Low-nitrogen energy-saving combustion unit of combustor

A combustion unit and burner technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve problems such as unevenness, low combustion efficiency, and long residence time of nitrogen molecules, achieve uniform temperature field distribution, and improve thermal efficiency. Remarkable effect of exchange rate and emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

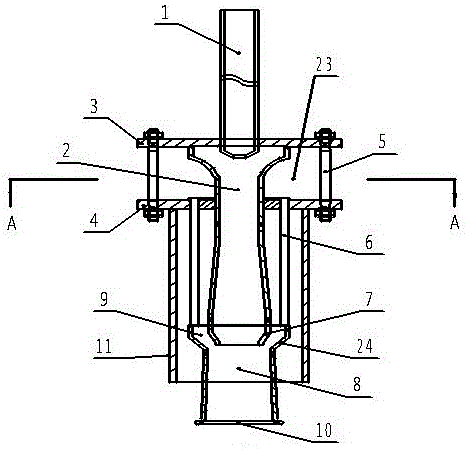

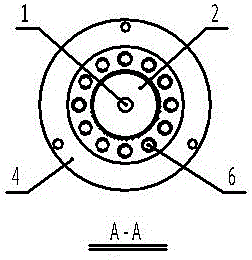

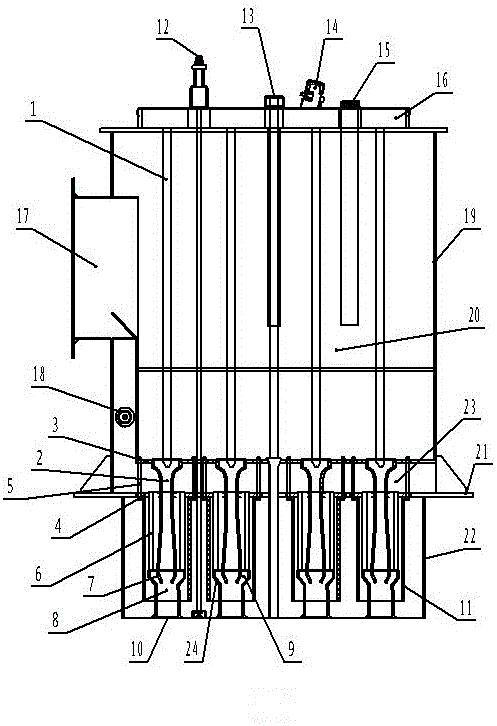

[0012] as attached figure 1 As shown, the diffusion throat mixing chamber 2 is in the shape of a cylinder as a whole, and its rear part is fixed by an air partition 3 and a flange 4. The rear end of the diffusion throat mixing chamber 2 communicates with the primary air distribution chamber 20, and the diffusion throat The middle and front parts of the mixing chamber 2 are fixed in the cylindrical shell 11, and the diffusion throat mixing chamber 2 is composed of three cones from the back to the front (the gas movement direction is the front), and the first cone is mixed in the diffusion throat. At the rear of chamber 2, the diameter gradually decreases from the rear end of the diffusion throat mixing chamber 2 to the front; the second conical shape is in the middle of the diffusion throat mixing chamber 2, and the diameter gradually increases from the rear to the front; the third conical shape That is, the front end outlet of the diffuser throat mixing chamber 2 shrinks inwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com