Patents

Literature

133results about How to "Emission reduction effect is obvious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

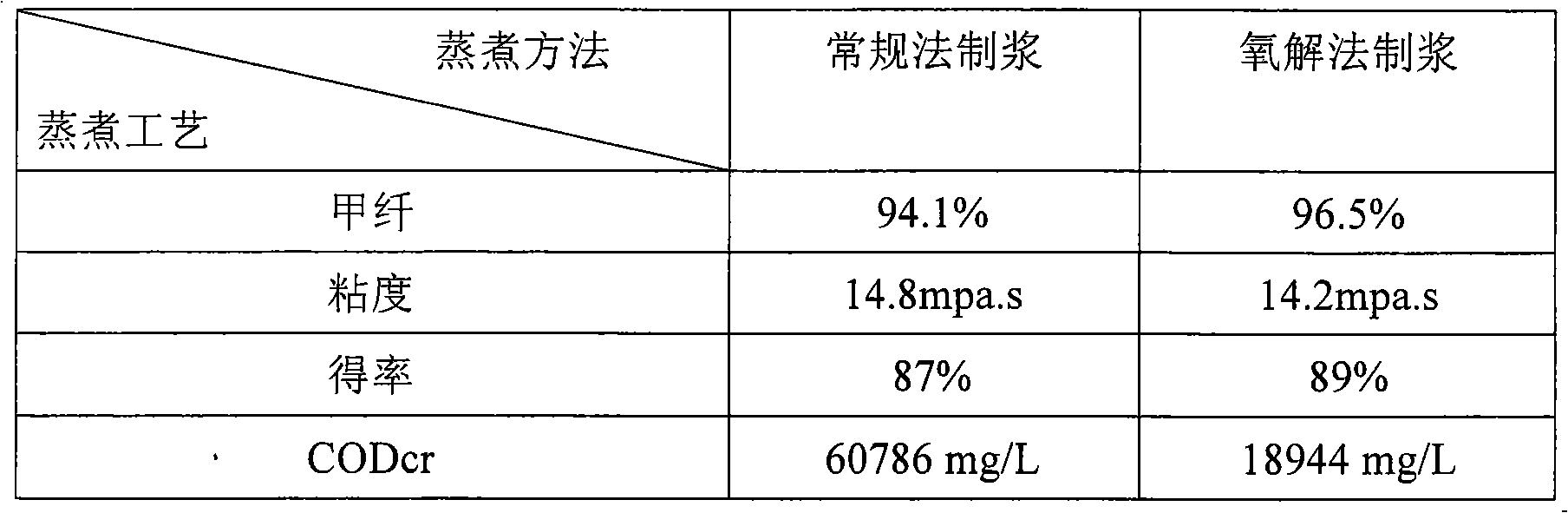

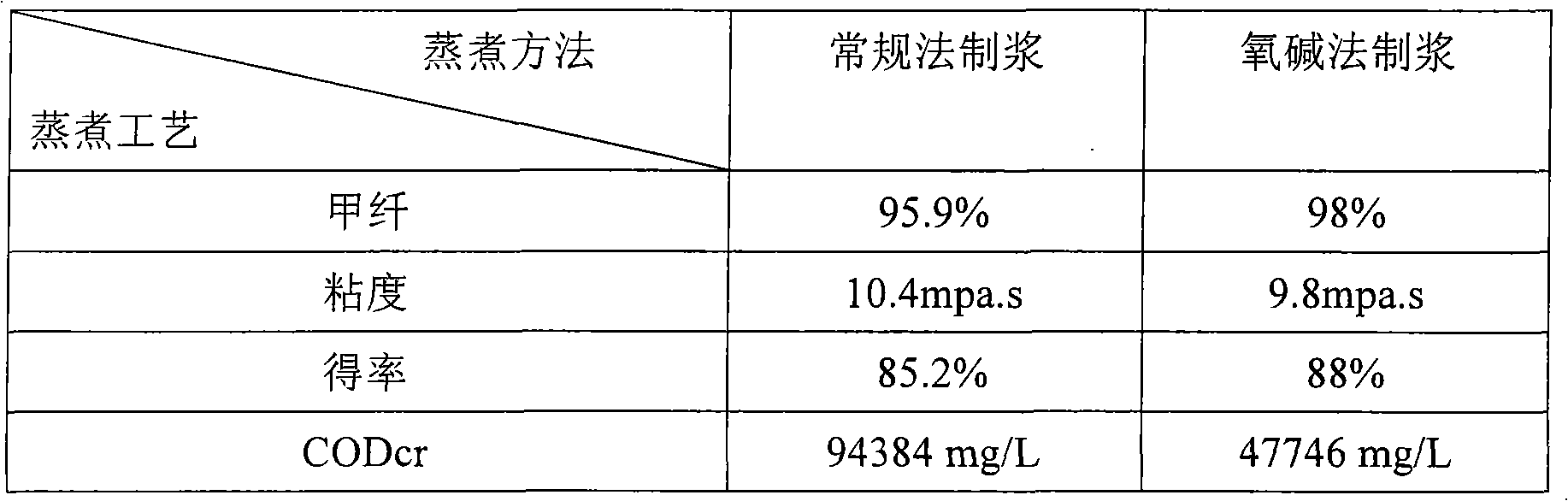

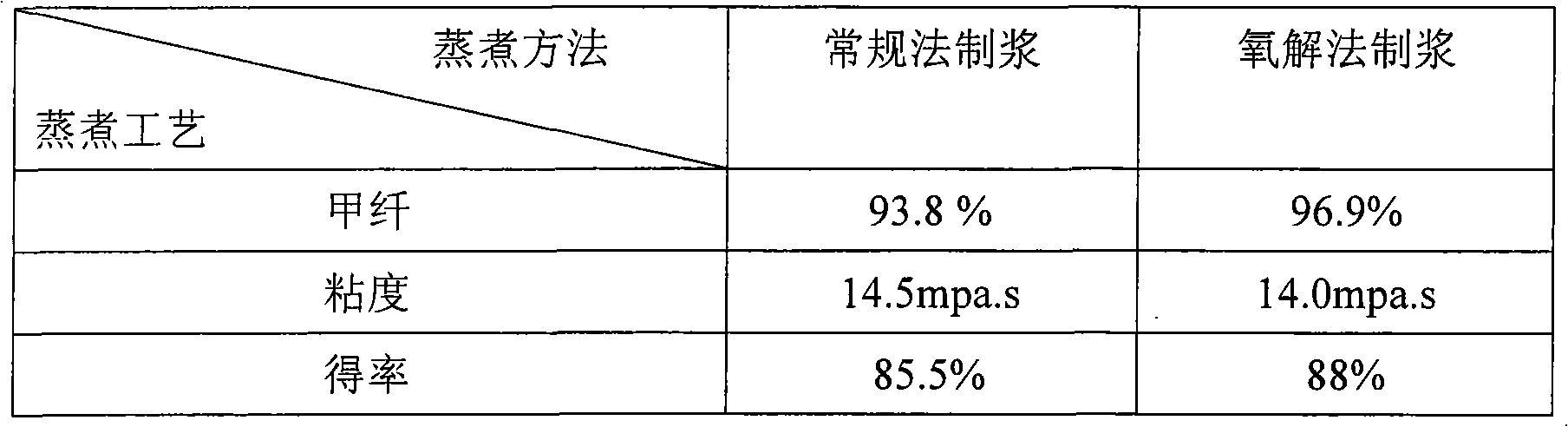

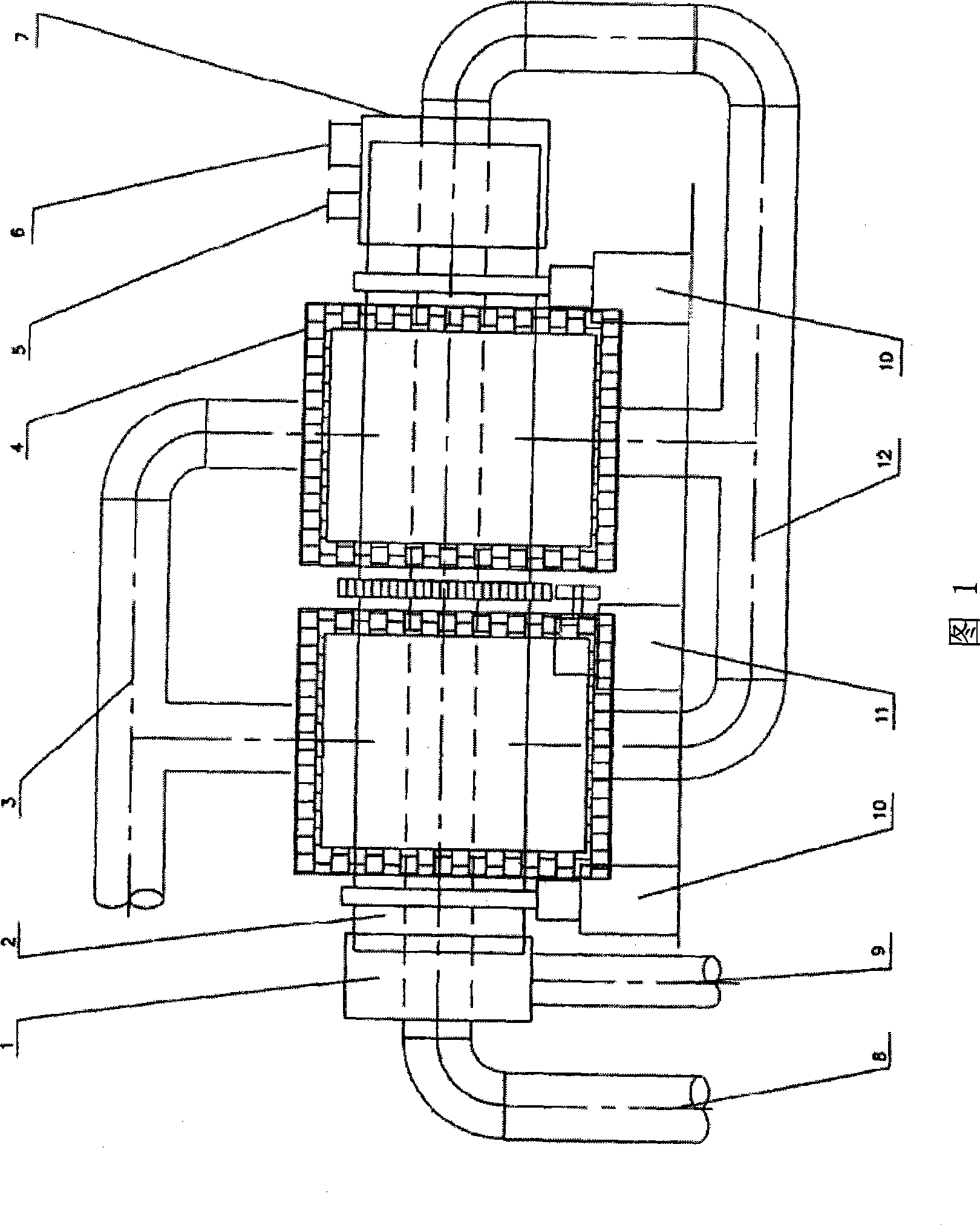

Process for preparing dissolved pulp by oxidative decomposition of paper pulp

InactiveCN101289761AReduce pollutionEmission reduction effect is obviousPulping with inorganic basesVegetable materialPollutantDecomposition

The invention discloses a method for preparing dissolving pulp through oxide degradation of pulp by adoption of the oxide degradation method so as to solve the problems in the prior dissolving pulp preparation technique of severe pollution, low yield, long period, resource shortage and so on. The method for preparing the dissolving pulp through oxide degradation of the pulp comprises the following processing steps of: alkalizing purification, squeezing preparation of alkali cellulose, oxygenization, and continuous oxide degradation and depolymerization. By adoption of the method, the production speed can be improved; the product quality can be improved; the steam consumption can be saved; and the generation of pollutants can be reduced.

Owner:宜宾长毅浆粕有限责任公司

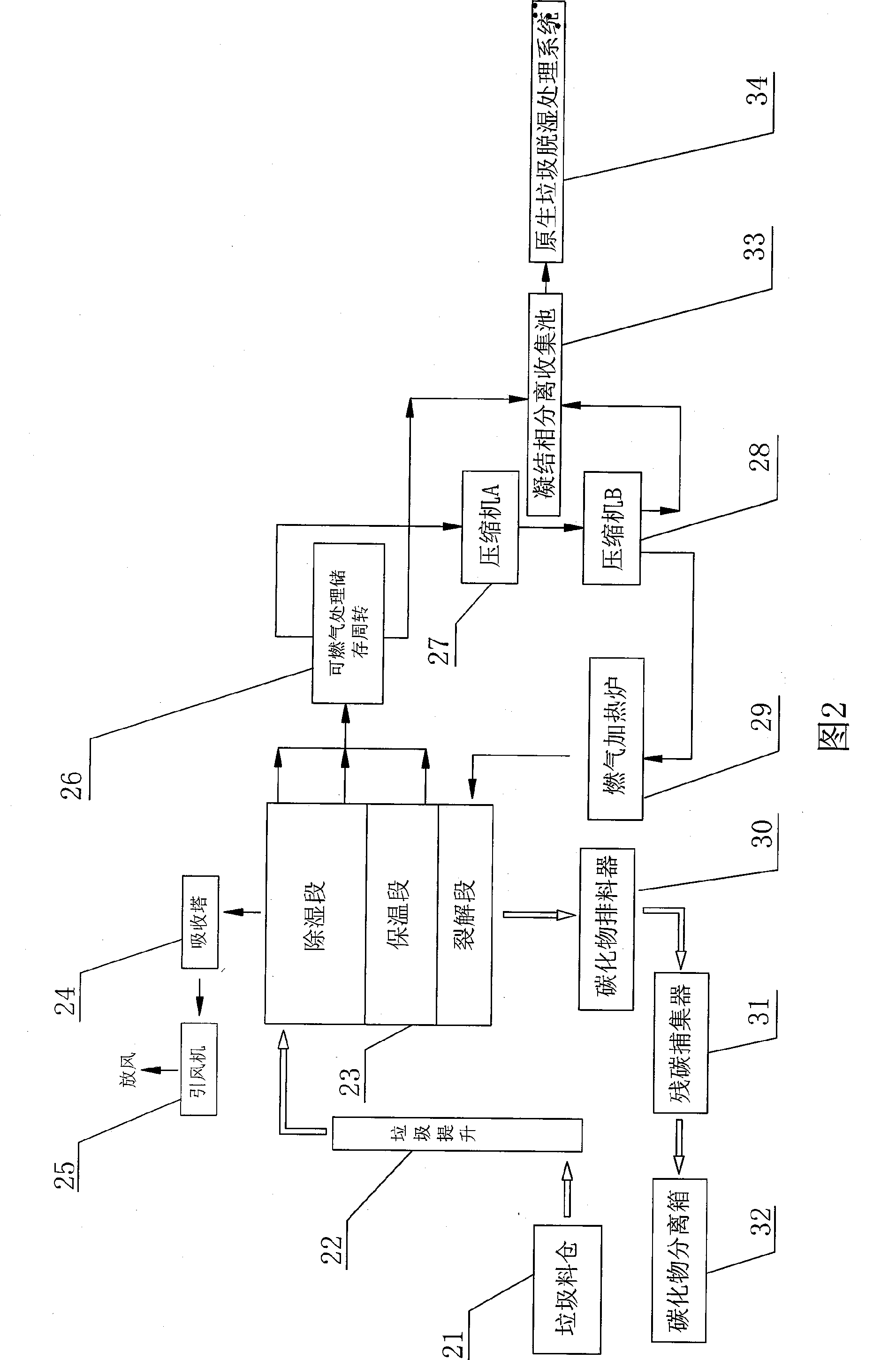

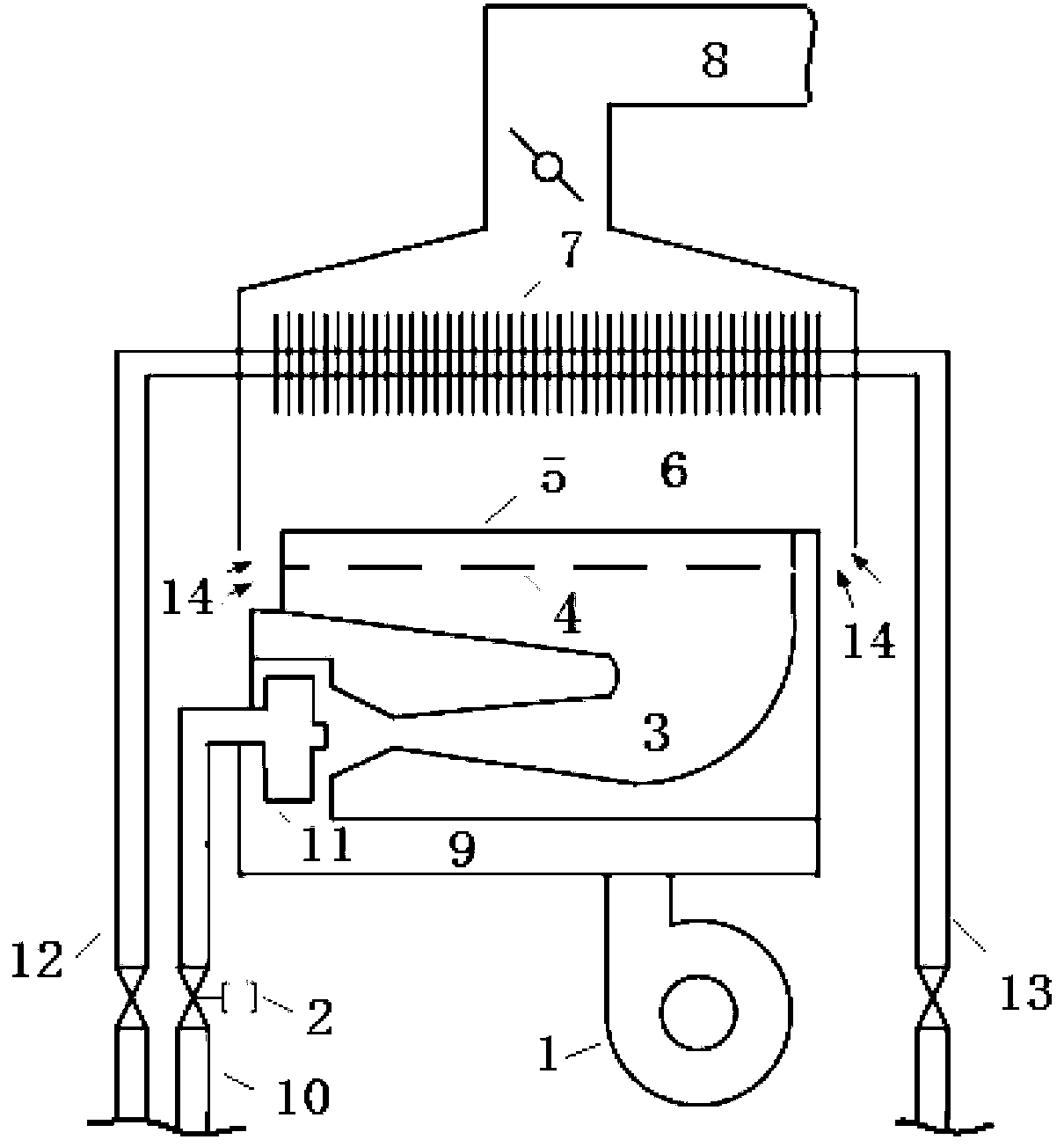

No-oxygen pyrolysis gasification processing device of urban domestic garbage and technique thereof

The present invention discloses a city domestic rubbish anaerobic schizolysis gasification processing apparatus and technical skill thereof, wherein the apparatus is composed by a rubbish storage hopper, a converting kiln, a compressor, an organic matter converting kiln and a sewage disposal system etc. The technical skill includes no exogenous source low energy consumption dispose and system secondary pollution control technique etc. Technical problems like system oxygen exhaust technology, domestic rubbish dehumidifying technology, flowing technology of solid material inside the system, heating technology during the process etc. are solved through the invention. Harmlessness and zero discharge, energy self-supply and basic energy source and substance recirculation in the process of production, social low cost input and facilitating operation of rubbish treatment, and every saving, exhaust reducing and material cycle in natural world can be realized.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

