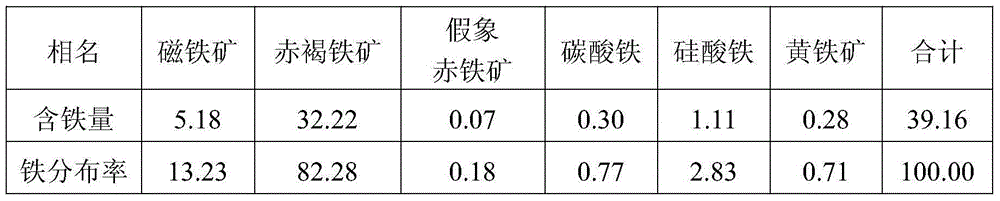

[0017] Multi-element analysis and iron phase analysis were carried out on the raw ore, and the results are shown in Table 1 and Table 2.

[0018] The analysis results show that the main useful mineral in the ore is hematite, followed by magnetite, the content of iron carbonate, iron silicate and pyrite is relatively low, and the iron of hematite accounts for 82.28%. The sulfur content of harmful impurities is 0.117%, and the phosphorus content is low, (CaO+MgO) / (SiO 2 +Al 2 o 3 )=0.176, it is an acidic ore.

[0019] Table 1 raw ore mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com