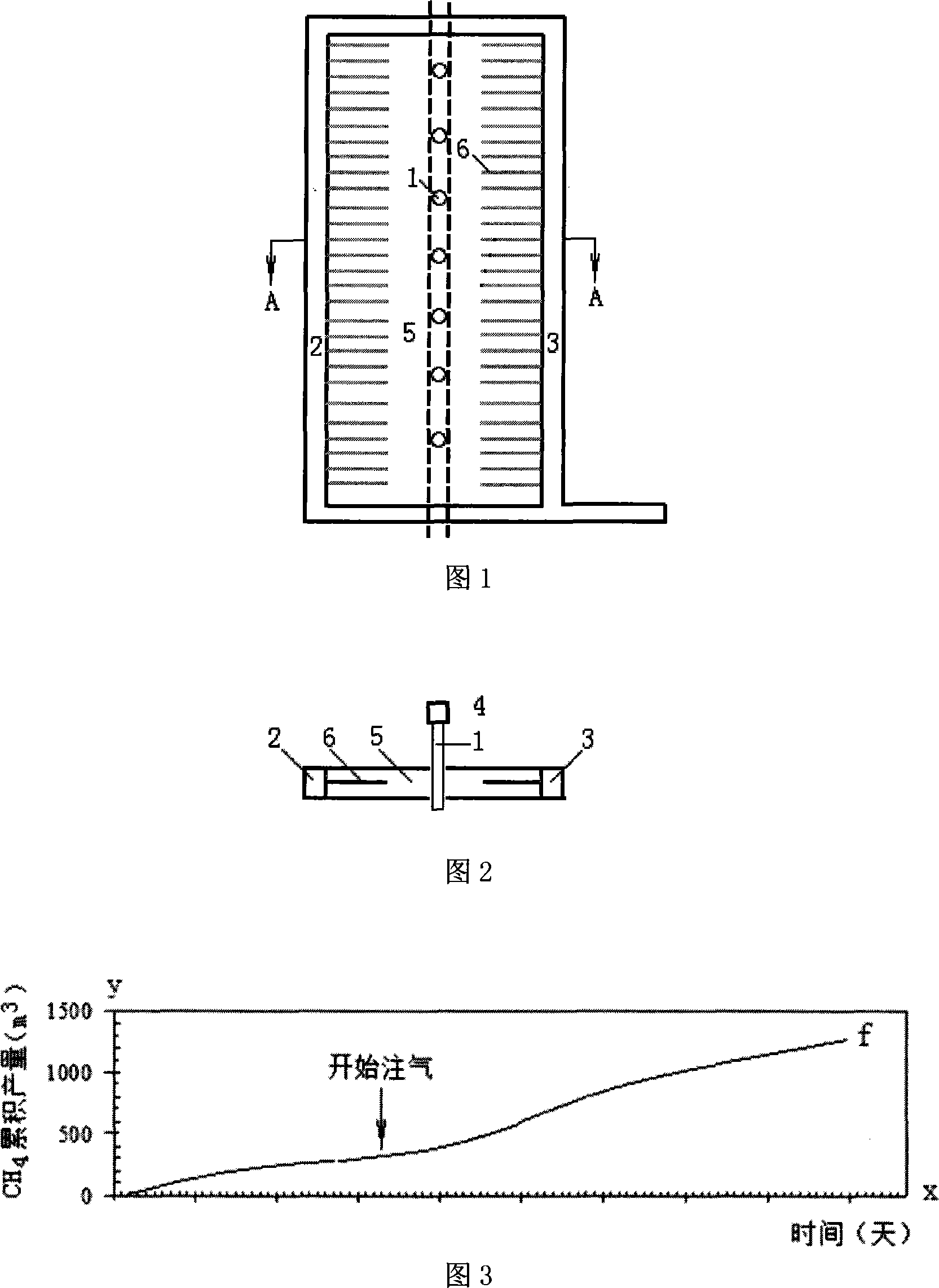

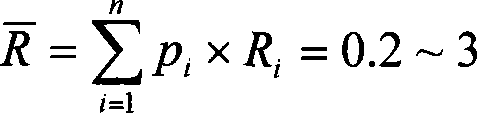

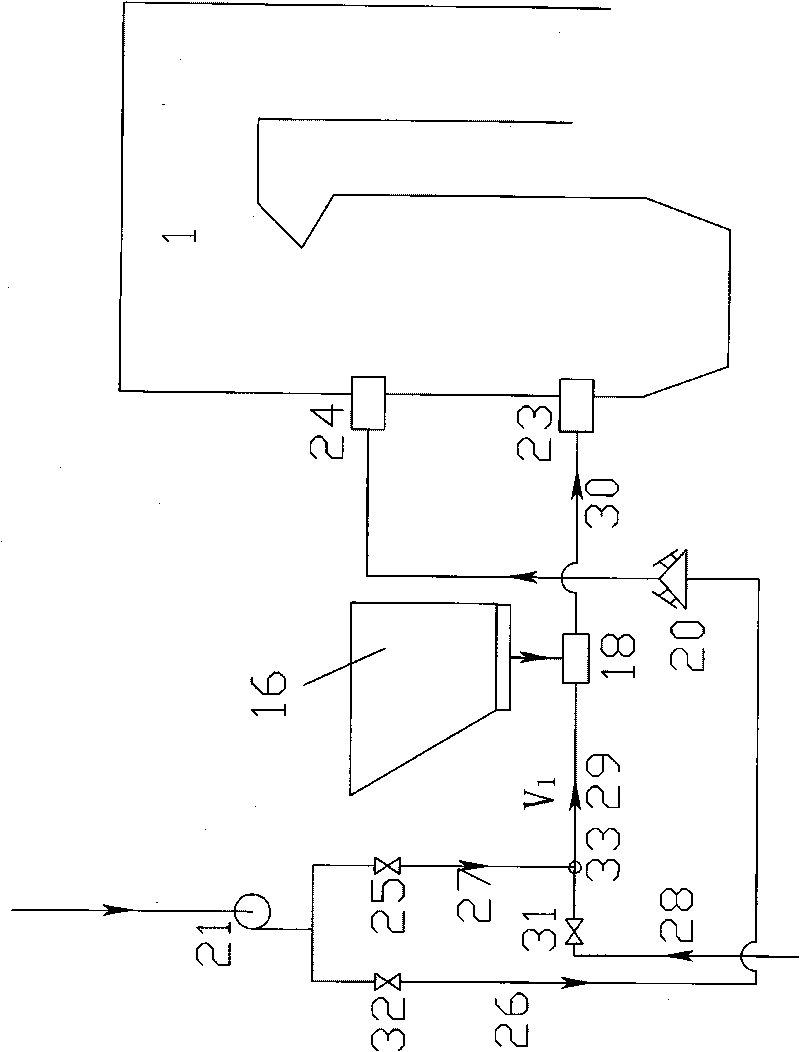

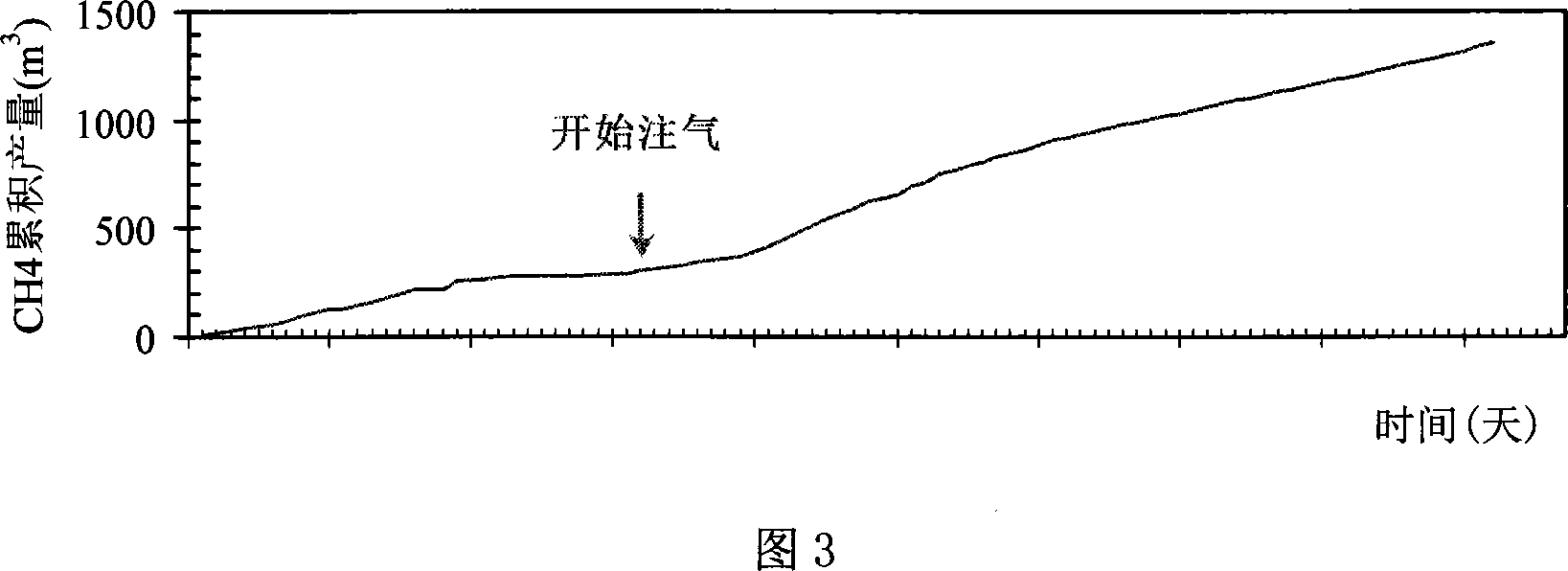

Down-hole pump drainage laneway exploitation system for mixing gas dispelling coal gas, and the method

InactiveCN101122217AImprove the security environmentReduce the impactFluid removalGas removalProduct gasHigh pressure

The invention discloses a system and a method for exploitation of mixed-gas coal-bed methane exploitation in a drainage roadway in an oil well, and relates to a coal-bed methane exploitation technology. The exploitation method comprises the following procedures: 1.various gases are integrated into a mixed gas; the mixed gas comprises a or a plurality of strongly exchanged gases, which comprises H2S, SO2 and CO2; the mixed gas also comprises a or a plurality of weakly exchanged gases, which comprises N2, H2 and He; 2. the mixed gas is injected into a coal bed (5) through an injection hole (1) with high pressure; 3. gas comprising the coal-bed methane is obtained from an drainage hole (6) with a drainage device, until the methane content is lower than the economic exploitation content and safety content. The invention promotes the exploitation rate and unit output of the coal-bed methane, and produces quite an obvious effect in reducing the greenhouse gas emission. Meanwhile, the invention is provided with the effect of reducing the outstanding risks of gas, and is applicable in the low-penetration exploitable coal-bed methane exploitation field.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

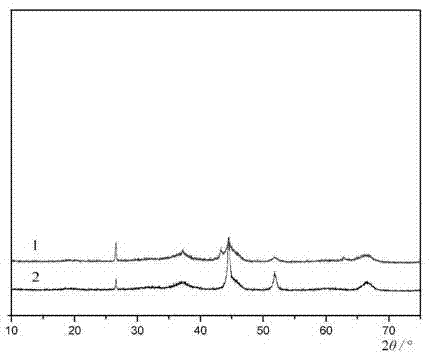

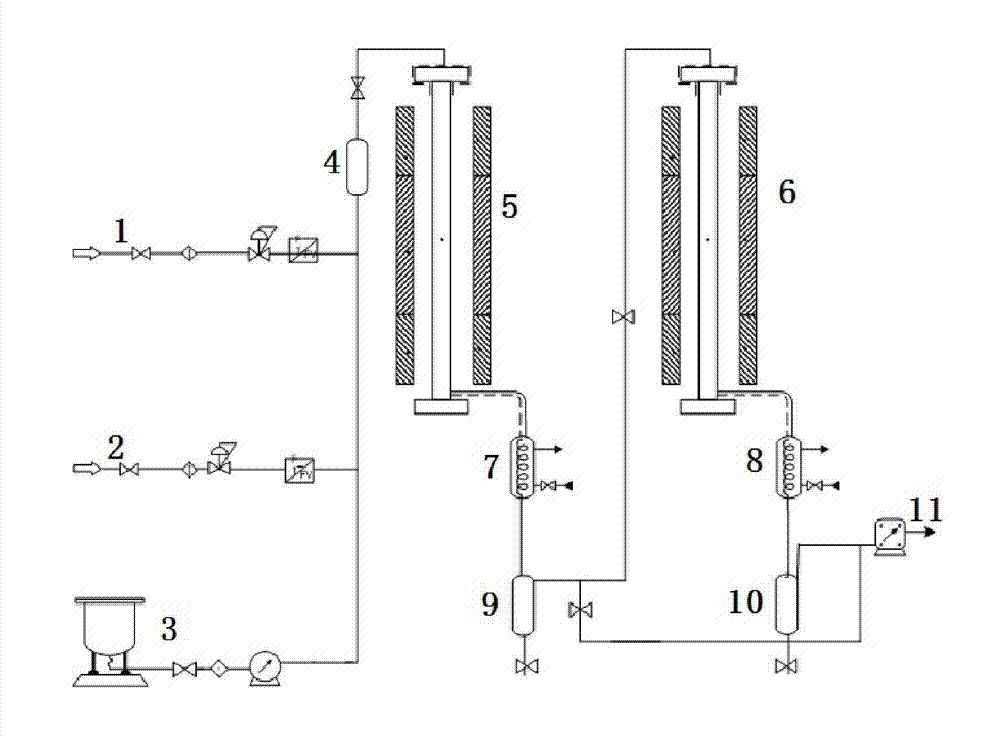

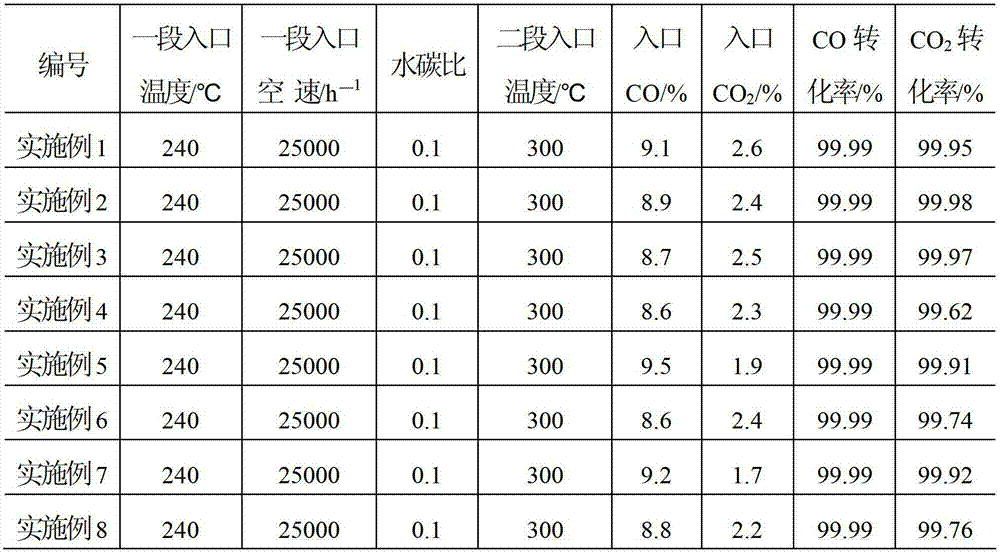

Methanation catalyst for synthesizing substitute natural gas and preparation method thereof

ActiveCN103191749ASimple structureImprove stabilityCatalyst carriersGaseous fuelsMethanationSpace velocity

The invention relates to a methanation catalyst for synthesizing substitute natural gas and a preparation method thereof. The methanation catalyst comprises Al2o3, MgO, NiO, La2O3, TiO2, CeO2 or ZrO2 and the mixture thereof. Compared with the existing methanation catalyst, the methanation catalyst prepared by using the method disclosed by the invention has high conversion ratio, great space velocity, high activity and good thermostability, so that the methanation catalyst and the preparation method thereof are suitable for the adiabatic non-circulation process and the adiabatic cycle process for synthesizing the substitute natural gas through the tail gas in hydrocarbon industries.

Owner:XIAN ORIGIN CHEM TECH

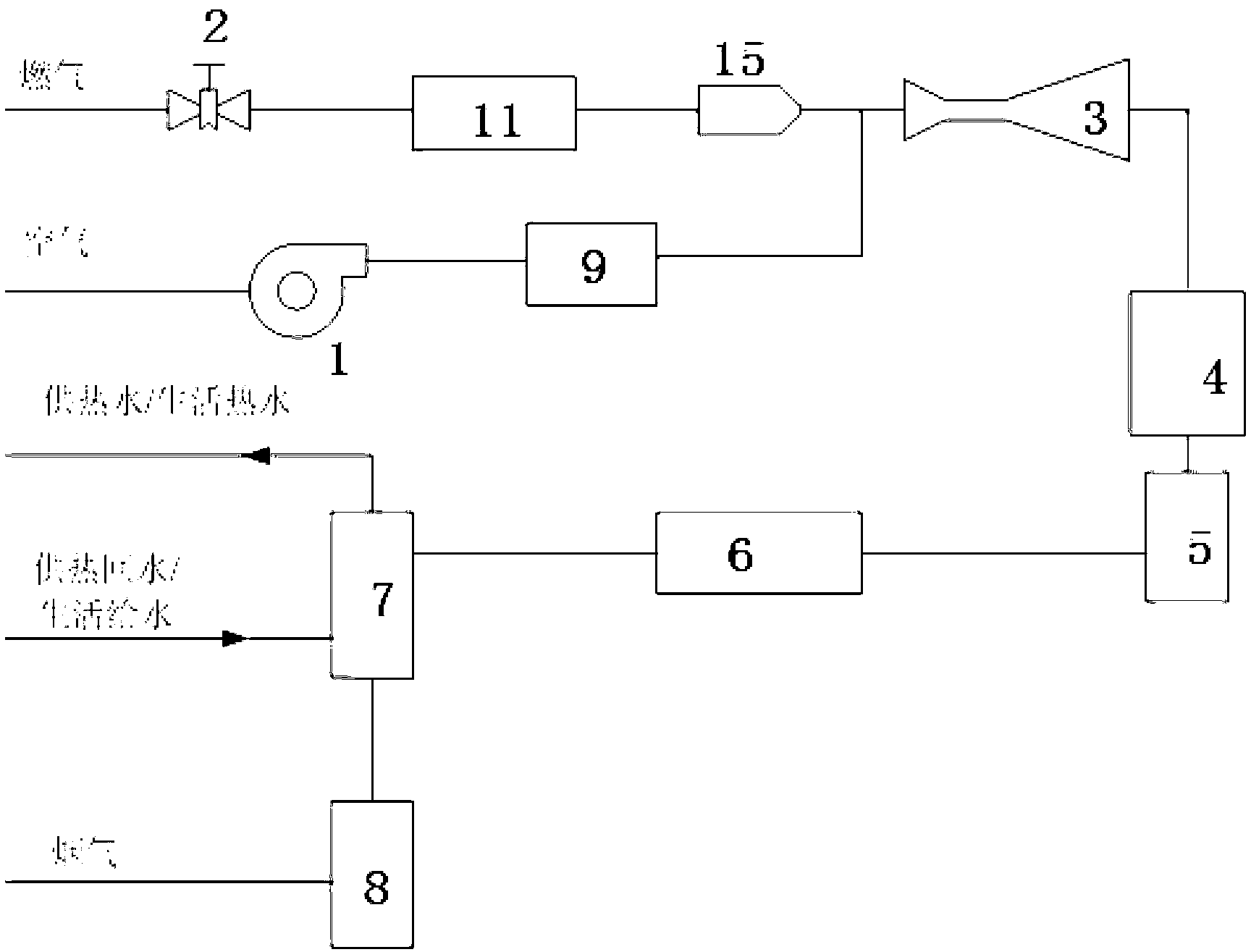

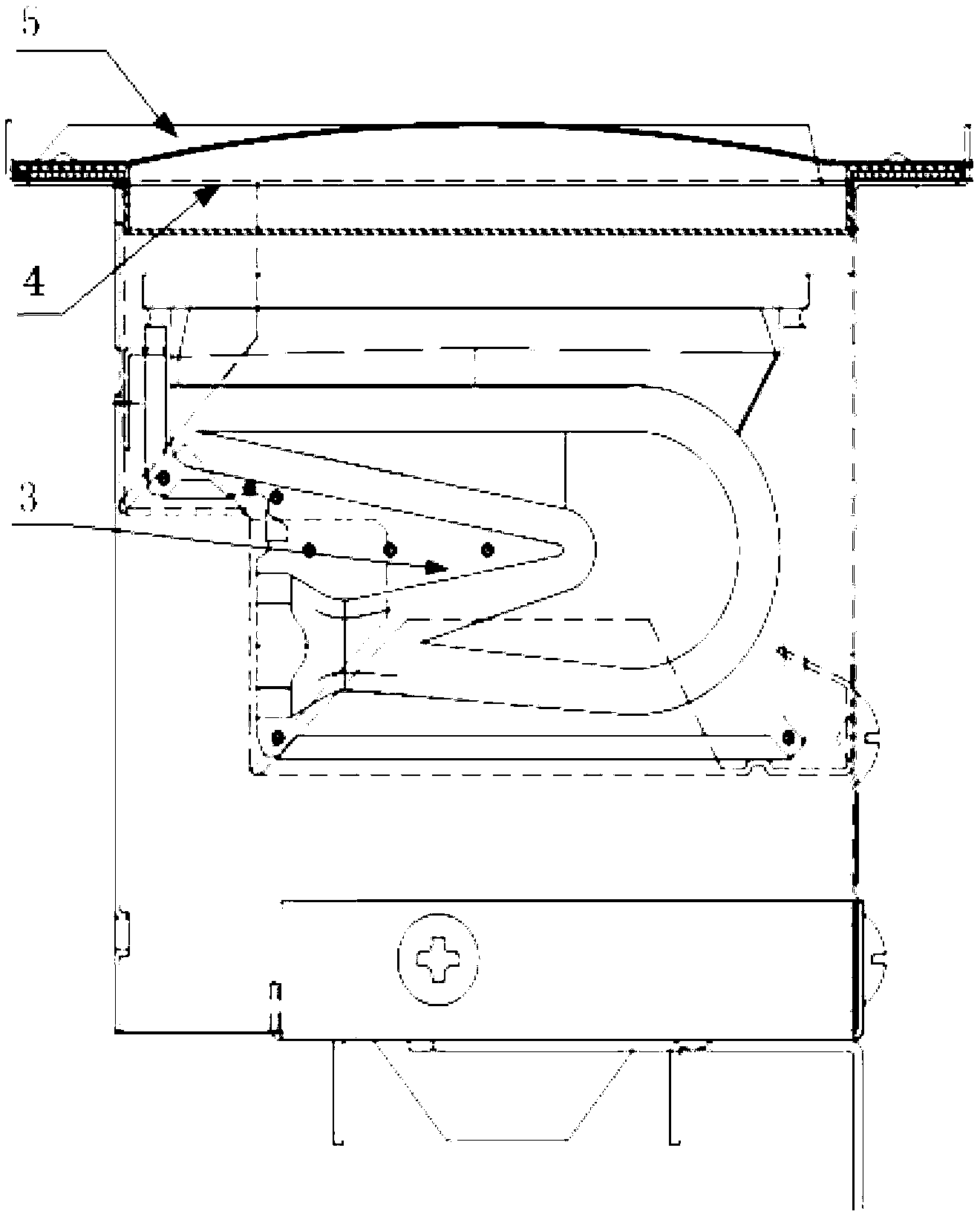

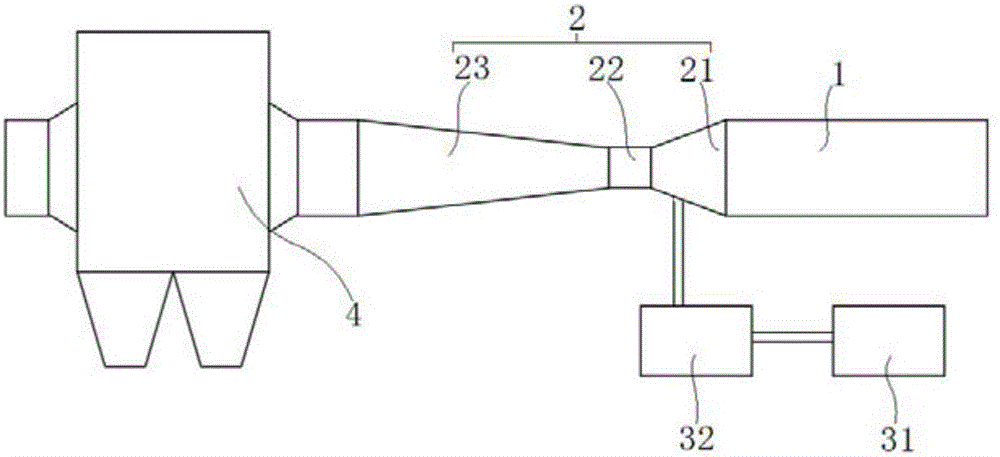

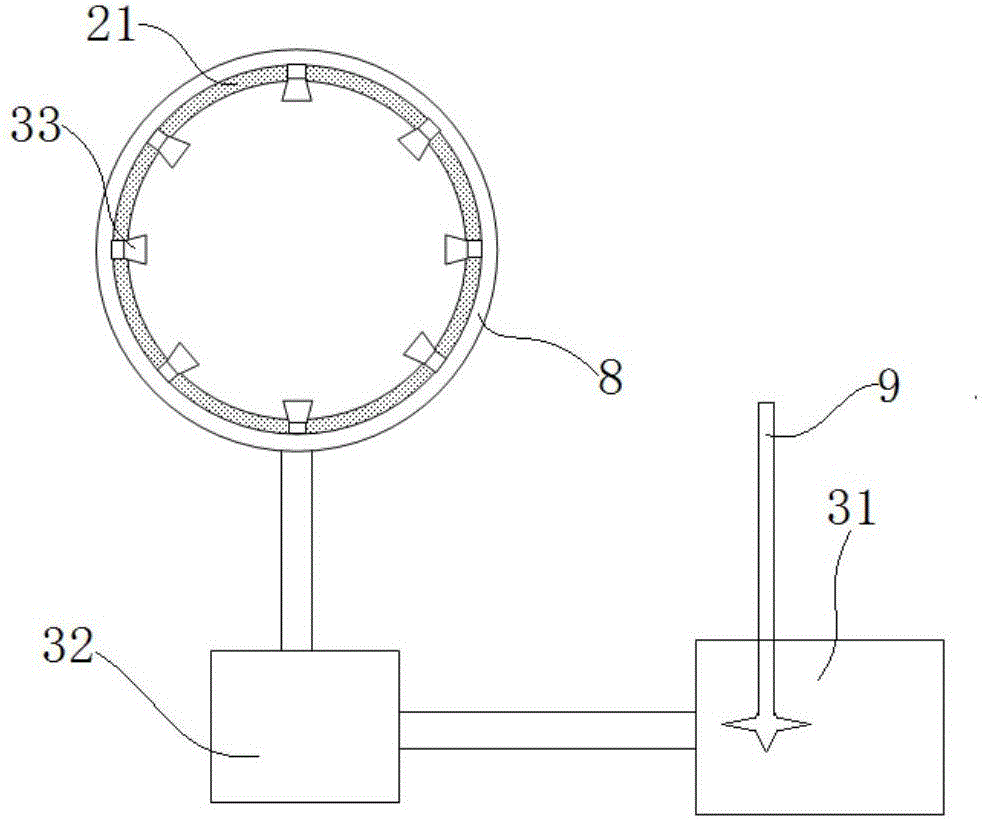

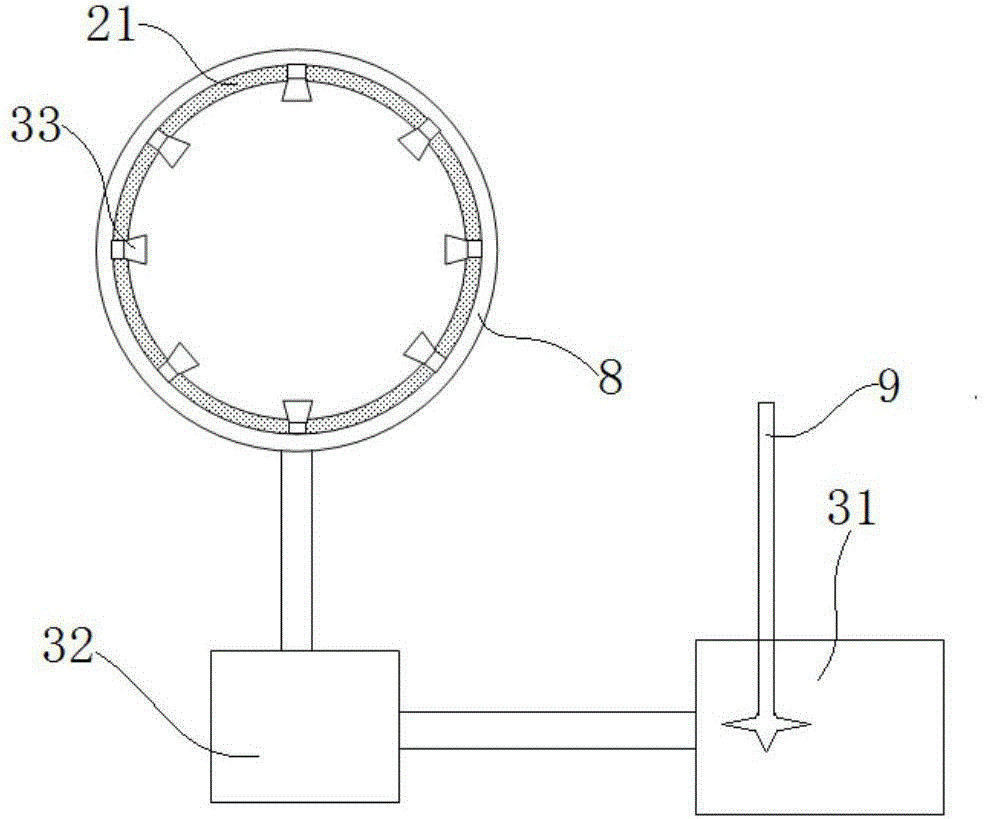

Positive-pressure-injecting type fully-premixed combustion heating device

InactiveCN103196218AEmission reduction effect is obviousEmission reductionWater heatersGaseous fuel burnerPositive pressureSafety control

The invention discloses a positive-pressure-injecting type fully-premixed combustion heating device comprising an air supply system, a fuel system, a combustor, a heat exchange system and a smoke exhausting system. The air supply system comprises a fan and an air distributing tube connected with an air supply port of the fan. The fuel system comprises a gas tube and a gas distributing tube connected with the gas tube. A group of gas nozzles are evenly arranged at the end of the gas distributing tube. Annular air inlet ports communicated with the air distributing tube are arranged on the peripheries of the gas nozzles. An injecting type mixer is arranged oppositely to the gas nozzles. A distributing hole plate and a fire hole plate are arranged at the top of the injecting type mixer from bottom to top. The combustor is arranged above the injecting type mixer, and an annular hole is arranged between the side wall of the combustor and the outer contour of the fire hole plate. The positive-pressure-injecting type fully-premixed combustion heating device is compact in structure, and safety control on the whole system is facilitated; gas and air are fully mixed during operation of the heating device, so that emission loads of carbon monoxide and nitric oxide in combustion products are low, and fully-premixed combustion of the gas and the air and low-pollutant emission during gas combustion are realized.

Owner:TIANJIN URBAN CONSTR COLLEGE

Preparation method of light calcium-alginate-base sponge body functional material

The invention discloses a preparation method of a light calcium-alginate-base sponge body functional material. The preparation method comprises the following steps: in room temperature, evenly mixing sodium alginate powder with soluble calcium salt, magnesium salt or aluminum salt, a reinforcing agent, peroxide and a catalyst to obtain a mixture; moistening with an alcohol-water solution to form paste; rolling by molding equipment to form a film material or a plate material; and then sequentially performing infiltration, complexation for pore formation, and expansion for pore formation. The preparation method has the characteristics of simple technology, low control difficulty, low equipment investment, energy-saving effect, low production cost and the like and is applicable to large-scaled industrial production; the prepared light calcium-alginate-base sponge body functional material is the same in structure and composition regardless of interior or exterior, good in quality, light in weight, high in mechanical strength, and excellent in imbibition performance and air permeability, and can be widely applicable to the fields of antibacterial materials, flame-resistant materials, adsorbing materials, acoustic materials, vibration-absorptive materials and the like; the market prospect is extensive.

Owner:QINGDAO UNIV

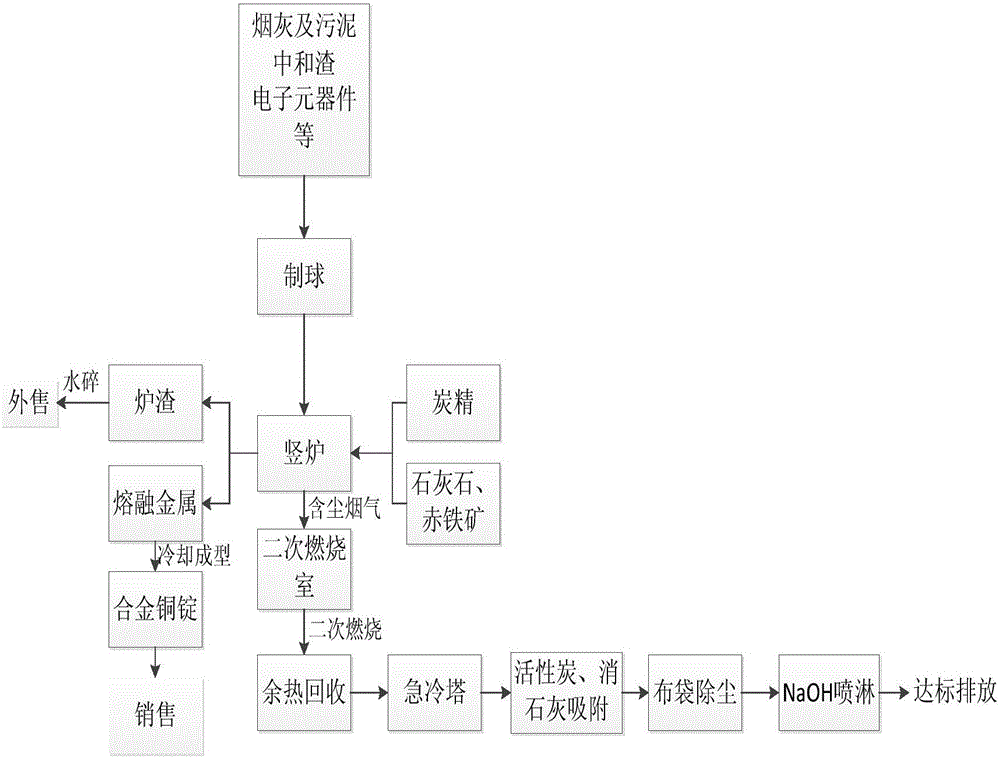

Cooperative treatment technology for copper-containing electronic wastes

InactiveCN105782986AEmission reduction effect is obviousReduce consumptionIncinerator apparatusSlagSludge

The invention discloses a cooperative treatment technology for copper-containing electronic wastes. In the technology, soot sludge, neutral dregs and electronic parts and components are treated by a pyrogenic-process shaft furnace smelting technology, and perfect environmental protection systems including waste heat utilization, smoke treatment and the like are used in an assisted manner. The cooperative treatment technology for the copper-containing electronic wastes specifically comprises the following steps: pretreatment, smelting, secondary combustion, waste heat recovery, smoke treatment and the like. By the treatment technology, waste mixed electronic parts and components, circuit boards with parts and components, circuit boards with cloth bag parts and components, electroplating sludge and smelting soot can be cooperatively treated in batches; by the treatment technology, labor for treatment and disposal can be greatly reduced, and energy consumption is also reduced; and by the treatment technology disclosed by the invention, the emission reduction effect is quite obvious, smoke emission can reach the standard, valuable metals are recycled effectively, and generated furnace slag can be used for building materials.

Owner:JIANGSU UNIV OF TECH

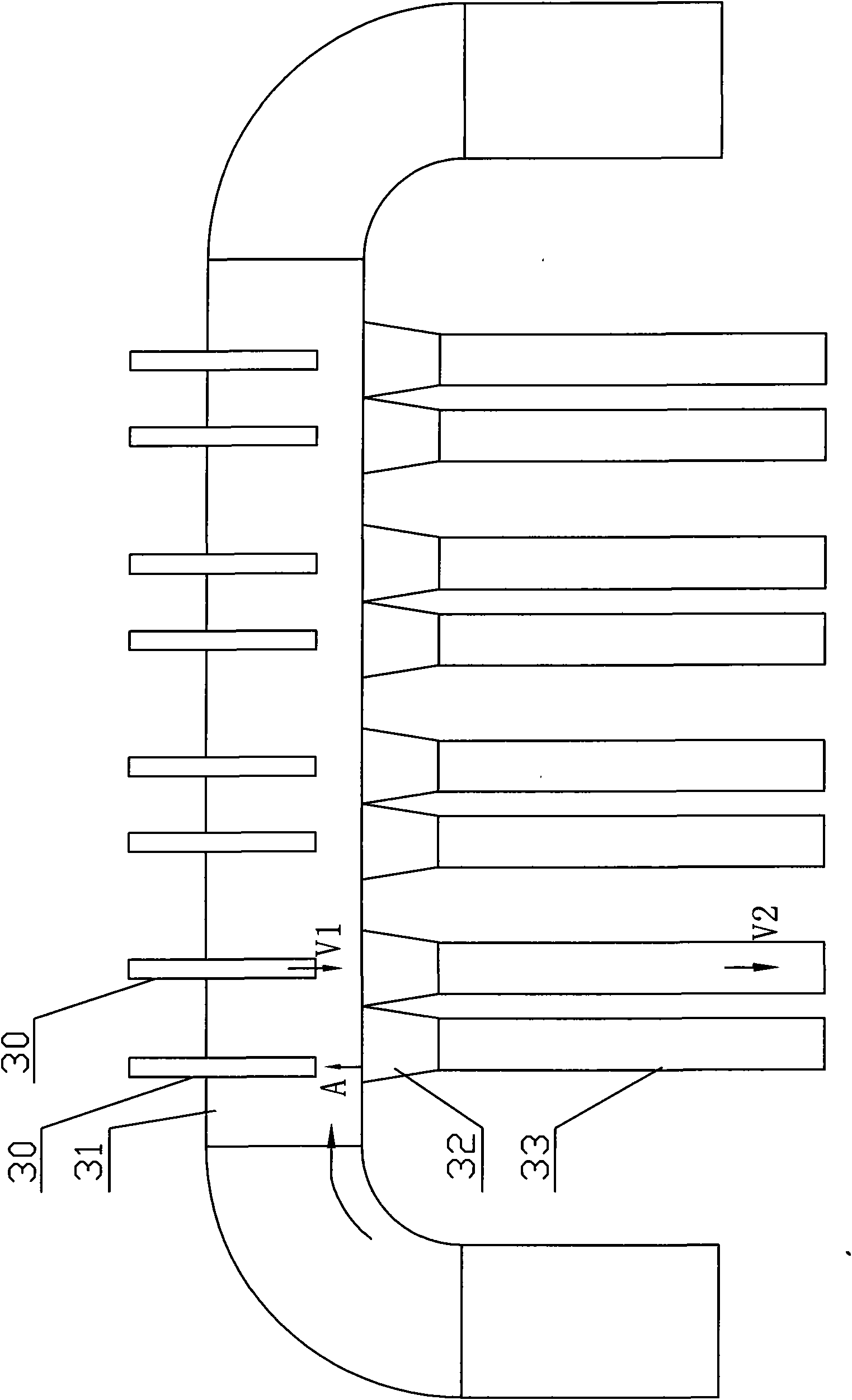

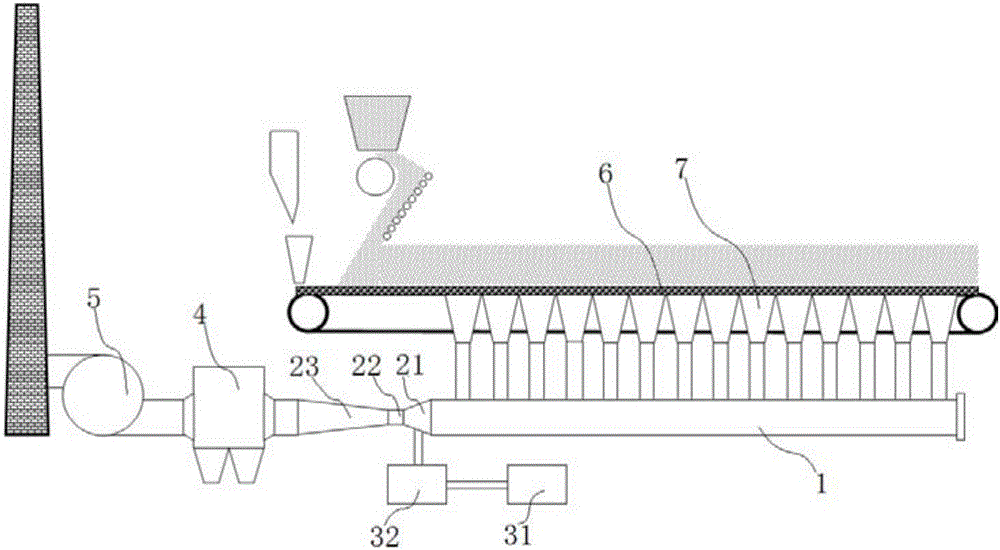

Exhaust gas and hot-blast air dual-medium powder feeding system

ActiveCN101725994ALower primary air temperaturePrevent slaggingLump/pulverulent fuel feeder/distributionAir volumeCombustor

The invention relates to a powder feeding system, in particular to an exhaust gas and hot-blast air dual-medium powder feeding system, which belongs to the technical field of coal-fired boilers. The powder feeding system solves the problems of high NOx discharge amount, easy scorification and the like which exist in the conventional hot-blast air powder feeding system boiler. One end of a tertiary air pipeline and one end of an exhaust gas pipeline are communicated with the output end of a mill exhauster; the other end of the tertiary air pipeline is communicated with a tertiary air nozzle on a boiler; an exhaust air bellow is arranged on the tertiary air pipeline; the outlet end of a hot-blast air pipeline and the other end of the exhaust gas pipeline are communicated with one end of a primary air pipeline; the other end of the primary air pipeline is communicated with an inlet of an air-powder mixer; and an outlet of the air-powder mixer is communicated with one end of a primary air powder feeding pipeline. The dual-medium powder feeding system can reduce the amount of air supplied to a main combustor area substantially; and the original tertiary air quantity of the main combustor area is supplied by a burn-out air nozzle of the upper part, so that the powder feeding system effectively ensures that the main combustor area operates under the condition of low excess air coefficients and the NOx production is reduced substantially.

Owner:HARBIN INST OF TECH

Method for inhibiting emission of fine particles in process of iron-ore sintering by agglomeration process

ActiveCN105797531AImprove reunion efficiencySpeed up the reunionAuxillary pretreatmentIron ore sinteringPollutant

The invention discloses a method for inhibiting emission of fine particles in the process of iron-ore sintering by an agglomeration process and belongs to the technical field of emission reduction of pollutants in the process of iron-ore sintering. The method comprises the following steps: (1) preparing agglomeration liquid, namely uniformly mixing components such as sodium carboxymethyl cellulose, polyacrylamide and an additive to obtain an agglomeration agent, and mixing the agglomeration agent and water to obtain the agglomeration liquid; (2) agglomerating fine particles, namely spraying the agglomeration liquid into flue gas to cause fine particles in the sintering flue gas to be agglomerated to grow larger under the action of the agglomeration liquid; and (3) trapping by a dust removing device, namely trapping and removing the fine particles agglomerated to grow larger by the dust removing device. The method disclosed by the invention has the advantages that agglomeration liquid droplets adsorbing the fine particles are nucleated and collide with each other and grow to form large-particle agglomerates under the condition of low pressure, and a dust-removing device is adopted to remove the fine particles agglomerated to be larger, so that an all-new emission-reducing path is provided for reducing the emission of fine particles in the process of iron-ore sintering.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

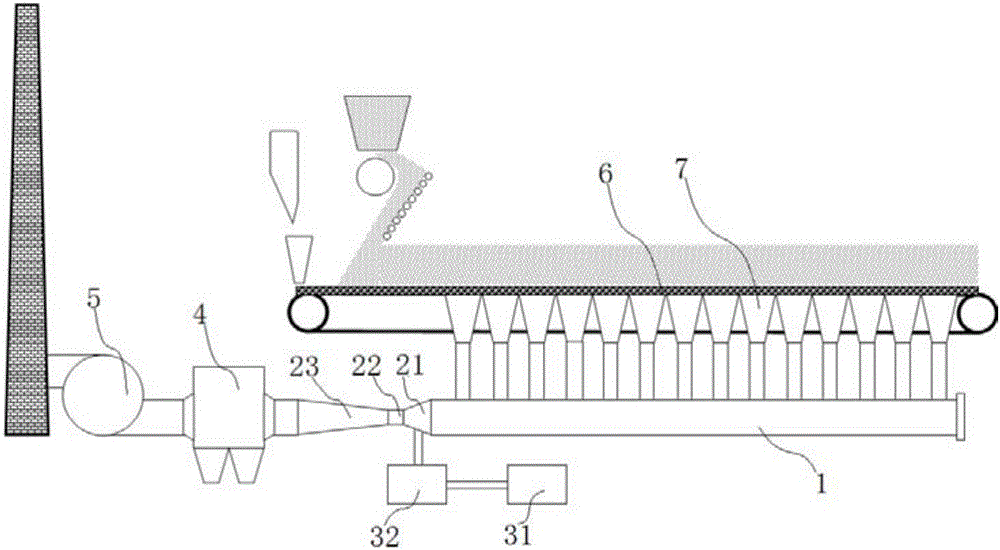

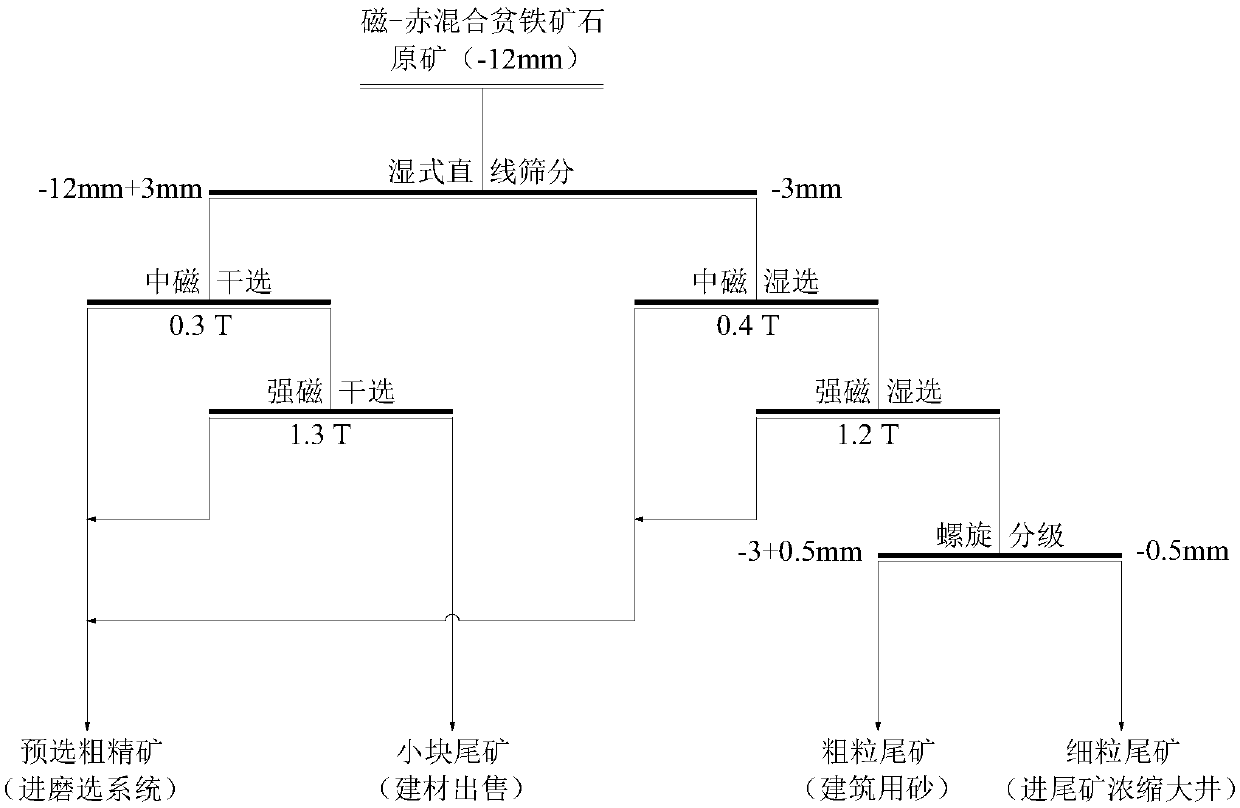

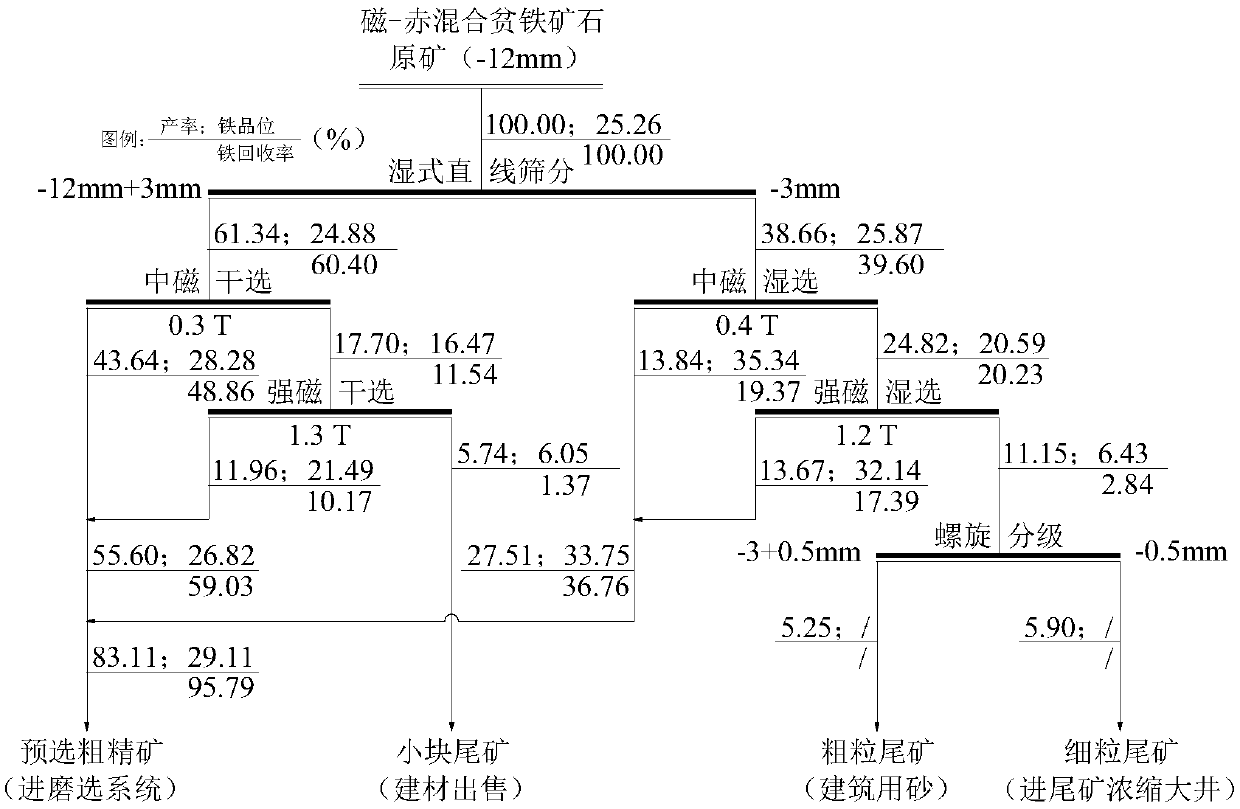

Magnetic-red mixed lean iron ore pre-concentration technology

InactiveCN109675715AGood supply conditionsWill not affect dry selection effectSievingScreeningIronstonePre concentration

The invention discloses a magnetic-red mixed lean iron ore pre-concentration technology and belongs to the field of iron ore concentration. The magnetic-red mixed lean iron ore pre-concentration technology includes the following steps that a, magnetic-red mixed lean iron ore is broken into -12 mm fine ground products through three sections and one closed loop; b, the fine ground products are subjected to wet type linear screen screening, and two fractions of -12+3 mm and -3 mm are obtained; c, the -3 mm fraction products are subjected to intermediate magnetic separation, intermediate magneticseparation tailings are subjected to strong magnetic separation, strong magnetic separation tailings are classified through a screw classifying machine, and intermediate magnetic separation concentrates and strong magnetic separation concentrates are merged, dewatered and then conveyed into a fine ore bin; and d, the -12+3 mm fraction products are subjected to intermediate magnetic dry separation,intermediate magnetic dry separation tailings are subjected to strong magnetic dry separation, and intermediate magnetic dry separation concentrates and strong magnetic dry separation concentrates are combined and conveyed into the fine ore bin. By means of the magnetic-red mixed lean iron ore pre-concentration technology, the defects that in the prior art, the concentration investment of magnetic-red mixed lean iron ore is large, and difficulty is high are overcome, and the magnetic-red mixed lean iron ore pre-concentration technology is provided and is particularly suitable for treating themagnetic-red mixed lean iron ore with the TFe grade ranging from 20.0% to 30.0%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

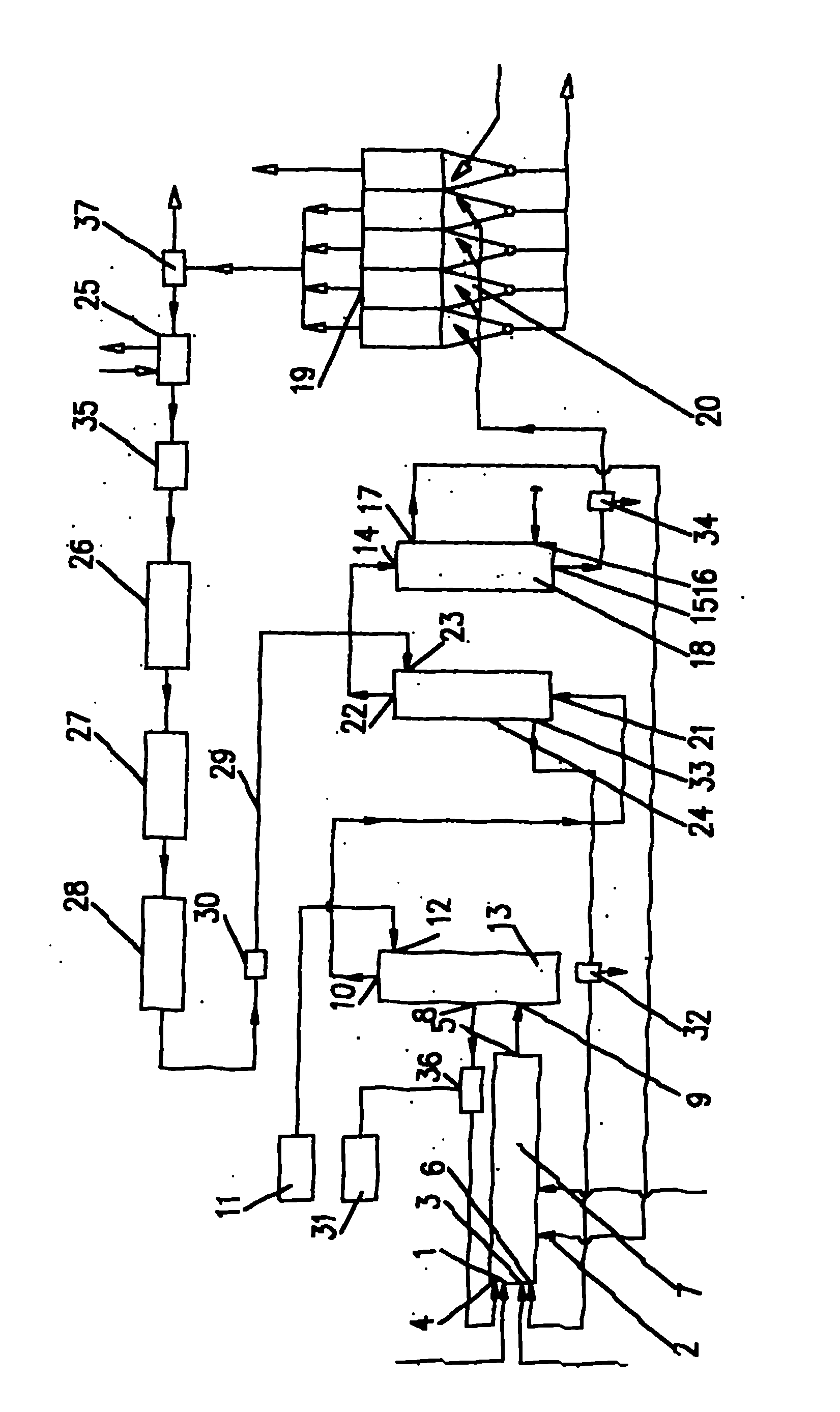

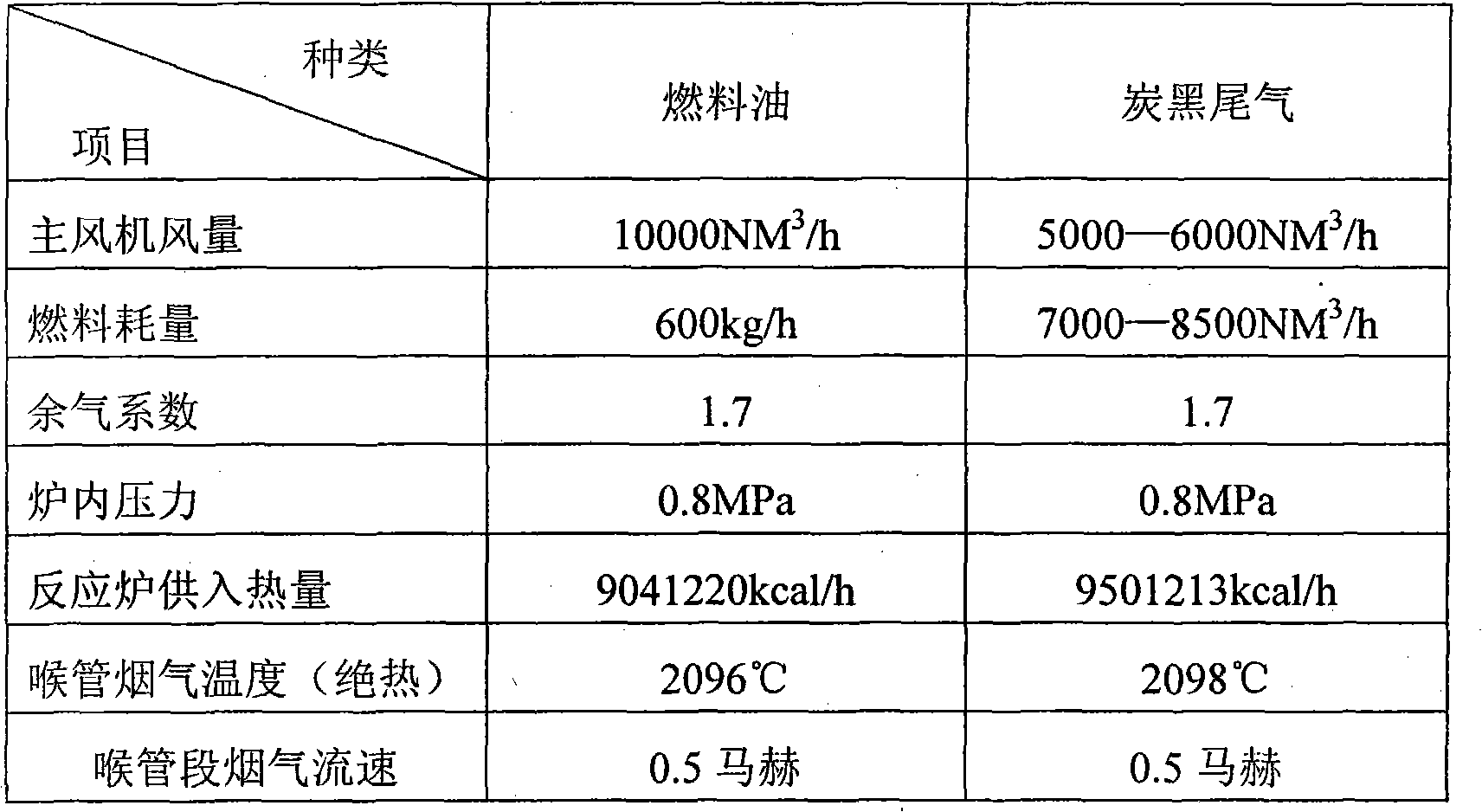

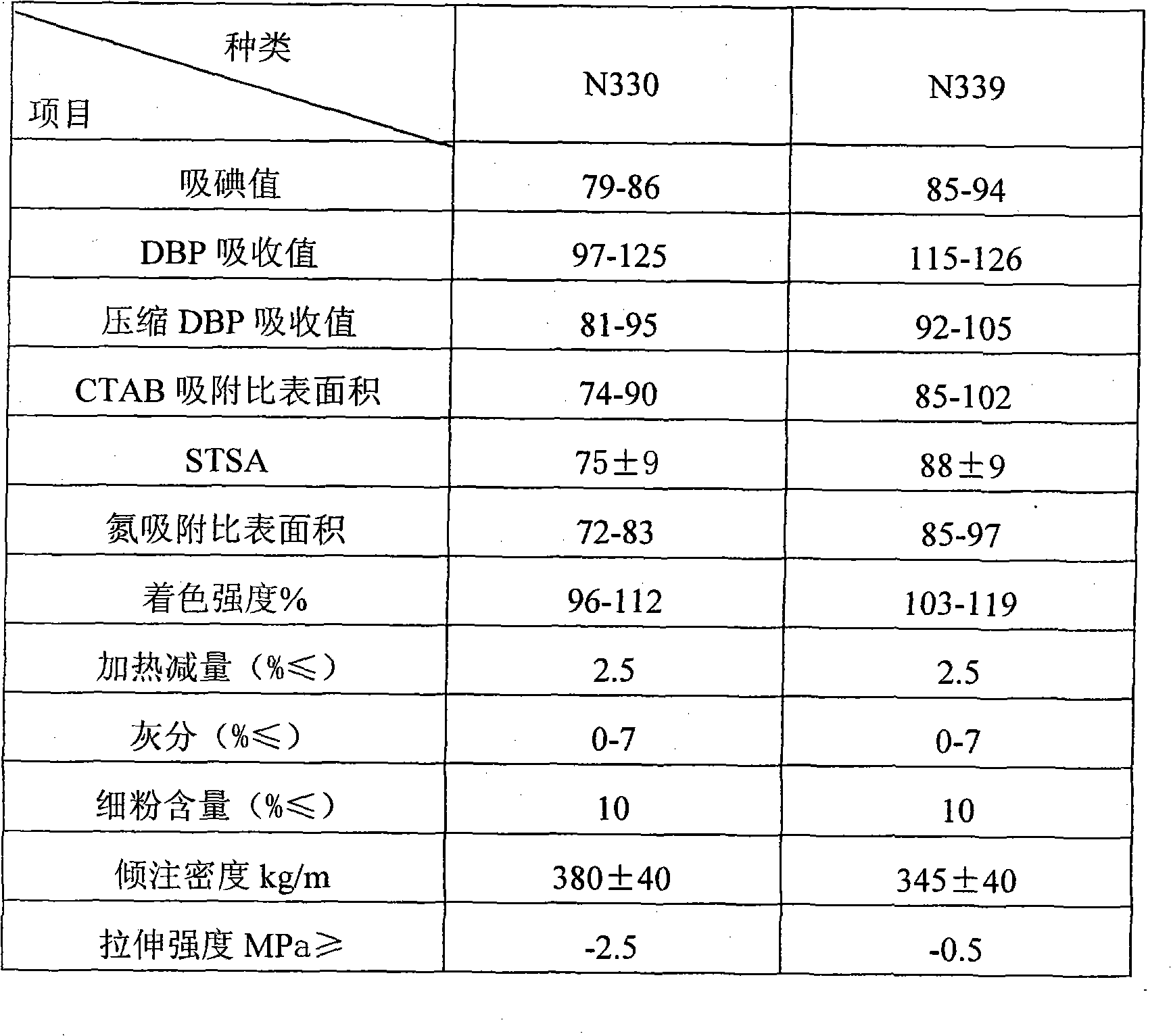

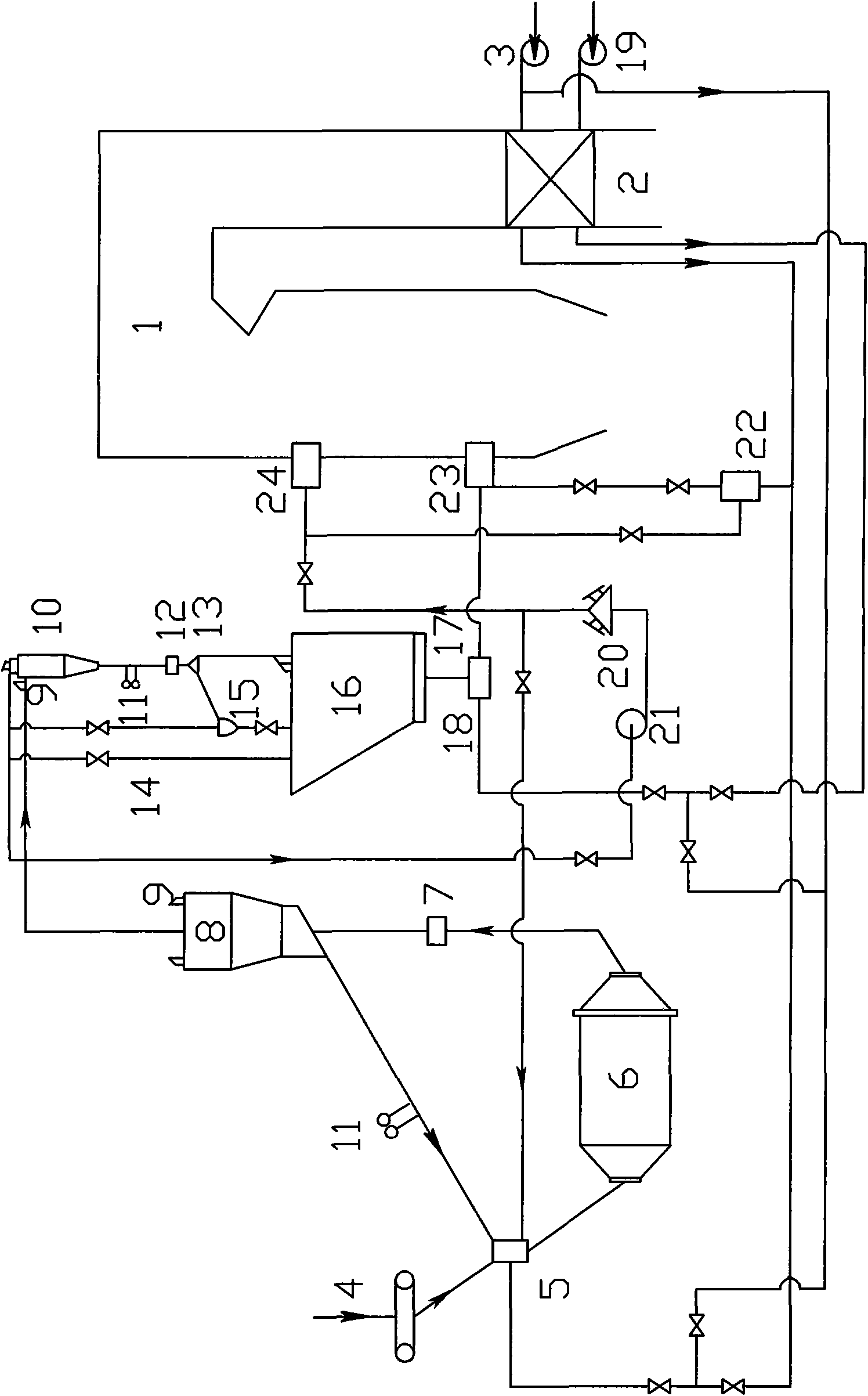

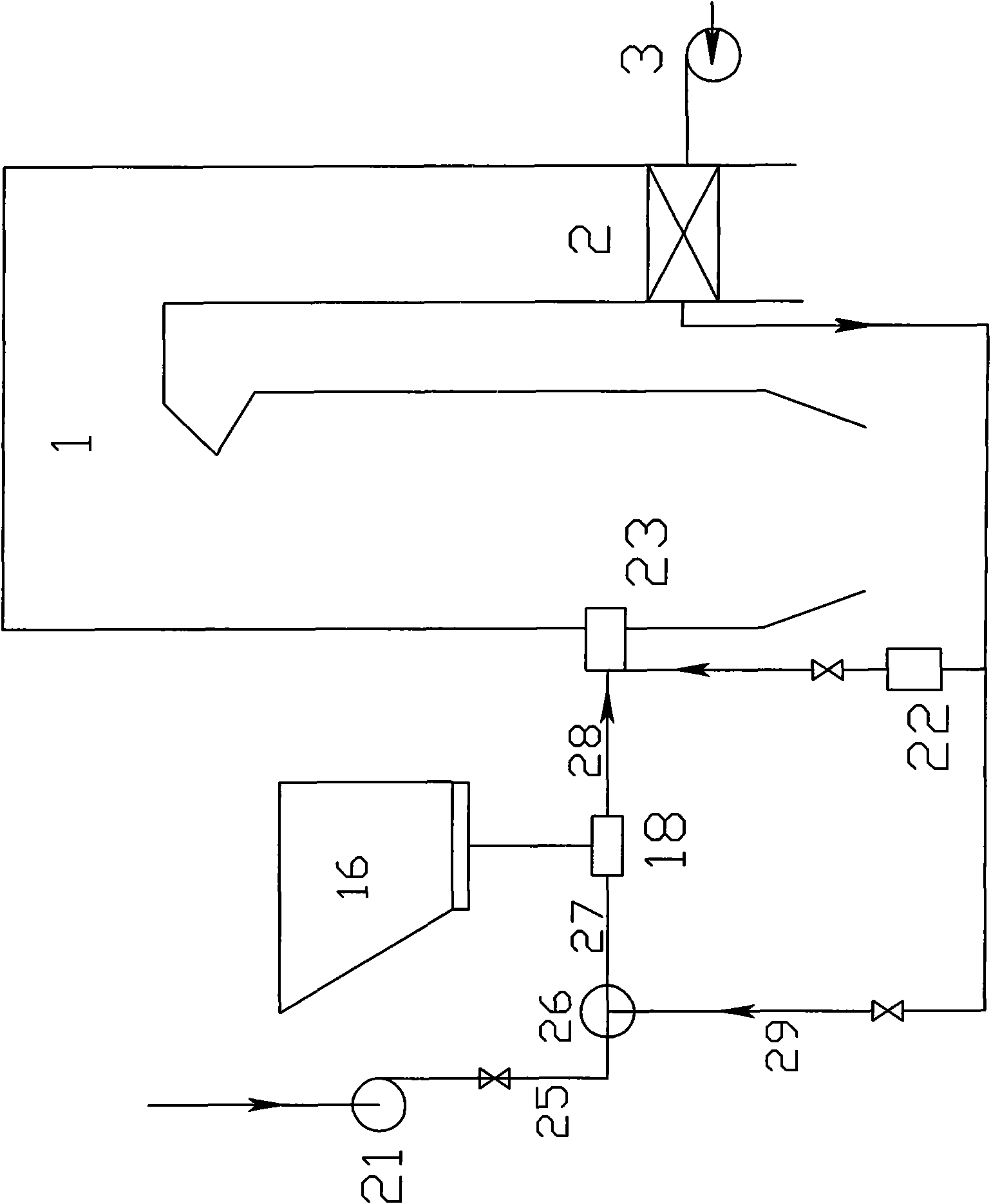

Energy-saving device and method for producing hard carbon black

InactiveCN101915428AEnsure safetyEnsure usabilityPigmenting treatmentCombustion processAir preheaterProcess engineering

The invention discloses an energy-saving device and an energy-saving method for producing hard carbon black. The energy-saving device for producing the hard carbon black are characterized by comprising a hard carbon black reaction furnace (7), a high-temperature air preheater (13) of a first smoke outlet (10), a tail gas preheater of a second smoke inlet (21) and a second smoke outlet (22), a raw oil preheater of a third smoke inlet (14) and a third smoke outlet (15), a low-temperature air preheater (25) and a low-pressure fan (35) sequentially, wherein the low-temperature air preheater (25) and the low-pressure fan (35) are communicated with a tail gas outlet (19) of a bag filtering box; the low-temperature air preheater is communicated with a condenser (26); the condenser is communicated with a gas-water separator (27); and a flow valve is communicated with a recovery tail gas inlet (23) of the tail gas preheater. A tail gas flow distributing valve (37) is arranged between the tail gas outlet (19) and the low-temperature air preheater (25); the low-pressure fan (35) is arranged between the low-temperature air preheater and the condenser; an oxygen-enriched mixer (36) and an oxygenator (31) are arranged between a high-temperature air outlet (8) of the high-temperature air preheater and a high-temperature oxygen-enriched air inlet (4); and the oxygen-enriched mixer is connected with the oxygenator.

Owner:张云斌

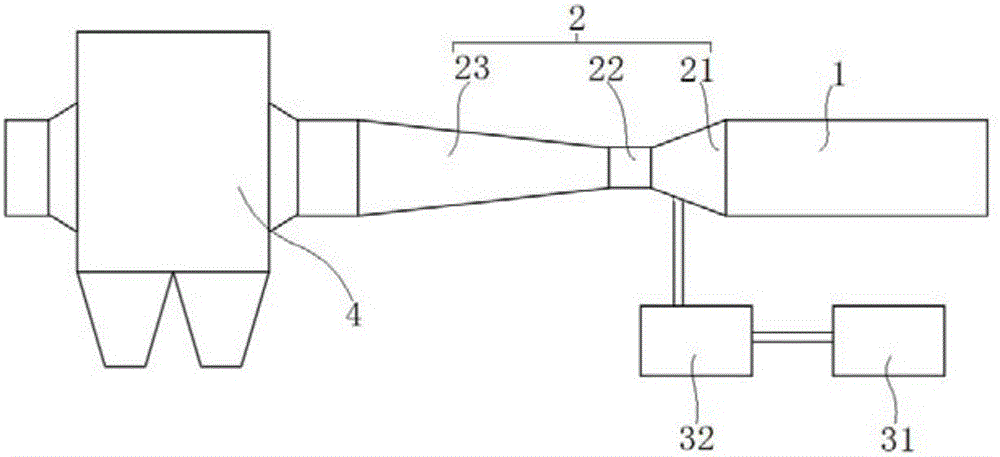

Hot air and exhaust gas double-medium powder delivery method and exhaust gas and hot air mixer

ActiveCN101596980AEmission reductionMeet the stability requirements of combustionBulk conveyorsLump/pulverulent fuel feeder/distributionEngineeringDelivery system

The invention provides a hot air and exhaust gas double-medium powder delivery method and an exhaust gas and hot air mixer and relates to a powder delivery method and a special exhaust gas and hot air mixer in the method, aiming at solving the problems that tertiary air in a hot air powder delivery system is not beneficial to the discharge reduction of NOx and the steady combustion of an exhaust gas powder delivery system boiler, and a primary air pipeline inlet and a valve thereof are severely abraded. Exhaust gas from an exhaust gas pipeline and hot air from a hot air pipeline are mixed and used as primary air together for delivering powder. A plurality of exhaust gas nozzles are dispersedly inserted on the side wall of an air distribution main pipe and communicated with the inner cavity of the air distribution main pipe, a plurality of round platform shape shrinkage pipes are positioned at the outside of the air distribution main pipe, the big ends of the round platform shape shrinkage pipes are respectively communicated with the inner cavity of the air distribution main pipe, and the small ends of the round platform shape shrinkage pipes are respectively communicated with one end of a plurality of mixed pipes. The invention obviously reduces the temperature of the primary air and the temperature of a main combustion area in a furnace, is beneficial to the discharge reduction of the NOx, meets the stability requirement of the combustion of the boiler and relieves the abrasion of the primary air pipeline inlet and the valve thereof.

Owner:HARBIN INST OF TECH

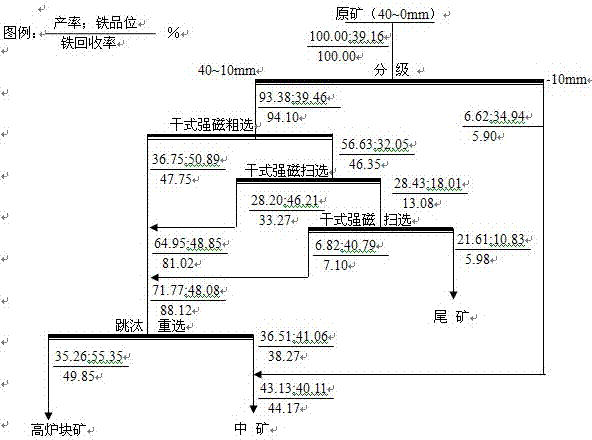

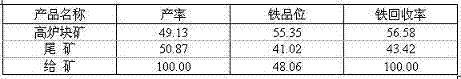

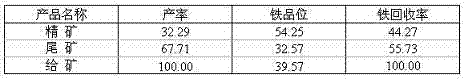

Beneficiation method for producing blast furnace lump ore by hematite at medium-high grade

InactiveCN102773156AHigh recovery rateThe amount of ball grinding is reducedMagnetic separationWet separationEnergy consumptionFerric

The invention discloses a beneficiation method for producing blast furnace lump ore by hematite at a medium-high grade. The method comprises the following steps of: crushing the hematite with the iron grade being greater than or equal to 39%, and grading the hematite into materials with two size fractions of 40mm-10mm and -10mm; carrying out dry-type strong magnetic roughing, primary dry-type strong magnetic scavenging and secondary dry-type strong magnetic scavenging on the materials with the size fraction of 4mm-10mm to respectively obtain dry-type strong magnetic roughing ore concentrate, primary dry-type strong magnetic scavenging ore concentrate, secondary dry-type strong magnetic scavenging ore concentrate and lump ore tails, and combining and feeding the dry-type strong magnetic scavenging ore concentrate, the primary dry-type strong magnetic scavenging ore concentrate and the secondary dry-type strong magnetic scavenging ore concentrate to a jigging reselection operation to obtain the blast furnace lump ore; and combining tails in the jigging reselection with the materials with the grade of -10mm into middlings, and feeding the middlings to subsequent grinding and selecting operations for grading. By adopting the method, part qualified blast furnace lump ore can be obtained in advance, the lump tails can be ejected, the goal ore grinding amount (namely the amount of the middlings) can be greatly reduced, and thus the energy consumption for grinding and selection can be greatly reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

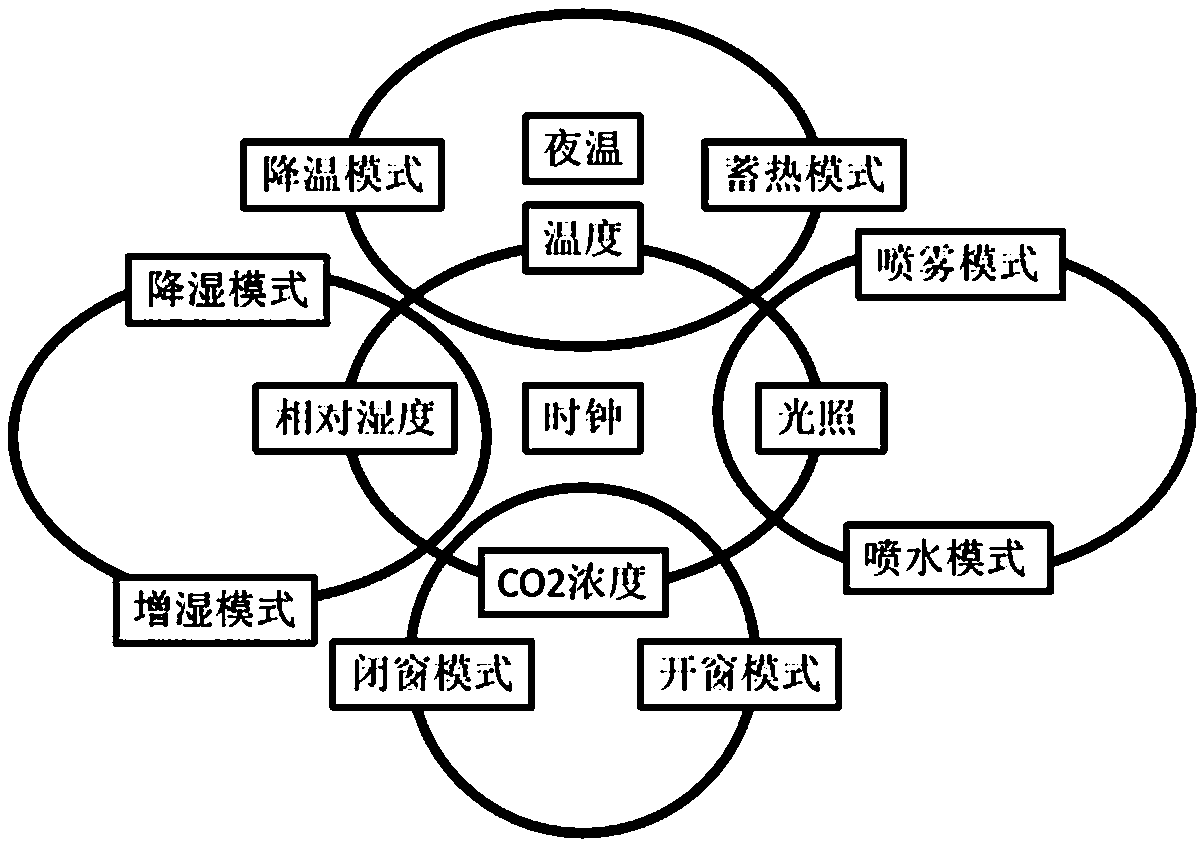

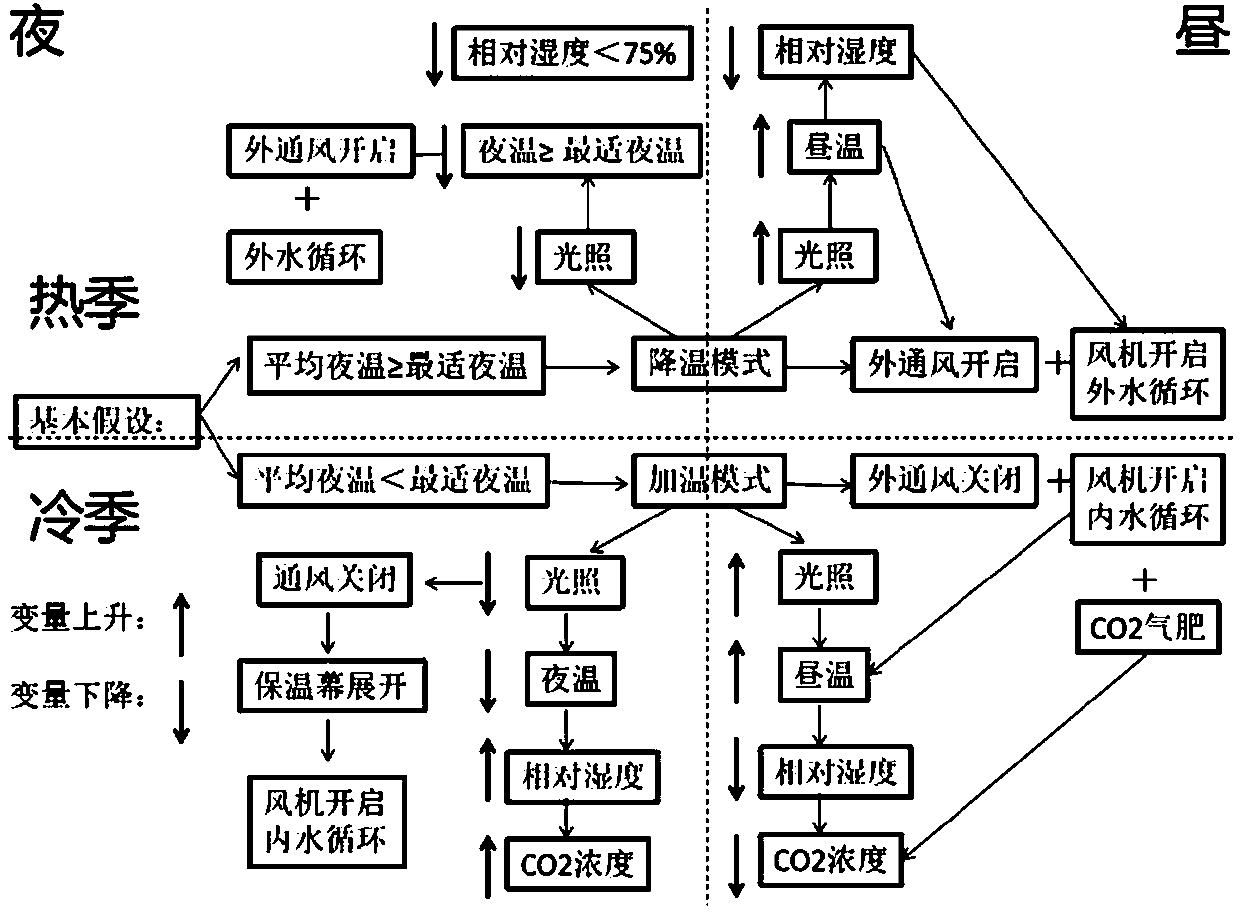

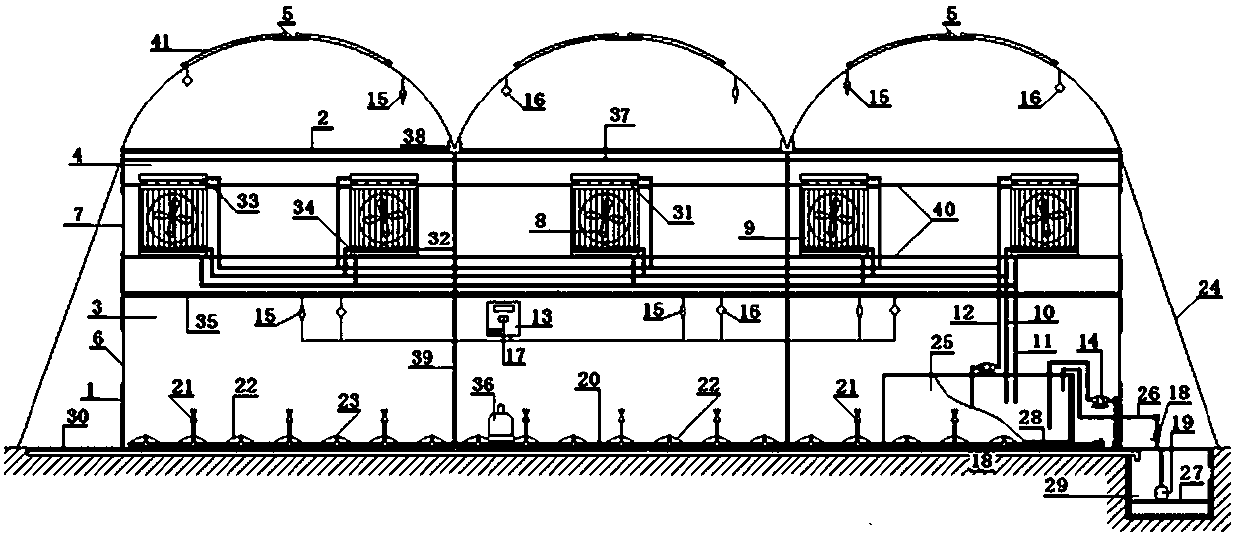

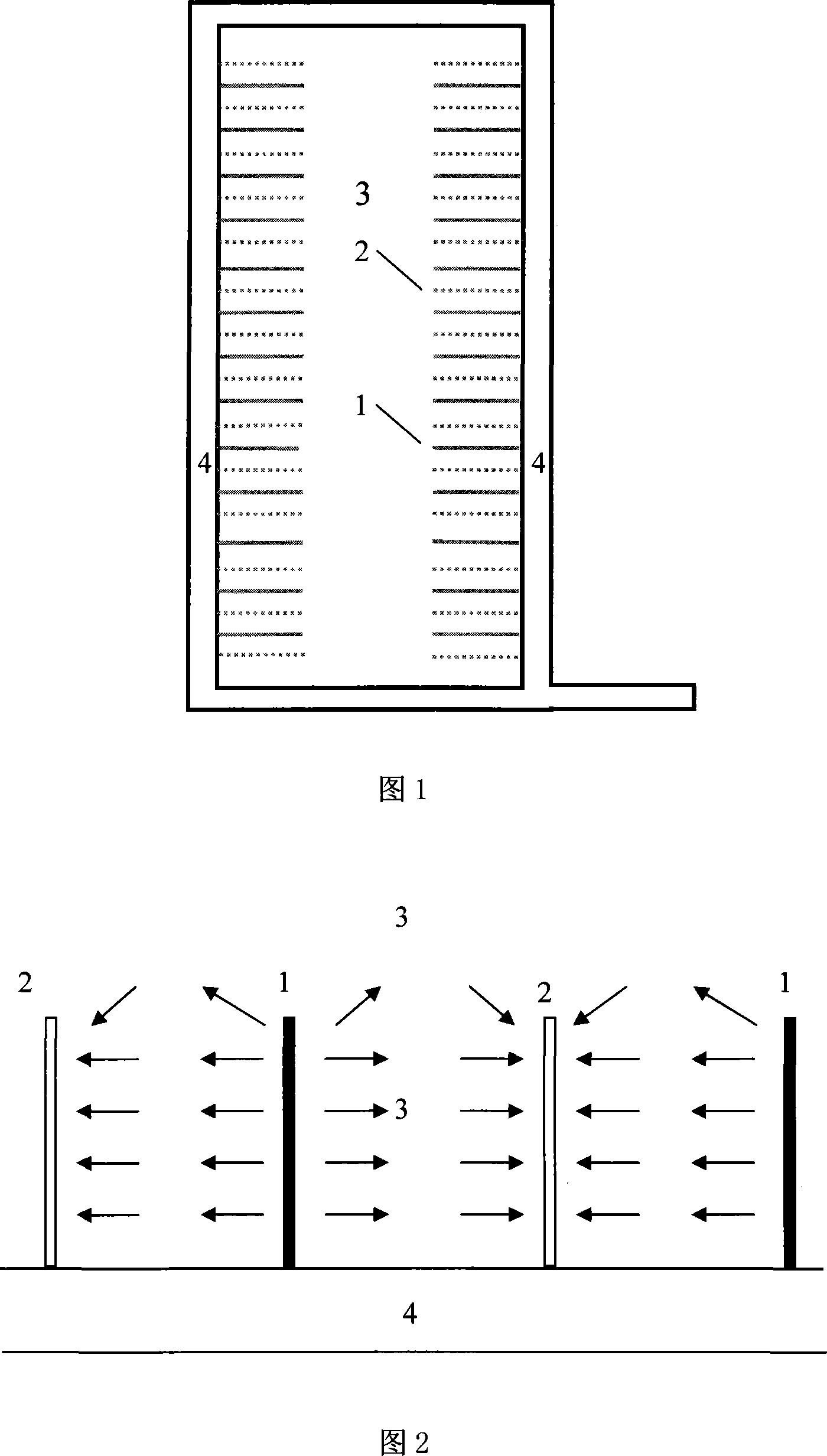

Intelligent greenhouse and environmental control method of using greenhouse effect for heat collection and fan coils for heat exchange

ActiveCN110178600AIncrease temperatureIncrease effective accumulated temperatureClimate change adaptationGreenhouse cultivationCold seasonAir volume

The invention discloses an intelligent greenhouse and environmental control method of using the greenhouse effect for heat collection and fan coils for heat exchange. The greenhouse is a multi-unit combined light-transmissive greenhouse with a highly overhead structure and comprises fan coil devices which are arranged at the middle-upper portions of the greenhouse, wherein each fan coil device integrating a heat exchanger and a wet curtain comprises a high-air-volume low-air-pressure fan and is provided with an inner water circulation pipe and an outer water circulation pipe, and the fan coildevices are connected to a heat storage pool through one water supply and return pipe. Two curtain layers are arranged above and below the devices respectively. An intelligent control system is designed, the greenhouse is closed for keeping warm in the cold season, the fans are started, internal water circulation of the coils is enabled, the solar heat is accumulated into water during daytime, andcrops are supplemented with CO2 gas fertilizer; the solar heat in the water is released into the air during nighttime. The greenhouse is opened for ventilation in the hot season, the fans are started, and external water circulation is enabled; the ventilation cooling effect is improved through evaporation and heat absorption on the surfaces of the heat exchangers. The problem that the cost is toohigh when existing methods are adopted for regulating the greenhouse environment is solved in an environment-friendly low-carbon mode, the remarkable effects of increasing the production, improving the quality, reducing the consumption of drugs and saving water are achieved, and transformation and upgrading of facility agricultural production modes are facilitated.

Owner:云南旭滇农业技术有限公司

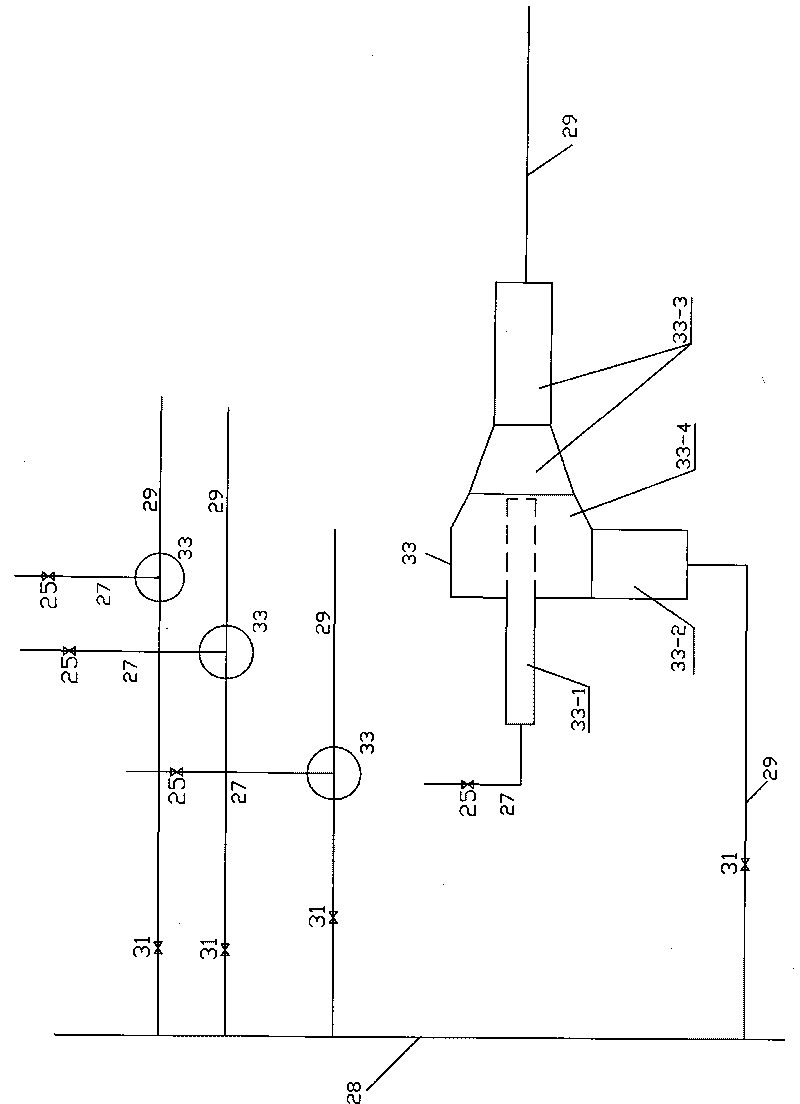

Down-hole horizontal hole exploitation system for mixing gas displacing coal gas, and the method

InactiveCN101122222AImprove the security environmentReduce the impactFluid removalGas removalProduct gasHigh pressure

The invention discloses a system and a method for exploitation of mixed-gas coal-bed methane exploitation in a horizontal hole in an oil well, and relates to a coal-bed methane exploitation technology. The exploitation method comprises the following procedures: 1. various gases are integrated into a mixed gas; the mixed gas comprises a or a plurality of strongly exchanged gases, which comprises H2S, SO2 and CO2; the mixed gas also comprises a or a plurality of weakly exchanged gases, which comprises N2, H2 and He; 2. the mixed gas is injected into a coal bed (3) through an injection hole (1) with high pressure; 3. gas comprising the coal-bed methane is obtained from an drainage hole (2) with a drainage device, until the methane content is lower than the economic exploitation content and safety content. The invention promotes the exploitation rate and unit output of the coal-bed methane, and produces quite an obvious effect in reducing the greenhouse gas emission. Meanwhile, the invention is provided with the effect of reducing the outstanding risks of gas, and is applicable in the low-penetration exploitable coal-bed methane exploitation field.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

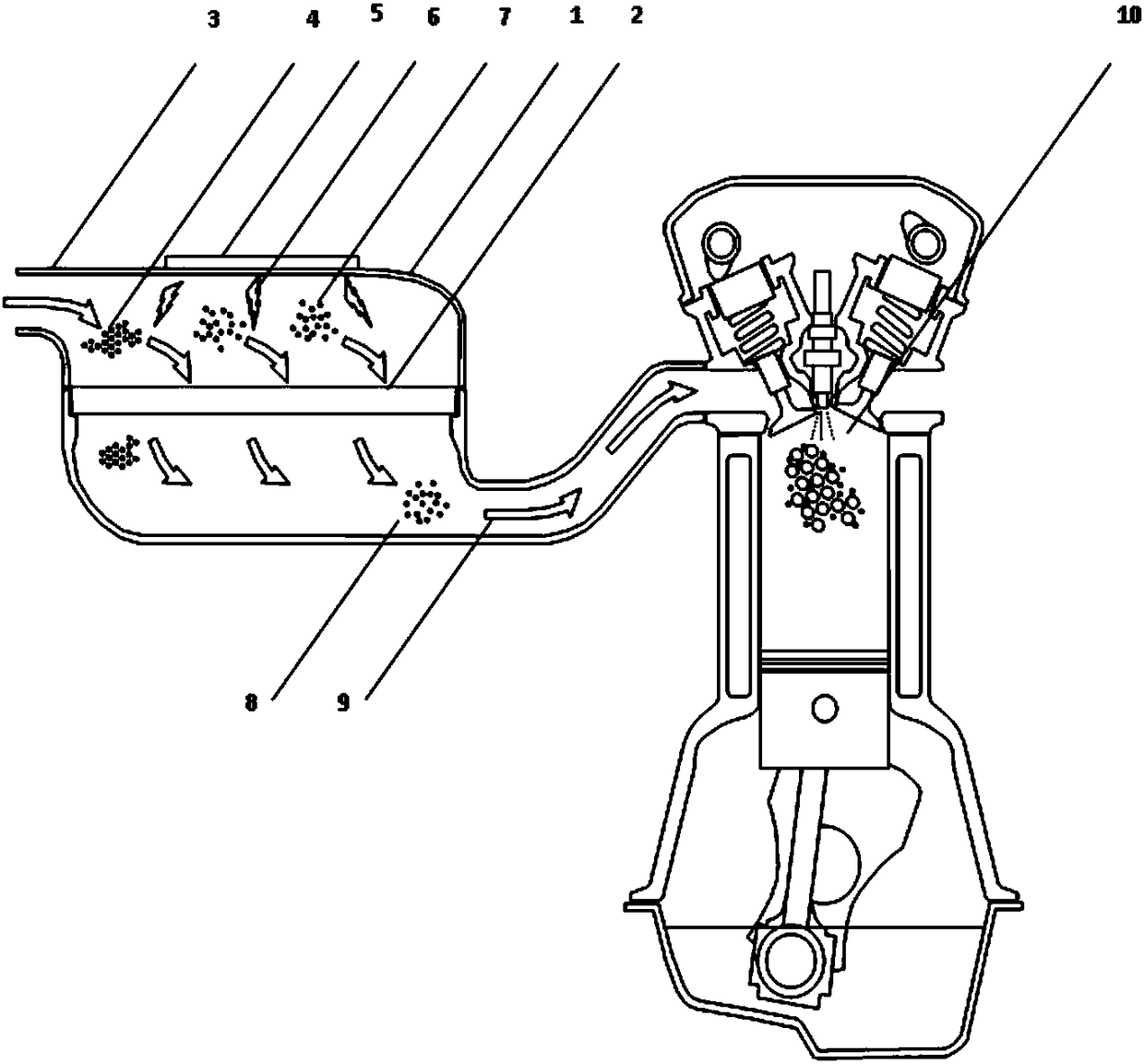

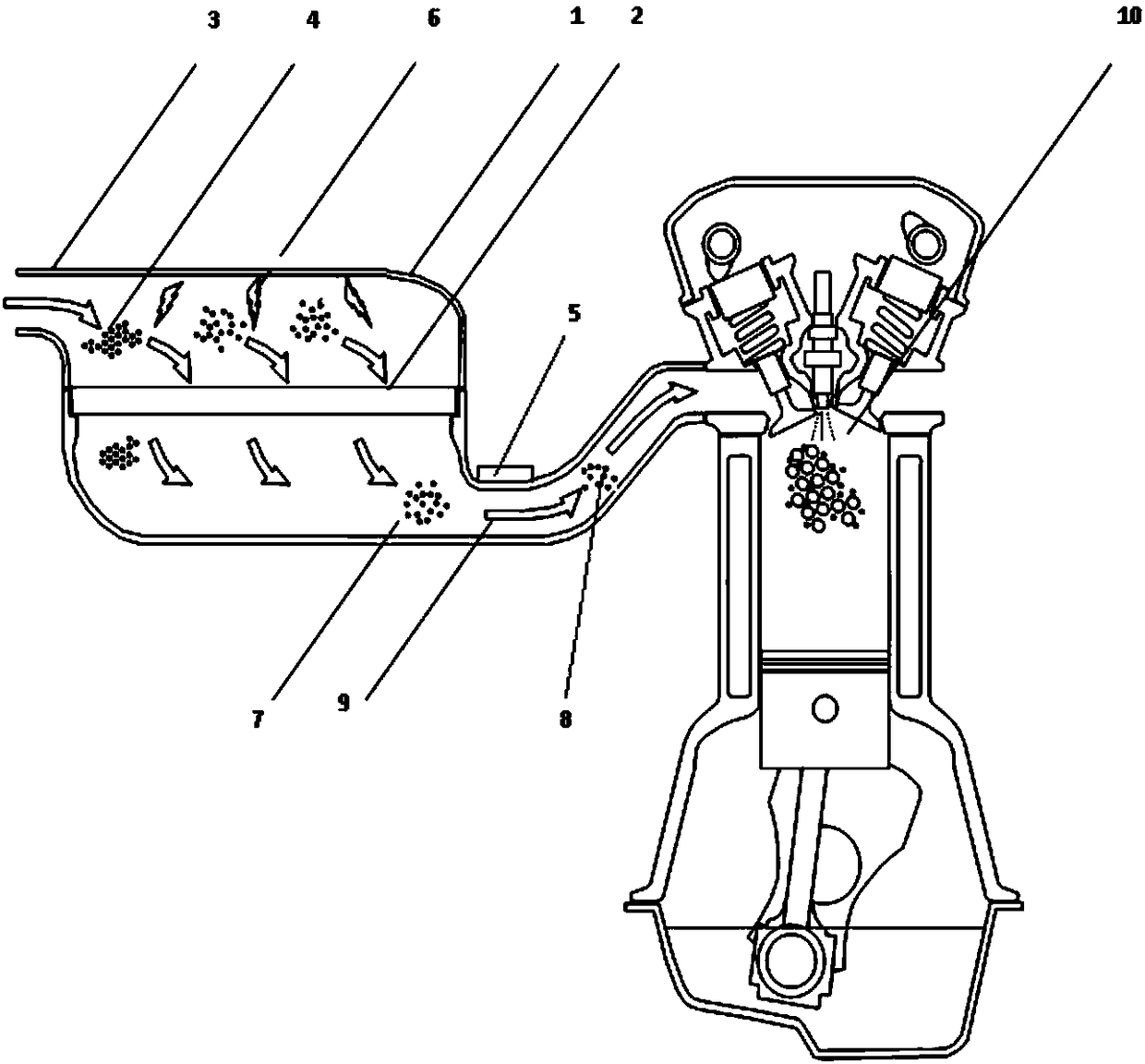

Air cleaner surface mount adhesive capable of reducing benzene emission and production and application methods

InactiveCN108314971AOne-time paste is effective for a long timeEasy to useInternal combustion piston enginesFilm/foil adhesivesBenzeneRare-earth element

The invention discloses an air cleaner surface mount adhesive capable of reducing benzene emission and a production method of the air cleaner surface mount adhesive. The air cleaner surface mount adhesive comprises a base material and a molecule activity activation material, wherein the molecule activity activation material is prepared from SiO2, Al2O3, Fe2O3, MgO, CaCO3, TiO2, MnO and a rare-earth element; natural ores containing the material are selected and are subjected to screening, primary processing and secondary processing until the natural ores reach a nano grade; a rare-earth material is added and is irradiated by utilizing THz irradiation equipment to be combined with the base material. When being used, the air cleaner surface mount adhesive is directly stuck on an air cleaner shell or covers a communication pipe. The invention relates to the air cleaner surface mount adhesive capable of reducing benzene emission and the production and application methods; more complete gasoline combustion can be promoted, and oil saving and power are remarkably improved. The total content of benzene substances is reduced and the emission reduction effect is remarkable. The surface mountadhesive is effective for a long period after disposable sticking and has the advantages of low cost and reasonable market price. The invention further relates to the production and application methods of the air cleaner surface mount adhesive; a production technology is simple and the utilization is convenient.

Owner:上海黻诚贸易有限公司

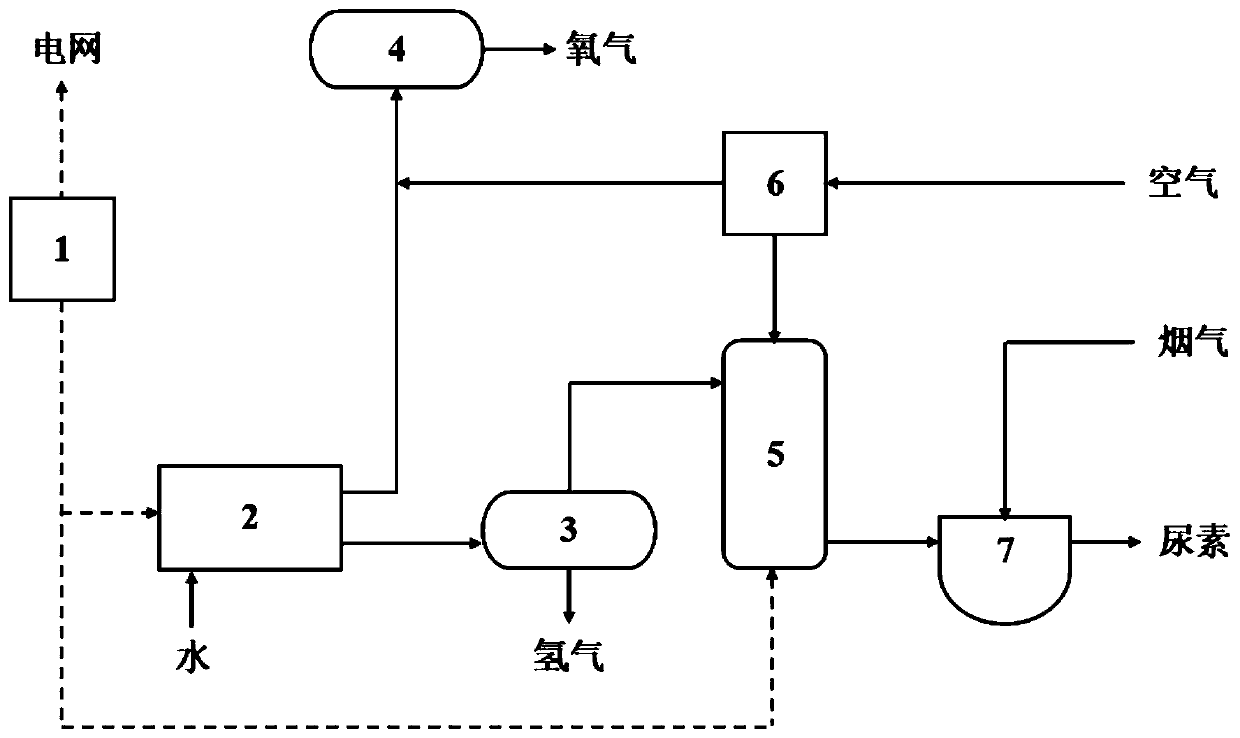

Energy storage system for co-production of hydrogen and urea and method thereof

PendingCN111378980ASolve the problem of abandoning water, wind and lightReduce reaction energy consumptionUrea derivatives preparationCellsElectrolysisNitrogen gas

The invention discloses an energy storage system for co-production of hydrogen and urea and a method thereof. The energy storage system comprises a renewable energy power supply, an electrolytic hydrogen production device, a hydrogen storage tank, an oxygen storage tank, an ammonia synthesis reactor, an air separation device and a urea synthesis reactor, water is introduced into the input end of the electrolytic hydrogen production device; the oxygen output end is connected to an oxygen storage tank; the hydrogen output end is connected to a hydrogen storage tank; the output end of the hydrogen storage tank is connected to a hydrogen inlet of an ammonia synthesis reactor; wherein air is introduced into the input end of the air separation device, the oxygen output end is connected to the oxygen storage tank, the nitrogen output end is connected to a nitrogen inlet of the ammonia synthesis reactor, the ammonia output end of the ammonia synthesis reactor is connected to an ammonia gas inlet of the urea synthesis reactor, and a flue gas inlet for introducing flue gas is further formed in the urea synthesis reactor; and the electrolytic hydrogen production device and the synthetic ammonia reactor are powered by a renewable energy power supply.

Owner:HUANENG CLEAN ENERGY RES INST

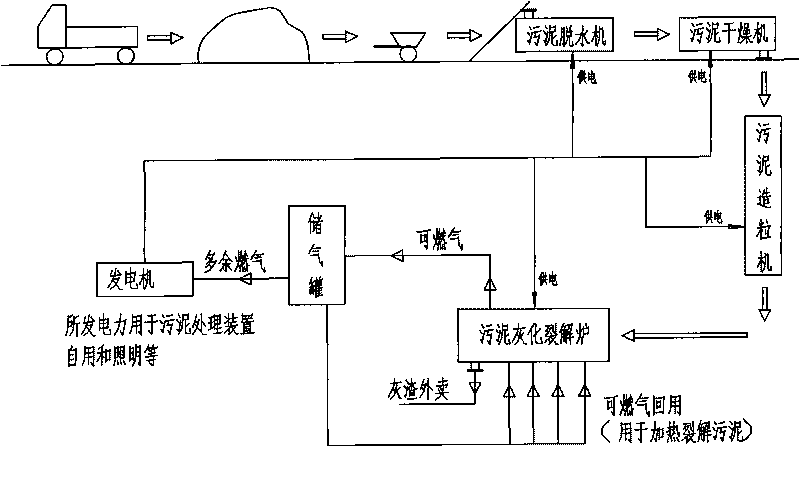

Harmless domestic sludge pyrolysis and carbonization treatment technique

InactiveCN101746939AHarmlessZero emissionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeCarbonization

The invention discloses a harmless domestic sludge pyrolysis and carbonization treatment technique. The technique includes pre-stage domestic sludge premixing and standing treatment, pre-dehydration, shaping, dehumidification, granulation, pre-reaction, pre-pyrolysis reaction, full carbonization reaction and other treatment processes, the completely reacted solid carbonized matter is discharged out of a system by a discharger, and is then collected and stored, the gas generated in sludge pyrolysis is separated by a gas condensation and separation system, the uncondensed flammable gas is guided into a gas holder and stored as heat source for the system, and the condensed gas is centrally treated by a reclaimed water system. The invention realizes purposes such as harmless and zero discharge in the process of production, energy self-sufficiency and low consumption in the process of production, resource and basic energy substance recycling, energy saving, discharge reduction and natural substance recycling, and has the advantages of easy operation, low investment cost, remarkable economic benefit, significant discharge reduction effect for the environment and the like.

Owner:SHANGHAI LOTUS ENVIRONMENTAL PROTECTION TECH

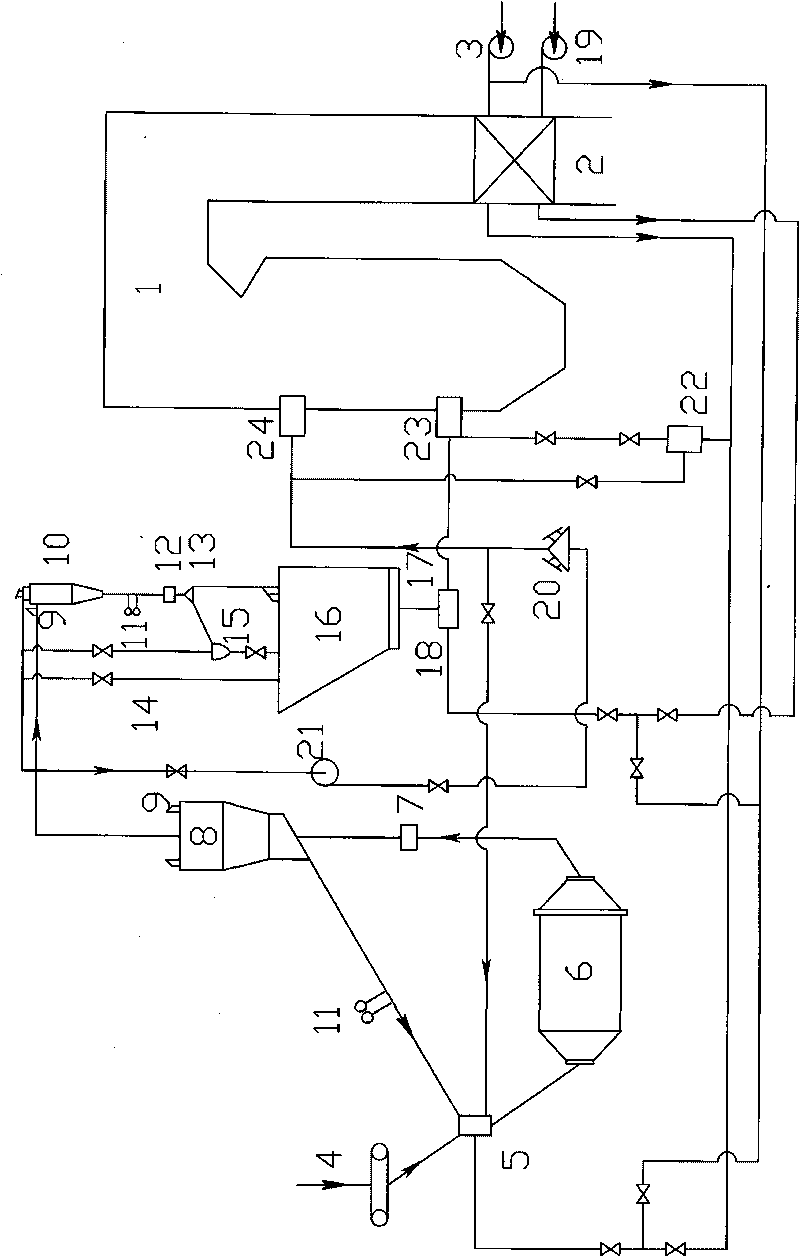

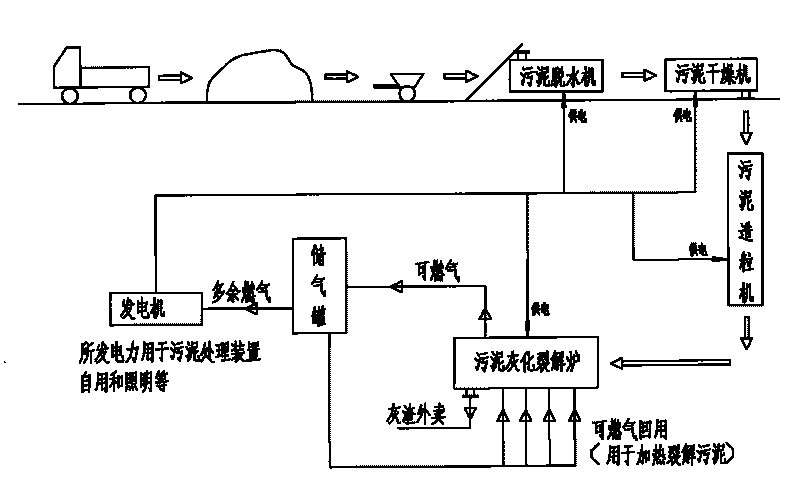

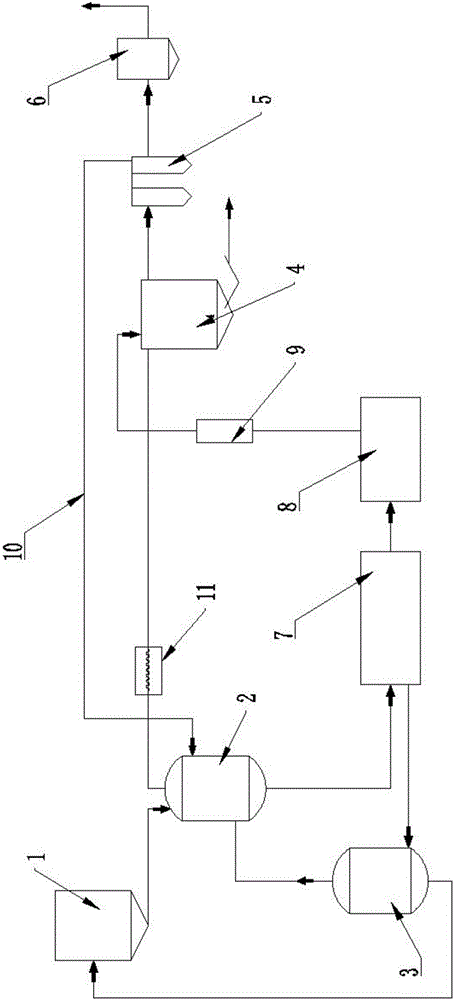

Sludge pyrohydrolysis and gasification processing system and treatment process thereof

InactiveCN106587561ASolve the problem of missing heat sourceLow toxicityCombination devicesSludge treatment by de-watering/drying/thickeningResource utilizationSludge

The invention discloses a sludge pyrohydrolysis and gasification processing system and a treatment process thereof. The sludge pyrohydrolysis and gasification processing system comprises a sludge slurrying device, a heating pressurization reactor, a flash evaporation pot, a machinery dehydration device, a pyrolysis vapourizing furnace, an exhaust-heat boiler and a flue gas processing device, the sludge slurrying device is connected with a heating pressurization reactor, gas de-watering equipment, the pyrolysis vapourizing furnace, the exhaust-heat boiler and the flue gas processing device in order through an extraction pump, the exhaust-heat boiler is connected with the heating pressurization reactor through a steam pipeline, the flash evaporation pot is connected between the heating pressurization reactor and the sludge slurrying device, and a heat exchanger, the machinery dehydration device and a feeding machine are connected between the heating pressurization reactor and the pyrolysis vapourizing furnace in order. By employing steam heating and pyrolysis vapourizing furnace for treatment, pathogen and insect ovum in the sludge are completely killed; no chemical agent is added in the treatment process, all the products enable resource utilization, so that the sludge pyrohydrolysis and gasification processing system has the advantages of safety and stability, low exhaust gas generation amount, and obvious emission reduction effect.

Owner:广东昕旺环保科技发展有限公司

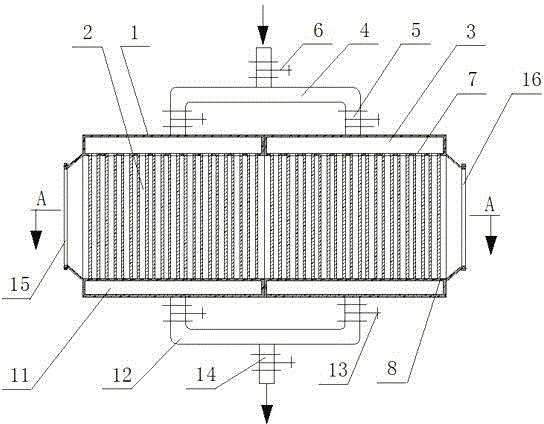

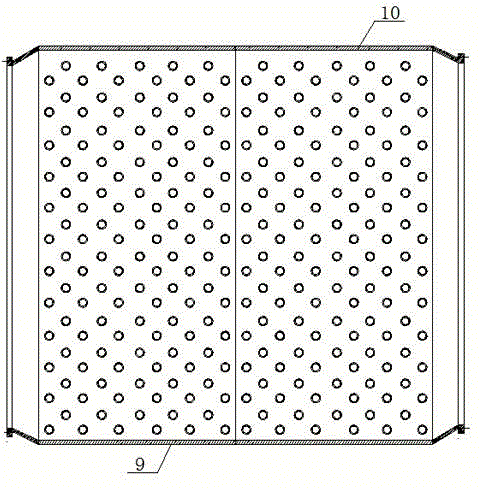

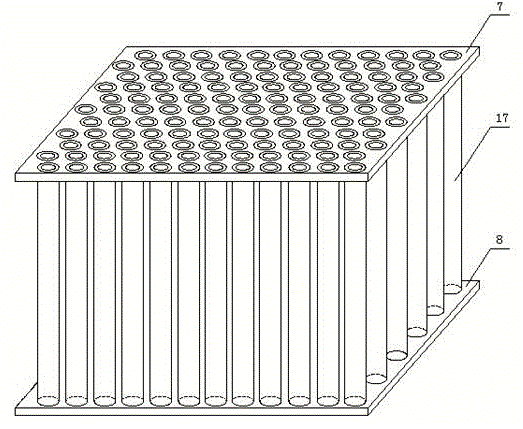

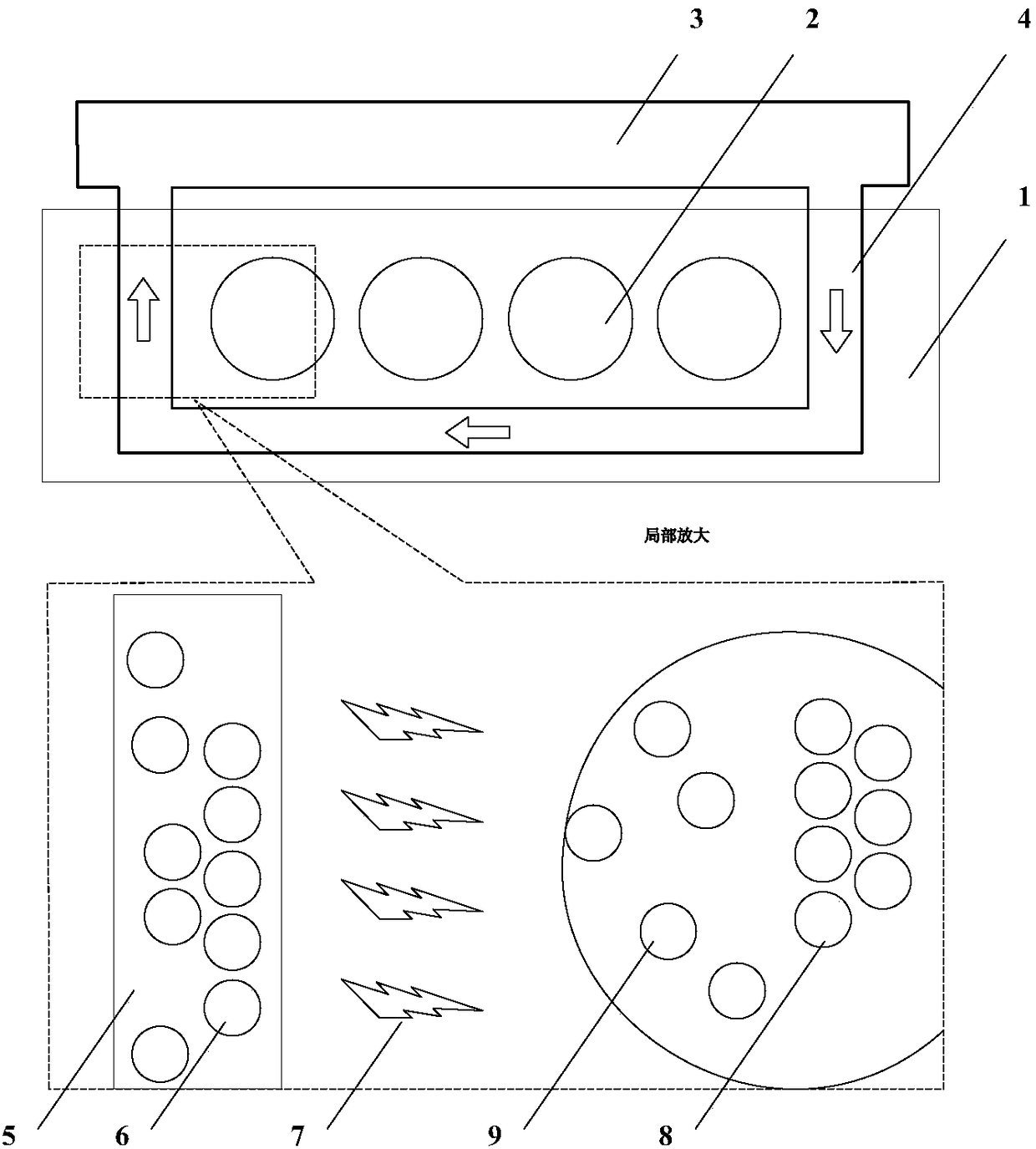

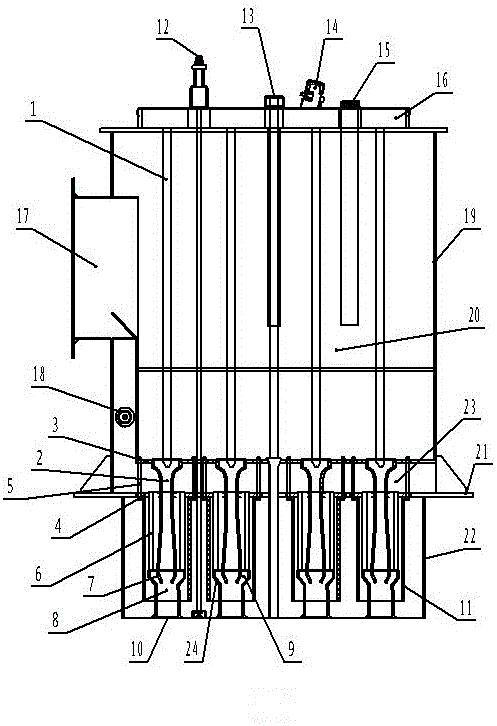

Micro-nano ceramic-tube-beam water-film type integrated removal apparatus for flue gas pollutants

InactiveCN105477955AEfficient removalEfficient emissionsUsing liquid separation agentMicro nanoWater vapor

The invention discloses a hollow porous micro-nano ceramic-tube-beam water-film type integrated removal apparatus for flue gas pollutants, and belongs to the coal-fired power plant energy-saving emission-reduction technologies. The apparatus comprises an upper cover plate (1), a hollow porous micro-nano ceramic-tube-beam assembly (2), a water inlet chamber (3) and associated pipelines (4) thereof, a sewage chamber (11) and associated pipelines (12) thereof, an upper glass fiber reinforced plastic support plate (7), a lower glass fiber reinforced plastic support plate (8), a front side plate (9), a rear side plate (10), and sealing fixing parts. Under driving of pressure difference, a dense water film is formed on the outer surface of a ceramic pipe (17), when flue gas transversely skims over the ceramic-tube-beam assembly (2), gypsum liquid drops, water vapor, tiny particles, and SO2, H2SO4(SO3) aerosol and other acidic compositions in flue gas are captured by the water film, the captured pollutants and condensed water float down the stream, are gathered in the sewage chamber (11), and are sent to a sewage disposal plant through the sewage pipelines (12). The apparatus is simple in structure, low in cost, resistant to corrosion and long in service life, is capable of realizing clean discharge of a coal-fired power plant, also is capable of recovering and utilizing water source in flue gas, and possesses extensive engineering application prospect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

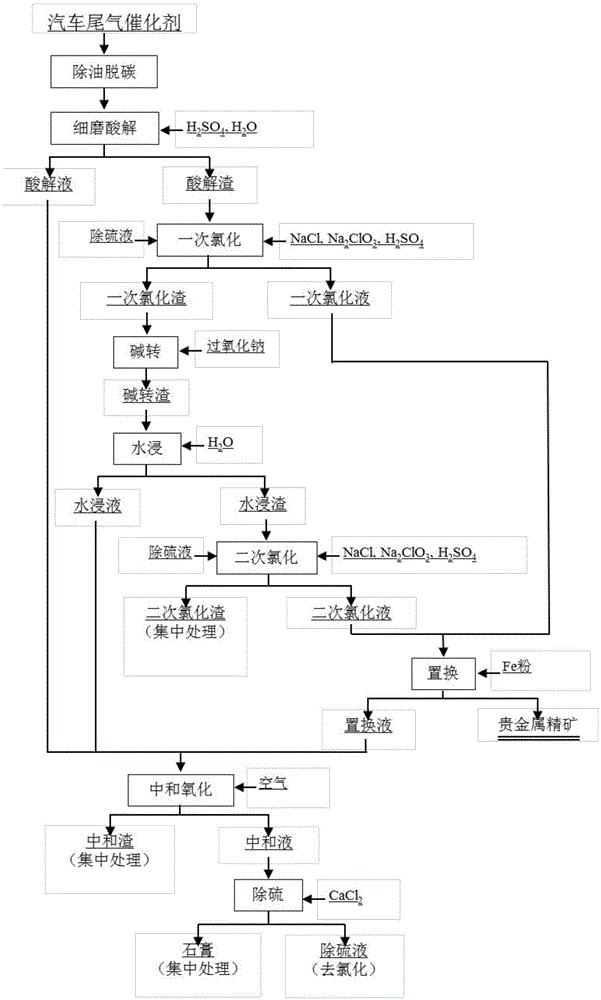

Method for recycling noble metal from automobile exhaust catalyst

ActiveCN104480312ASmooth leachingSmooth recyclingProcess efficiency improvementSodium chlorateResource recovery

The invention provides a method for recycling noble metal from an automobile exhaust catalyst, and belongs to the technical field of resource recycling. The method comprises the following steps: deoiling and decarbonizing the automobile exhaust catalyst, finely pulverizing, and carrying out acid leaching; carrying out primary chlorination on acid leaching residues in a solution of sodium chloride, sodium chlorate and sulfuric acid; mixing primary chlorination residues with sodium peroxide, carrying out water leaching on an alkaline transfer residue, carrying out secondary chlorination on a water leaching residue; mixing primary chlorination liquid with secondary chlorination liquid, and replacing with Fe powder, so as to obtain a displacement liquid and precious metal ore concentrate; mixing an acid leaching liquid, the water leaching liquid and the replacement liquid, and carrying out neutralization-oxidization; and adding calcium chloride to a neutralization liquid, carrying out desulphuration treatment, and returning a desulphuration liquid to primary chlorination and secondary chlorination procedures by adjusting the amount of sodium chloride, sodium chlorate and sulfuric acid. According to the method disclosed by the invention, noble metal is smoothly leached and recovered; the problems of noble metal recovery and environment protection of the automobile exhaust catalyst are solved; and the method has the characterizes of high adaptability and simple equipment, and is suitable for industrialized production and environmental friendly.

Owner:UNIV OF SCI & TECH BEIJING +1

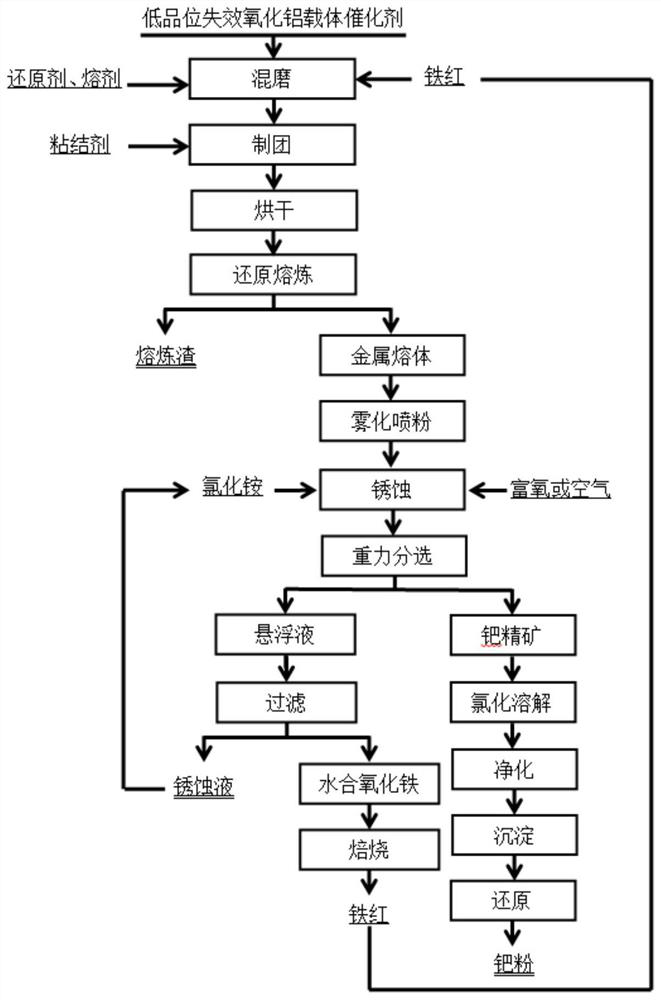

Method for extracting palladium from low-grade spent alumina carrier catalyst

InactiveCN112267025AAvoid large amountsAvoid processing powerTransportation and packagingMetal-working apparatusHydration reactionPtru catalyst

The invention discloses a method for extracting palladium from a low-grade spent alumina carrier catalyst. The method comprises the following steps of mixing the low-grade spent alumina carrier catalyst with a reducing agent, red iron oxide, a flux, a binder and water for grinding to prepare pellets, drying the pellets, and carrying out reduction smelting to obtain a metal melt and smelting slag;carrying out atomization powder spraying on the metal melt to obtain palladium-containing iron alloy powder; carrying out rust treatment on the palladium-containing iron alloy powder, then conductinggravity separation to obtain palladium concentrate and suspension liquid; filtering the suspension liquid for separating ferric oxide hydrate and rust residual liquid; roasting and dehydrating the ferric oxide hydrate to obtain the red iron oxide, and returning the ferric oxide hydrate to the mixing procedure to be used as a trapping agent; dissolving the palladium concentrate by chlorination, andcarrying out filtering to obtain a palladium-containing pregnant solution and filter residues; and purifying, precipitating and reducing the palladium-containing pregnant solution to obtain palladiumpowder. By adopting the method to extract palladium, the palladium recovery rate is greater than 97.0%, the palladium content in the palladium powder is greater than 99.95%, the trapping agent and the rust liquid can be recycled, the emission reduction effect is remarkable, the extraction cost is low, the related equipment is mature, and the industrialization prospect is good.

Owner:HONGHE COLLEGE

Method for preparing agglomeration liquid for restraining iron mine sintering flue gas fine particle emissions

ActiveCN105833655AImprove reunion efficiencySpeed up the reunionAuxillary pretreatmentMass ratioFlue gas

The invention discloses a method for preparing agglomeration liquid for restraining iron mine sintering flue gas fine particle emissions, and belongs to the technical field of iron mine sintering process pollutant emission reduction .The method comprises the specific steps that A, 20-40 parts of polyacrylamide, 0-20 parts of aluminium polychlorid, 20-40 parts of sodium carboxymethylcellulose and 20-40 parts of polyacrylamide are mixed to be uniform, and a mixture A is obtained; B, 2-5 parts by mass of additive is weighed and added into the mixture A, the mixture is mixed to be uniform, and a compound agglomeration agent is obtained; C, the compound agglomeration agent in the step B is mixed with water, the mass ratio of the compound agglomeration agent to the water is 1:(2,000-10,000), and the agglomeration liquid is prepared .Agglomeration liquid mist drops on which fine particles are adsorbed are nucleated, collide and grow under the low pressure condition, large particle agglomerate is formed, agglomerated and grown fine particles are removed through a dust removal device, therefore, emissions of pollutants are restrained, and a brand-new emission reducing path is provided for emission reduction of the fine particles in the iron mine sintering process.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

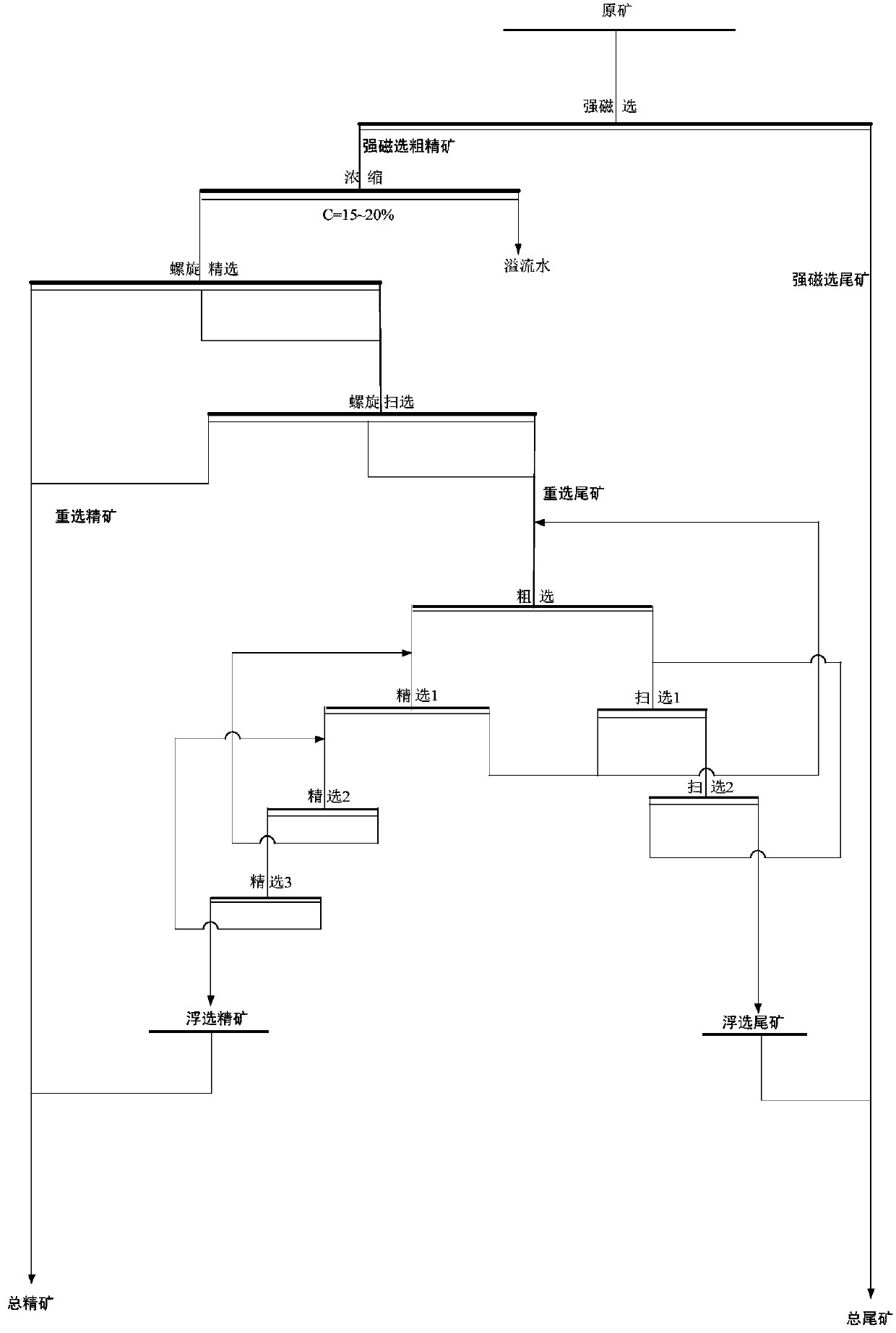

Beneficiation method for strengthened recycling of fine-particle chromite

The invention discloses a beneficiation method for strengthened recycling of fine-particle chromite. The beneficiation method comprises the following steps that firstly, magnetic separation is conducted, raw ore is subjected to strong magnetic separation, and strong magnetic separation rough concentrates and strong magnetic separation tailings are obtained; secondly, reselection is conducted, thestrong magnetic separation rough concentrates obtained in the first step are subjected to reselection, and reselection concentrates and reselection tailings are obtained; and thirdly, flotation is conducted, the ore pulp mass concentration of the reselection tailings in the second step is adjusted, a collecting agent and a foaming agent are sequentially added, one-time rough fine selection is conducted, then, the flotation closed-loop process including at least three times of fine selection, at least two times of scavenging and middling sequential return is conducted, and flotation concentrates and flotation tailings are obtained. The magnetic-reselection-flotation combined technology is adopted in the beneficiation method, the fine-fraction chromite can be effectively recycled, comprehensive concentrate reselection is conducted, the final chromite concentrate Cr2O3 grade is 42% or above, the recycling rate is 80%-90%, the chromite resource is effectively recycled, the integral cost islow, and the high technology index can be reached.

Owner:广东省资源综合利用研究所

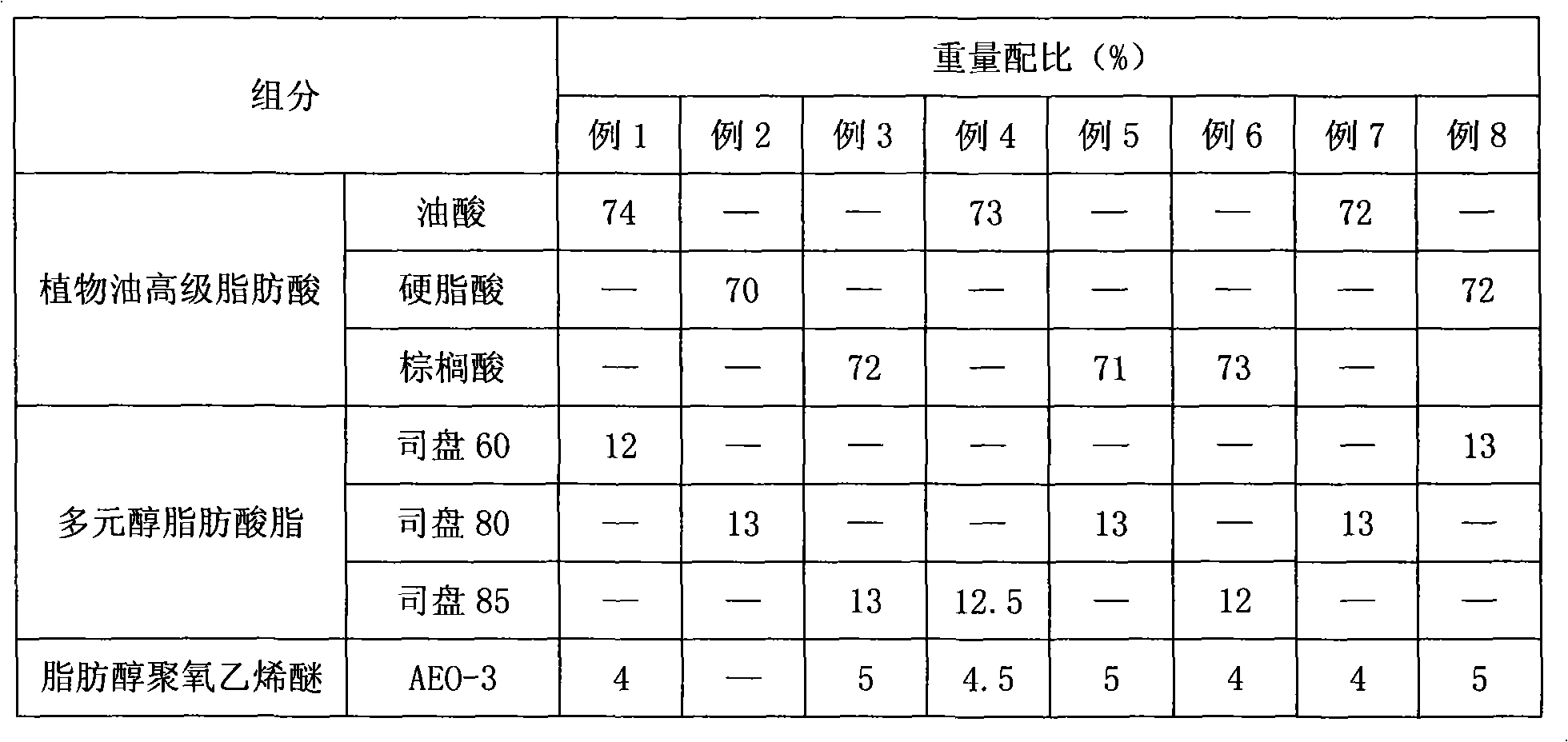

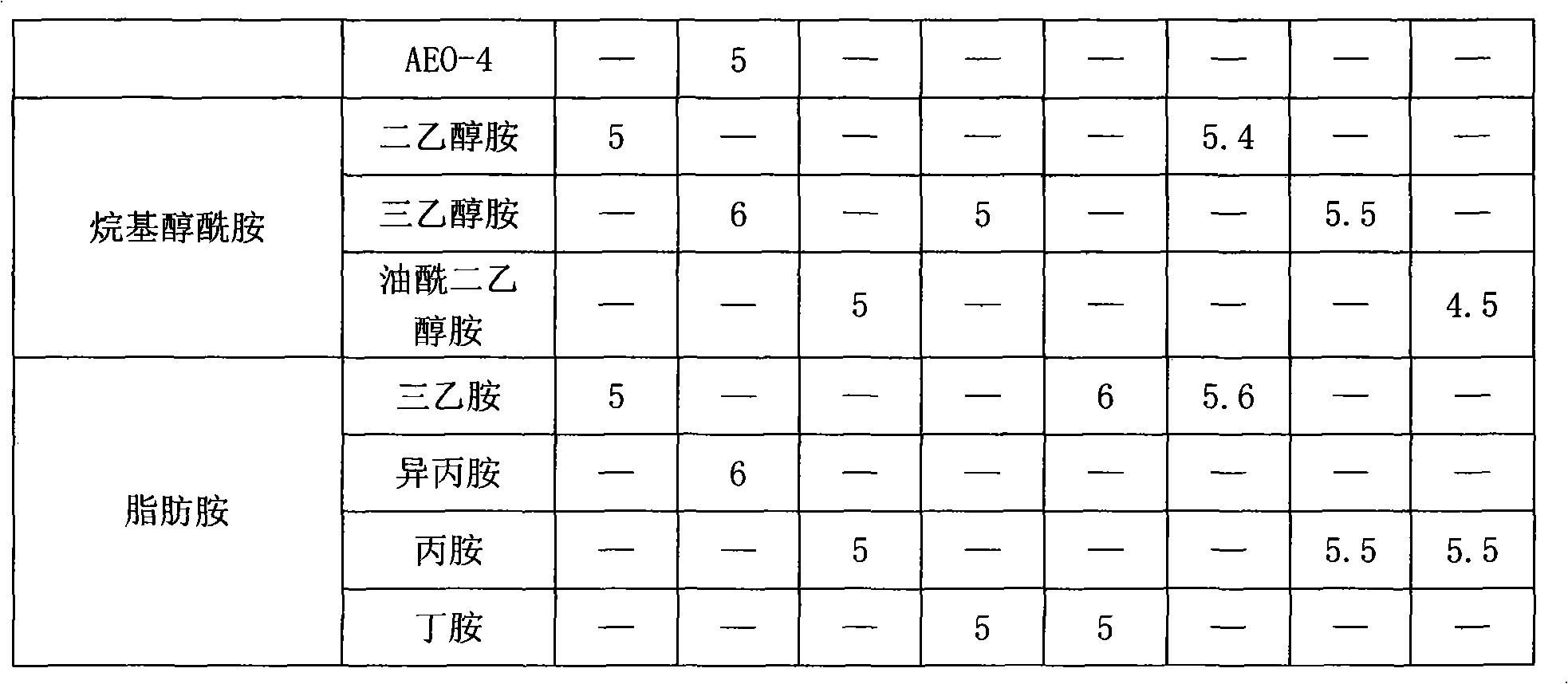

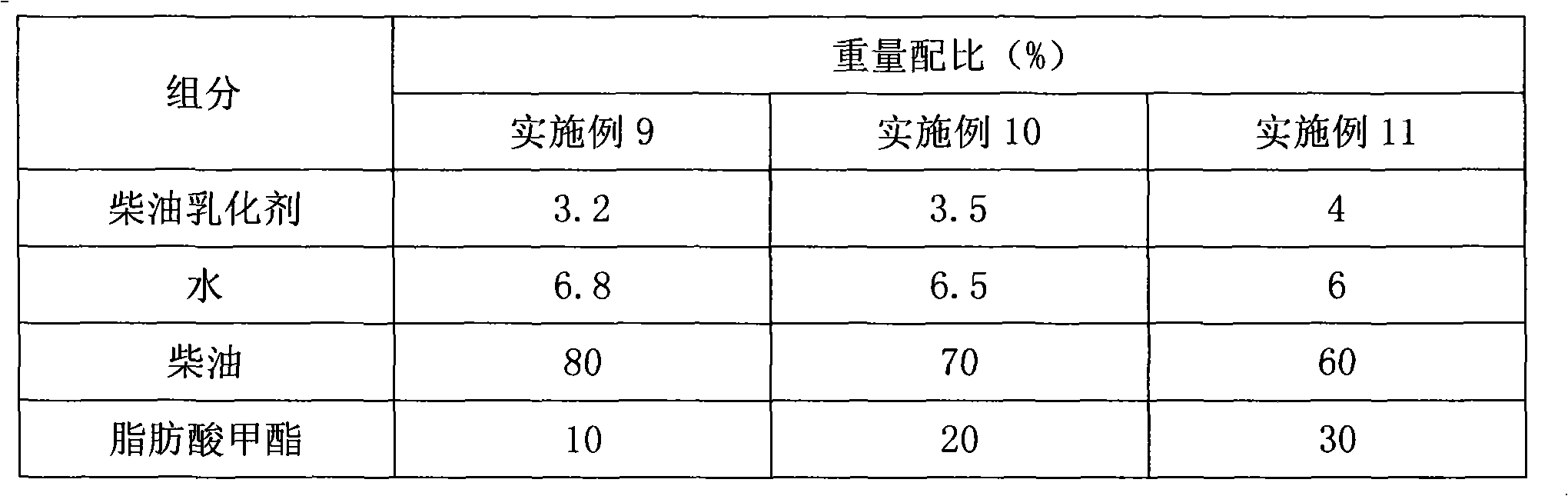

Biological emulsified diesel oil

ActiveCN102108313AHas microemulsion propertiesImprove stabilityLiquid carbonaceous fuelsVegetable oilFatty amine

The invention relates to a diesel oil emulsifier in the technical field of emulsifier. The diesel oil emulsifier comprises the following components by weight percent: 70-74% of vegetable oil higher fatty acid, 12-13% of polyol fatty acid ester, 4-5% of fatty alcohol-polyoxyethylene ether, 5-6% of alkylolamide and 5-6% of fatty amine. The invention also discloses a preparation method of the dieseloil emulsifier, biological emulsified diesel oil prepared from the emulsified diesel oil and a preparation method of the biological emulsified diesel oil. The biological emulsified diesel oil prepared from the diesel oil emulsifier has high stability; and the energy can be reduced by more than 20% and the smoke (tail gas) emission average decreasing amplitude is more than 50%.

Owner:上海纽孚尔能源技术有限公司

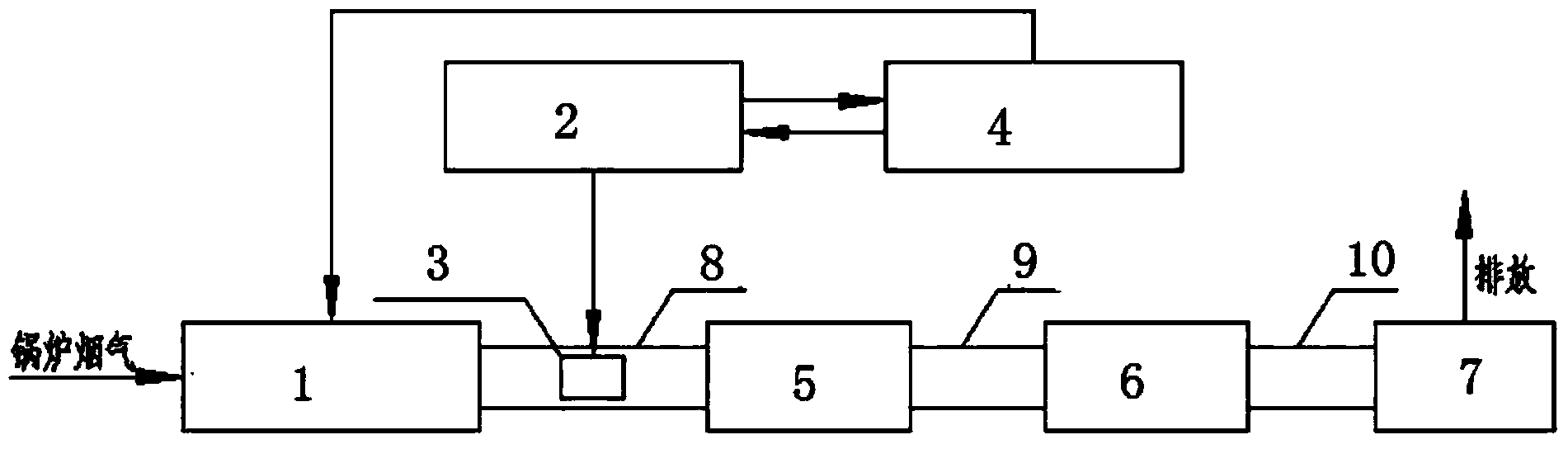

Process and device for realizing up-to-standard emission of boiler flue gas with coupling technology

ActiveCN104075335ALess investmentSmall footprintLighting and heating apparatusDispersed particle separationSmall footprintEngineering

The invention discloses a process and a device for realizing up-to-standard emission of boiler flue gas with a coupling technology. The device comprises an electrostatic synergetic dust remover, wherein the electrostatic synergetic dust remover is connected with an induced draft fan through a flue I, the other end of the induced draft fan is connected with an inlet of a desulfurizing tower through a flue II, and an outlet of the desulfurizing tower is connected with a chimney through a flue III; a mixer is arranged in the flue I; an ozone generator is connected with the mixer through an ozone delivery pipeline; a process water tank is connected with the electrostatic synergetic dust remover and the ozone generator respectively through water delivery pipelines. According to the process and the device, measures such as partial transformation of an existing electrostatic dust remover, addition of the ozone generator and the like are taken, coupling of three technologies of electrostatic synergetic dust removal, ozonation and wet absorption is realized successfully, and units such as an oxidation reactor, an absorption tower and the like are not required to be newly built for technology implementation, so that the process and the device have the advantages of low investment, small occupied area, low transformation workload, low operation cost and the like.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL +1

A treatment method for recycling dyeing residue

ActiveCN104291398BReduce processImprove economic efficiencyWater/sewage treatmentWaste water treatment from textile industrySewage treatmentDyeing

The invention provides a treatment method for recycling dyeing residual liquid. The method comprises the following steps: adding an organic liquid into the acidic dyeing residual liquid to separate color developing substances in the dyeing residual liquid into the organic liquid so as to decolorize the dyeing residual liquid; and recycling the decolorized dyeing residual liquid according to a dyeing process. In the method, the dyeing residual liquid is decolorized by utilizing the organic liquid, so that the decolorized dyeing residual liquid has low chromaticity and the decolorization rate can be over 99 percent; moreover, salt in the residual liquid can be maintained, so that the decolorized salt-containing dyeing residual liquid can be recycled in the dyeing process, salt in the dyeing residual liquid can be reasonably and effectively utilized, salt adding amount in the dyeing process can be reduced, emission of high-salt high-chromaticity residual liquid can be avoided, production cost can be saved, and pressure of sewage treatment can be relieved.

Owner:沈阳惠宇化工环保科技有限公司

Coolant additive for reducing benzene emission, production method and using method

InactiveCN108165327AOne-time addition is effective for a long timeLow costLiquid carbonaceous fuelsFuel additivesRare-earth elementMixed materials

The invention discloses a coolant additive for reducing benzene emission, a production method and a using method. The coolant additive comprises SiO2, Al2O3, Fe2O3, MgO, CaCO3, TiO2, MnO and rare earth element. The production method comprises the following steps: selecting natural ore containing formula materials, and screening according to far-infrared wavelength distribution of each formula material, primarily pulverizing the screened ore, then secondarily processing till nanometer scale, then adding a rare earth material for mixing, and irradiating the mixed material by using THz irradiating equipment. The using method comprises the steps of directly adding the coolant additive into a vehicle cooling system. After addition of the coolant additive for reducing the benzene emission, provided by the invention, more complete combustion of gasoline can be promoted, and the fuel-saving and power-lifting effects are obvious; the coolant additive has an obvious and stable effect of reducingthe total content of benzene substances and an obvious emission reducing effect; the coolant additive has a significant effect of saving energy of a gasoline vehicle and an ethanol gasoline vehicle,and has a certain effect on a hybrid vehicle and a gas vehicle; in addition, the coolant additive is effective for a long time after one-time addition and is low in cost.

Owner:上海黻诚贸易有限公司

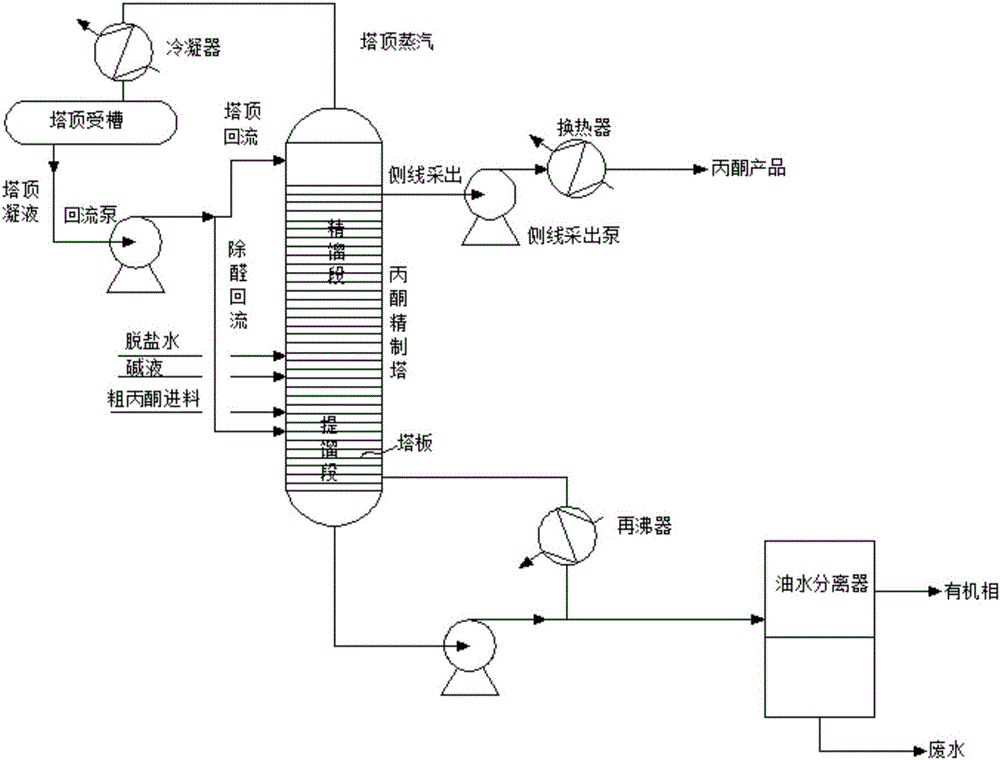

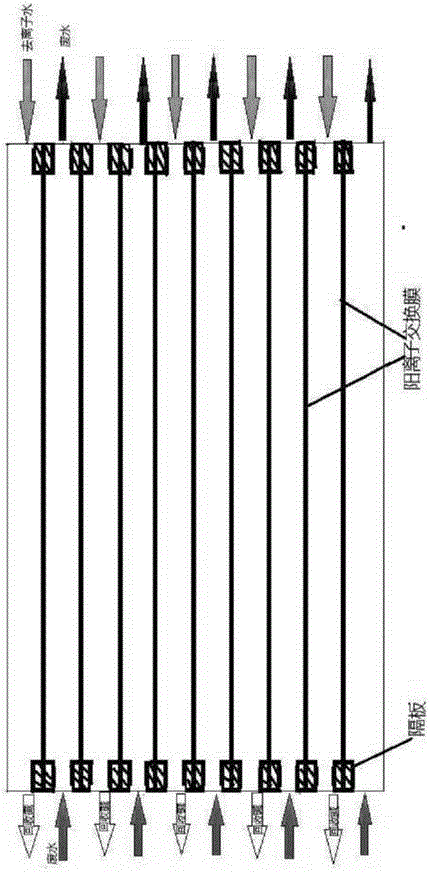

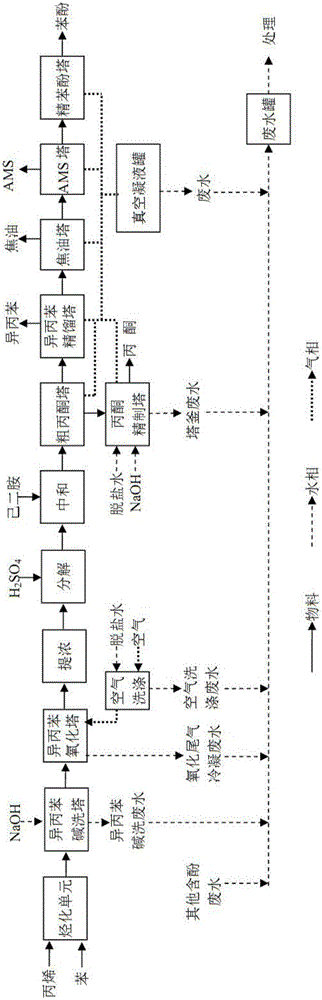

Method for reducing pollutant discharge in phenol-acetone production

ActiveCN105819588AReduce processing difficultyHigh yieldWater/sewage treatment by neutralisationSustainable biological treatmentEnhanced degradationWater quality

The invention discloses a method for reducing pollutant discharge in phenol-acetone production. The method comprises at least one of the following steps: (A) collecting phenolic wastewater generated by a phenol-acetone production device, adjusting the pH value to be less than 7, and performing extraction and recovery on phenols in wastewater by taking cumene as an extracting agent; (B) through process optimization of an acetone refining tower, reducing the acetone content of wastewater in a tower kettle; (C) treating the wastewater in the tower kettle of the acetone refining tower with a permselective membrane, and recovering alkali; (D) neutralizing the wastewater in the tower kettle of the acetone refining tower after recovering alkali in the step (C), mixing the neutralized wastewater with a condensed liquid at the top of a cumene oxidation tower, and performing detoxification treatment; (E) performing oil separation treatment on total discharged water of the phenol-acetone device, and recovering organic matters comprising hydrocarbons; and (F) performing biological treatment, coagulation sedimentation treatment and enhanced degradation treatment on the wastewater subjected to the oil separation treatment. The method has at least one of characteristics of being capable of recovering resources, increasing product yield and reducing pollutant discharge, and being low in wastewater treatment cost and stable in outlet water quality.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

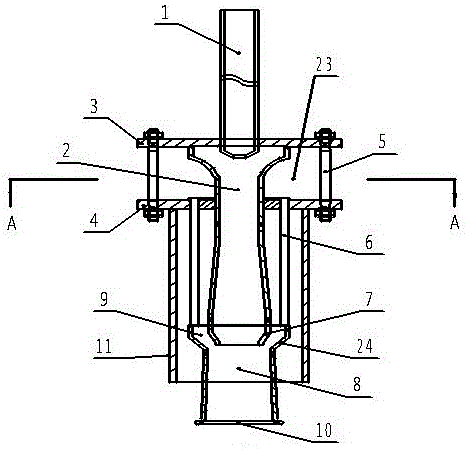

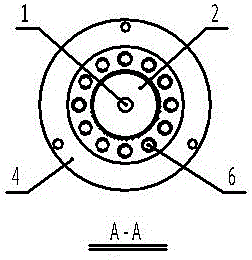

Low-nitrogen energy-saving combustion unit of combustor

ActiveCN105805743ASpeed up the flowUniform distribution of temperature fieldGaseous fuel burnerCombustorSpray nozzle

The invention discloses a low-nitrogen energy-saving combustion unit of a combustor. The low-nitrogen energy-saving combustion unit of the combustor comprises a cylindrical shell and a diffusion throat pipe mixing chamber. The front portion of the diffusion throat pipe mixing chamber is arranged in the cylindrical shell. The low-nitrogen energy-saving combustion unit of the combustor is characterized in that the front end of the diffusion throat pipe mixing chamber is conical, and a conical cover is installed in front of a conical shrinkable throat pipe; an annular gap air duct is formed between the outer wall of the conical shrinkable throat pipe and the inner wall of the conical cover; a secondary air pipe communicates with the annular gap air duct; and a conical combustion nozzle is fixed to the front end of the conical cover. By the adoption of the structure, gas can be combusted twice, and the speed of a flame sprayed out of the cylindrical combustion nozzle is high, so that sufficient stirring is achieved in a furnace, the temperature field distribution in the furnace is uniform, and the heat exchange rate is increased; and the energy can be saved by 10% or over by the adoption of the low-nitrogen energy-saving combustion unit. According to the low-nitrogen energy-saving combustion unit of the combustor, the discharge of oxynitride is lower than 40 mg / m<3> and is much lower than the national standard, and the energy saving and emission reduction effects are extremely remarkable.

Owner:北京中宇先创能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com